Auxiliary tool for installing building wall nail

An installation auxiliary and building wall technology, which is applied in the field of building wall nail installation auxiliary tools, can solve the problems of bending and the direction of the force of the nail is not straight, and achieves the effect of improving practicability and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

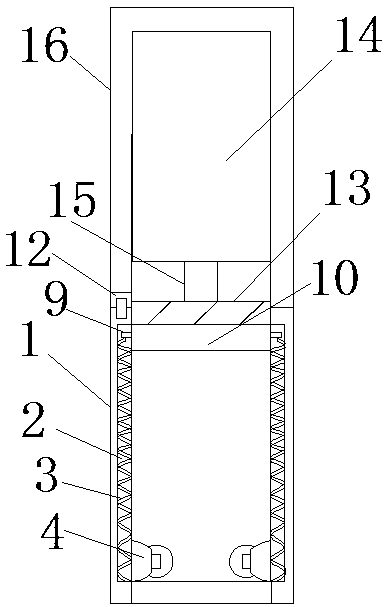

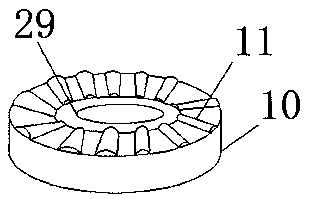

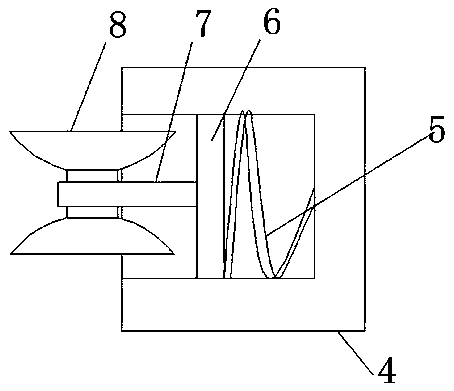

[0030] refer to Figure 1-7 , an auxiliary tool for installation of building wall nails, comprising a first cavity 1, both sides of the first cavity 1 are provided with strip-shaped grooves 2, and the first cavity 1 is welded with a second strip-shaped groove 2 A spring 3, the top of the first spring 3 is welded with a sliding block 9, one side of the sliding block 9 is welded with a mating ring 10, the top of the first cavity 1 is provided with a second cavity 16, the second An air motor 14 is welded on the inner wall of the top end of the cavity 16, an output shaft 15 is welded on the bottom end of the air motor 14, a rotating ring 13 is welded on the bottom end of the output shaft 15, and a rotating ring 13 is welded to the outside of the mating ring 10. Several arc-shaped bars 11, one side of the second cavity 16 is provided with a circular groove, and the second cavity 16 is welded with a first expansion joint 12 at the circular groove, and the inside of the first expansi...

Embodiment 2

[0039] refer to Figure 8 , an auxiliary tool for installing building wall nails. Compared with Embodiment 1, in this embodiment, in order to prevent the nail from shifting inside the first cavity, the bottom end of the curved block 26 is welded with a rubber layer 30, and the rubber layer 30 One side is provided with an anti-slip pattern 31, when the nail and the curved block 26 collide with each other, the anti-slip pattern 31 increases the friction with the top of the nail, prevents the nail from shifting inside the first cavity 1, and improves the stability of the nail .

[0040] When in use, by turning on the air motor 14, the air motor 14 drives the rotating ring 13 and the arc-shaped bar 11 on the matching ring 10 to squeeze each other, the first spring 3 keeps reciprocating, and knocks the matching ring 10 by constantly squeezing, the matching ring 10 drives the inner ring 29 to knock the front end of the nail continuously, so that the nail is continuously nailed into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com