Electrostatic spinning device and device for efficiently preparing nanofiber yarns

A nanofiber, electrospinning technology, applied in electrospinning, fiber processing, yarn and other directions, can solve the problems of difficult control of the production process, low silk output, mutual interference of jets, etc., to achieve easy control of the production process and improve production. Efficiency, the effect of facilitating agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Utilize described electrospinning device to prepare the method for nanofiber yarn, carry out according to the following steps:

[0073] Step 1: Dissolving polyacrylonitrile (PAN) in N, N-dimethylformamide (DMF), stirring thoroughly to prepare a spinning solution with a concentration of 12wt%, and injecting it into the syringe 114;

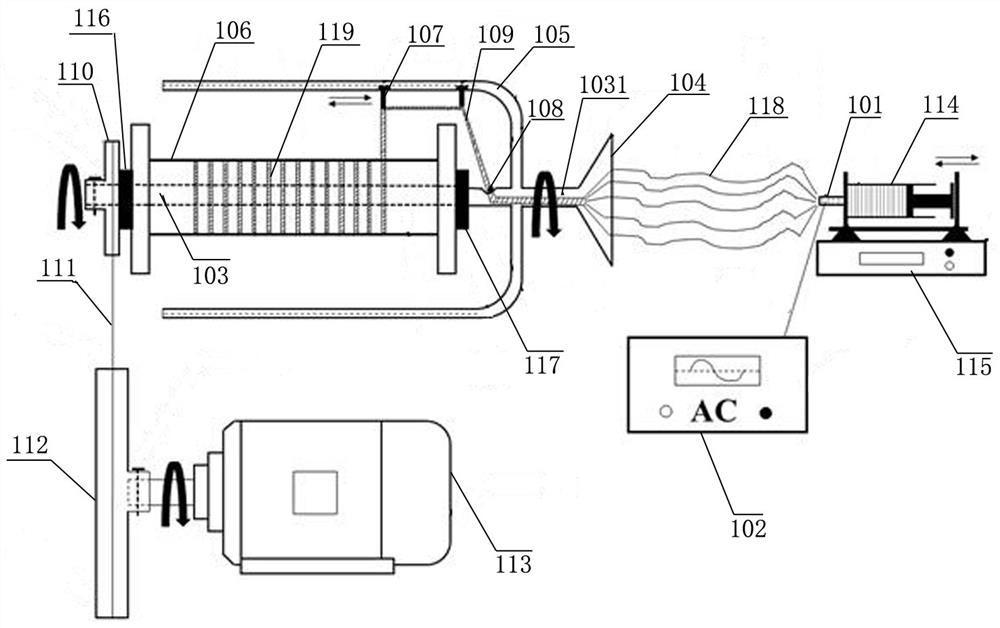

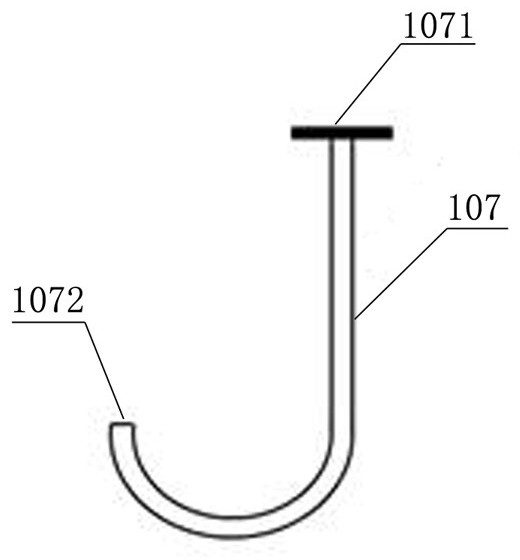

[0074] Step 2: In an environment with room temperature and a relative humidity of 40%, adjust the distance between the receiving part 104 and the metal spinning needle 101 to 100 mm to 200 mm, adjust the position of the guide hook 107, and check whether the gear transmission system is normal;

[0075] Step 3: Turn on the micro-injection pump 115, adjust the propulsion speed of the spinning solution to 0.5mL / h, and when the spinning solution evenly flows out from the metal spinning needle 101, turn on the AC high voltage generator 102, and adjust its voltage to 25kV , so that the head end of the metal spinneret 101 generates a stable jet unde...

Embodiment 2

[0079] Utilize described electrospinning device to prepare the method for nanofiber yarn, carry out according to the following steps:

[0080] Step 1: Dissolving polyacrylonitrile (PAN) in N, N-dimethylformamide (DMF), stirring thoroughly to prepare a spinning solution with a concentration of 12wt%, and injecting it into the syringe 114;

[0081] Step 2: In an environment with room temperature and a relative humidity of 40%, adjust the distance between the receiving part 104 and the metal spinning needle 101 to 100 mm to 200 mm, adjust the position of the guide hook 107, and check whether the gear transmission system is normal;

[0082] Step 3: Turn on the micro-injection pump 115, adjust the propulsion speed of the spinning solution to 0.5mL / h, and when the spinning solution evenly flows out from the metal spinning needle 101, turn on the AC high voltage generator 102, and adjust its voltage to 25kV , so that the tip of the metal spinneret 101 generates a stable jet under the...

Embodiment 3

[0086] Utilize described electrospinning device to prepare the method for nanofiber yarn, carry out according to the following steps:

[0087] Step 1: Dissolving polyacrylonitrile (PAN) in N, N-dimethylformamide (DMF), stirring thoroughly to prepare a spinning solution with a concentration of 12wt%, and injecting it into the syringe 114;

[0088] Step 2: In an environment with room temperature and a relative humidity of 40%, adjust the distance between the receiving part 104 and the metal spinning needle 101 to 100 mm to 200 mm, adjust the position of the guide hook 107, and check whether the gear transmission system is normal;

[0089] Step 3: Turn on the micro-injection pump 115, adjust the propulsion speed of the spinning solution to 0.5mL / h, and when the spinning solution evenly flows out from the metal spinning needle 101, turn on the AC high voltage generator 102, and adjust its voltage to 25kV , so that the tip of the metal spinneret 101 generates a stable jet under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com