Manufacturing method of metal spinning part

A technology of metal spinning and manufacturing methods, applied in the field of mechanical processing, can solve the problems of large tensile stress on the outer surface, serious cold hardening of materials, and large deformation of parts, so as to improve tensile strength and elongation, and eliminate cold Effect of hardening and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for manufacturing a metal spinning part, comprising the following steps:

[0030] Step 1: Use a hydraulic press to pre-stretch the O-state LD10 aluminum alloy sheet into a rod-shaped blank, and set the pressure value of the hydraulic press to 20MPa;

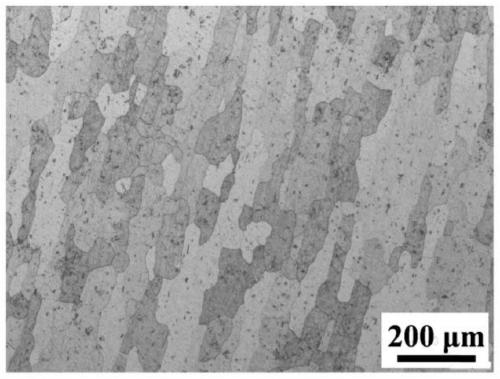

[0031] Step 2: After the blank is coated with lubricant, it is placed on the inter-roll spinning machine for the first spinning, the spindle speed is 20r / min, the spindle pump pressure is 10MPa, and then complete annealing treatment: first raise the temperature to 300°C, Insulate for 3 hours, then cool down with the furnace to obtain a processed product;

[0032] Step 3: Coat the primary treatment product with lubricant and place it on the inter-roll spinning machine for the second pass spinning, the spindle speed is 10r / min, and the spindle pump pressure is 15MPa; then carry out incomplete annealing treatment: first raise the temperature to 350°C, hold for 1 hour, cool down at a rate of ...

Embodiment 2

[0036] This embodiment provides a method for manufacturing a metal spinning part, comprising the following steps:

[0037] Step 1: Use a hydraulic press to pre-stretch the O-state LD10 aluminum alloy sheet into a rod-shaped blank, and set the pressure value of the hydraulic press to 20MPa;

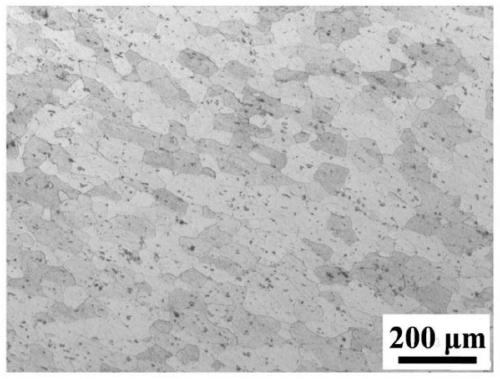

[0038] Step 2: After the blank is coated with lubricant, it is placed on the inter-roll spinning machine for the first spinning, the spindle speed is 10r / min, the spindle pump pressure is 20MPa, and then complete annealing treatment: first raise the temperature to 320°C, Insulate for 3 hours, then cool down with the furnace to obtain a processed product;

[0039] Step 3: Coat the primary treatment product with lubricant and place it on the inter-roll spinning machine for the second spinning, the spindle speed is 5r / min, the spindle pump pressure is 30MPa; first perform incomplete annealing treatment, and heat up to 370 ℃, keep warm for 1h, then lower the temperature at a rate of 50°C / h, t...

Embodiment 3

[0043] This embodiment provides a method for manufacturing a metal spinning part, comprising the following steps:

[0044] Step 1: Use a hydraulic press to pre-stretch the O-state LD10 aluminum alloy sheet into a rod-shaped blank, and set the pressure value of the hydraulic press to 20MPa;

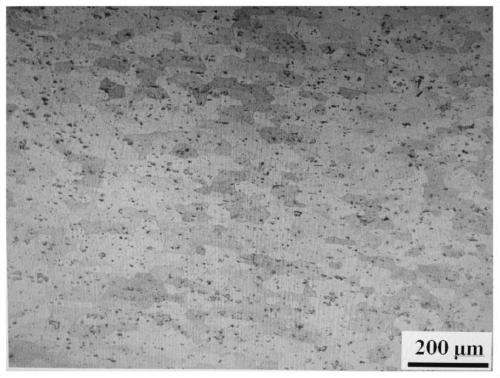

[0045] Step 2: After the blank is coated with lubricant, it is placed on the inter-roller spinning machine for the first spinning, the spindle speed is r / min, the spindle pump pressure is 20MPa, and then complete annealing treatment: first raise the temperature to 250°C, Keep warm for 8 hours, then cool down with the furnace to obtain a primary treatment product;

[0046] Step 3: Apply lubricant to the primary treatment product and place it on the inter-roller spinning machine for the second pass spinning, the spindle speed is 10r / min, the spindle pump pressure is 20MPa; first perform incomplete annealing treatment, and heat up to 250 ℃, keep warm for 10h, then lower the temperature at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com