Process for producing moxa sticks

A processing technology, the technology of moxa sticks, which is applied in the field of processing technology for producing moxa sticks, can solve the problems of difficulty in drug efficacy, and achieve the effect of good drug effect, fast coiling process, and enhanced drug effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

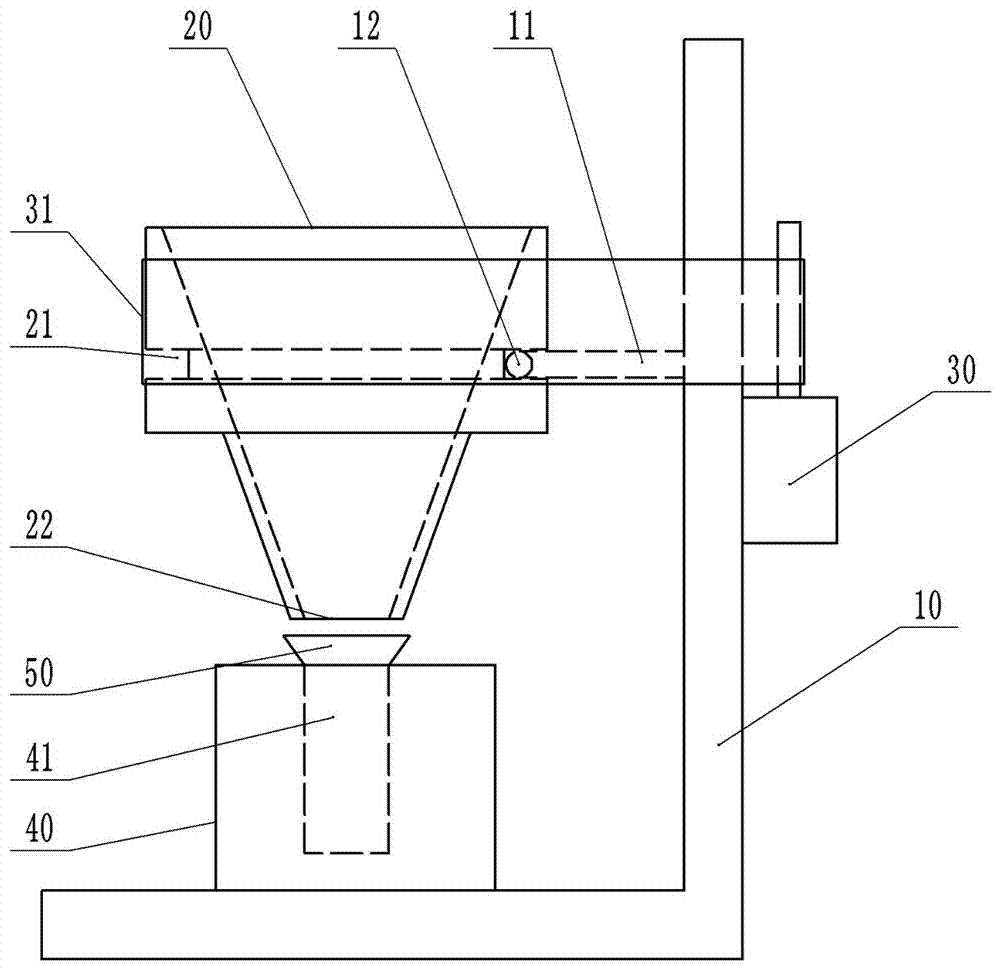

Image

Examples

Embodiment 1

[0024] This embodiment discloses a processing technology for producing moxa sticks, comprising the following steps:

[0025] (1) Material selection: select moxa velvet made from moxa leaves that have been sealed and kept away from light for 3 years;

[0026] (2) For pharmaceuticals, medicinal materials are taken according to the number of parts by mass: 10 parts of tangerine peel, 35 parts of Jiangxiang, 20 parts of Angelica dahurica, 10 parts of salvia miltiorrhiza, 25 parts of cassia twig, 25 parts of galangal, 10 parts of Cyperus cyperi, 15 parts of Shengchuanwu , 10 parts of patchouli, 2.5 parts of realgar; fly or pulverize realgar into 4000 mesh to obtain realgar powder, crush other medicinal materials to 1000 mesh to obtain medicinal powder, compound the medicinal powder and realgar powder, sieve, and mix evenly to obtain mixed powder;

[0027] (3) For medicine, use the steam of boiling water to steam the moxa for 1 minute, then spread the medicinal powder evenly on the...

Embodiment 2

[0035] The difference between embodiment 2 and embodiment 1 is:

[0036] In the step (1), select 5-year-old mugwort leaves that are sealed and kept away from light;

[0037] In step (2), the medicinal materials are taken according to the number of parts by mass: 15 parts of tangerine peel, 40 parts of Jiangxiang, 225 parts of Angelica dahurica, 15 parts of salvia miltiorrhiza, 30 parts of cassia twig, 30 parts of galangal, 15 parts of Cyperus cyperi, 20 parts of Shengchuanwu , 15 parts of patchouli, 3 parts of realgar; water fly or crush realgar into 3000 mesh to obtain realgar powder, and crush other medicinal materials to 800 mesh to obtain medicinal powder.

[0038] After experimental testing, through the processing technology of this embodiment, moxibustion is carried out on the human body with the moxa sticks produced. After ten days of continuous moxibustion, it is found that the effect of promoting qi and blood and expelling cold and damp is excellent, and it can treat ...

Embodiment 3

[0040] The difference between embodiment 3 and embodiment 1 is:

[0041] In step (3), use the steam of boiling water to steam the moxa for 1.5 minutes,

[0042] The drying temperature in step (4) is 60°C, and bake for 4 minutes;

[0043] In step (5), the inner lower end of the feed hopper 20 is a discharge hole 22 with a diameter of 40mm,

[0044] After experimental testing, through the processing technology of this embodiment, moxibustion is carried out on the human body with the moxa sticks produced. After ten days of continuous moxibustion, it is found that the effect of promoting qi and blood and expelling cold and damp is excellent, and it can treat wind-cold-damp arthralgia, muscle numbness, Pain in the joints and limbs, and cold pain in the stomach and abdomen are very effective.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com