Waste-reused aerogel for solar sewage purification and production method thereof

A technology of reuse and solar energy, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. Time and other issues, to achieve the effects of environmental protection, low cost, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

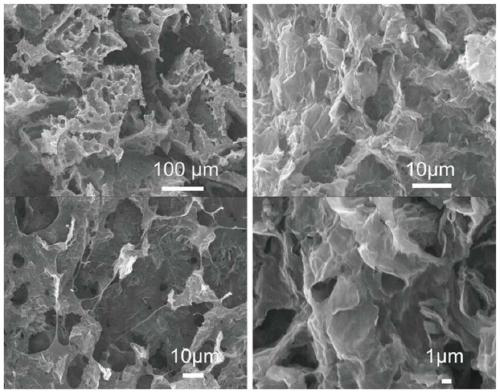

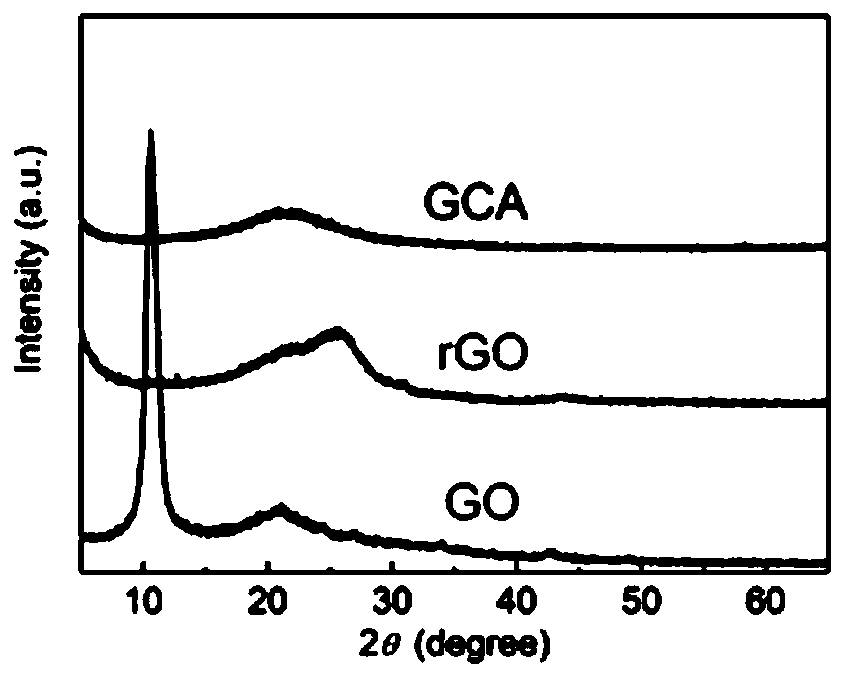

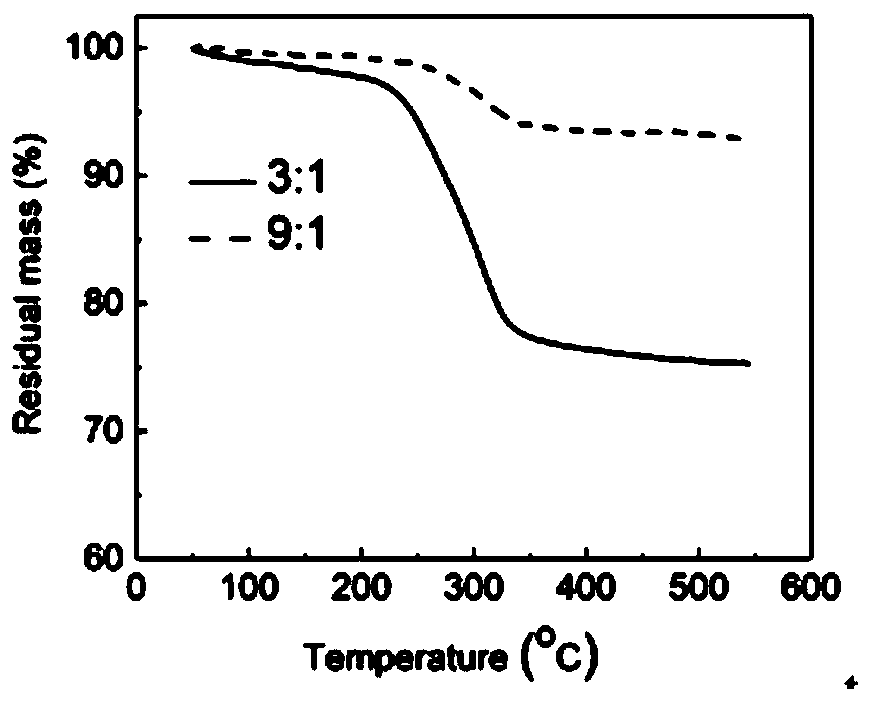

Image

Examples

Embodiment 1

[0040] A preparation method for waste recycling solar sewage purification airgel, comprising the following steps:

[0041] (1) Add 1.5g graphite powder and 0.5g NaNO to the container 3 and 50ml of concentrated sulfuric acid, ice bath for 20min, then gradually add 4g KMnO 4 , the temperature was kept at 4 °C during this process, then stirred at 30 °C for 0.5 h, added 100 ml of deionized water and stirred at 95 °C for 20 min, and then added 20 ml of 30 wt% H 2 o 2Aqueous solution and 20ml deionized water, after cooling to room temperature, centrifuged at 8000rpm for 15min, first washed twice with 5wt%-10wt% HCl solution, then repeatedly centrifuged and washed with deionized water until the pH of the supernatant was 4-5, finally adopting the method of freeze-drying to obtain graphene oxide powder;

[0042] (2), in graphene oxide powder, mix 5wt% flake graphite powder, put into microwave oven, heat 5s under the power of 800W, obtain reduced graphene oxide;

[0043] (3), in the...

Embodiment 2

[0046] A preparation method for waste recycling solar sewage purification airgel, comprising the following steps:

[0047] (1) Add 2.5g graphite powder and 1.5g NaNO to the container 3 and 60ml of concentrated sulfuric acid, ice bath for 40min, then gradually add 8g KMnO 4 , the temperature was kept at 10°C during this process, then stirred at 40°C for 1.5h, added 100ml of deionized water and stirred at 95°C for 40min, and then added 40ml of 30wt% H 2 o 2 Aqueous solution and 20ml deionized water, after cooling to room temperature, centrifuged at 8000rpm for 15min, first washed twice with 5wt%-10wt% HCl solution, then repeatedly centrifuged and washed with deionized water until the pH of the supernatant was 4-5, finally adopting the method of freeze-drying to obtain graphene oxide powder;

[0048] (2), mix 7wt% graphite powder in graphene oxide powder, put into microwave oven, heat 10s under the power of 800W, obtain reduced graphene oxide;

[0049] (3), in the mixed solut...

Embodiment 3

[0052] A preparation method for waste recycling solar sewage purification airgel, comprising the following steps:

[0053] (1), add 2g graphite powder and 1g NaNO to the container 3 and 55ml of concentrated sulfuric acid, ice bath for 30min, then gradually add 6g KMnO 4 , the temperature was kept at 8 °C during this process, then stirred at 35 °C for 1 h, added 100 ml of deionized water and stirred at 95 °C for 30 min, and then added 30 ml of 30 wt% H 2 o 2 and 20ml of deionized water, after cooling to room temperature, centrifuge at 8000rpm for 15min, wash twice with 5wt%-10wt% HCl solution, then repeatedly wash with deionized water until the pH of the supernatant is 4 —5, finally adopting the freeze-drying method to obtain graphene oxide powder;

[0054] (2), in graphene oxide powder, mix 6wt% flake graphite powder, put into microwave oven, heat 7s under the power of 800W, obtain reduced graphene oxide;

[0055] (3), in the mixed solution of 100ml water, 2g NaOH and 10g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com