Patents

Literature

66results about How to "Coil tightly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

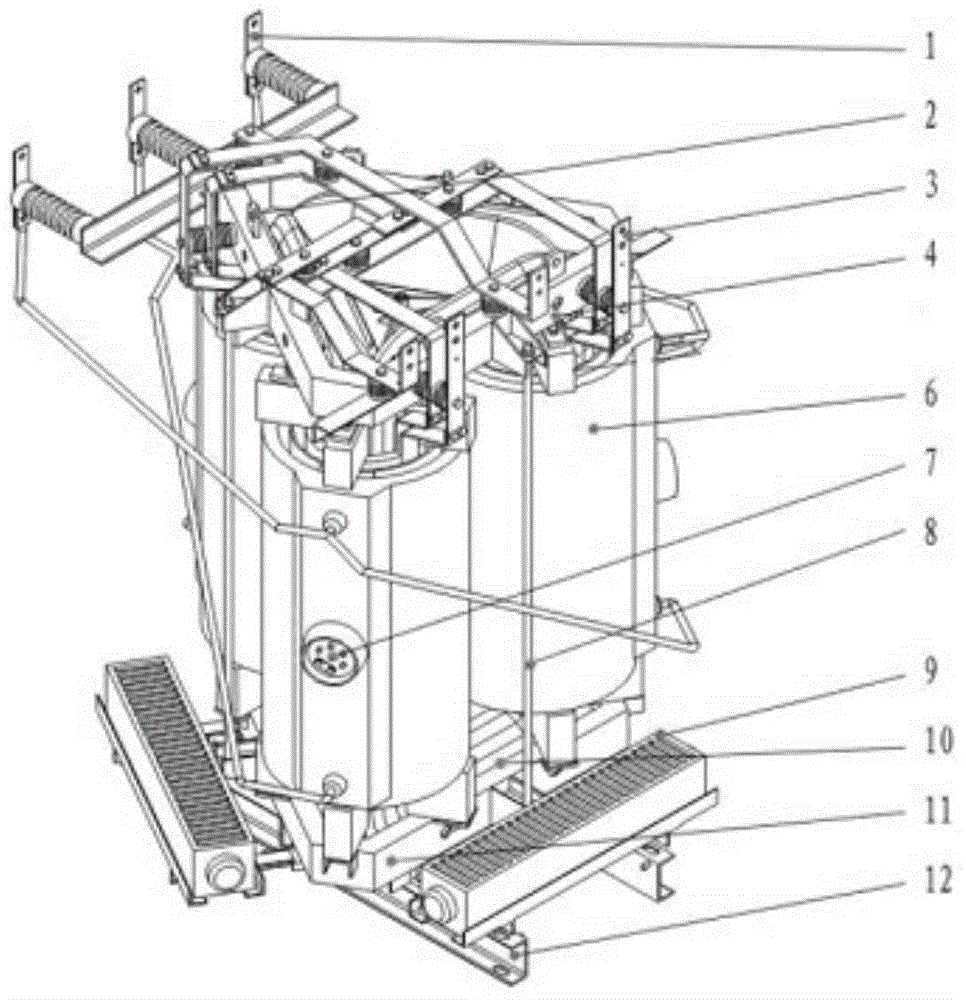

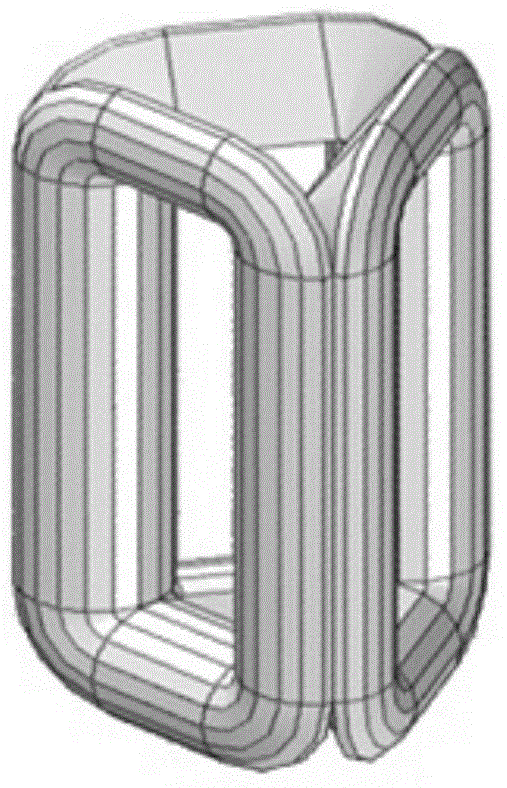

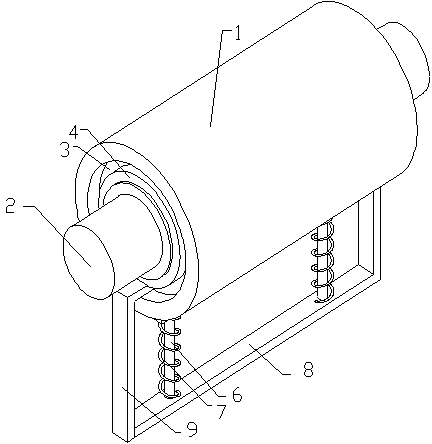

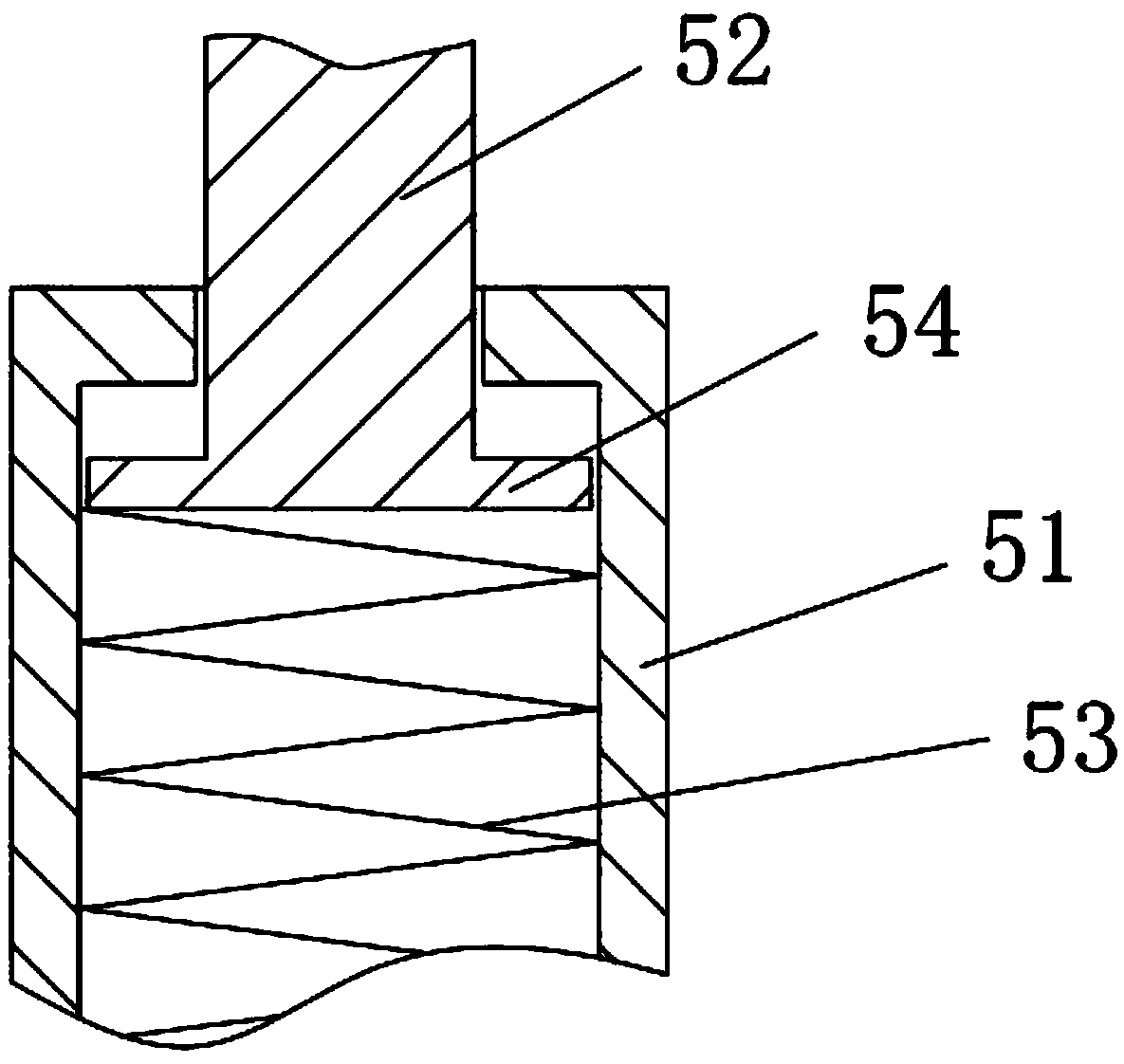

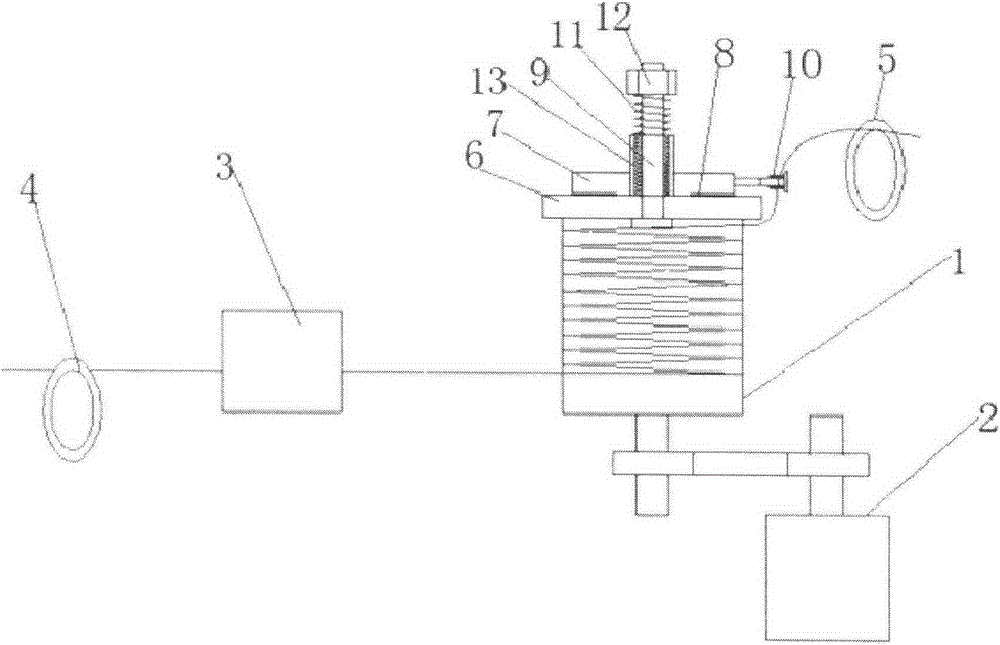

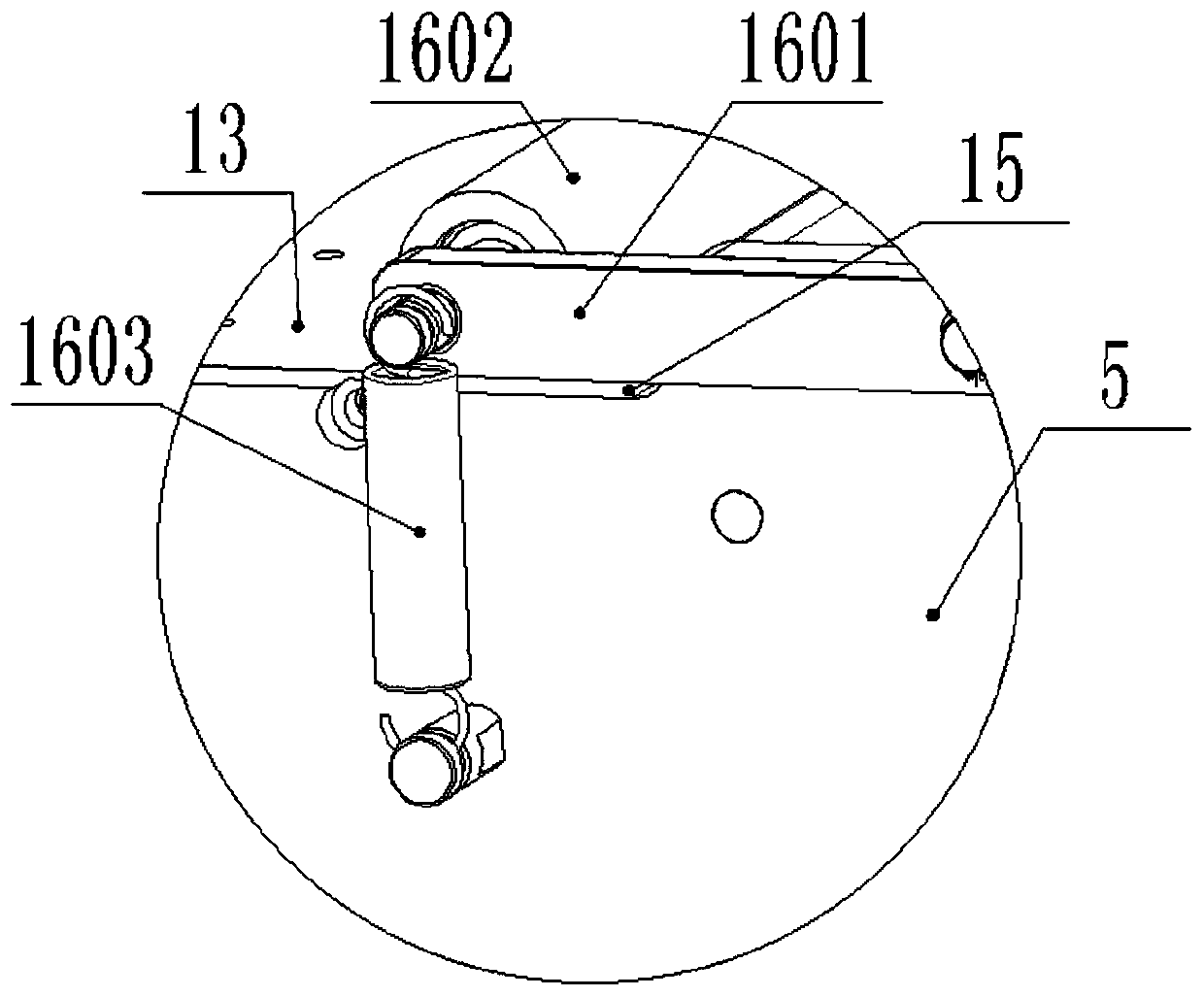

Resin insulation dry type transformer with three-dimensional roll iron core

InactiveCN105529145AReduce leftoversImprove fill factorTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLow noiseEpoxy

The invention discloses a resin insulation dry type transformer with a three-dimensional roll iron core. The resin insulation dry type transformer comprises a transformer base, an upper clamping part, a lower clamping part and a three-dimensional roll iron core, wherein the upper clamping part and the lower clamping part are correspondingly arranged on the transformer base up and down, and the three-dimensional roll iron core is clamped between the upper clamping part and the lower clamping part; the three-dimensional roll iron core comprises three single frames, the middle parts of the single frames are hollowed out, and the single frames are of rounded rectangle structures in shape; the three single frames are arranged and spliced together in an equilateral triangle shape three-dimensionally; each single frame is formed by continuously winding a plurality of silicon steel trapezoid material straps in sequence; a coil is wound at the joint of every two single frames respectively; each coil is integrally poured by a curing agent and is formed through heating curing; and the exterior of each coil is encapsulated by epoxy resin respectively. The resin insulation dry type transformer is provided with the three-dimensional roll iron core, and has the characteristics of energy conservation and material saving, low no-load loss, low no-load current, low noise, good electrical performance, low partial discharge value, high lightning impulse resistance, high short-circuit resistance and high mechanical strength.

Owner:STATE GRID CORP OF CHINA +1

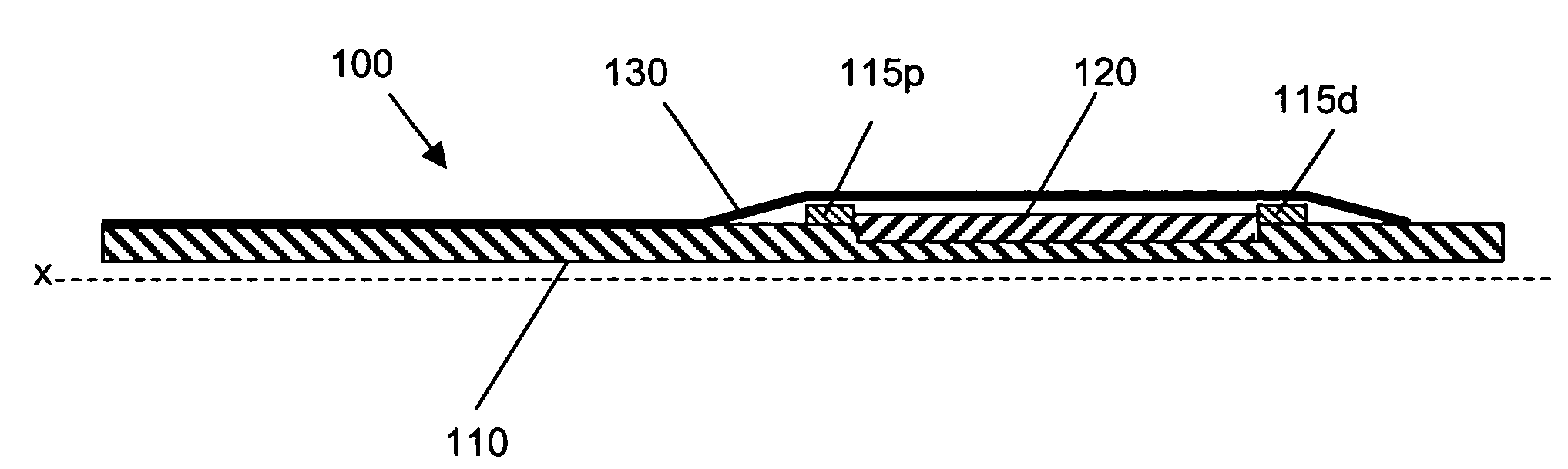

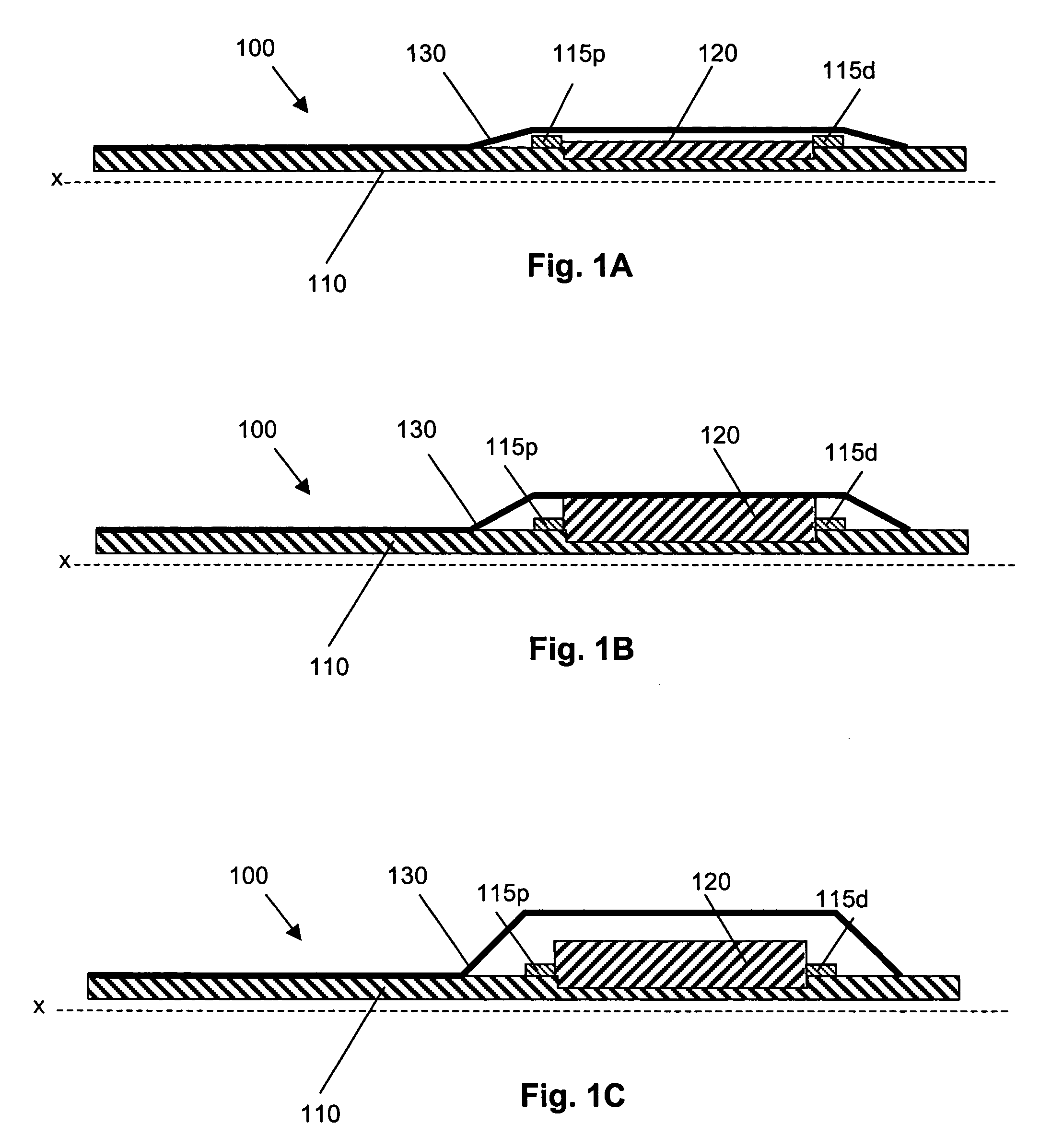

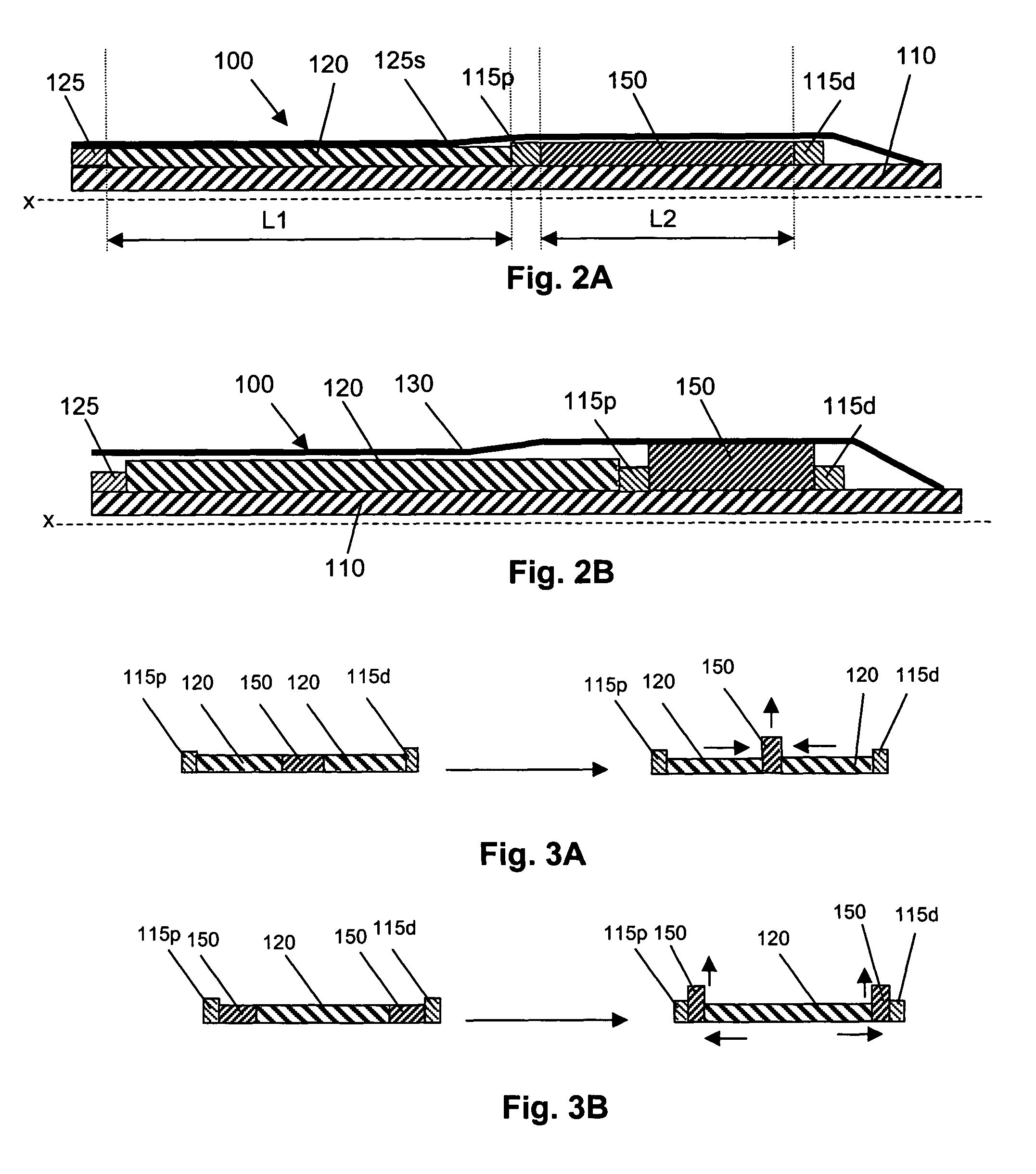

Electrically actuated medical devices

InactiveUS8398693B2Easy to operateImprove retrieval performanceStentsElectrotherapyCatheterMedical device

The present invention relates to medical devices for implantation or insertion into body lumens, for example, catheters, guidewires, stents and aneurysm coils. The devices of the present invention comprise electrically actuated materials, such as electroactive polymers and piezoelectric and electrostrictive materials, which enhance or expand their functionality.

Owner:BOSTON SCI SCIMED INC

Batching cylinder

Owner:CHONGQING YUBI TEXTILE

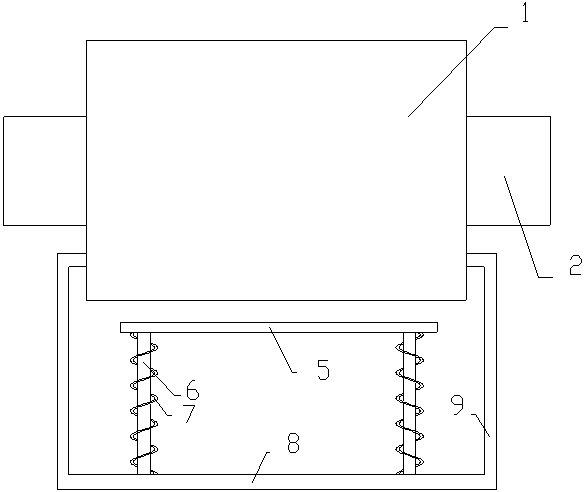

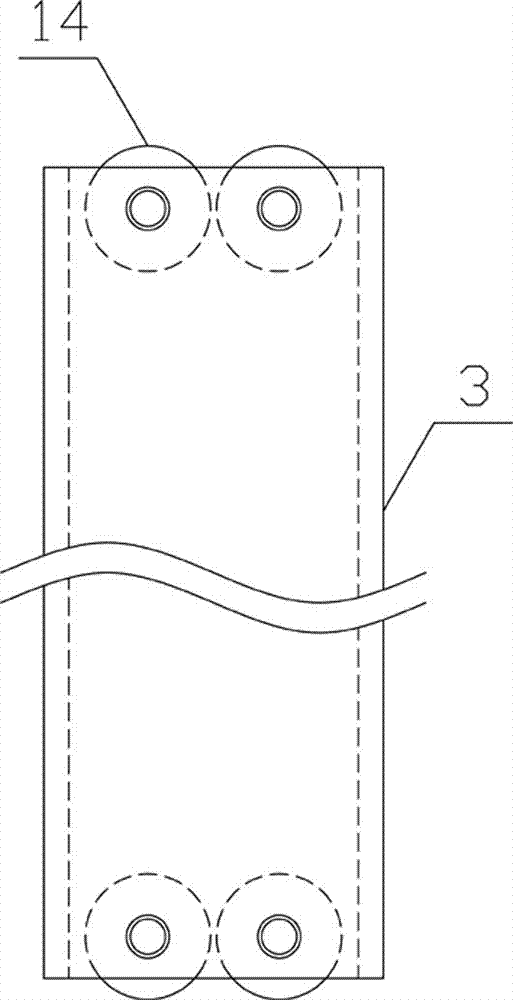

Electrode group structure of winding type accumulator

InactiveCN1801505ACoil tightWinding upFinal product manufactureCell electrodesEngineeringLow density

The invention discloses an electrode group structure of winding accumulator, which comprises an anode (1), a cathode (2), and insulator between two electrodes. The density or thickness of electrode along winding is different, such as the winding core has low density or thin thickness. As hard to fracture during winding, this invention can wind the electrode group more tightly to reduce hidden danger of short circuit or micro short circuit, and improves up-to-standard rate or product.

Owner:BAILE ELECTROTHERMIC ELECTRIC APPLIANCE JIANGSU

Process for producing moxa sticks

InactiveCN107049774AImprove efficacyGood toughnessDevices for heating/cooling reflex pointsAntipyreticMaterial selectionMedicine

The invention belongs to the technical field of wormwood processing, and particularly discloses a process for producing moxa sticks. The process comprises the following steps: (1) material selection, (2) medicine preparation, (3) medicine adaptation, (4) drying, (5) rolling and (6) re-drying. Compared with the prior art, the process has the advantages that by adding ten processed Chinese herbal medicines to moxa, the drug properties of moxa are better, and more drug properties are realized for the prepared moxa sticks; and the moxa sticks are rolled by means of a self-made rolling machine, so that the moxa sticks can be rolled quickly and effortlessly, and the rolling effect is better.

Owner:贵州务川国韵生态农业有限公司

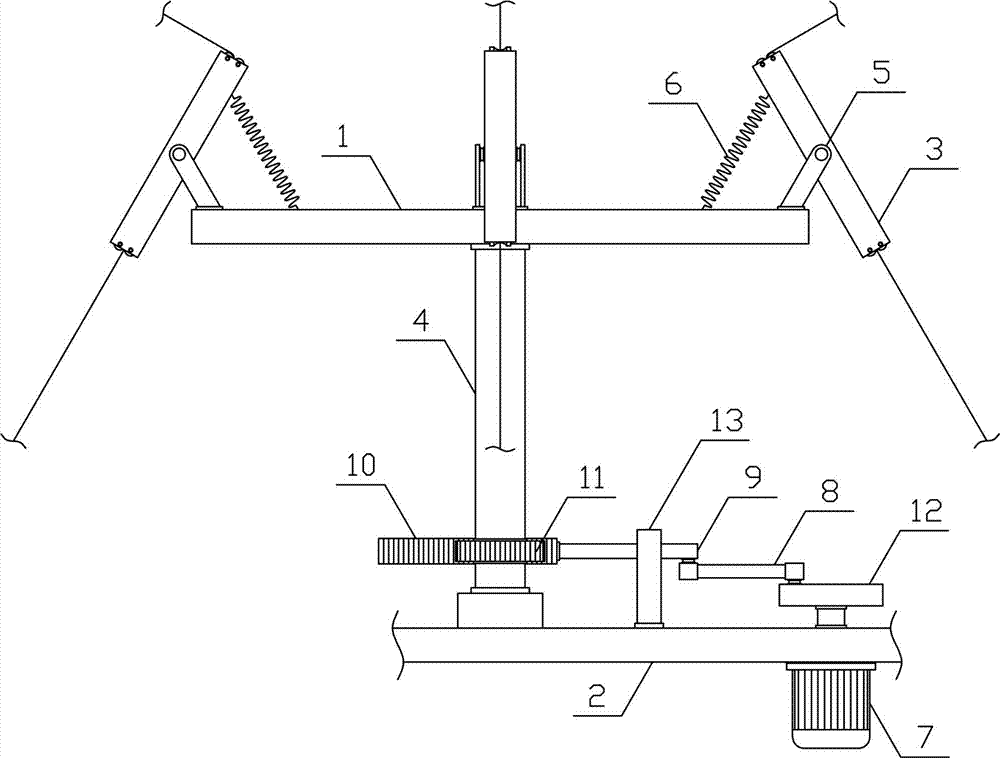

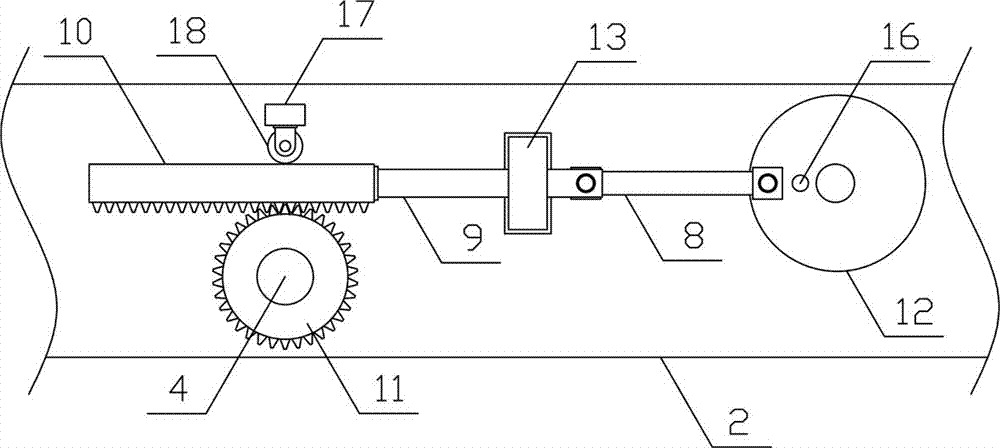

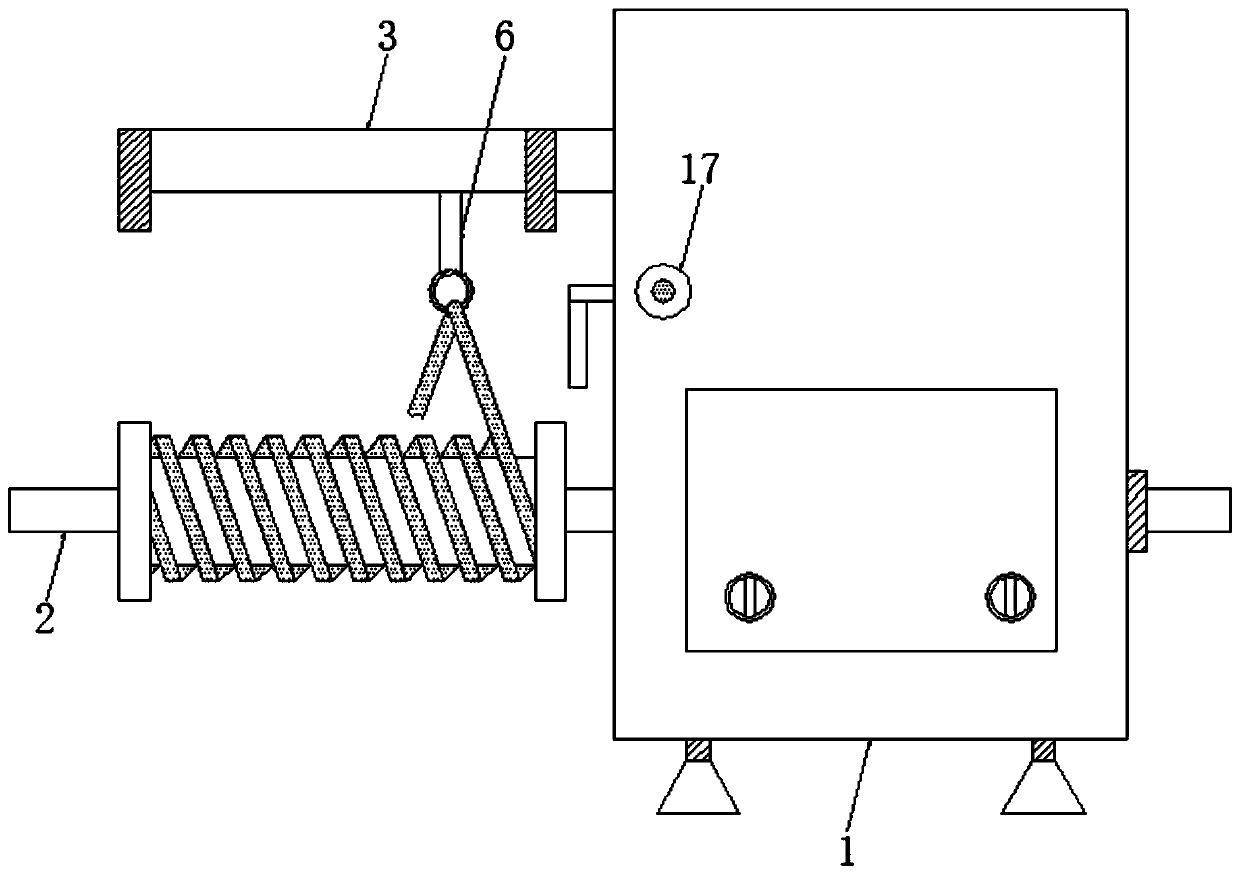

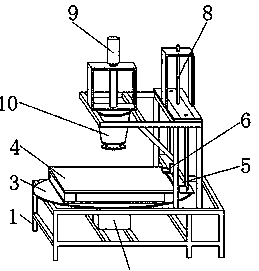

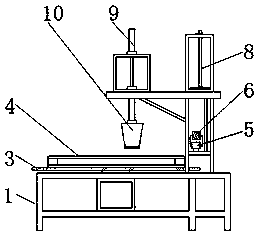

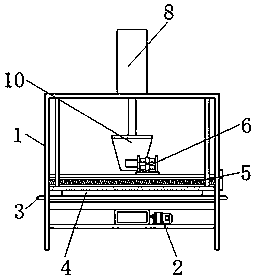

Yarn-guiding mechanism for yarn delivery

InactiveCN106882641ASmooth transmissionAccurate and smooth transmissionFilament handlingYarnEngineering

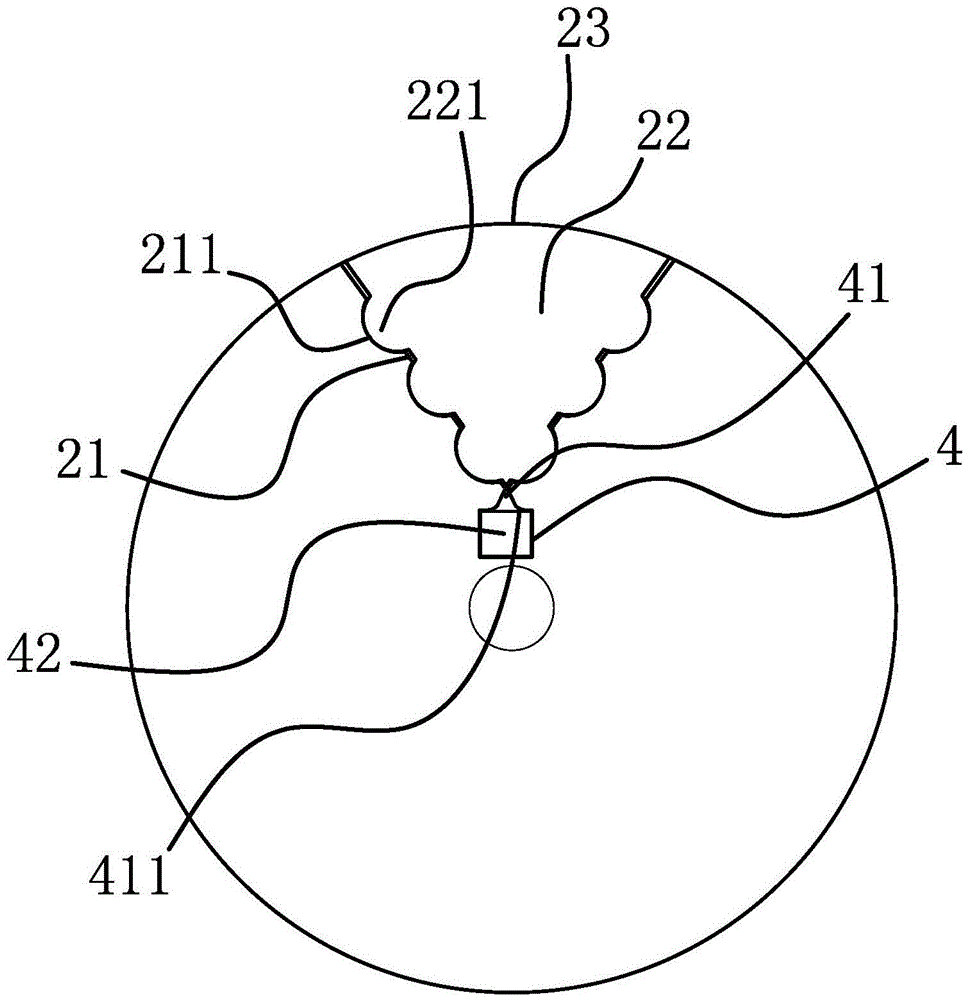

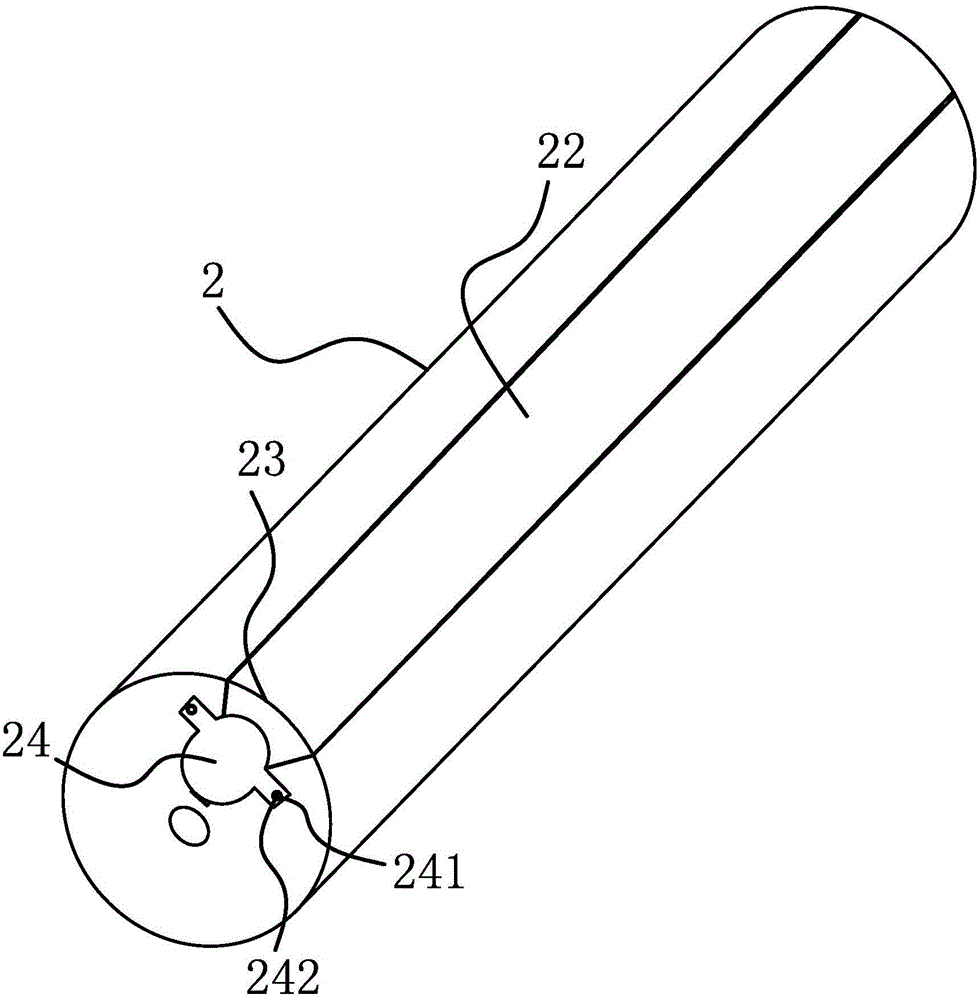

The invention discloses a yarn conveying and guiding mechanism, which belongs to the field of textile processing machinery and equipment. The invention comprises a yarn guiding circular plate, a fixed bracket, a yarn guiding tube, a rotating shaft and a reciprocating drive mechanism. The reciprocating driving mechanism is horizontally arranged on the fixed bracket at the lower end of the rotating shaft, and the yarn guiding circular plate is horizontally arranged on the upper side of the rotating shaft. The middle part of the yarn guide tube is hinged to the rotating bracket. The reciprocating drive mechanism includes a rotating motor, a connecting rod, a translation rod, a translation gear plate and a rotation gear. A connecting rod is arranged horizontally, and the translation gear plate is arranged horizontally on one side of the rotating gear and meshed with the rotating gear. The invention has a reasonable structural design, and can quickly and efficiently swing multiple yarns in a synchronous and stable reciprocating manner during the transmission process, so that the multiple yarns can be individually and evenly wound, meeting the needs of production and use.

Owner:ZHEJIANG HONGFENG WARP & WEFT KNITTING

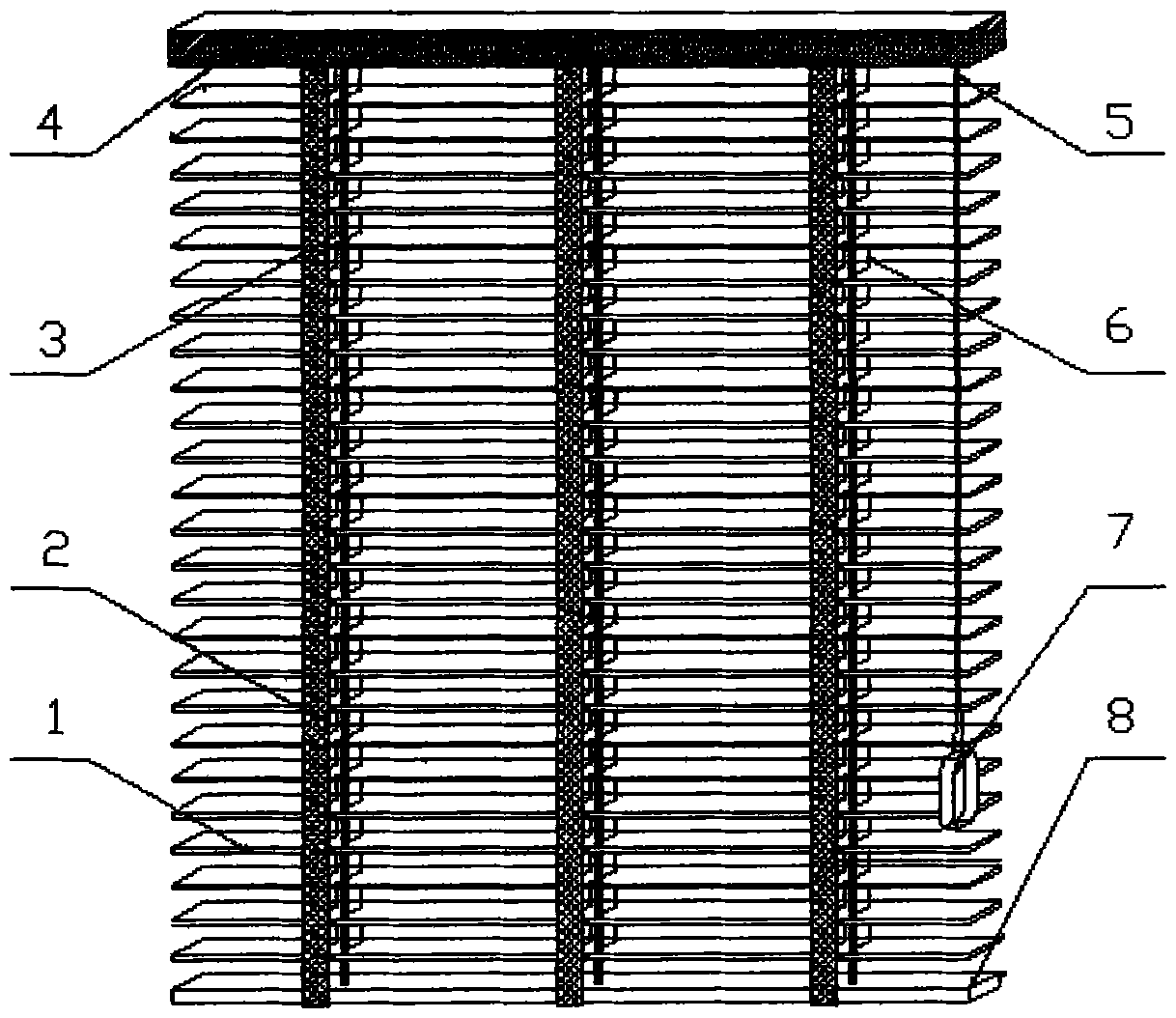

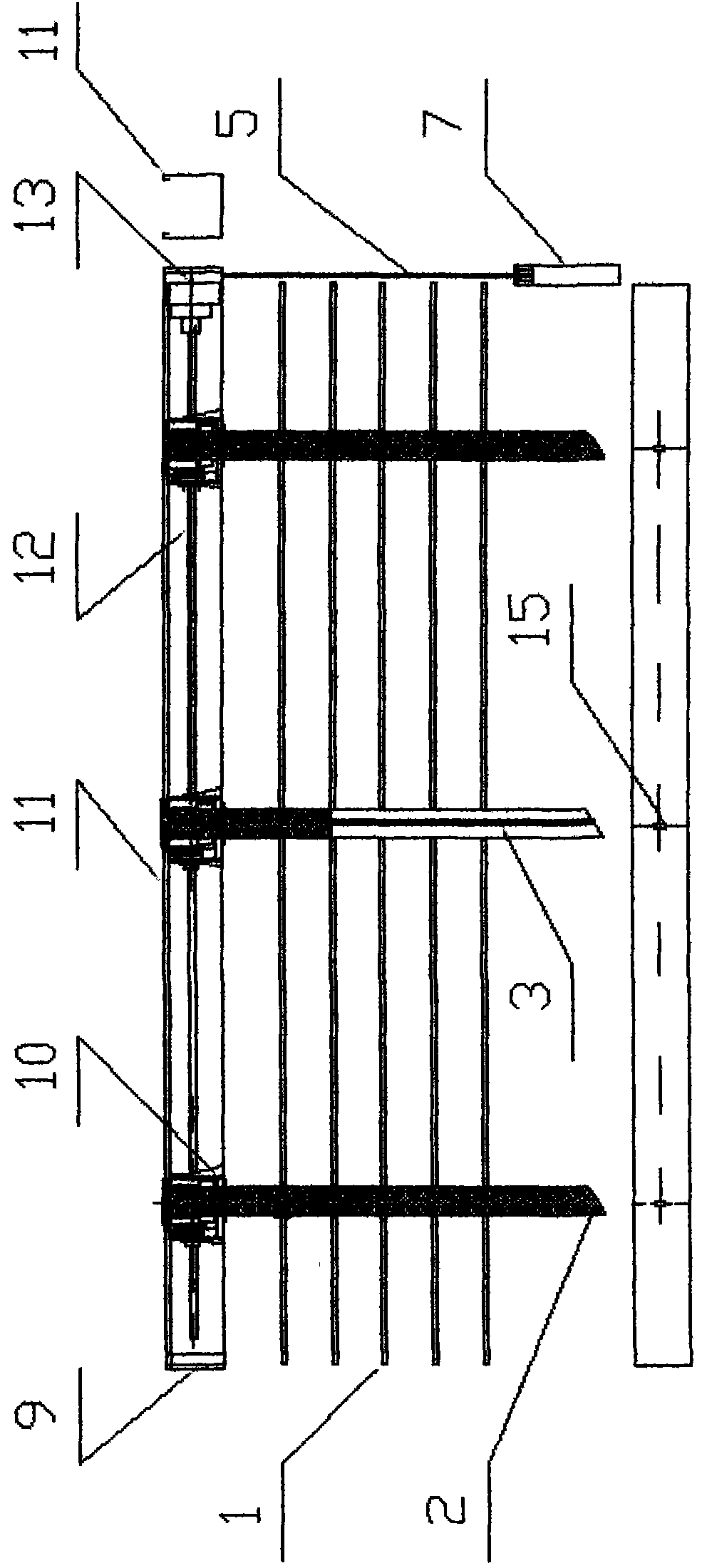

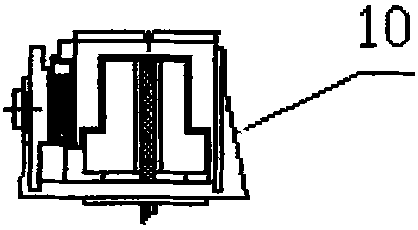

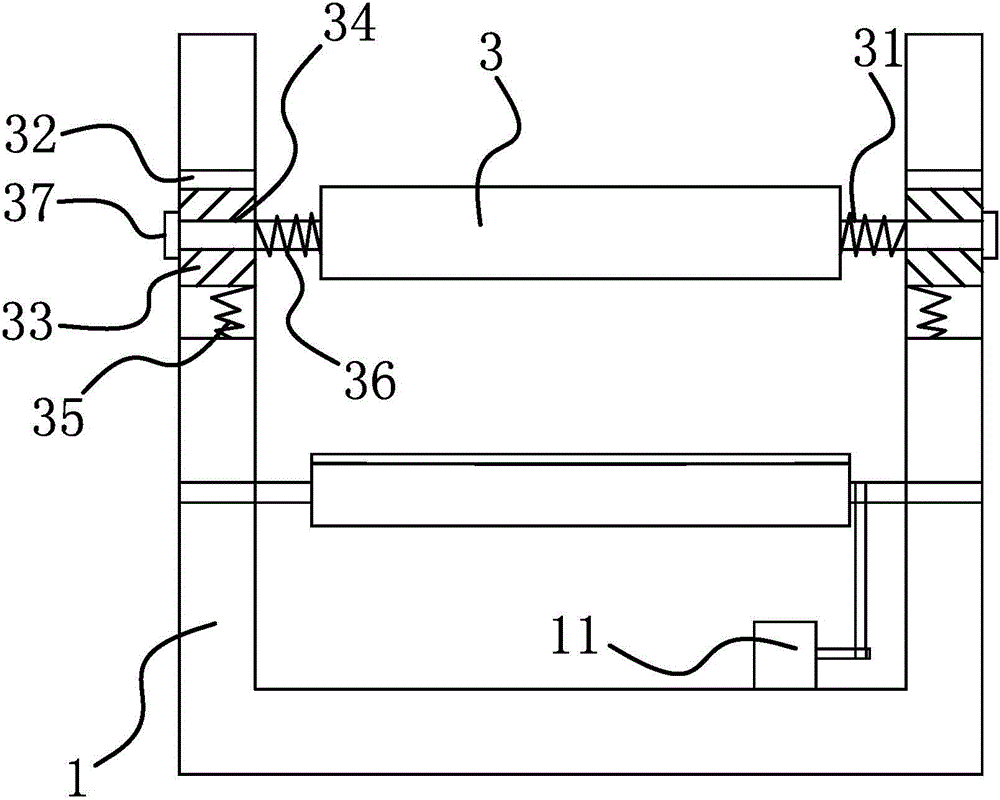

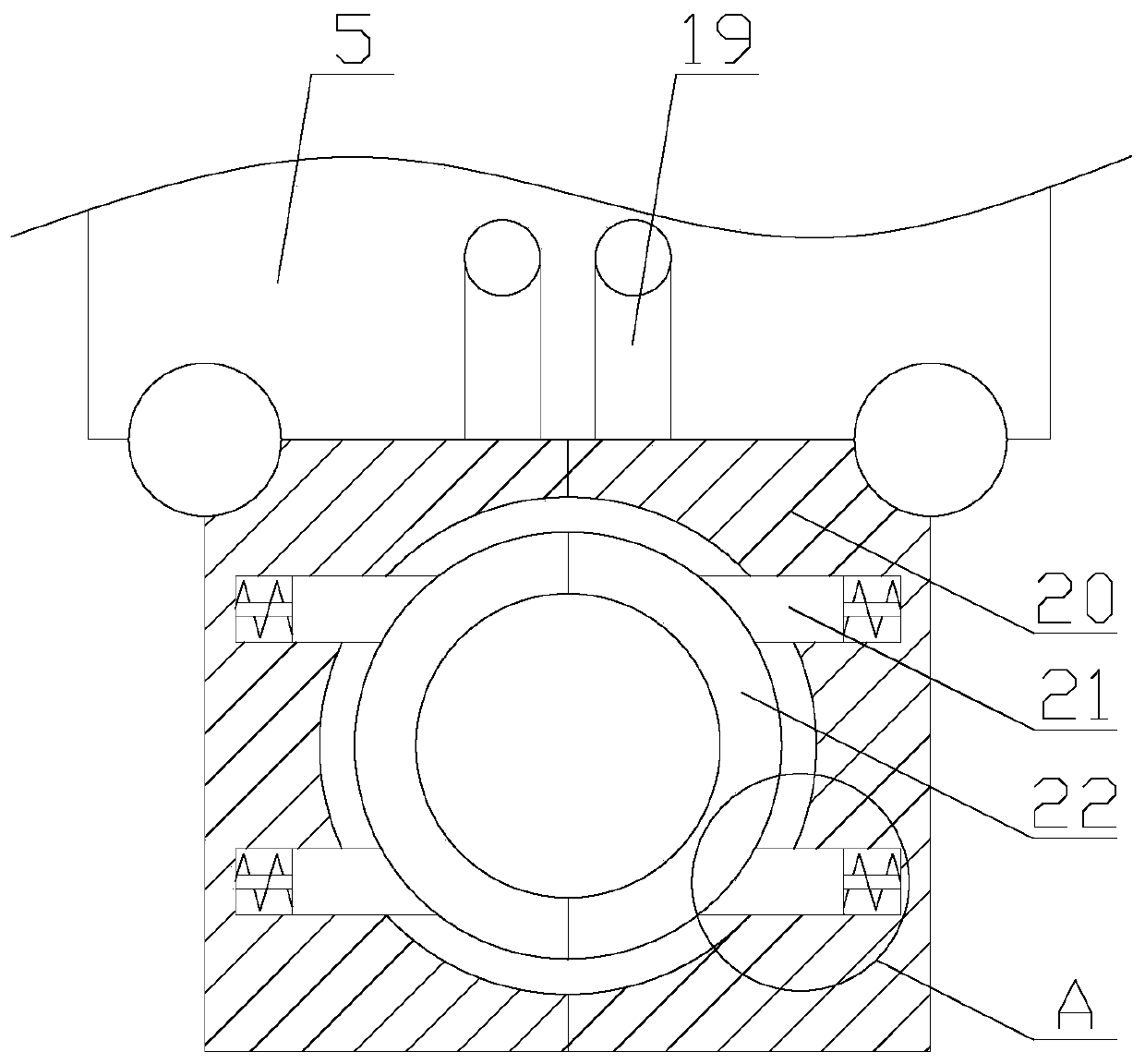

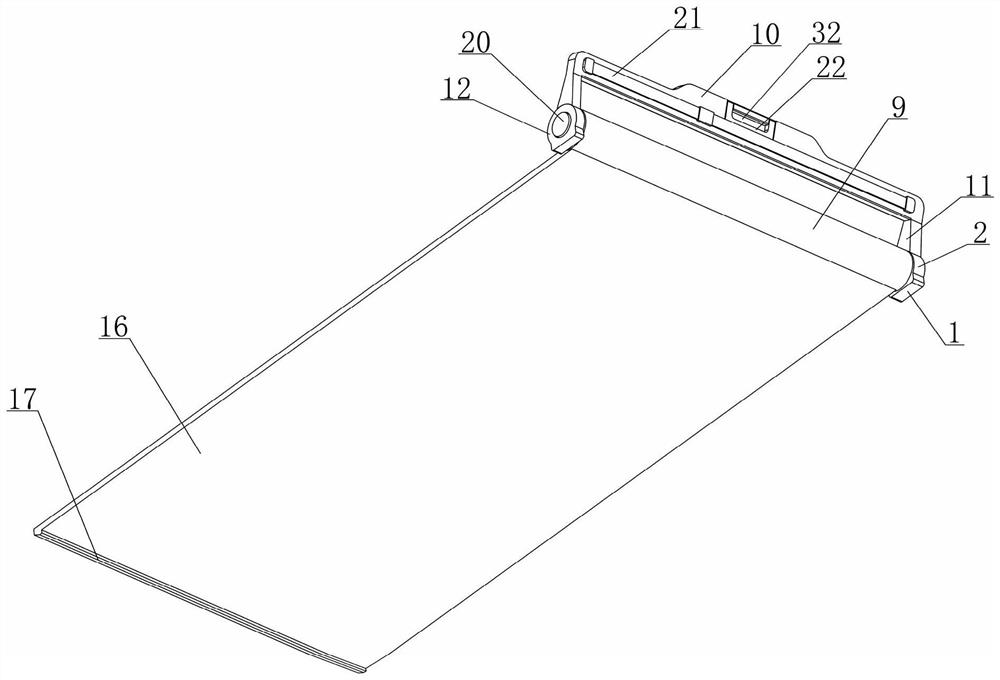

Lift venetian blinds

ActiveCN101886516AReasonable structureClosely connectedLight protection screensElectric machineryEngineering

The invention discloses venetian blinds, wherein one end of an upper beam (11) is provided with a rope-locking device (13), the other end is provided with a side cover (9); the inside of an upper beam assembling system is provided with a cross shaft (12); a rope-locking device is arranged at one end of the cross shaft, the other end is assembled with a lifter; and a lifter component (10) is assembled by a lifter connecting base (16), a cloth ladder wheel brake shaft (17), a cloth wheel stop elastic device (18), a cloth ladder wheel (19), a bearing seat (20), a bearing (21), an elevating belt rotating wheel (22) and the like. The venetian blinds provided by the invention furthest solves the problem that rope holes on the strips of the blinds leak light; and the lifting belts can be freely retractable in the lifting or dropping process of the venetian blinds, the venetian blinds can not twist together, the operation is easy, convenient and labor-saving and has no noise, the track space is saved, and the venetian blinds of the electric motor is easy to hide.

Owner:LANTEX WINDOW FASHIONS CO LTD

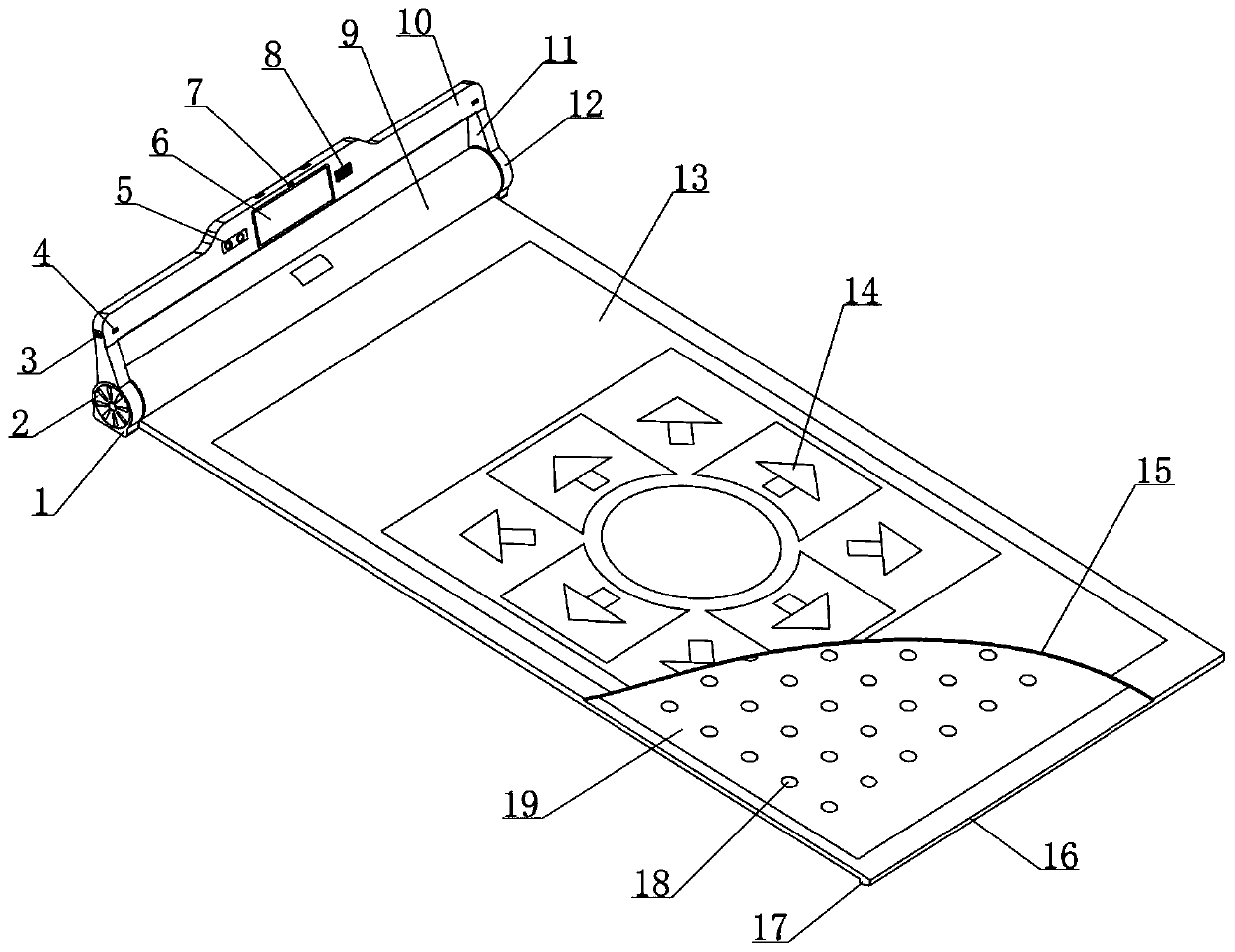

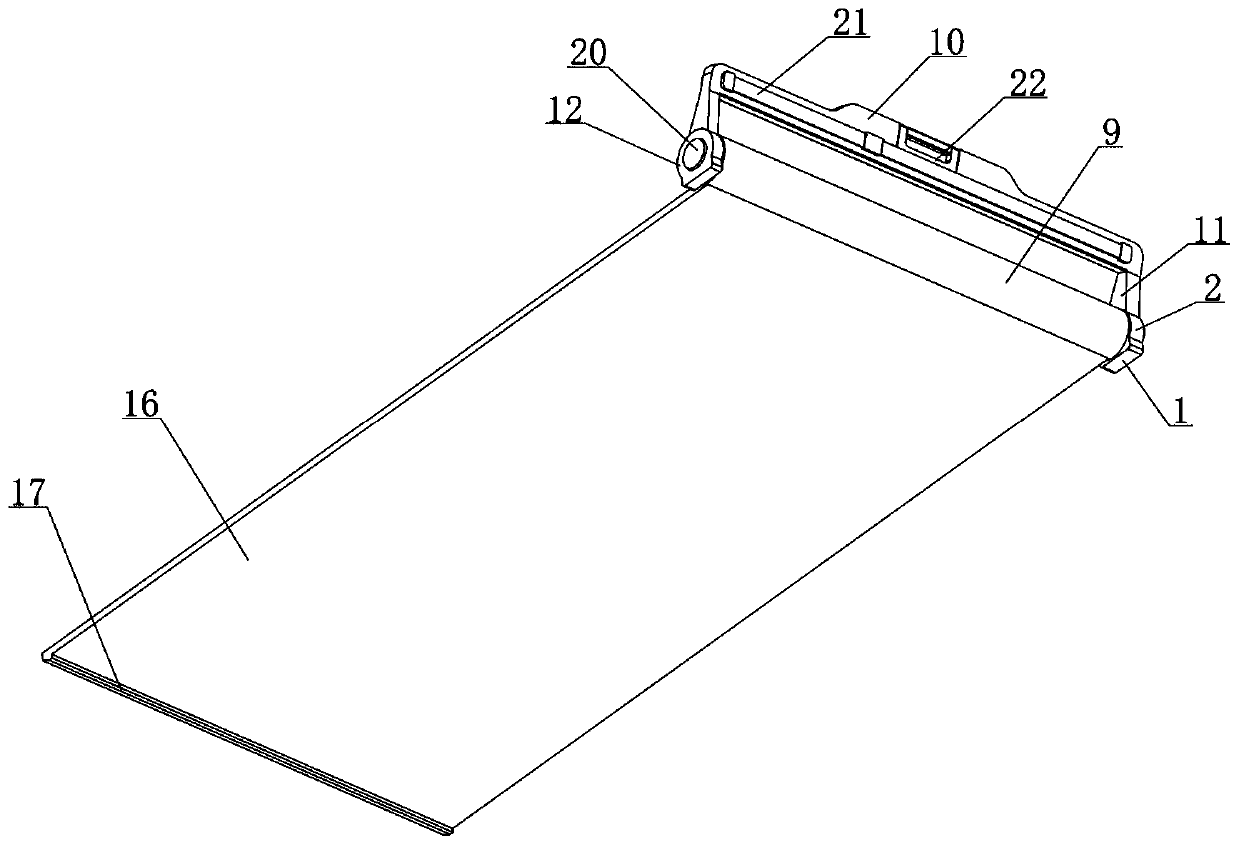

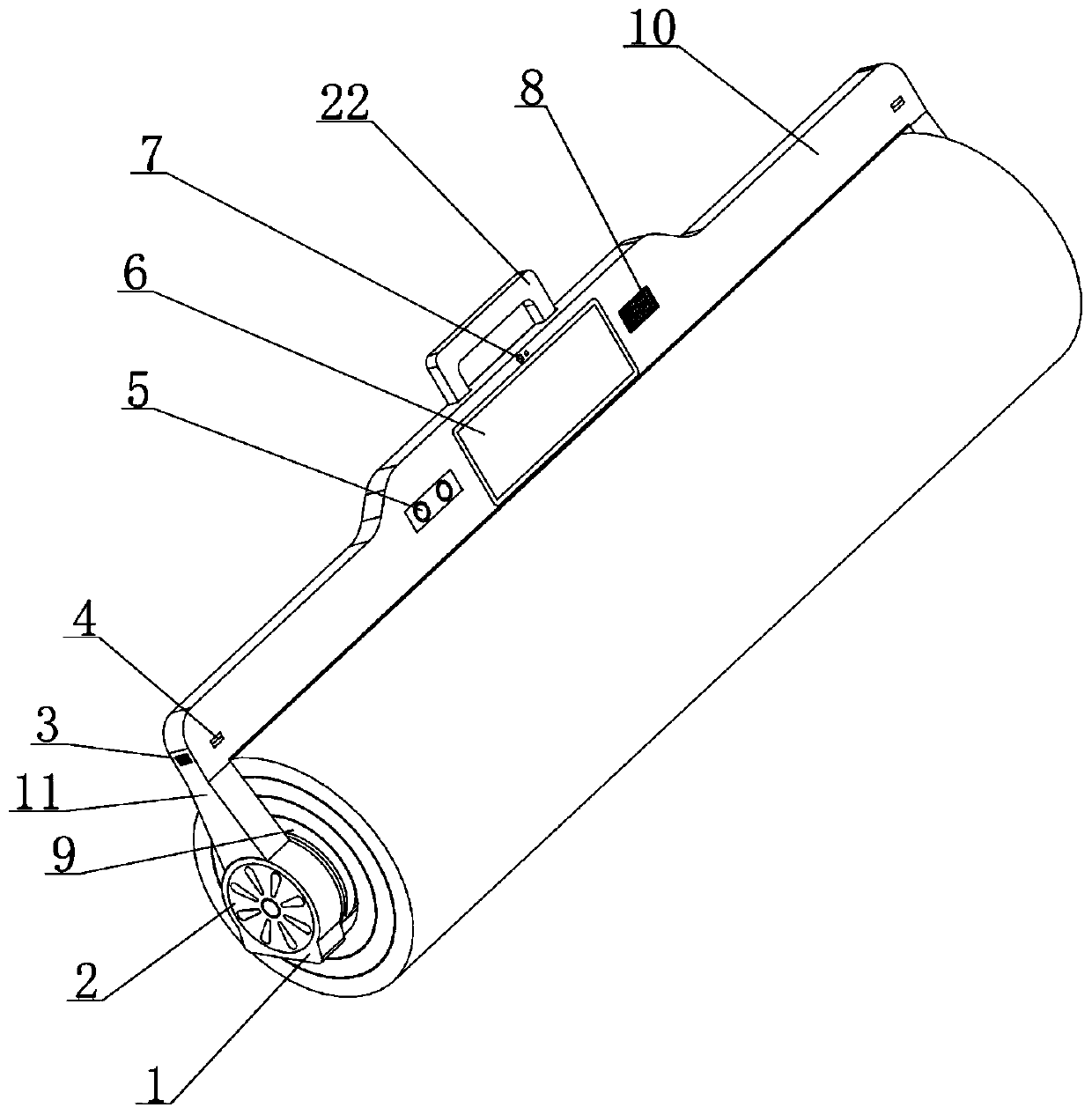

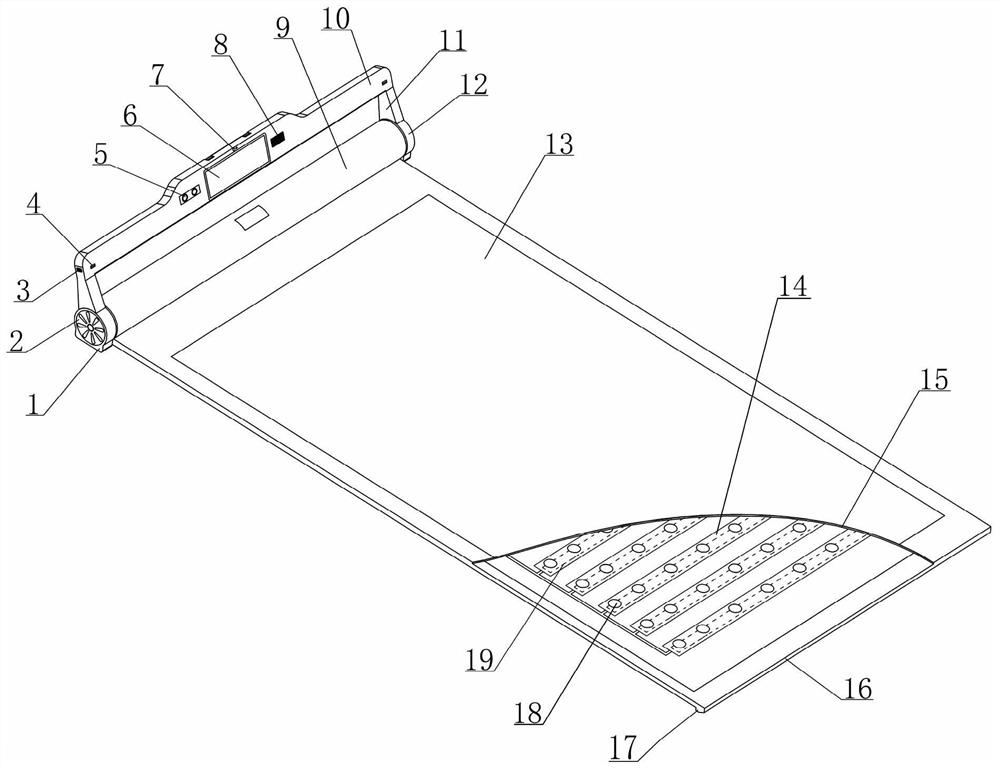

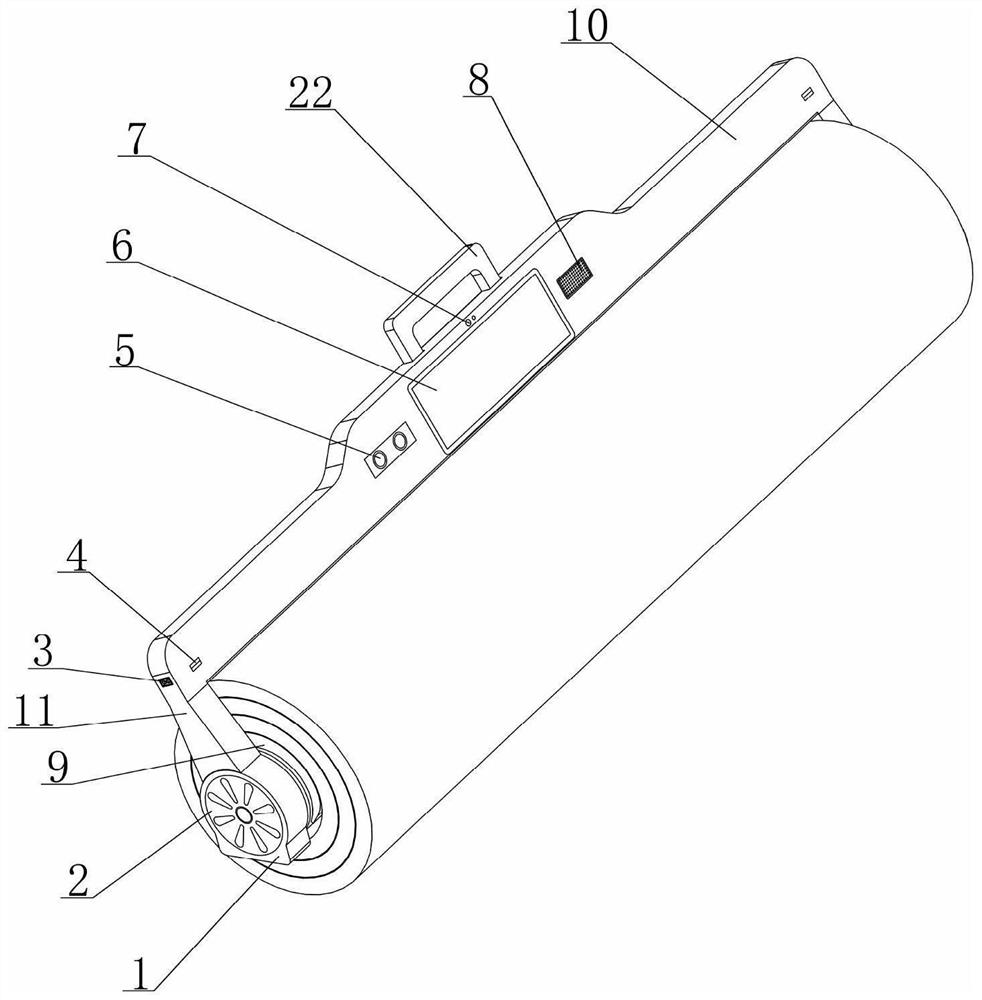

Multifunctional fitness mat

ActiveCN110292741ARich multimedia functionsFunctionalSpace saving gamesVideo gamesLocal pressurePhysical exercise

The invention relates to a multifunctional fitness mat, which consists of a mat body, a winding roller, an electric storage rack, a pressure sensing assembly, and a computer component. The winding roller is used for winding the mat body on the outside; the electric storage rack is rotatably connected with the winding roller, and a motor can drive the winding roller to perform winding and unwindingon the mat body; the pressure sensing assembly can output local pressure change data reflecting a local pressure change of the mat body during training; the computer component is integrated in the electric storage rack and has conventional functions such as data uploading / downloading, video recording / playback, and third-party program installation / running, the local pressure change data can be received, exercise data can be obtained through corresponding operation methods, and a dance game program is internally arranged; the multifunctional fitness mat has a exercise monitoring function, corresponding exercise data can be generated for each exercising process, and thus exercise is more scientific; the multifunctional fitness mat has a multimedia functions, and various needs in the exercising process can be met; and the multifunctional fitness mat has electric winding and unwinding functions, operation is convenient and fast, and time and effort are saved.

Owner:云道图山东智能技术有限公司

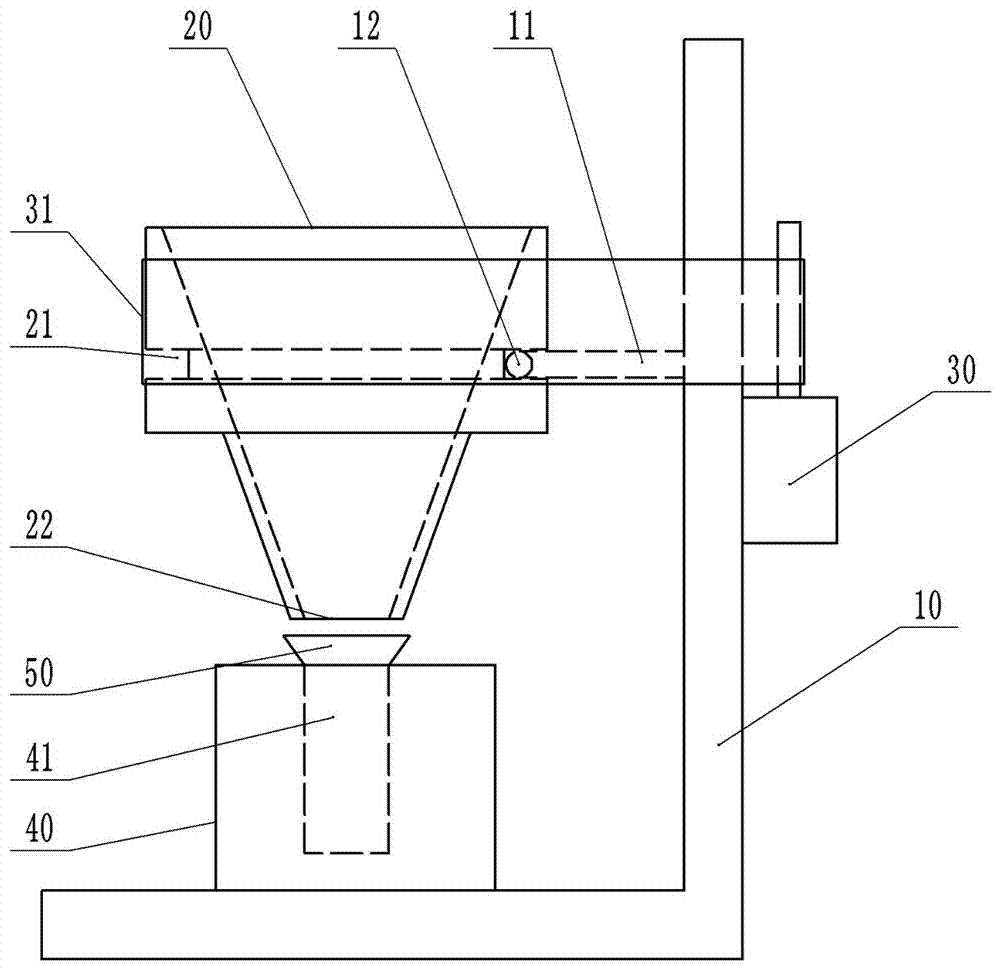

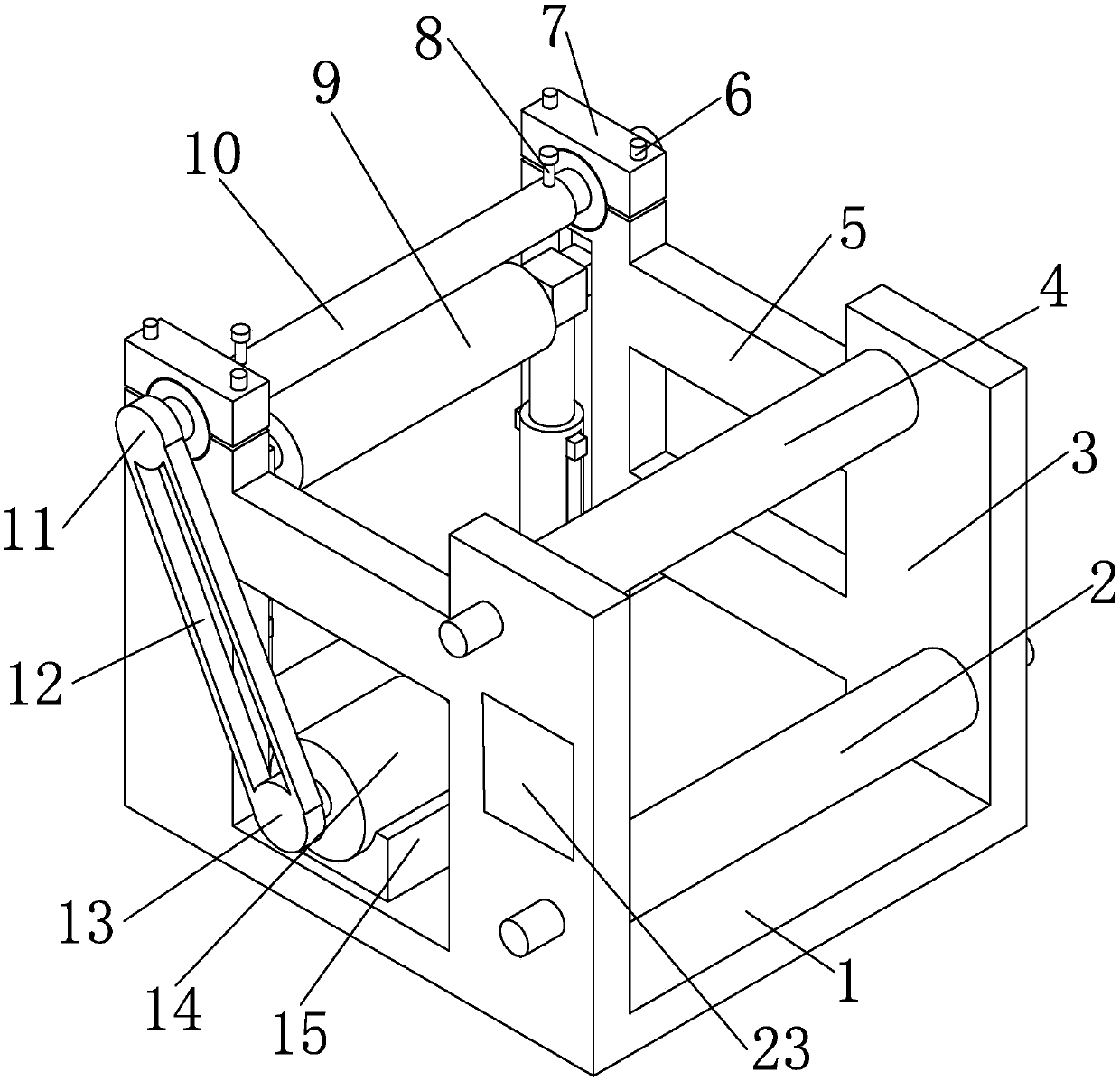

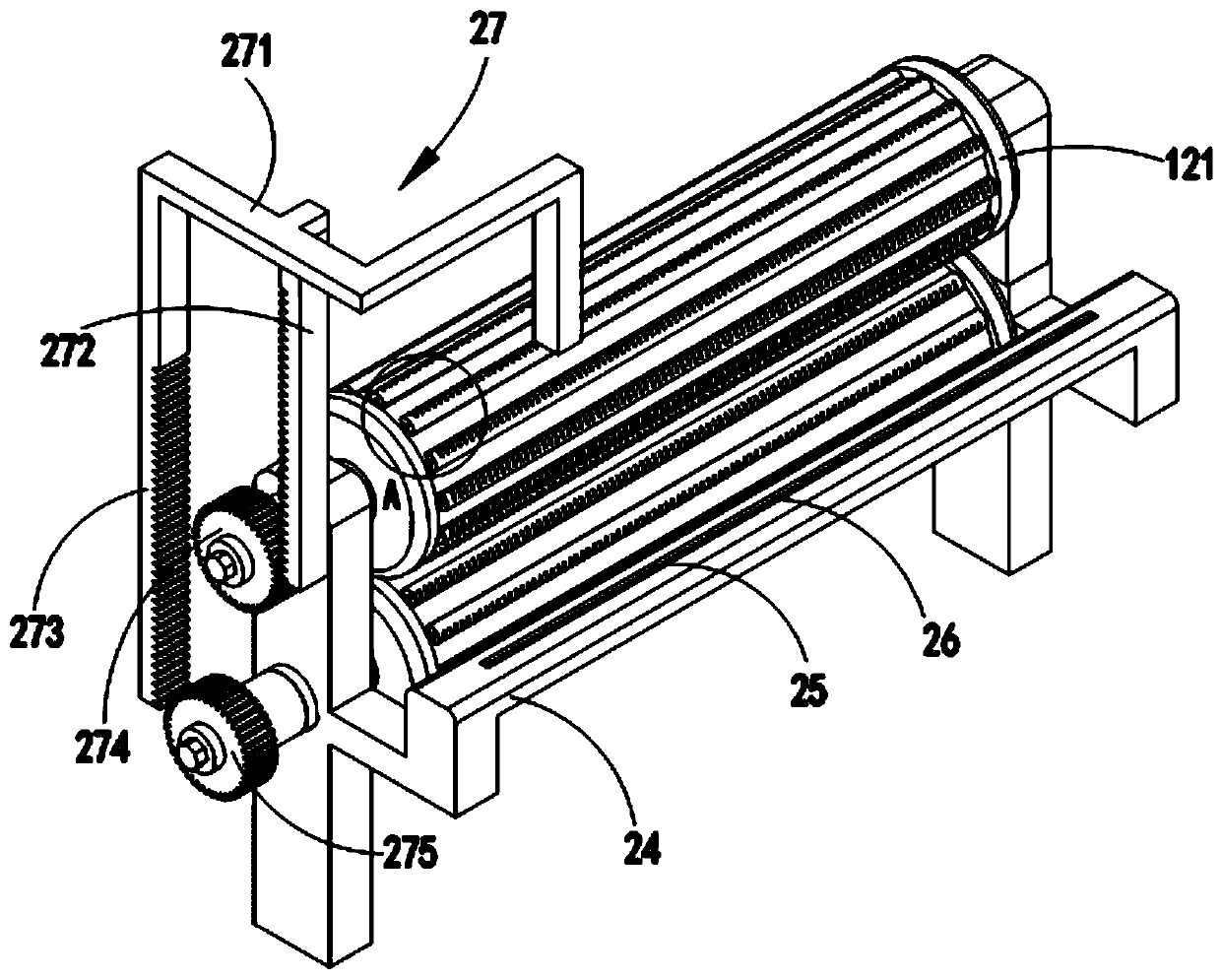

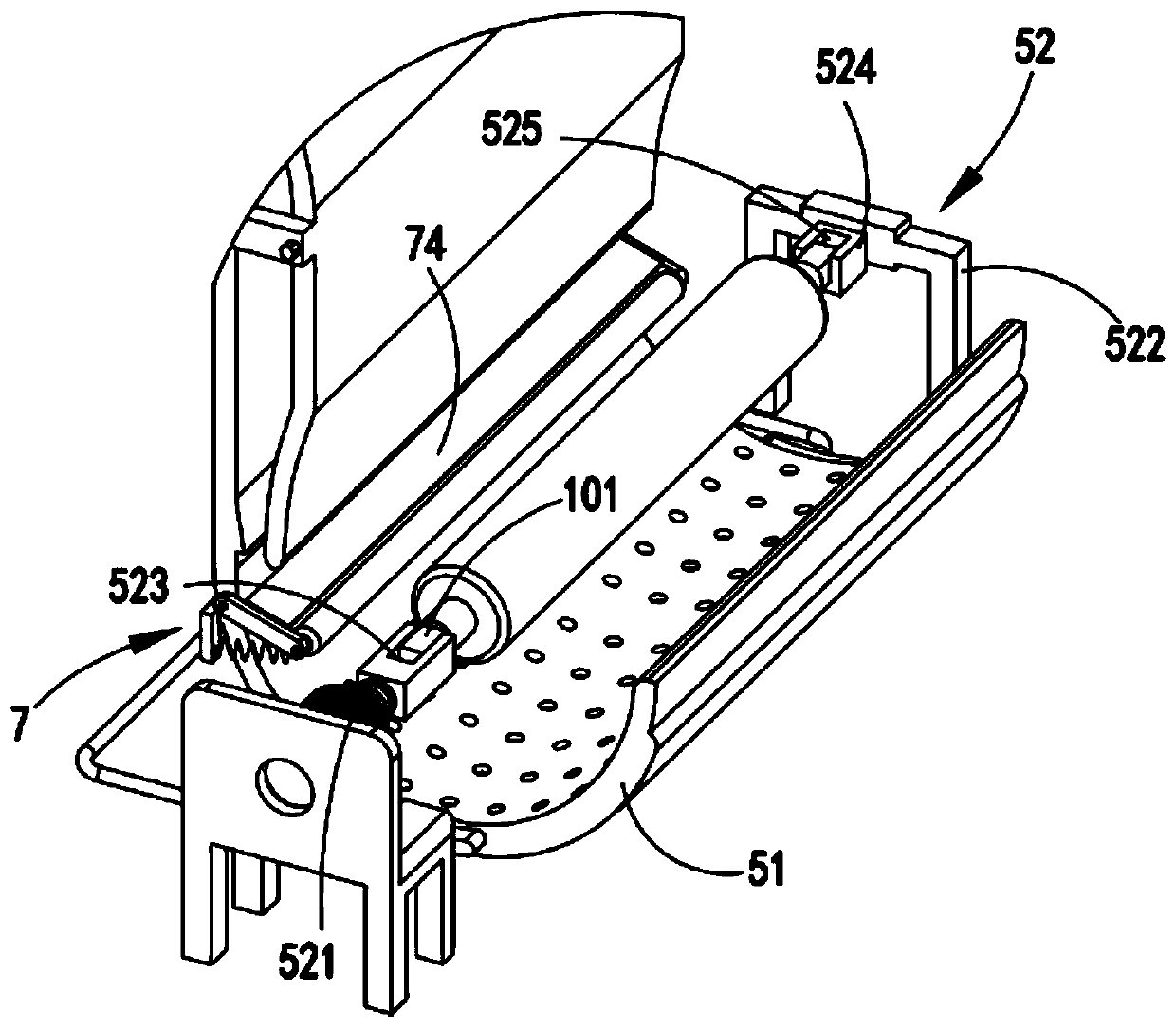

Winding device suitable for silk semi-finished products

ActiveCN104444499ACoil tightlySimple structureFunction indicatorsWebs handlingEngineeringMechanical engineering

Owner:HUZHOU SIYI SILK

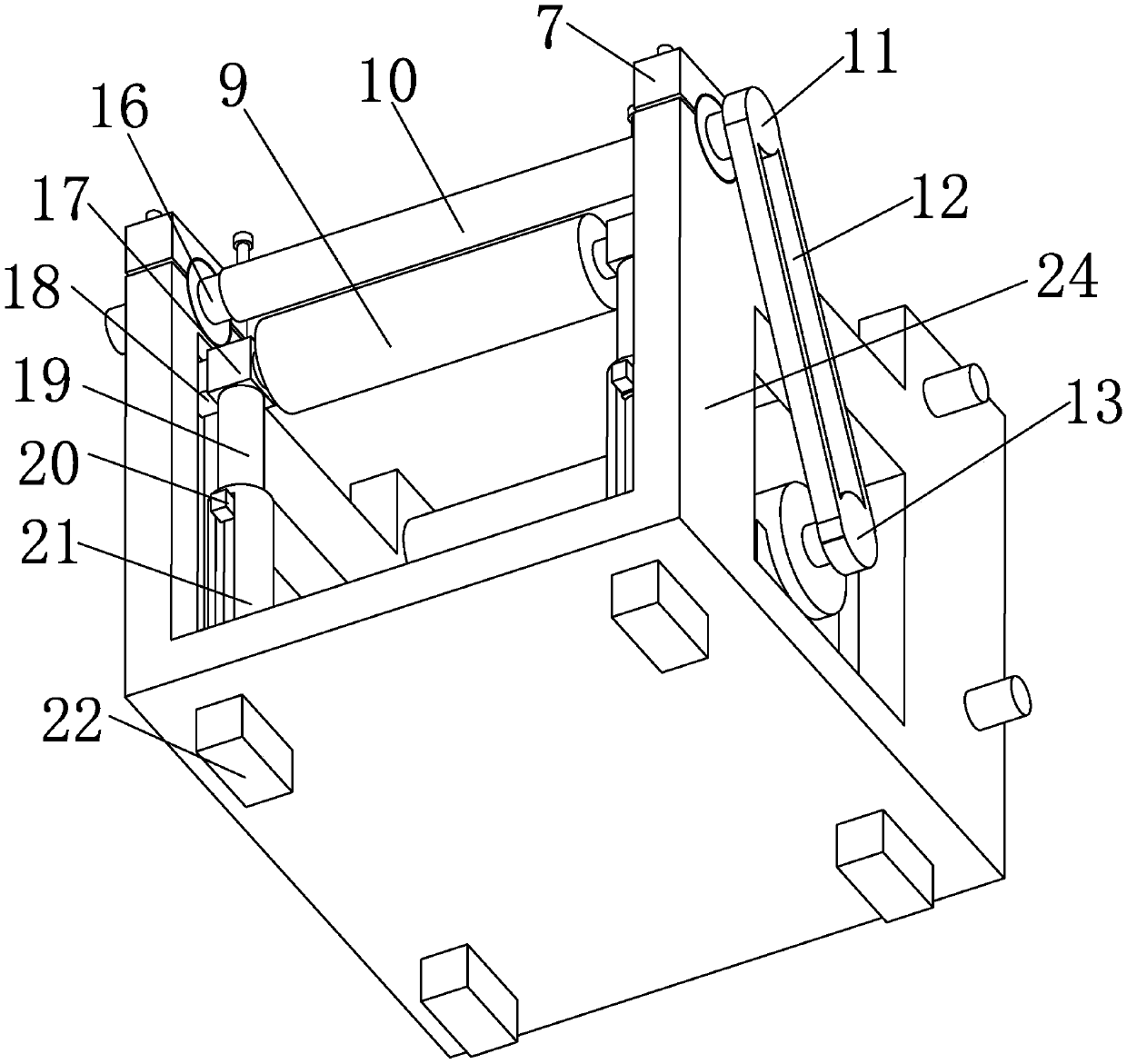

Winding device for shell fabric processing

InactiveCN109552918ACoil tightlyWinding will not looseMechanical cleaningPressure cleaningConductor CoilMechanical engineering

The invention discloses a winding device for shell fabric processing. The winding device for shell fabric processing comprises a base, and two installing supporting frames are correspondingly fixed tothe two ends of the top face of the base. According to the winding device for shell fabric processing, by arranging a spring tube and a first spring tube, a press roll and a first press roll are enabled to press a winding roll and a guide roll tightly through a spring positioned in the spring tube and a first spring positioned in the first spring tube, and thus the winding of shell fabrics is compact and does not loose; by arranging two inclined rolls, two first motors rotate in the opposite directions, the two inclined rolls correspondingly rotate towards the center line of the shell fabrics, and thus hair brushes on the two inclined rolls can clean out float hairs on the surfaces of the shell fabrics towards the two sides of the shell fabrics correspondingly; and then the function of cleaning out the float hairs and the function of supporting the shell fabrics towards the two sides are realized, and thus the shell fabrics which are winded are more compact and neat; and by arranginga vibrator, a flap plate can play the role of flapping the shell fabrics under the action of a second spring, and thus the function of shaking the float hairs of the shell fabrics off is achieved effectively.

Owner:恒天(江苏)化纤家纺科技有限公司

Adhesive film rolls automatic coiler

InactiveCN108675037AStable structureReduce wearWebs handlingWork safetyElectrical and Electronics engineering

The invention discloses an adhesive film rolls automatic coiler. The adhesive film roll automatic coiler includes a support plate; two first fixing plates and two second fixing plates arranged on theupper surface of the support plate, wherein the first fixing plates are correspondingly arranged on the left and right sides, the first fixing plates and the second fixing plates are correspondingly arranged on the front and back sides; press blocks arranged on the upper surfaces of the two fixing plates, wherein the press blocks are fixedly connected to the second fixing plates by fixing bolts; bearings arranged between the second fixing plates and the press blocks; a forth roll shaft arranged between the two second fixing plates, wherein the both ends of the forth roll shaft are connected tothe bearing; and a coiler mandrel arranged on a side surface of the forth roll shaft. The film roll automatic coiler has a firm structure, and is stable and durable, which can reduce equipment wear,increase the service life of the equipment, and provide convenience for the use. Furthermore, the film roll automatic coiler of the invention can improve working efficiency, and has high working safety. The material on the coiler mandrel are tightly coiled during coiling, which prevents wrinkling or cracking of the film and thus reduces losses of manufacturers.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

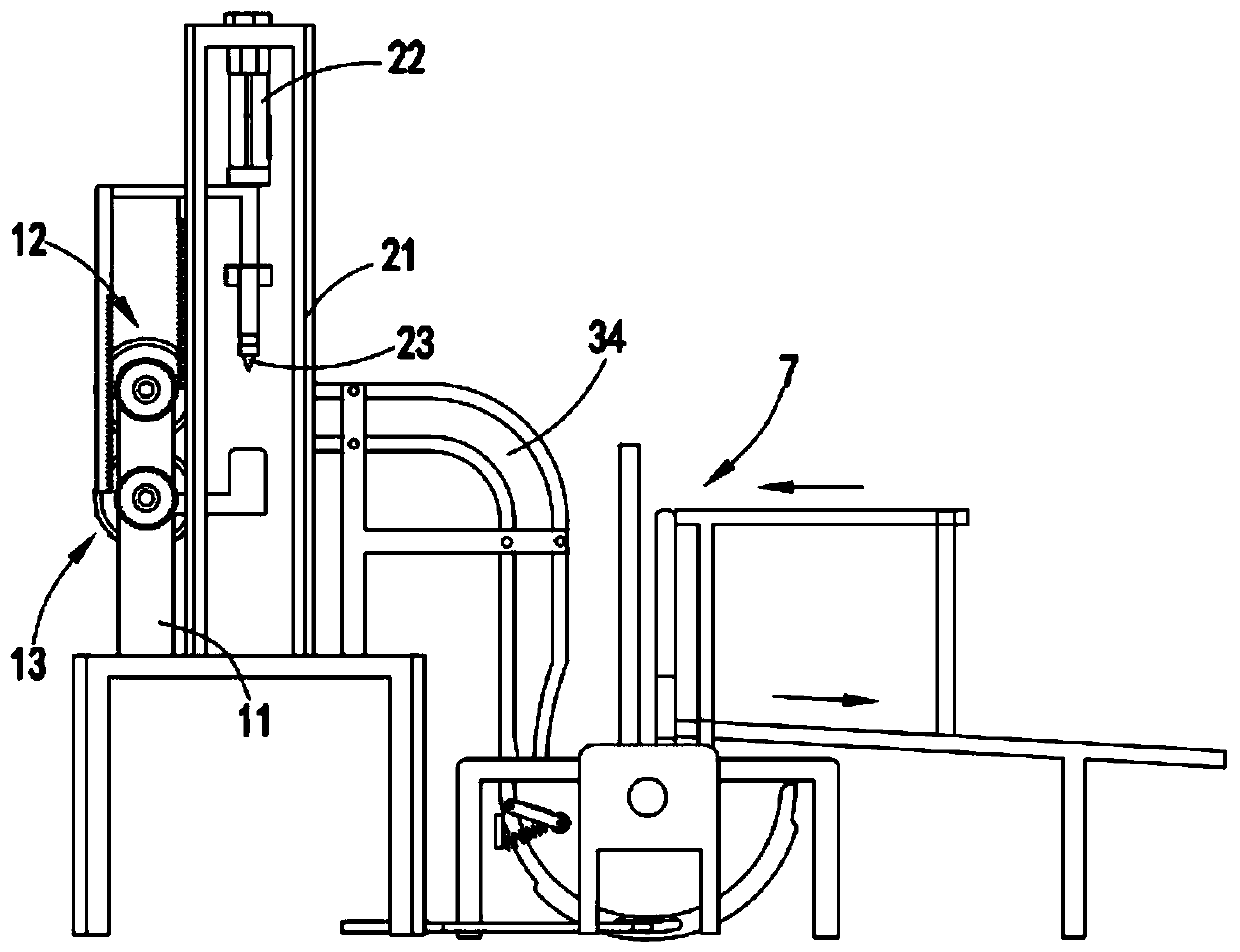

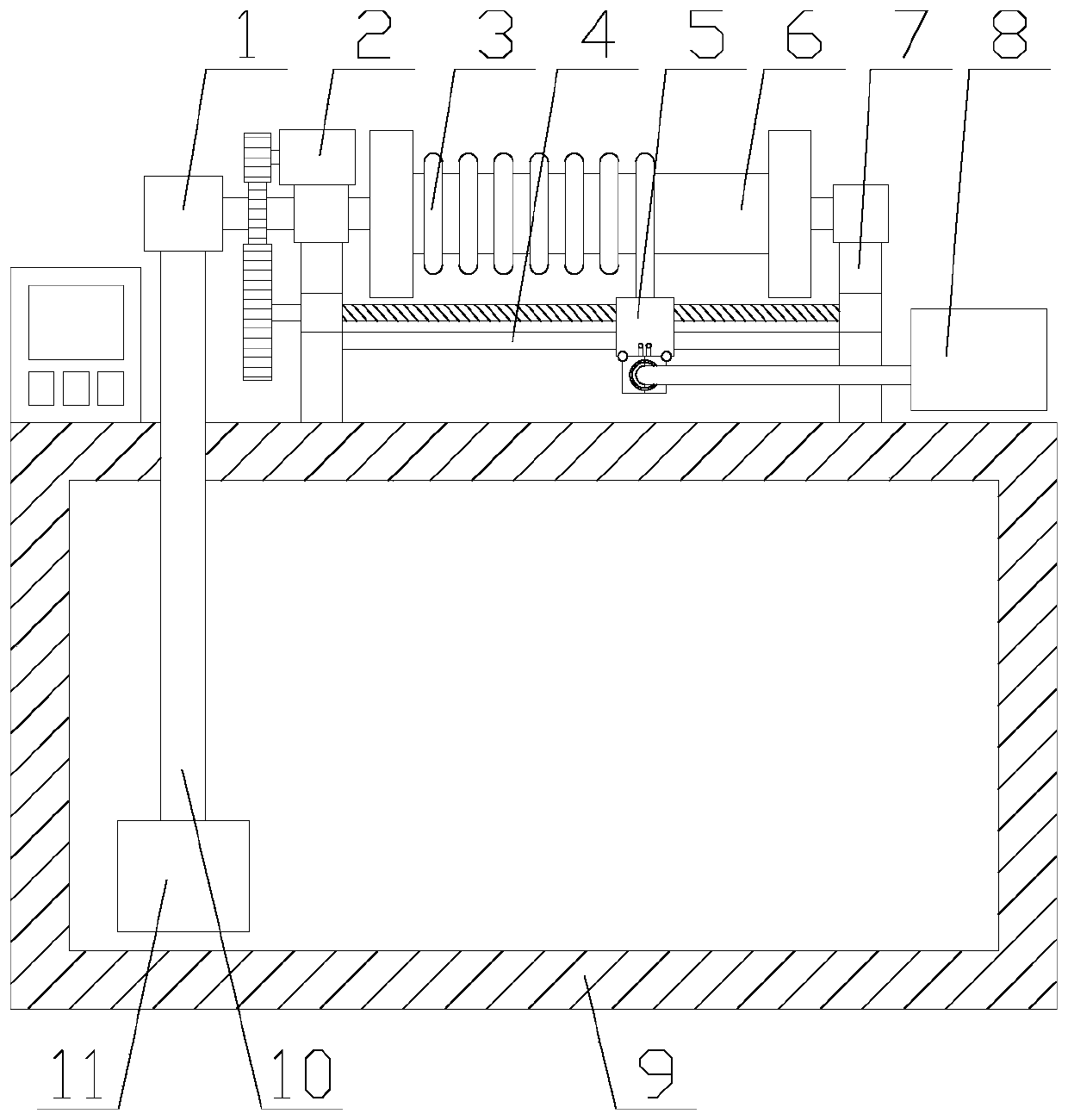

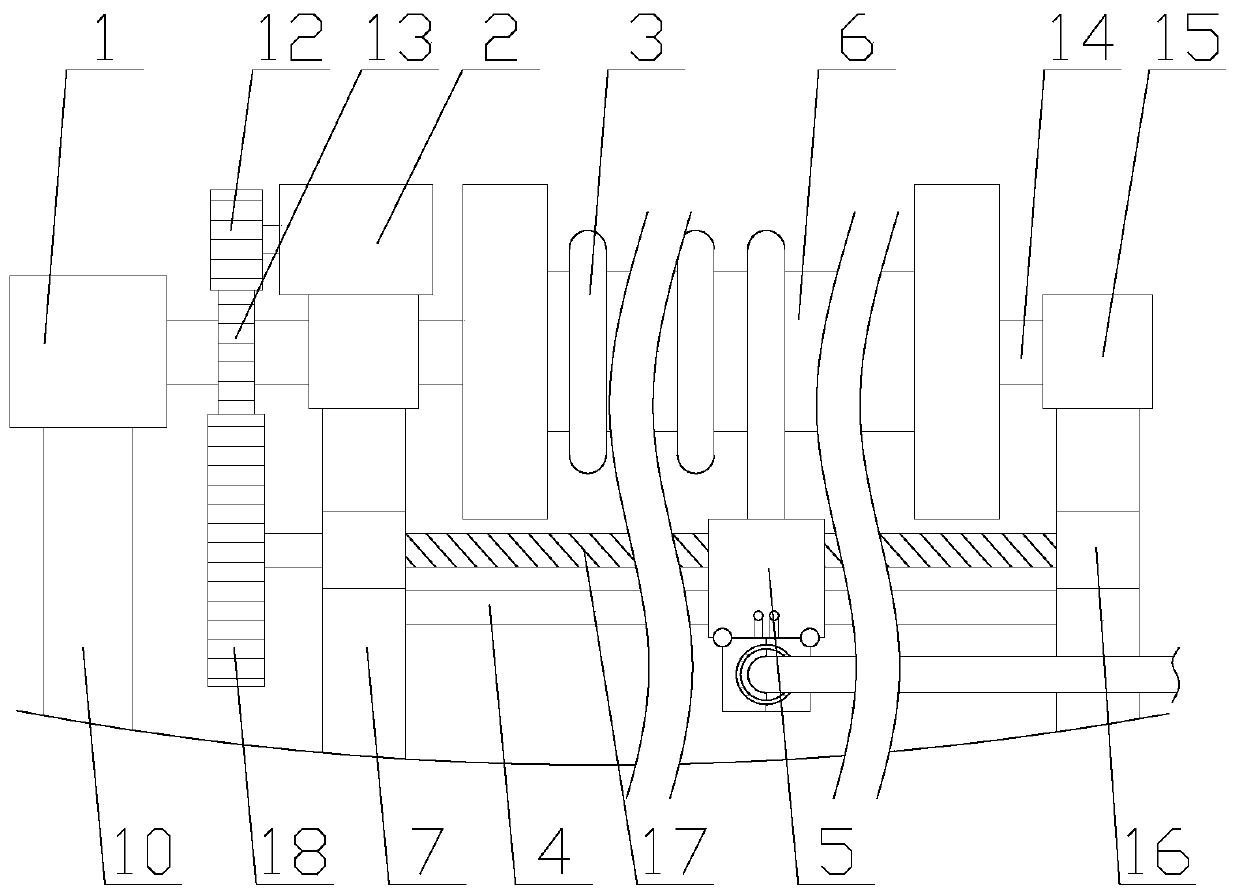

Textile warp knitting production equipment and textile warp knitting production method

ActiveCN111101287AIngenious structureGood effectWarp knittingMechanical engineeringIndustrial engineering

The invention relates to textile warp knitting production equipment and a textile warp knitting production method. The equipment comprises a pedestal, rolling rollers, a cloth delivery mechanism, a cutting mechanism, a guide mechanism and a rolling mechanism, wherein the cutting mechanism is arranged behind the cloth delivery mechanism, the guide mechanism is arranged behind the cutting mechanism,and the rolling mechanism is arranged at the tail end of the guide mechanism; after the rolling roller at the rolling mechanism completes rolling, the cloth delivery mechanism is matched with the cutting mechanism to cut cloth, the cutting mechanism resets after cutting is completed, the cloth delivery mechanism drives unwound cloth to be conveyed to the rolling mechanism along the guide mechanism in the resetting process, and the rolling mechanism is matched with the next rolling roller to continuously wind the cloth. The problems that in the cloth rolling process, the rolling efficiency islow, the upper rolling roller and the lower rolling roller need to be manually dragged to be connected after cutting, time and labor are wasted, cloth rolling is not tight in the rolling process, andthe rolling space is wasted are solved.

Owner:CHANGXING JINFA TEXTILE

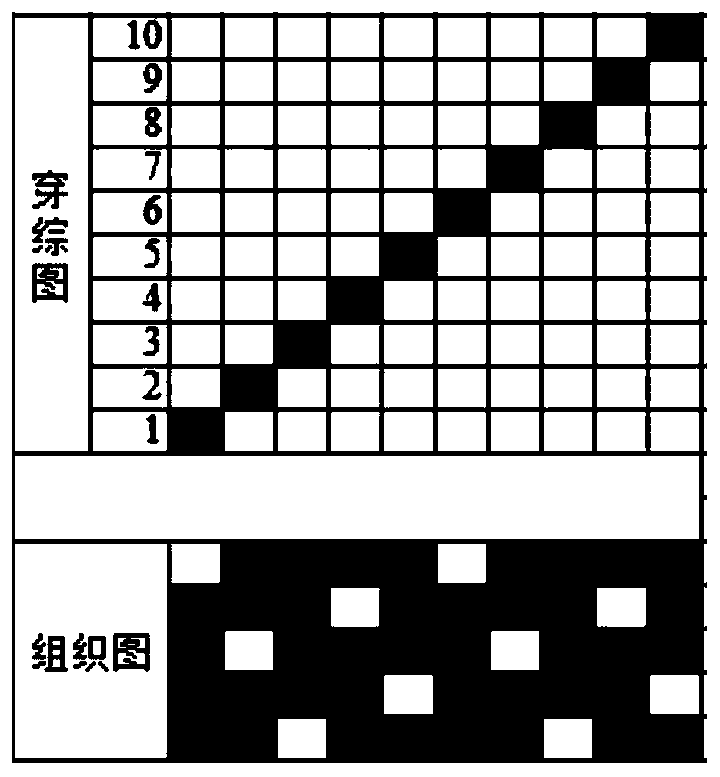

Novel warp knitting fabric

PendingCN111020858ATo achieve the effect of not curlingIncrease elasticityWarp knittingBraidManufacturing engineering

The invention provides a novel warp knitting fabric. The novel warp knitting fabric comprises a fabric body formed by knitting of at least three guide bars of a warp knitting machine, the fabric bodycomprises a surface layer and a bottom layer, the surface layer is formed in the mode that a group of yarns Y1 composed of a plurality of yarns is knitted and formed on the front face of the fabric body by means of a warp satin weave structure through the first guide bar, a group of yarns Y2 composed of a plurality of yarns are knitted by using a variable double-loop-stitch structure through the second guide bar and a group of yarns Y3 composed of a plurality of yarns is knitted by using a pad-lacking weft insertion weave structure through the third guide bar, and then the bottom layer is formed through co-forming of the yarns 2 and the yarns 3 on the bottom surface of the fabric body, wherein the yarns Y1, the yarns Y2 and the yarns Y3 are connected with each other in a penetrating and sleeving manner, and any two or three groups of the yarns Y1, the yarns Y2 and the yarns Y3 are elastic yarns. The fabric has the advantages of being not prone to edge curling and loosening and having elasticity in the warp and weft directions larger than or equal to 80%, the utilization rate of the fabric is increased, the garment manufacturing cost is reduced, and the garment wearing comfort and attractiveness of consumers are improved.

Owner:BEST PACIFIC TEXTILE

Damping adjusting device of steel wire pay-off machine

InactiveCN104030081ASteel wire coiled neatly and tightlyReduce labor intensityFilament handlingAgricultural engineeringUltimate tensile strength

The invention discloses a damping adjusting device of a steel wire pay-off machine. The damping adjusting device comprises a fixing shaft, a flexibly packaged steel wire, a brake disc, a damping device, a bottom plate and fixing bolts. The bottom plate is fixedly connected with the fixing bolts and is provided with the fixing shaft and the damping device, the brake disc is arranged on the fixing shaft, and the flexibly packaged steel wire is placed on the fixing shaft. The damping adjusting device of the steel wire pay-off machine has the advantages that the damping adjusting device is suitable for reeling steel wires with different sizes, accordingly, the purpose of neatly and tightly winding the steel wires can be achieved, the labor intensity of operators can be greatly relieved, and an operating rate can be increased.

Owner:GUIZHOU WIRE ROPE

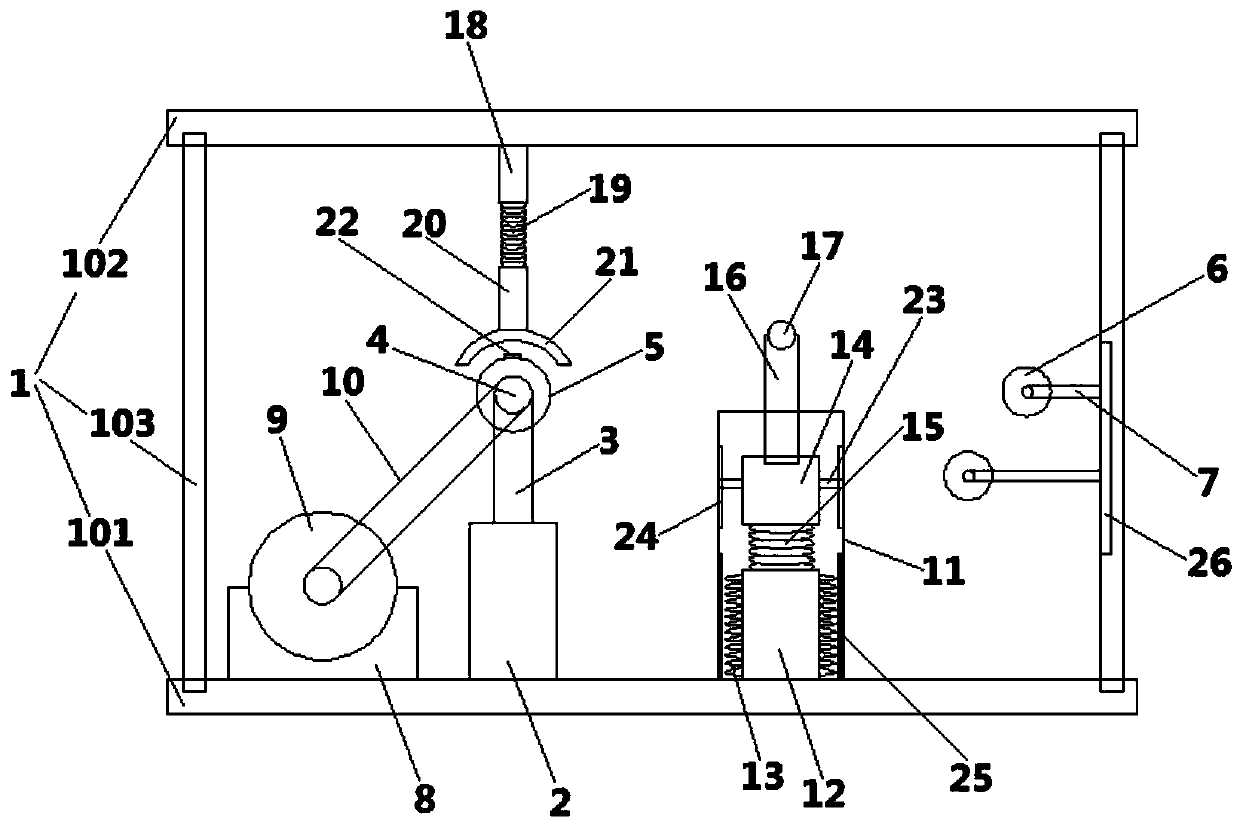

Winding machine ensuring uniform and tighter winding on basis of electromagnetic principle

The invention relates to the field of network information technologies, and discloses a winding machine ensuring uniform and tighter winding on the basis of an electromagnetic principle. The winding machine comprises a box body, wherein a rotating shaft is movably connected in the box body, winding is performed through rotation of the rotating shaft, a fixed rod is fixedly connected above the rotating shaft, through the cooperation between a first rotating disc and a second rotating disc for use, when winding is stopped, the rotating shaft stops rotating and drives the first rotating disc to synchronously stop moving, so that a brake rod emergently brakes a cable, the situation that the cable shakes when winding is stopped, and consequently wound cable is loosened is avoided, through the use of a limiting rod, the limiting rod moves left and right in the winding process, winding is more uniform, and through cooperative use of a fixing disc, the limiting rod and a second gear, when winding is stopped, the second gear and the limiting rod are connected in a clamped mode, so that the rotating shaft is stopped synchronously, and the situation that the wound coil is loosened and not wound tightly is avoided.

Owner:南通益纳森智能科技有限公司

Spray coating machine having conveying pipe storing function and used for treating methanal

The invention relates to a spray coating machine having a conveying pipe storing function and used for treating methanal. The spray coating machine comprises a main body, a conveying pipe and a spraying gun and further comprises a contracting and releasing mechanism and a cleaning mechanism. The contracting and releasing mechanism comprises a rotating connector, a drum, a drive pipe, a drawing pipe, a power pump, a screw rod, a sliding rod, a moving block, a second gear, a third gear, two first bearings, two second bearings and two supports. The cleaning mechanism comprises two clamping blocks, two elastic ropes, two cleaning brushes and four connecting assemblies. A drive assembly comprises a motor and a first gear. Each connecting assembly comprises a cylindrical notch, a connecting column and a spring. According to the spray coating machine having the conveying pipe storing function and used for treating methanal, by means of the contracting and releasing mechanism, winding and storing of a conveying pipe can be achieved, use convenience of the spray coating machine is improved, by means of the cleaning mechanism, the conveying pipe is cleaned, abrasion speed of the conveying pipe is reduced, and practicality of the spray coating machine is improved.

Owner:GUANGZHOU ZHONGTAN AIR PURIFICATION TECH CO LTD

High-count and high-density polyester cotton composite yarn fabric and weaving method thereof

The invention relates to a high-count and high-density polyester cotton composite yarn fabric and a weaving method thereof. The fabric is composed of face textile fabric and back textile fabric; the face textile fabric is five-ends and three-steps satin, and the back textile fabric is the five-ends and 3-steps sateen; the warp yarns of the face textile fabric and the back textile fabric are all polyester cotton composite yarns, and the weft yarns are all pure cotton yarns; the weight of the polyamide in the polyester cotton composite yarn is (20-30)%, the fineness of the polyester cotton composite yarn is (50-75)D, and the fineness of the weft yarn is (60-100)S; the specific weaving technology comprises warping, slashing, drafting, reeding, weaving and the other steps. Through the weavingmethod disclosed by the invention, the fabric parameters are meticulously designed by starting from the fabric style, and the parameters of various weaving procedures are reasonably adjusted by starting from the weaving efficiency and the gray cloth quality, the weaving problem of this fabric is solved, the weaving efficiency is high, and the quality goods rate is high.

Owner:江阴市华锋纺织科技有限公司

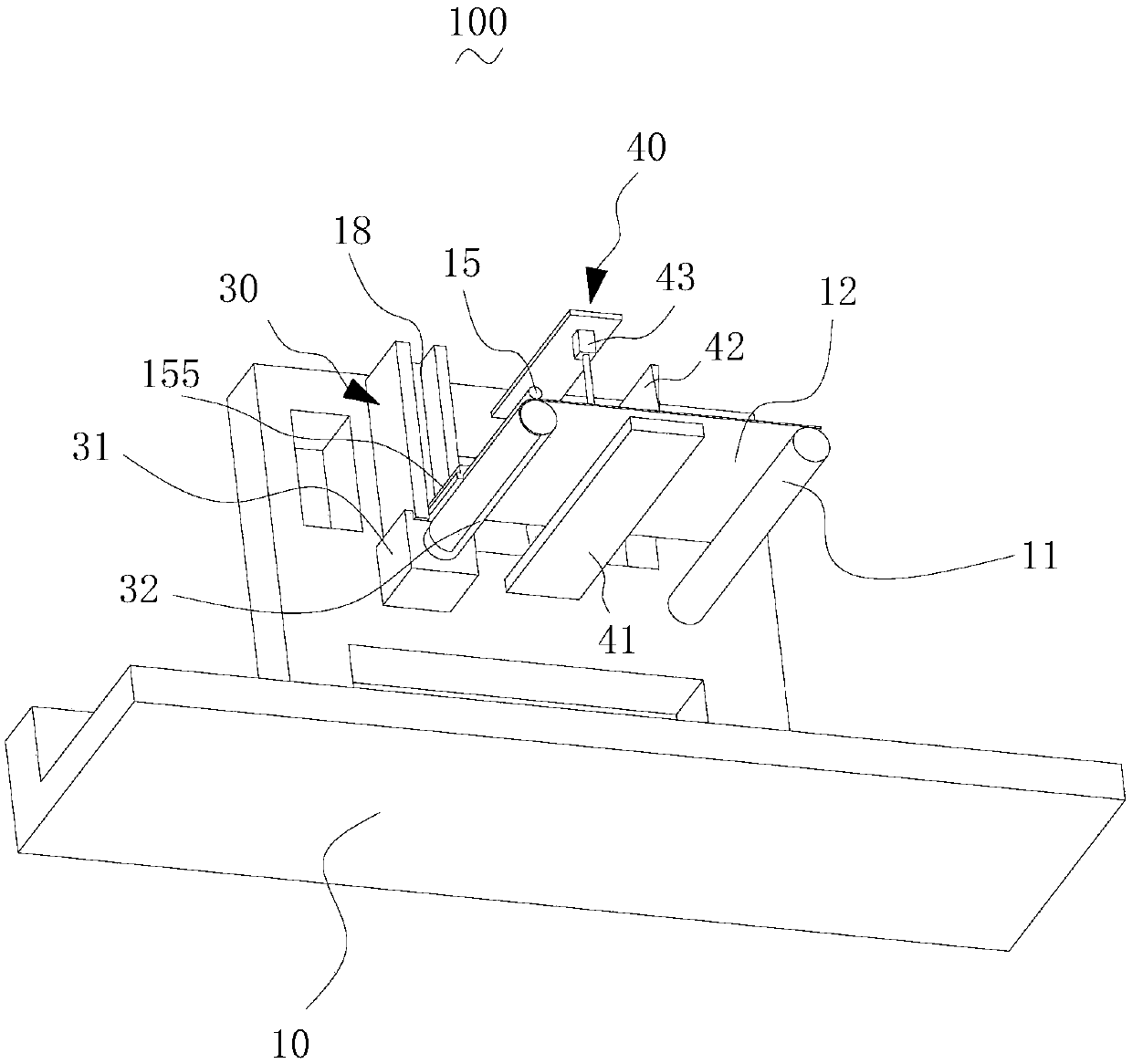

Belt material rolling mechanism

PendingCN109368324AFast windingImprove the winding effectWebs handlingMechanical engineeringEngineering

The invention discloses a belt material rolling mechanism and relates to the technical field of finished belt material rolling. The belt material rolling mechanism comprises a machine seat, a fixing seat and an air expansion shaft. A rotating shaft is rotatably arranged on the machine seat in a supported manner. One end of the rotating shaft is fixedly connected with the air expansion shaft. The fixing seat is located below the air expansion shaft and comprises elastic support legs and a fixing plate, wherein the fixing plate is fixed to the elastic support legs. A carrying roller is rotatablysupported by the fixing plate. By means of the belt material rolling mechanism, the rolling effect of a belt material is greatly improved; and meanwhile, by means of the air expansion shaft, rollingshafts of different diameters can be fixed, and the rolling scope can be wider.

Owner:四川高德特科技有限公司

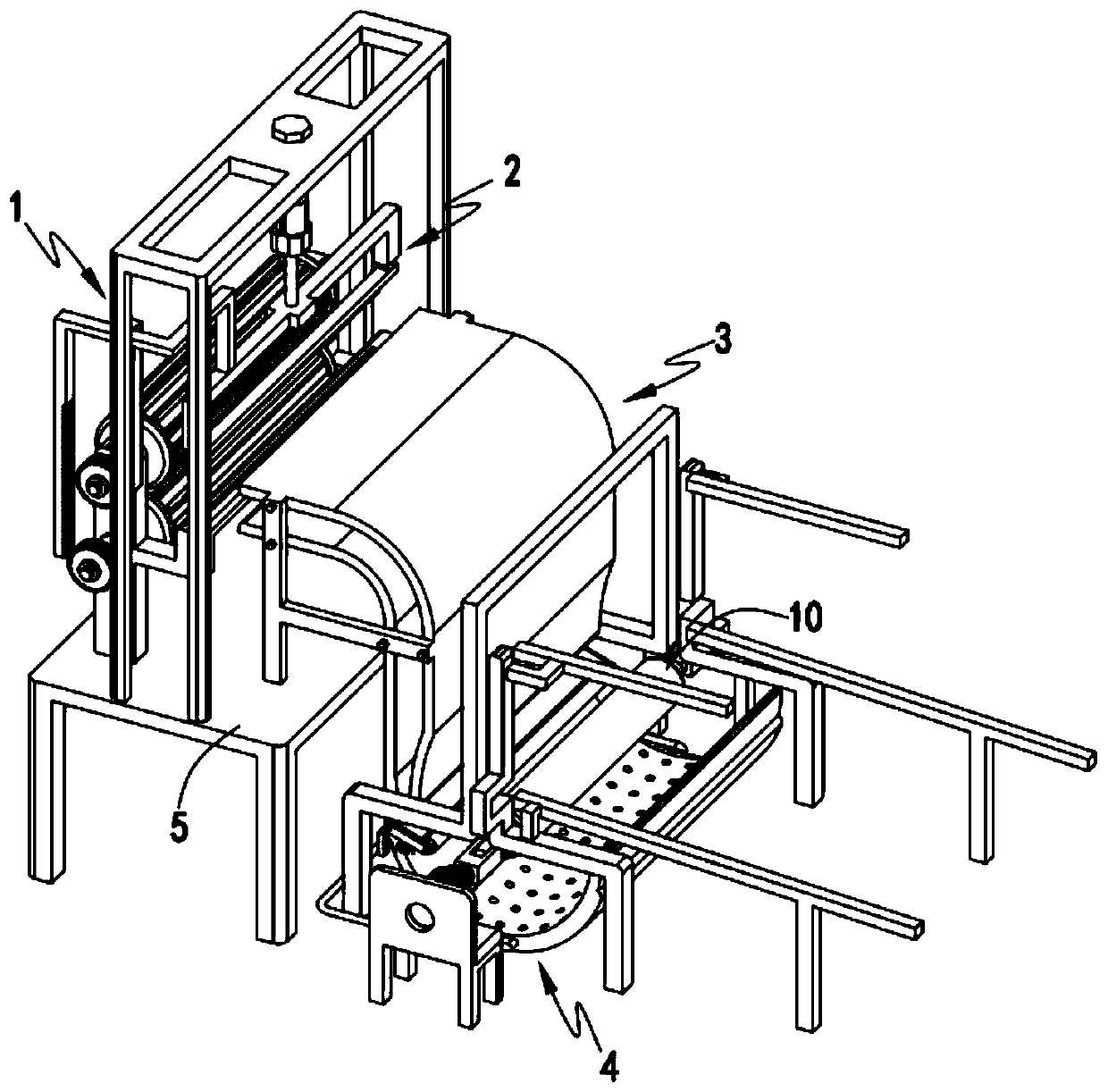

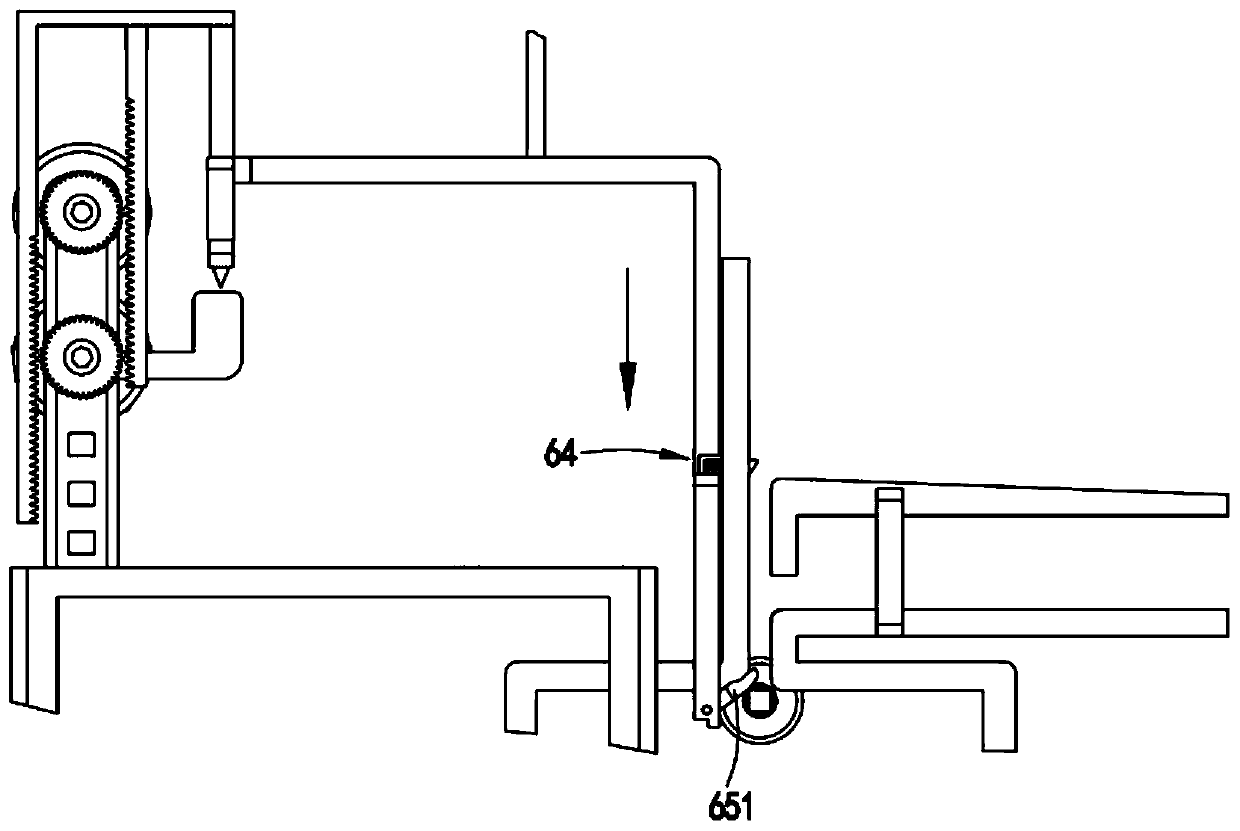

Warp-knitted fabric continuous rolling and outputting equipment

ActiveCN110921377AGuaranteed continuityGuaranteed high efficiencyWebs handlingManufacturing engineeringMechanical engineering

The invention relates to a set of warp-knitted fabric continuous rolling and outputting equipment. The warp-knitted fabric continuous rolling and outputting equipment comprises a base. A delivery mechanism and a guide mechanism are arranged on the base from front to back in sequence, a cutting mechanism is arranged between the delivery mechanism and the guide mechanism, a rolling mechanism is arranged at the tail end of the guide mechanism, and an outputting mechanism used for inlet and outlet of a cloth roller is arranged above the rolling mechanism. The cloth roller completes rolling of fabric under driving of the rolling mechanism, the delivery mechanism cooperates with the cutting mechanism to cut the fabric after rolling is completed, the cutting mechanism resets after cutting is completed and drives the end of fabric to be rolled through the delivery mechanism in the resetting process to convey the fabric to be rolled to the rolling mechanism along the guide mechanism, meanwhile,the cutting mechanism cooperates with the outputting mechanism to drive the cloth roller completing rolling to be output from the outputting mechanism, and a new cloth roller is put into the rollingmechanism to cooperate with the rolling mechanism to roll subsequent fabric. The warp-knitted fabric continuous rolling and outputting equipment solves the problems that in the cloth rolling process,the rolling work needs to be stopped to replace the cloth roller in the cloth rolling process, the efficiency is low, and rolling is not tight in the rolling process.

Owner:CHANGXING JINFA TEXTILE

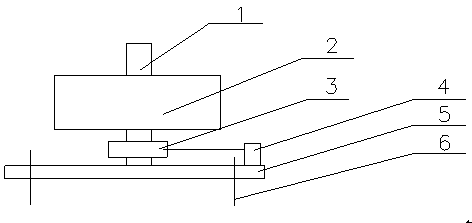

Wire drawing machine

The invention relates to a wire drawing machine which comprises a winding drum, a winding drum drive mechanism, a wire drawing die box, a guide wheel, a winding drum friction disk mechanism and a guiding-out wheel, wherein the winding drum friction disk mechanism is arranged on a winding drum cover, and comprises a friction disk, a friction sheet, a friction disk shaft, a wire drawing wheel assembly and a compacting spring, the compacting spring is arranged above the friction disk and arranged on the friction disk shaft, a regulating nut block is arranged at the top end of the compacting spring, the regulating nut block is matched with the top end of the friction disk shaft in a thread manner, the friction sheet is arranged between the friction disk and the winding drum cover, a rubber sleeve is arranged between the friction disk shaft and the friction disk, the wire drawing wheel assembly is connected onto the friction disk, and the guiding-out wheel is arranged aslant above a wire drawing wheel.

Owner:常州市正阳焊接材料有限公司

Winding device with anti-deformation function for production of automobile air conditioner hose

The invention discloses a winding device with an anti-deformation function for production of an automobile air conditioner hose. The winding device comprises a bottom plate, a working shaft, a connecting shaft and a winding structure, side plates and a front plate are fixed on the bottom plate, a second horizontal belt is installed on a second driven cylinder, a second special-shaped wheel is connected with the bottom end of a second vertical belt, the bottom end of the second special-shaped wheel is connected with the bottom end of the second vertical belt, a second movable frame and a mounting frame are connected with each other, the top end of a telescopic rod is connected with a top shaft, moreover, the top shaft is fixed to the lower end surface of a sliding block, and the winding structure is fixed on the side plates. According to the winding device, and the structure of a traditional winding device for producing the automobile air conditioning hose is improved by adopting a novel structural design, so that the automobile air conditioner hose can be uniformly and orderly wound and stored through the winding device, and the device can apply proper compression on an automobileair conditioning hose which is to be wound and stored so that the automobile air conditioning hose can be tightly wound around a storage device.

Owner:施彦春

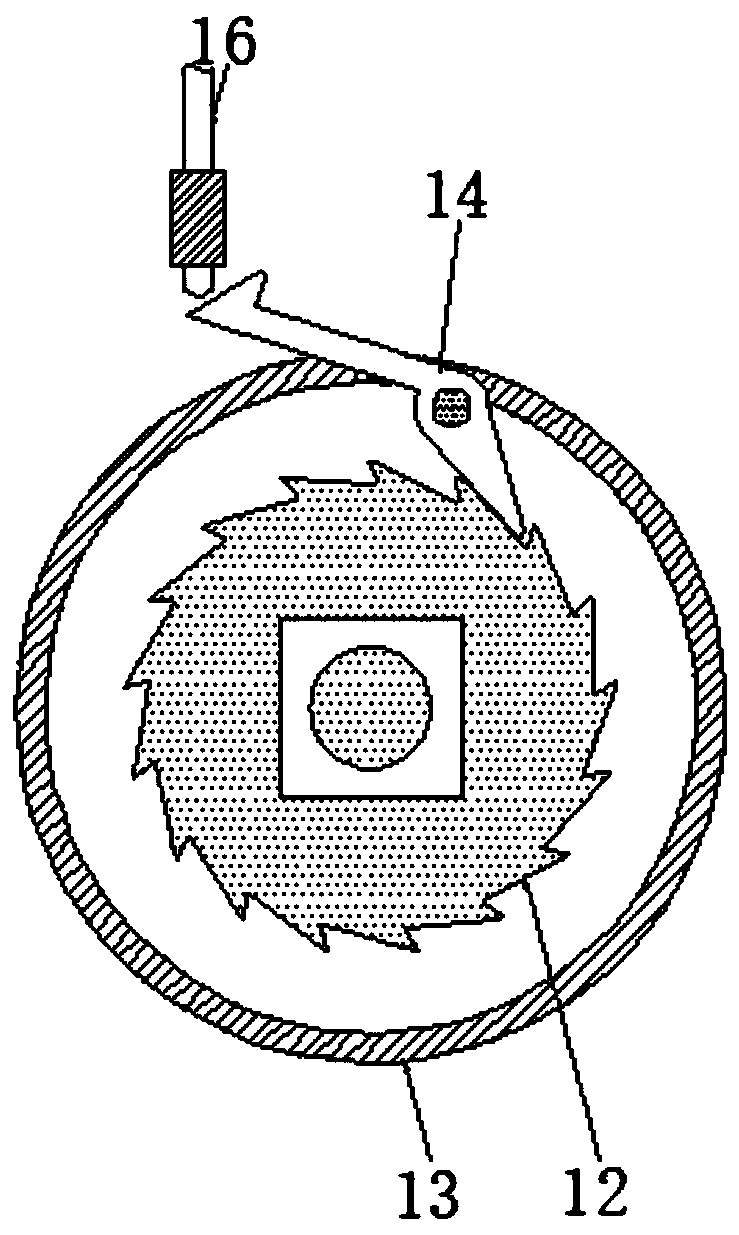

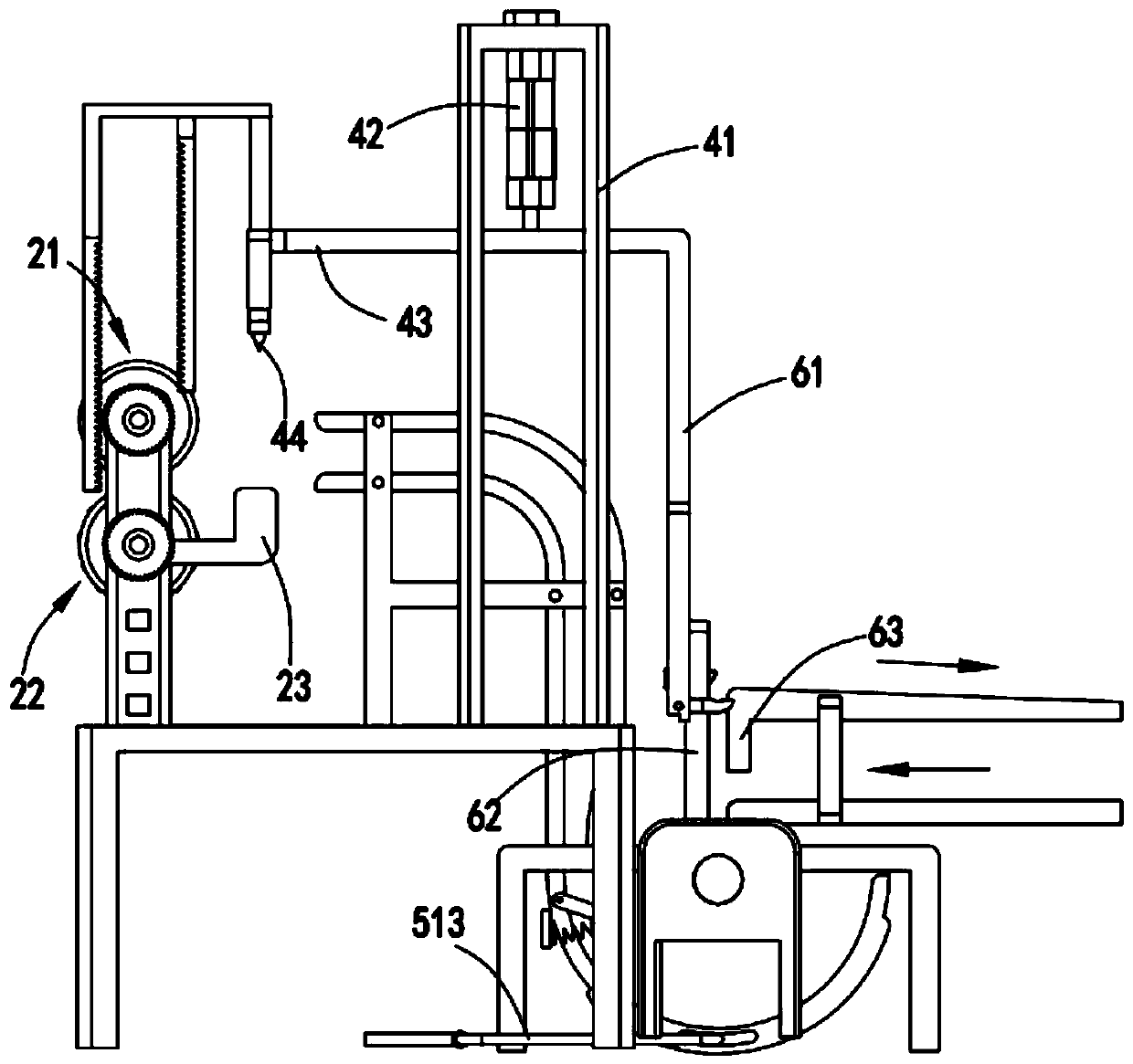

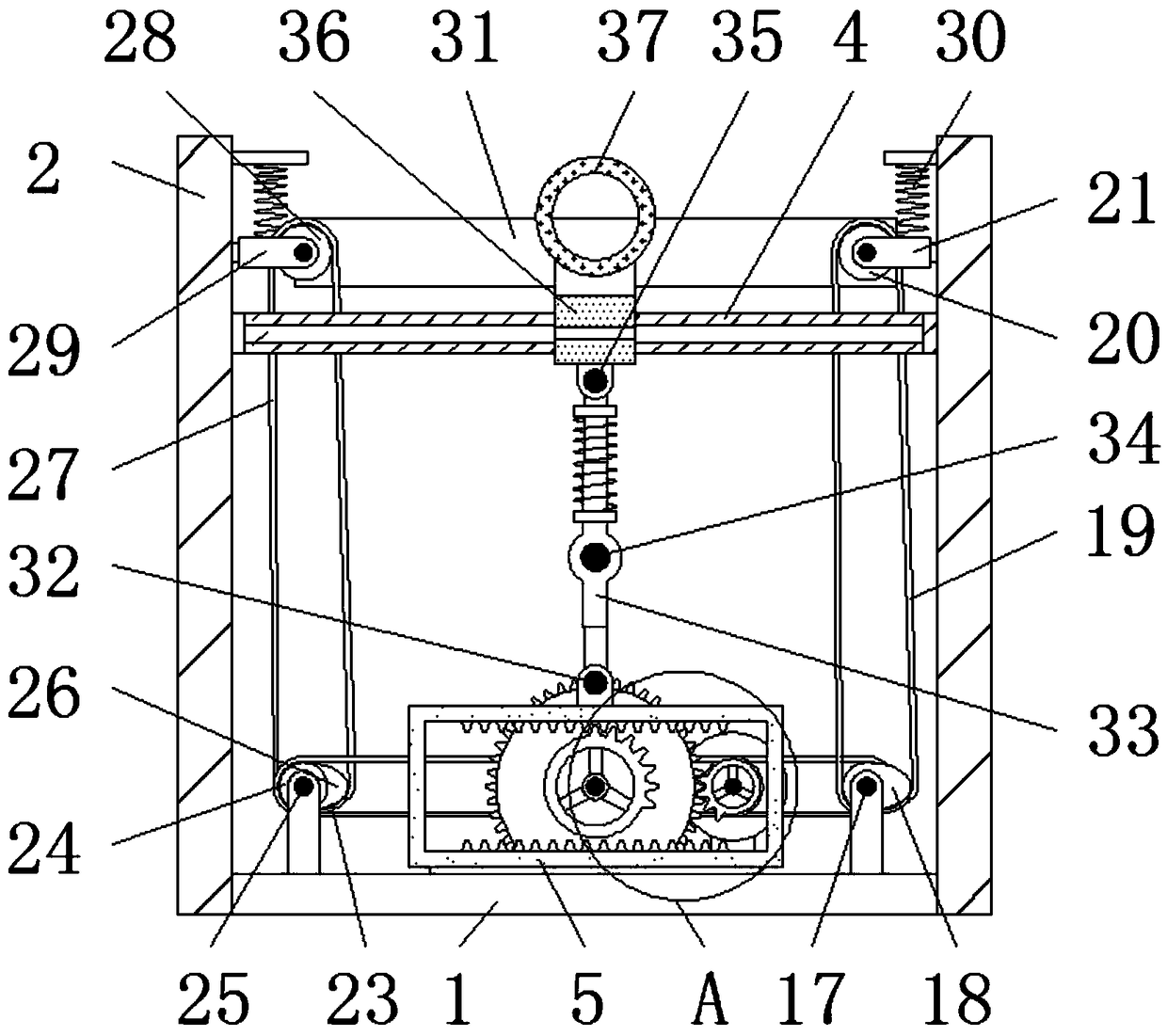

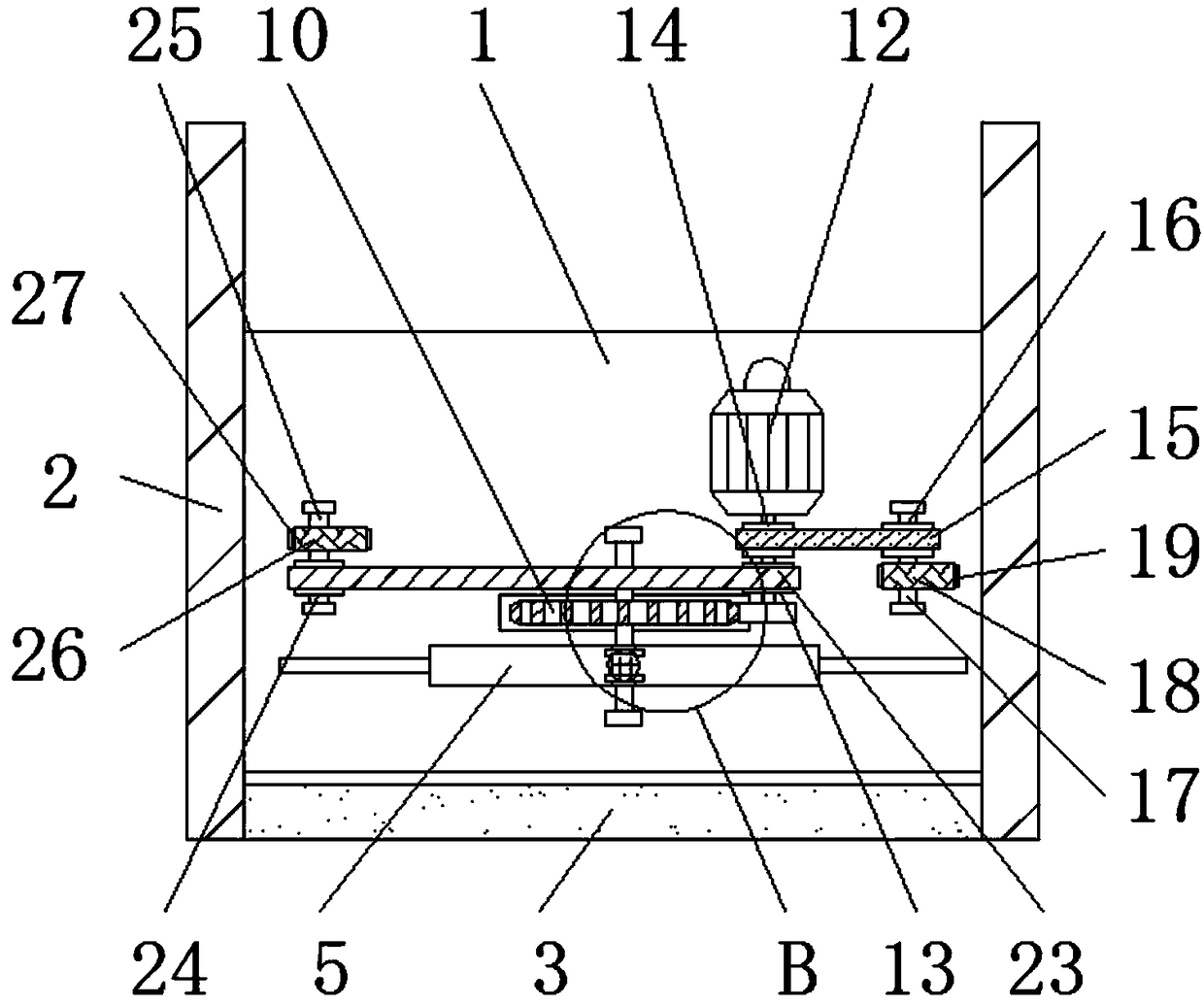

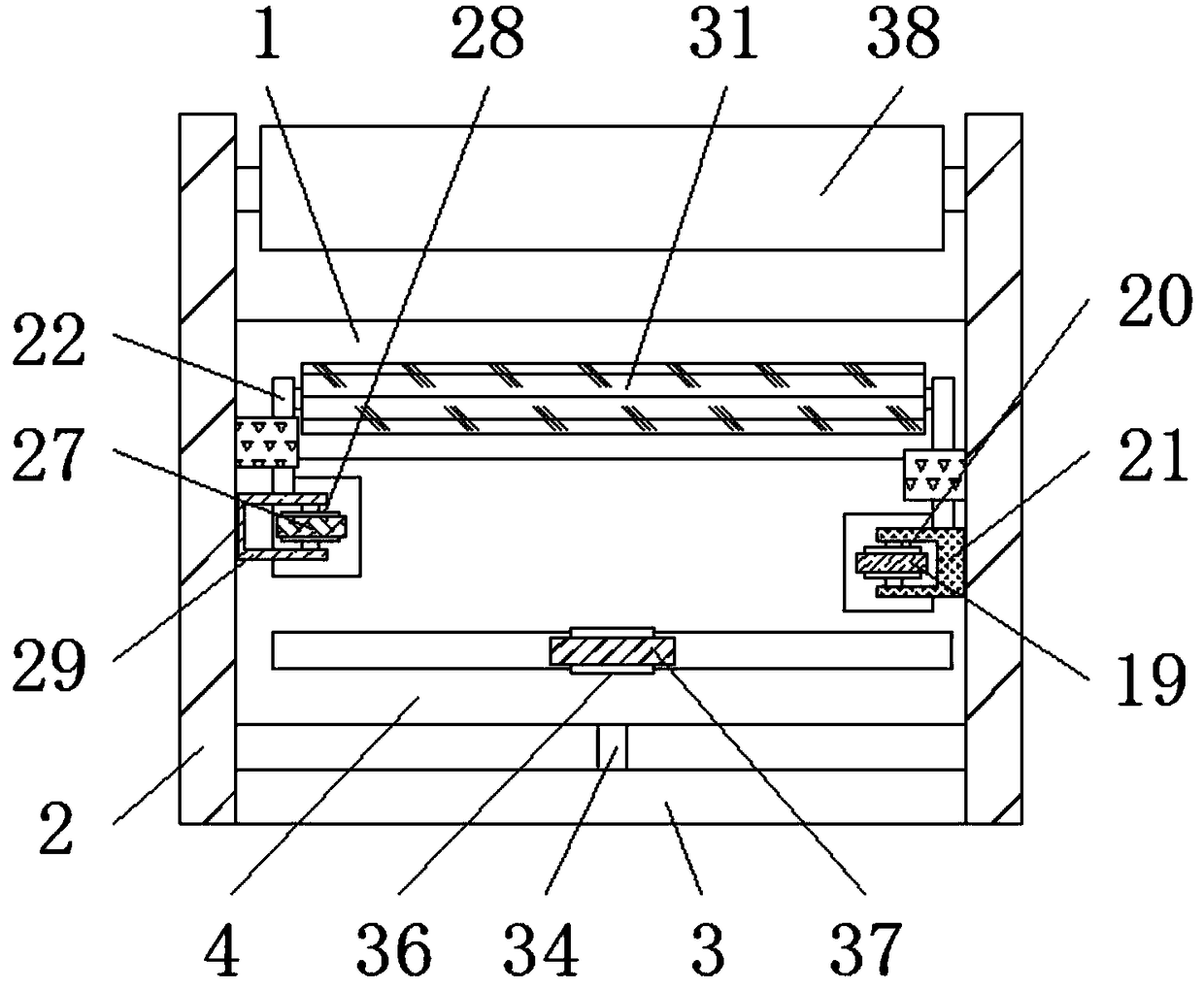

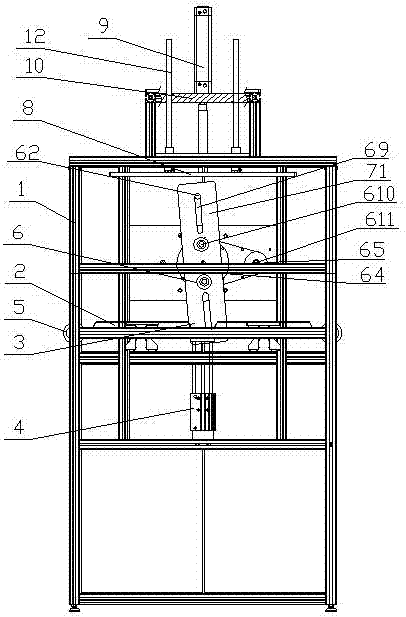

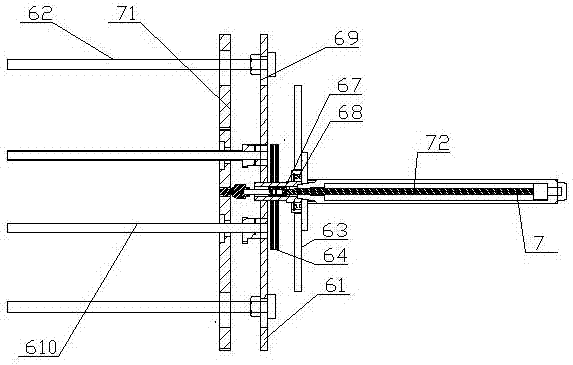

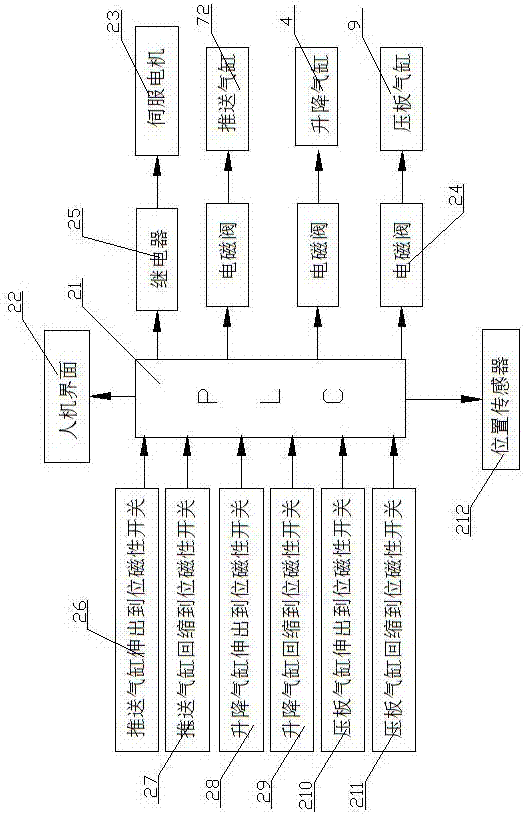

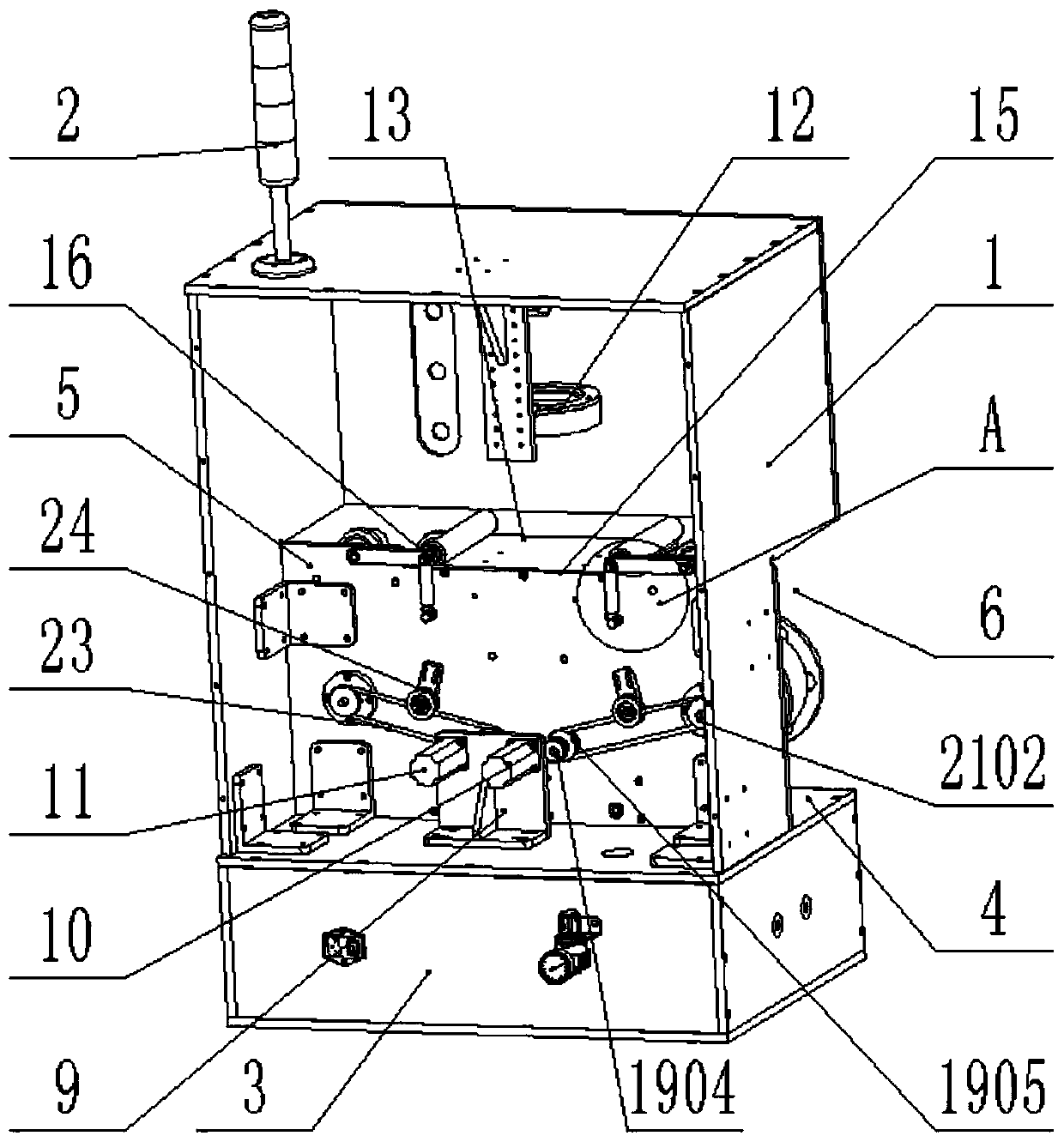

Automatic control filter bag folding machine

ActiveCN107472955AWinding flatCoil tightlyHuman health protectionWebs handlingAutomatic controlEngineering

The invention relates to an automatic control filter bag folding machine and relates to the field of mechanical equipment. The automatic control filter bag folding machine comprises a rack. A floating plate which is capable of rising and falling and used for holding to-be-folded filter bags is arranged on the rack. A gap is formed in the middle of the floating plate. A lifting air cylinder mounted on the rack is arranged under the floating plate. The output end of the lifting air cylinder is connected with the floating plate, so that the floating plate is driven to shift upwards and downwards. A winding mechanism used for winding and folding the filter bags is arranged on the upper portion of the floating plate. A horizontally-arranged press plate and a press plate air cylinder for driving the press plate to rise and fall are arranged above the winding mechanism. Before the winding mechanism winds and folds the filter bags, a winding shaft located on the lower portion of the winding mechanism is arranged in the gap in the middle of the floating plate, and the press plate is driven by the press plate air cylinder to move downwards close to a winding shaft located on the upper portion of the winding mechanism. According to the automatic control filter bag folding machine provided by the invention, the press plate is arranged, the filter bags are subjected to a winding procedure under pressure of the press plate, it is guaranteed that the filter bags are wound flat and tight, and loosing is avoided.

Owner:HAIAN SOOCHOW UNIV ADVANCED ROBOT RES INST

Automatic winding machine

ActiveCN109534047ACoil tightlyNot easy to relaxArticle deliveryWebs handlingWinding machineEngineering

The invention relates to an automatic winding machine. The automatic winding machine comprises a support frame, a first shaft rod, a diaphragm, a winding module and a cutting module; the first shaft rod is rotationally mounted on the support frame; the diaphragm is wound on the first shaft rod; the winding module comprises a winding cylinder and a second shaft rod; the winding cylinder is mountedon the support frame; the second shaft rod is detachably connected to the winding cylinder; a free end of the diaphragm is wound on the second shaft rod; an elastic pressing body is arranged on the support frame; the diaphragm is pressed on the first shaft rod through the elastic pressing body; the cutting module comprises a bearing table, a cutter and a cutting cylinder; and the bearing table isprojected on the support frame. The automatic winding machine can wind the diaphragm more tightly.

Owner:四川佰纳川超声波设备有限公司

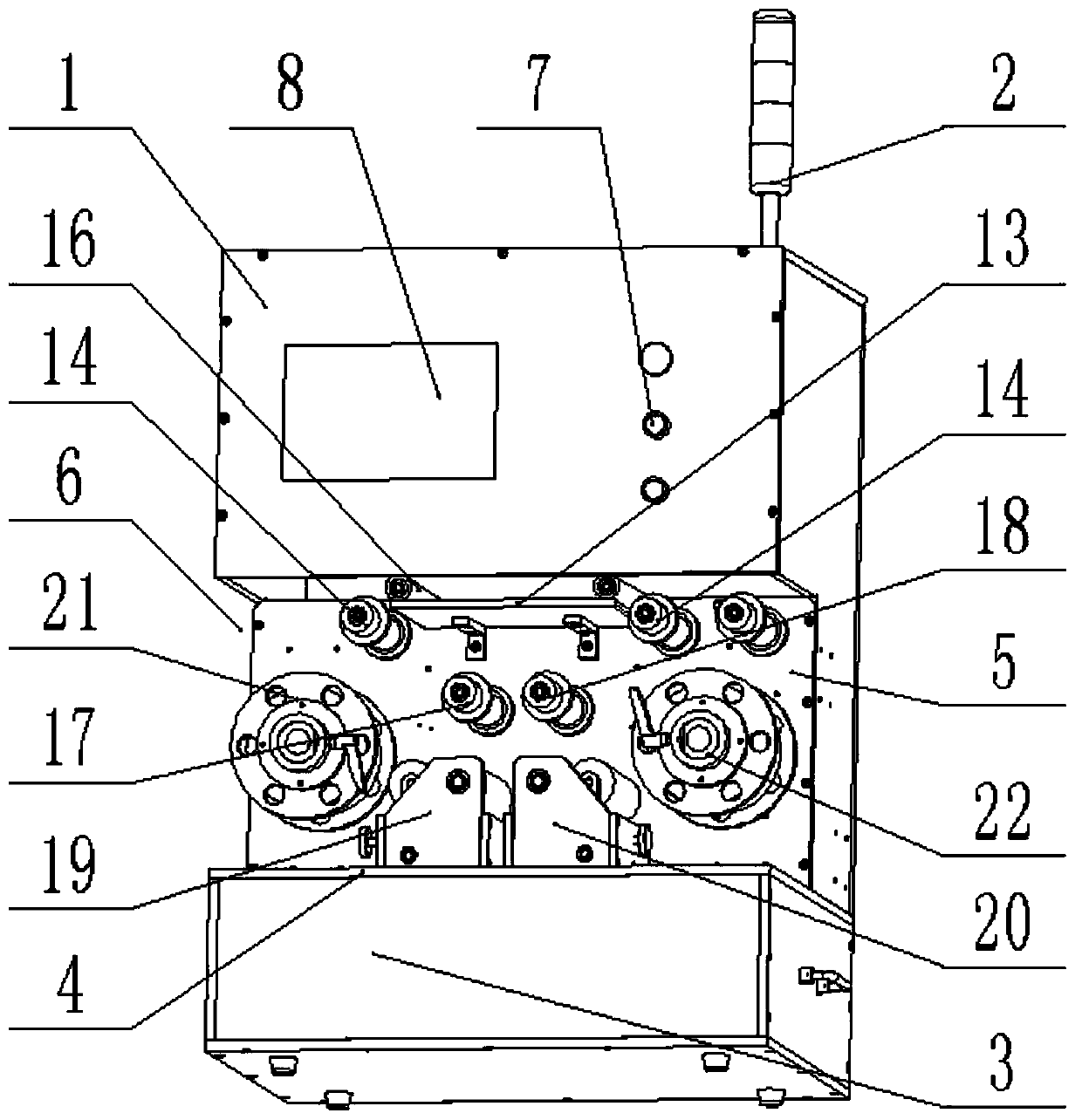

Rewinding device for label detection

PendingCN109823889ACompact structureReduce volumeOptically investigating flaws/contaminationWebs handlingDrive motorEngineering

The invention discloses a rewinding device for label detection, and belongs to the technical field of label detection. The rewinding device comprises a box body, wherein a control box is arranged under the box body; a worktable is arranged between the control box and the box body; a mounting plate is positioned on one side of the worktable and is fixedly mounted on the box body; a working area isformed through cooperation among the worktable, the mounting plate and the box body; a support is positioned in the box body and is fixedly mounted on the mounting plate; a first driving motor and a second driving motor are arranged on the support; a detection platform which is matched with a vision detection device is arranged on the mounting plate; the vision detection device is positioned abovethe detection platform and is arranged in the box body; variable material guiding rollers are arranged on the two sides of the detection platform; a groove is formed in the mounting plate; a materialcompression device is arranged in the groove; a left auxiliary material guiding roller and a right auxiliary material guiding roller are positioned under the detection platform and are arranged on the mounting plate; a first pre-tightening driving device is positioned under the left auxiliary material guiding roller and arranged on the mounting plate and is connected with a first material tray fixing device; and a second pre-tightening driving device is connected with a second material tray fixing device.

Owner:山东红宝自动化有限公司

Automatic material rolling machine

The invention discloses an automatic material rolling machine. The automatic material rolling machine comprises a frame body, a pallet, a feeding device, an inserting block, a screw rod and a middle shaft clamping device, a motor assembling unit is arranged inside the frame body, a rotating table is erected on the portion, close to the motor assembling unit, of the frame body, moreover, the rotating table is connected with one side of the motor assembling unit, the pallet is placed on the body wall of one side of the rotating table, an electric cylinder is arranged in the portion, close to therotating table, of the frame body, the feeding device is arranged on the outer side of the electric cylinder, the inserting block is fixed on one side of the feeding device and is close to the pallet, the screw rod is arranged on the frame body. According the automatic material rolling machine, the rotating table which is transversely placed is arranged, the rotating table is driven by the motorassembling unit to rotate, the pallet is placed on the rotating table, the rotating table can synchronously drive the pallet to rotate for material rolling, moreover, the middle shaft clamping deviceof the automatic material rolling machine can also be driven by the air cylinder to move up and down, then the height can be adjusted during material taking, a forklift can be conveniently and directly use to take away the pallet after material rolling, simplicity, convenience and high efficiency are achieved, and manpower is saved.

Owner:TAICANG TONGLI MACHINERY EQUIP

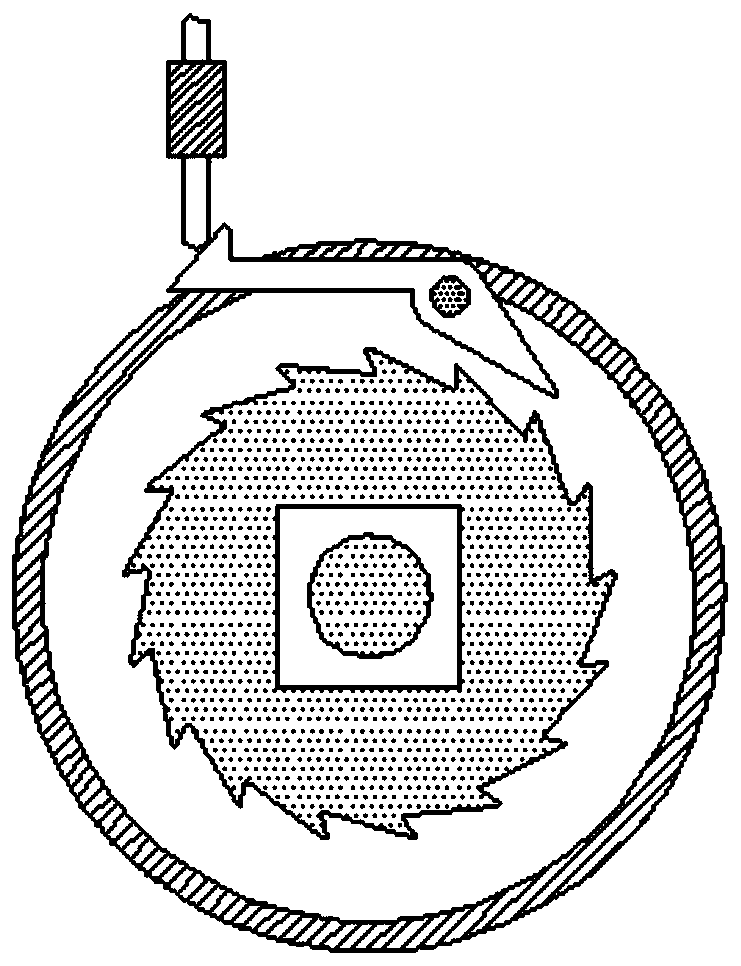

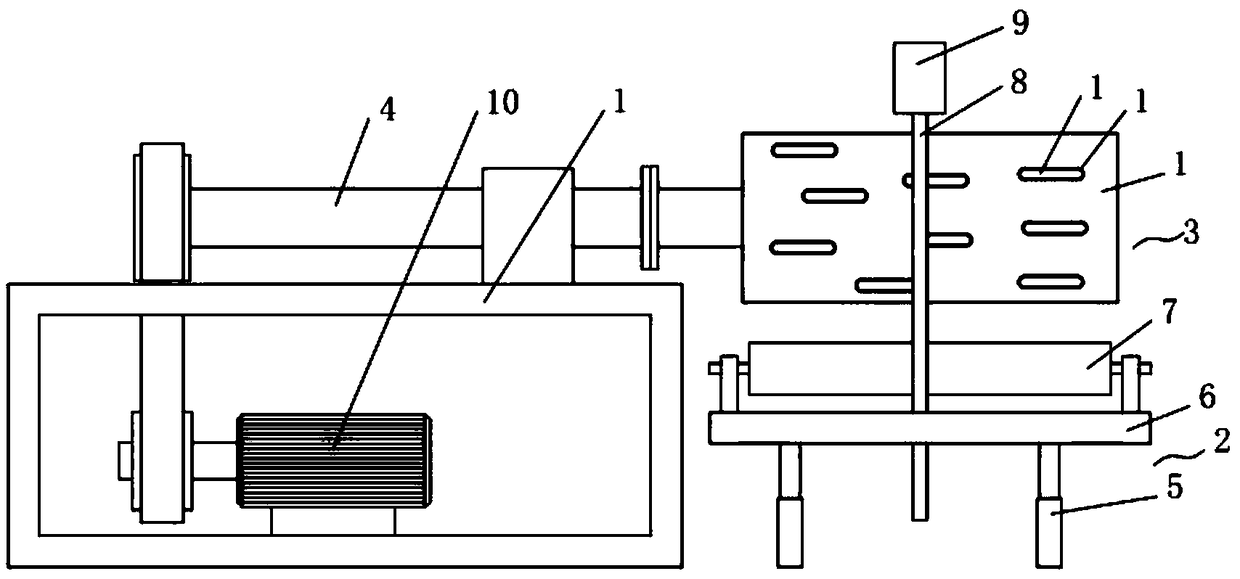

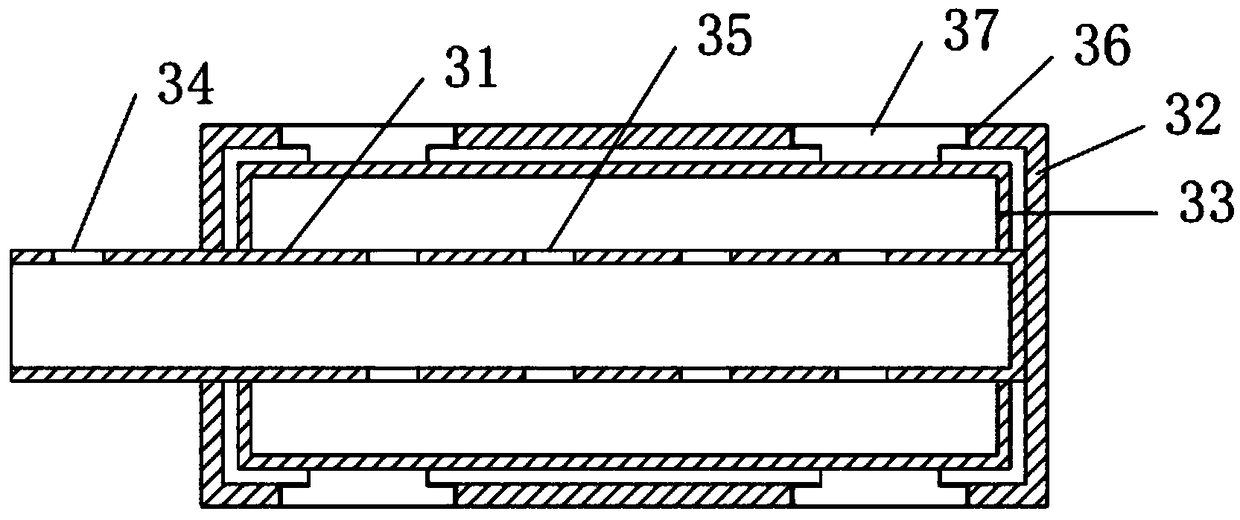

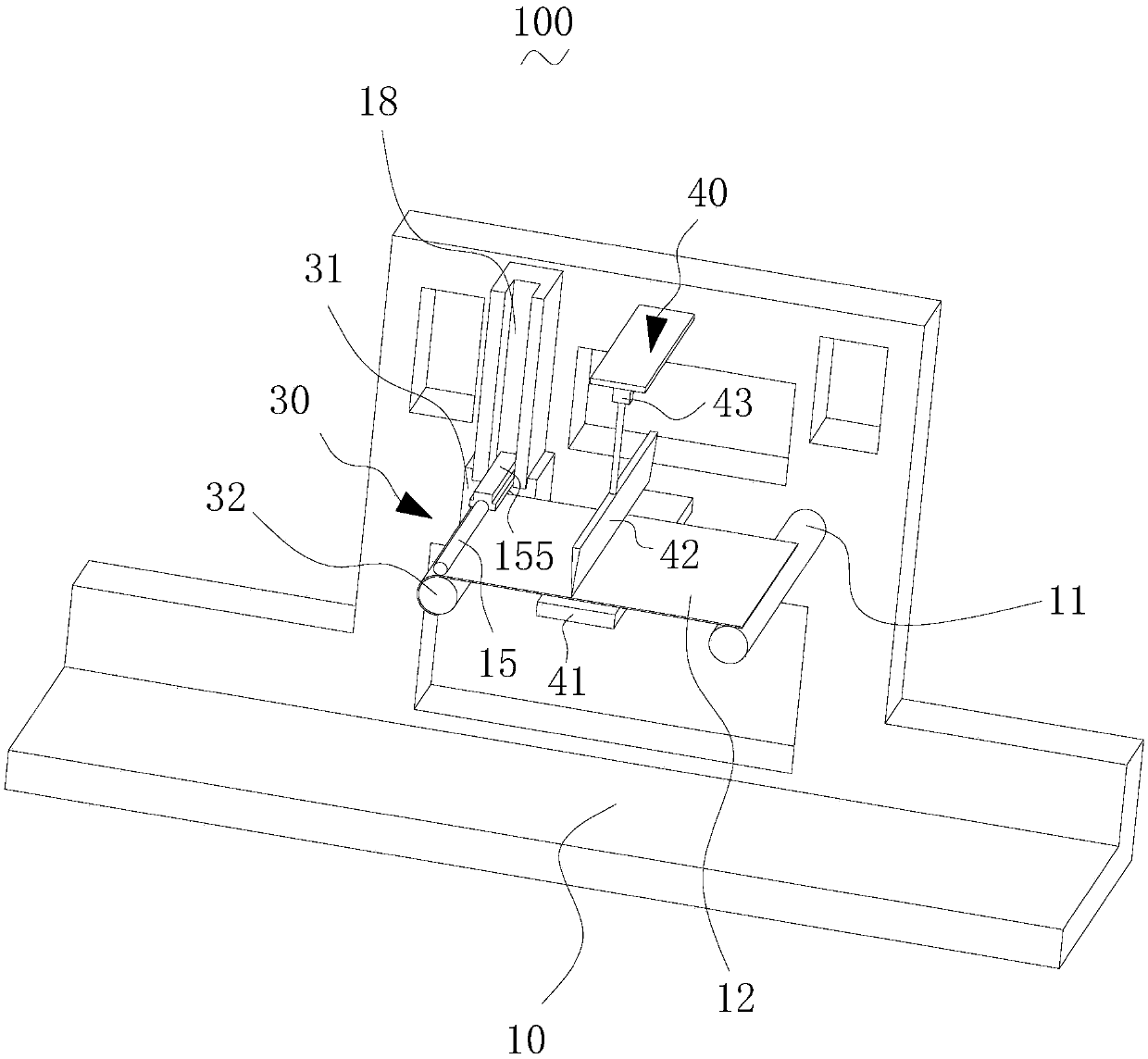

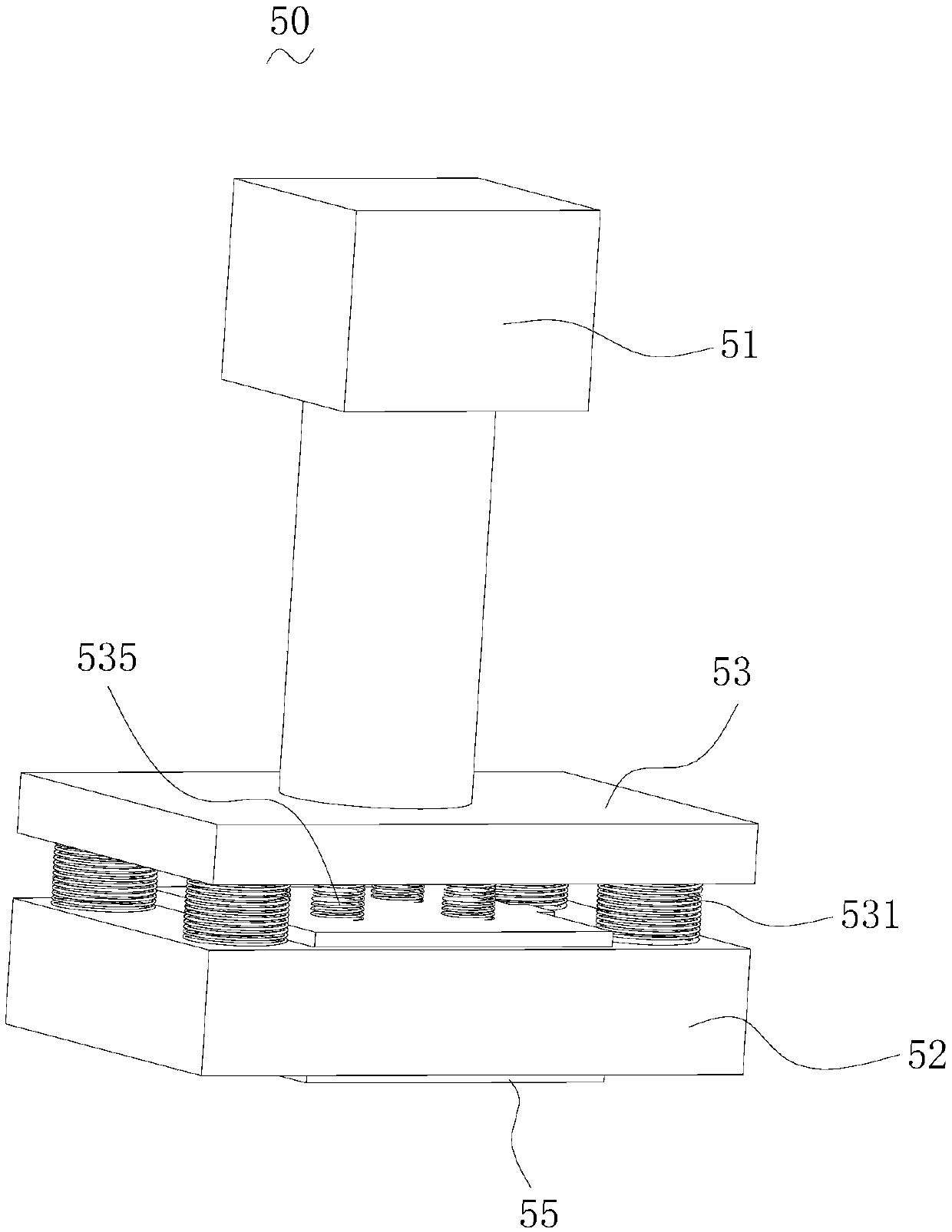

Handle of golf ball brassy manufacture and manufacturing device

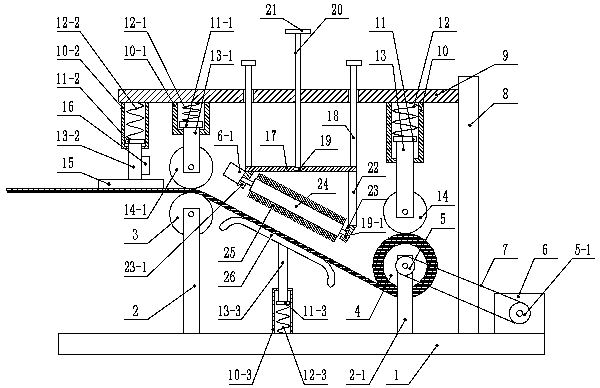

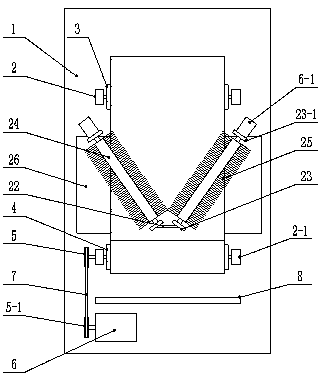

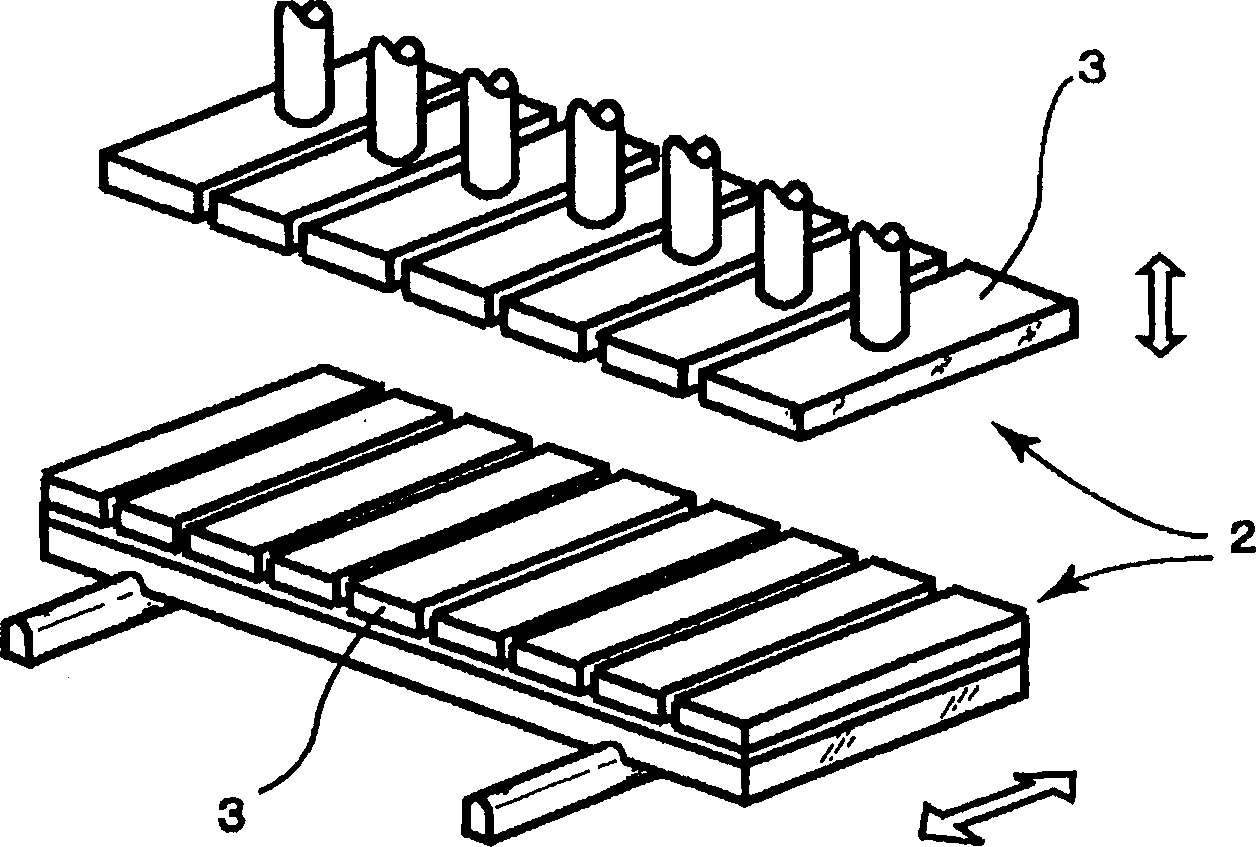

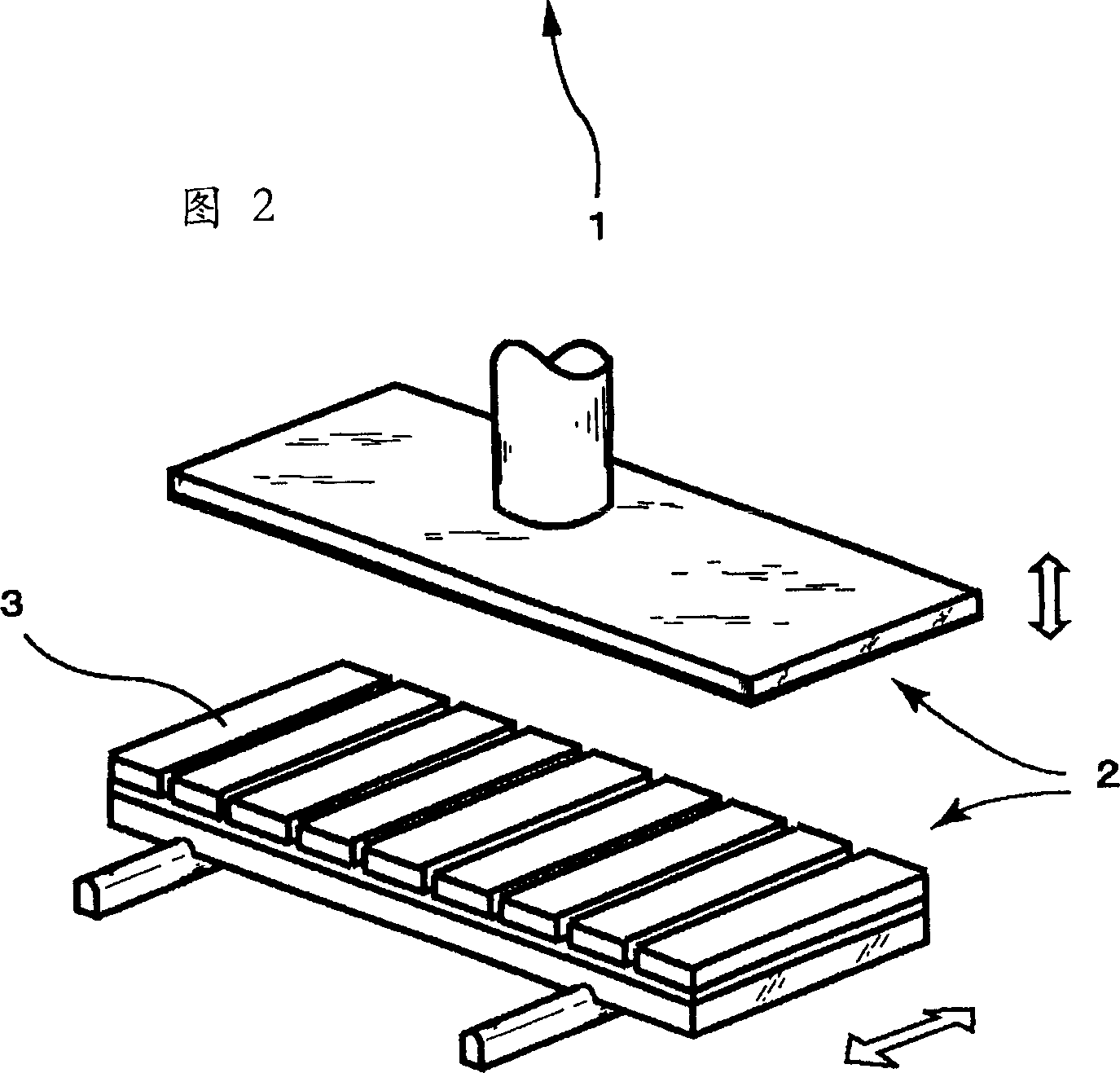

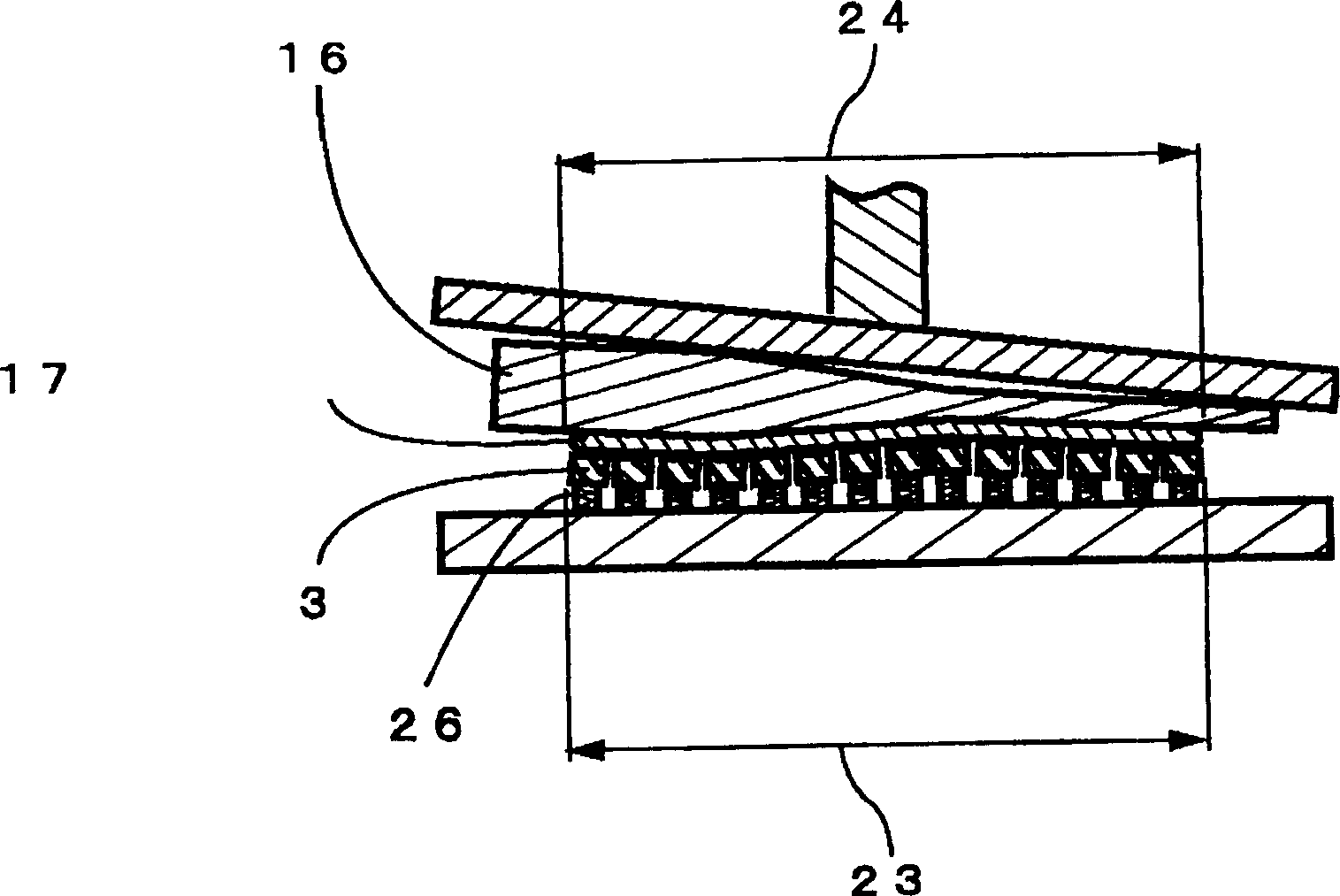

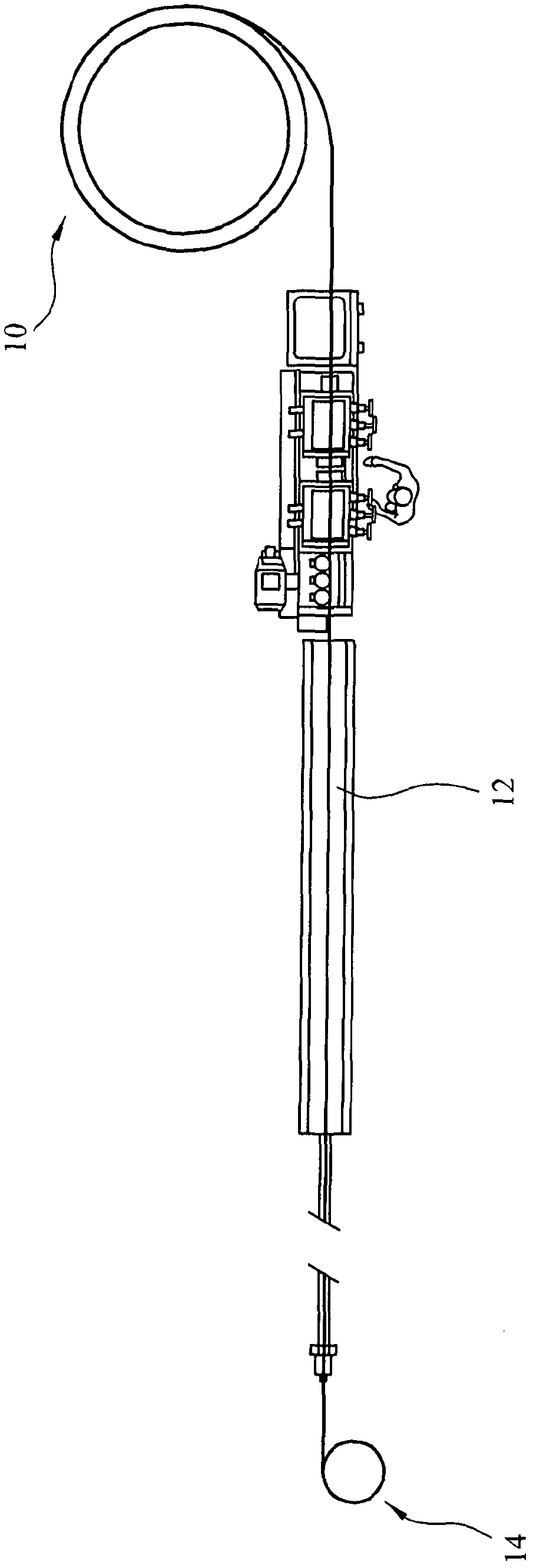

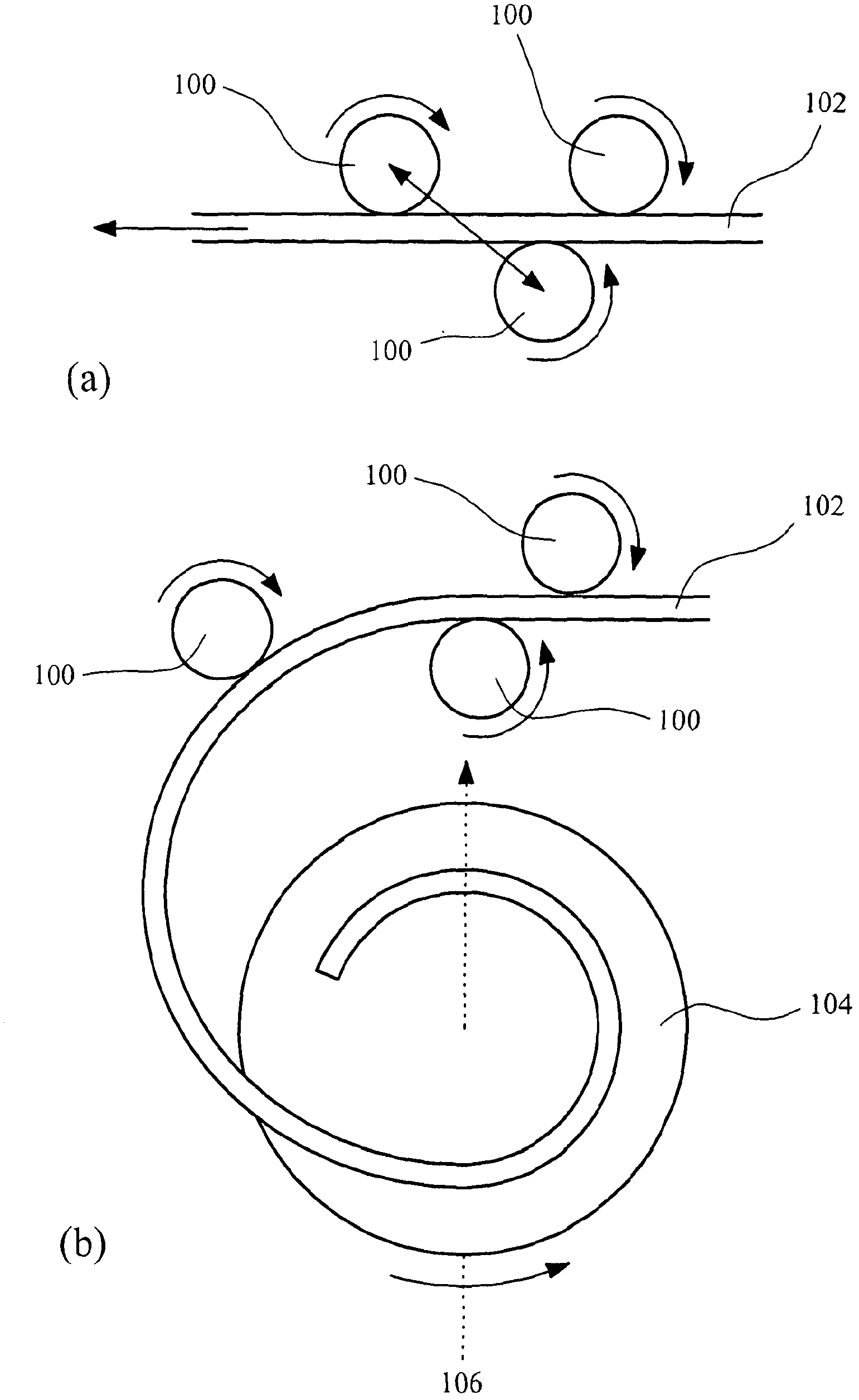

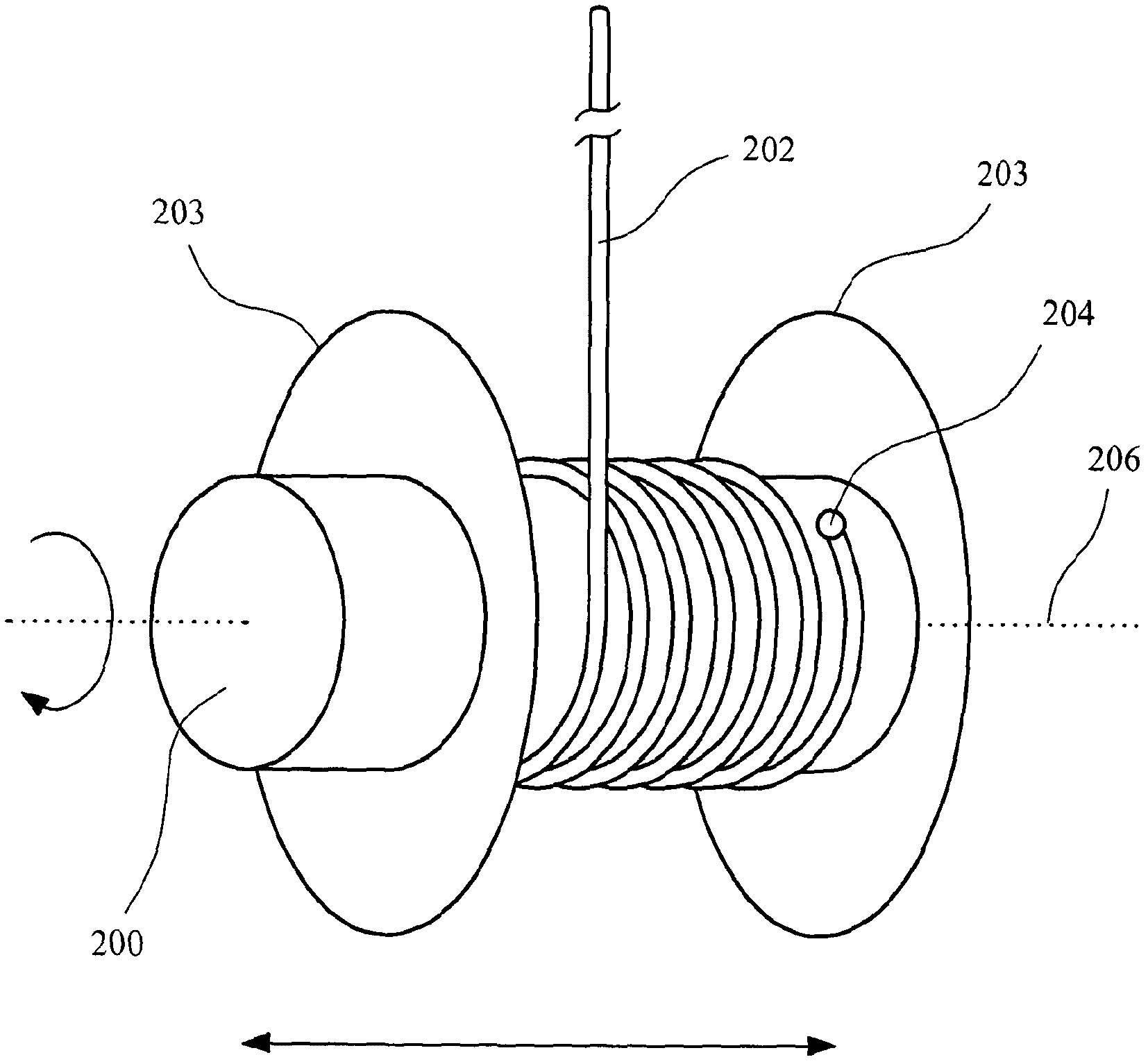

Provided is a manufacturing apparatus and method of a golf club shaft having a mandrel on which pre-preg can tightly be wound though the outer surface of the mandrel varies complicatedly and capable of obtaining the shaft with stabilized quality. The manufacturing apparatus 1 of the golf club shaft has a pair of upper and lower pressing plates 2 arranged so that their pressurizing surfaces face each other, the pre-preg for molding the golf shaft and the mandrel are inserted and held between the pressing plates 2, and the mandrel is rotated to wind the pre-preg onto the mandrel. The pressing plates 2 are formed of a plurality of pressing plate members 3.

Owner:MIZUNO CORPORATION

Intelligent physical exercise cushion

InactiveCN111672051AWith motion monitoring functionExercise scienceSpace saving gamesShock absorber matsThird partyPhysical medicine and rehabilitation

The invention relates to an intelligent physical exercise cushion, which is composed of a cushion body, a winding roller, a storage rack, a motion acquisition assembly and a computer assembly, whereinthe cushion body is wound on the winding roller; the storage rack is rotatably connected with the winding roller and can drive the winding roller to wind and unwind the cushion body through using a motor; the motion acquisition assembly can output real-time compression data capable of reflecting a contact state of a sporter and the cushion body and perform wireless transmission; and the computerassembly is integrated in the storage rack, has the conventional functions of data uploading / downloading, audio and video recording / playing, third-party program installation / operation and the like, can generate pressed dynamic data on the basis of continuously received and stored real-time pressed data, and obtains motion data through a corresponding operation method. The intelligent physical exercise cushion has a motion monitoring function, and corresponding motion data can be generated for each motion process, so that the motion is more scientific; the intelligent physical exercise cushionhas a multimedia function and can meet various requirements in the sports process; and the intelligent physical exercise cushion has electric winding and unwinding functions, and is convenient and fast to operate, time-saving and labor-saving.

Owner:王述位

Electromagnetic cloth rolling machine

ActiveCN107902173ASimple structureEasy to operatePackagingWebs handlingElectric machineryEngineering

The invention discloses an electromagnetic cloth rolling machine. The electromagnetic cloth rolling machine comprises a machine frame, a reel, a guide cylinder and an adjusting cylinder, wherein the reel, the guide cylinder and the adjusting cylinder are erected on the machine frame; the reel is driven by a motor to carry out cloth rolling; a supporting column is arranged below the adjusting cylinder, and the supporting column is arranged on a magnetic block; the bottom of the magnetic block is connected with an iron core through a supporting spring, a coil is wound outside the iron core, a sleeve is arranged on the iron core, and the coil and the motor are connected in series in the same power loop; and a pressing mechanism capable of applying pressure to the reel is arranged right abovethe reel. The electromagnetic cloth rolling machine is simple in structure, low in using cost and suitable for being used by small-sized fabric production and processing enterprises; and meanwhile, inthe using process, the looseness degree of the cloth can be automatically adjusted according to the rolling speed of the cloth, so that the cloth rolling effect is good while the cloth is not damaged, and the compactness of the rolled cloth is guaranteed because of the matching of the pressing mechanism.

Owner:武汉市依翎针织有限责任公司

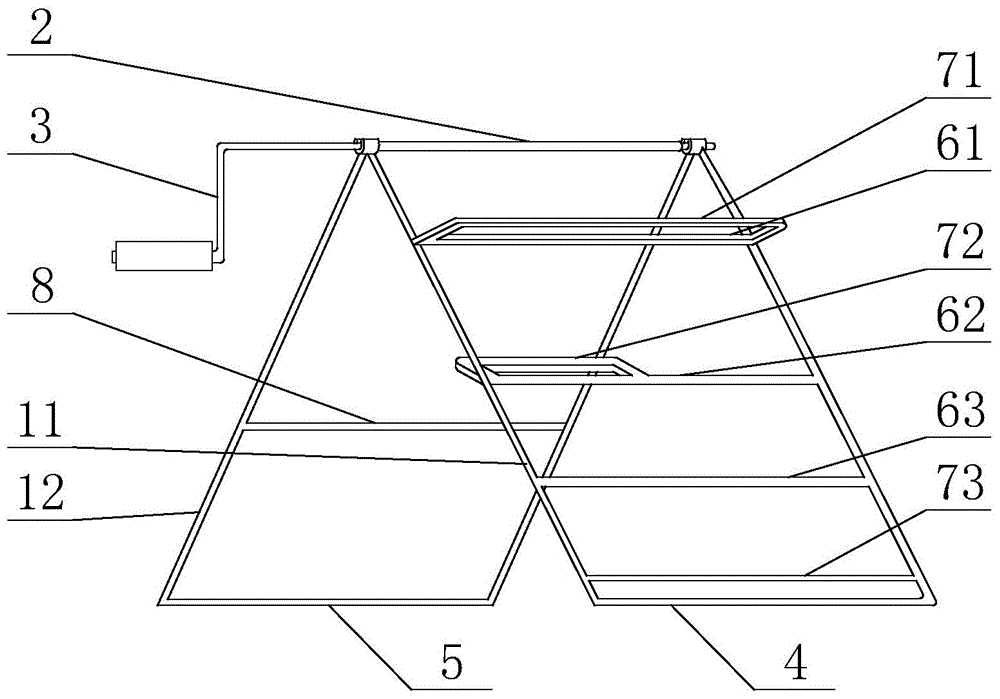

Hand-operated rolling frame for packaging tape

The invention discloses a hand-operated rolling frame for packaging tape. The hand-operated rolling frame is composed of two herringbone supports, a detachable rolling shaft is supported at the tops of the two supports, a rocker arm is arranged at one end of the rolling shaft, and multiple transverse rods and auxiliary rods arranged horizontally are arranged on one side of the two supports, and a transverse reinforcement rod is arranged on the other side of the two supports. The hand-operated rolling frame for the packaging tape is simple in structure, based on friction force between the transverse rods, the auxiliary rods and the surface of the packaging tape, the packaging tape can be rapidly rolled by an operator through the rolling frame, and the rolled packaging tape is wound compactly and not prone to loosen.

Owner:ANHUI NINGGUO DONGBO FASTENER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com