Giant land turtle-shaped cable paying-off and conveying method

A technology of cable conveying and cable conveyor, which is applied in the direction of cable laying equipment, transportation and packaging, and conveying filamentous materials, etc. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

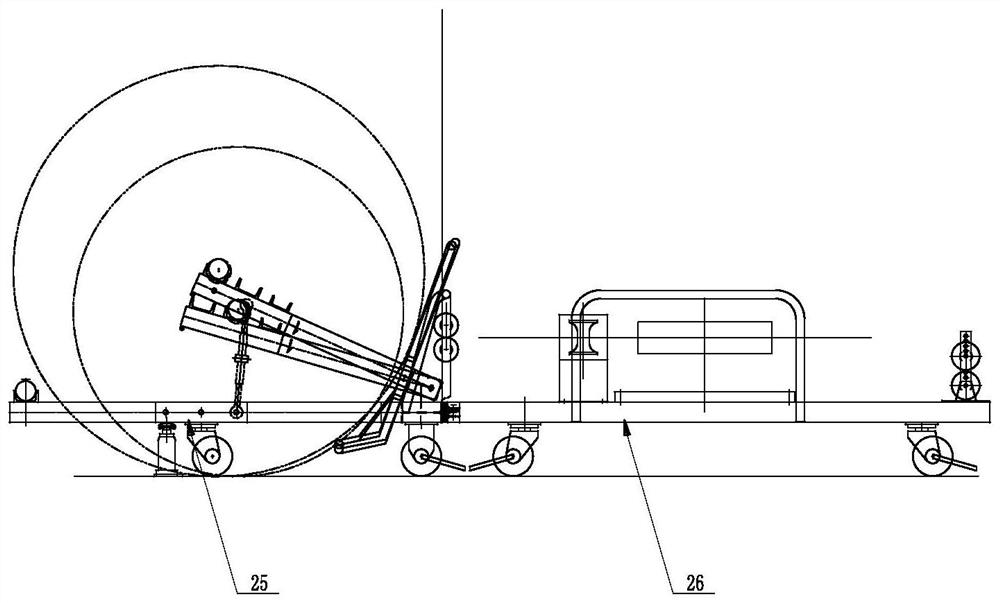

[0053] Such as Figure 1-5 Shown, the Bi-Xi cable pay-off and conveying method of the present invention adopts the Bi-Xi cable pay-off and the transport vehicle, and the Bi-Xi cable pay-off and the transport vehicle include the Bi-Xi cable pay-off vehicle 25 and the Bi-Xi cable delivery Car 26, comprising the steps of:

[0054] Step 1. Push the Bixi cable pay-off trolley 25 to the proper position of the cable shaft;

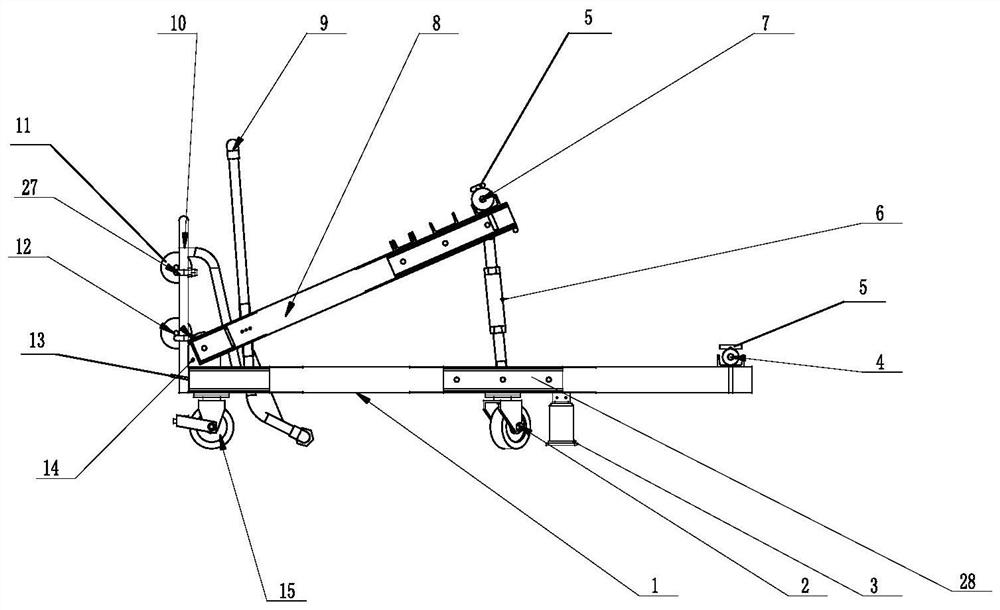

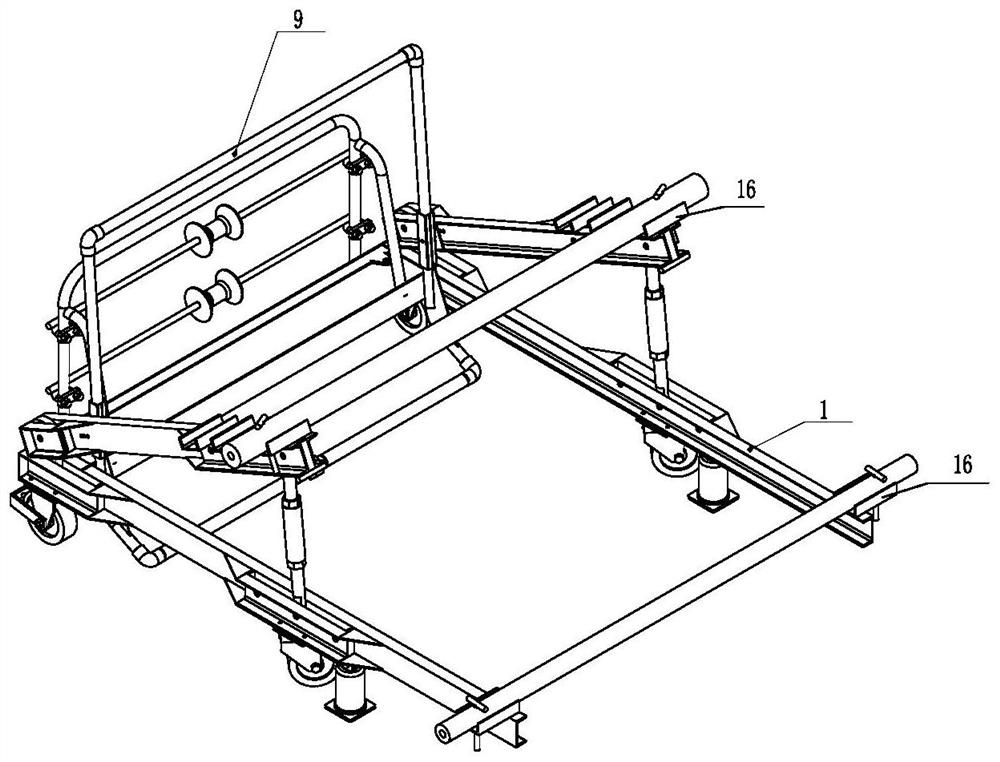

[0055] Step 2. Insert the rear bar 7 of the cable pay-off trolley 25 into the center hole of the cable shaft, and place the rear bar 7 on the bar fixing bracket 16 of the support arm 8 to fix it;

[0056] Step 3, place the front bumper 4 on the front bumper fixing bracket 16 of the vehicle frame 1 of the cable pay-off vehicle 25 and fix it;

[0057] Step 4. Use a meter ruler to measure the position between the two ends of the center point of the back bar 7 of the cable pay-off vehicle 25 and the ground. If there is any difference, you need to operate the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com