Radiation proof composite woolen yarn and its production equipment

A technology of anti-radiation and wool, which is applied in the direction of textiles, papermaking, electrical components, yarns, etc., can solve the problems of uncomfortable wearing, hard texture, simple and unsightly industrial clothing style, etc., and achieve soft hand feeling, strong warmth retention, The effect of excellent anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

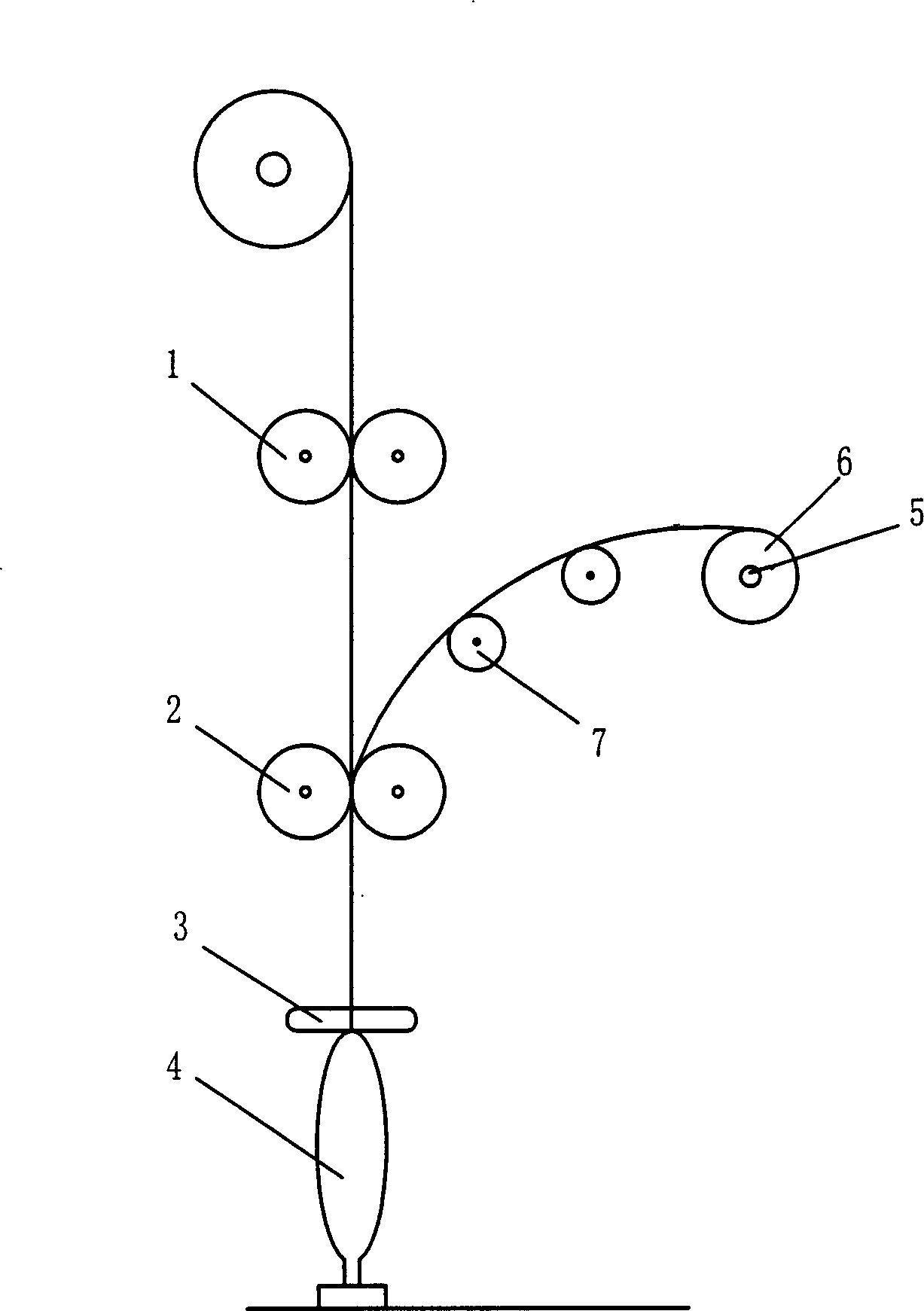

[0011] see figure 1 , the anti-radiation composite woolen yarn of the present invention comprises a core wire and a wrapping woolen yarn wrapped around the core wire, and the core wire is a radiation-proof textile metal wire (available for purchase), wherein the diameter of the metal wire It is 59-64 μm, taking the total amount of composite wool as a reference benchmark, metal wire accounts for 12%-20%, and the rest is wool. The more metal wire occupies, the stronger its radiation protection effect can be selected according to the working environment.

[0012] The metal wire for weaving is a conductive radiation-proof metal wire. The yarn is various kinds of animal hair or wool for weaving, such as wool, cashmere and the like.

[0013] The thickness of the anti-radiation composite wool of the invention is between 16-38 metric.

[0014] The anti-radiation composite wool of the present invention has been tested. In the frequency range of 900-2000MHz, the shielding effectivene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com