Patents

Literature

30results about How to "Good coiling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

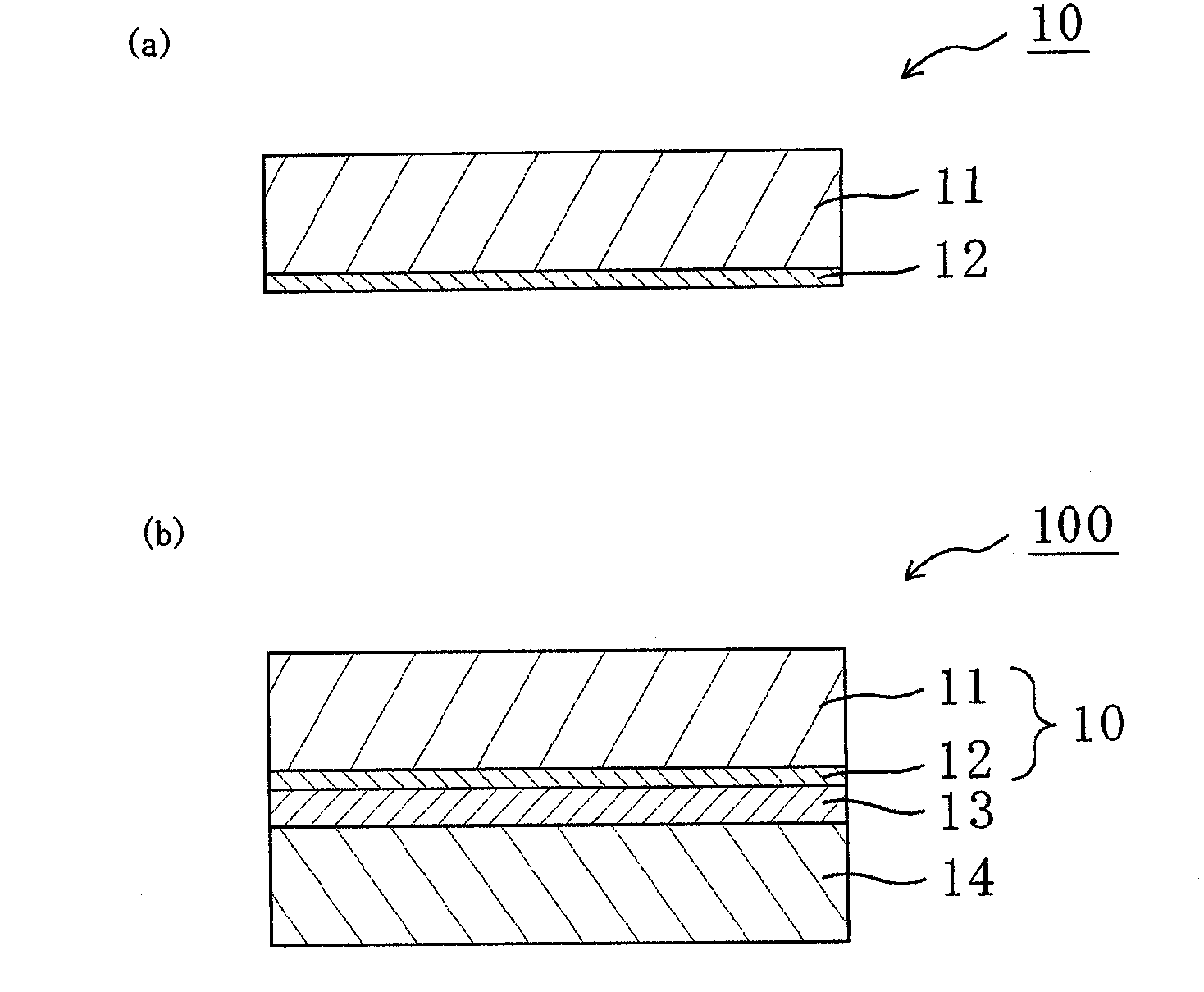

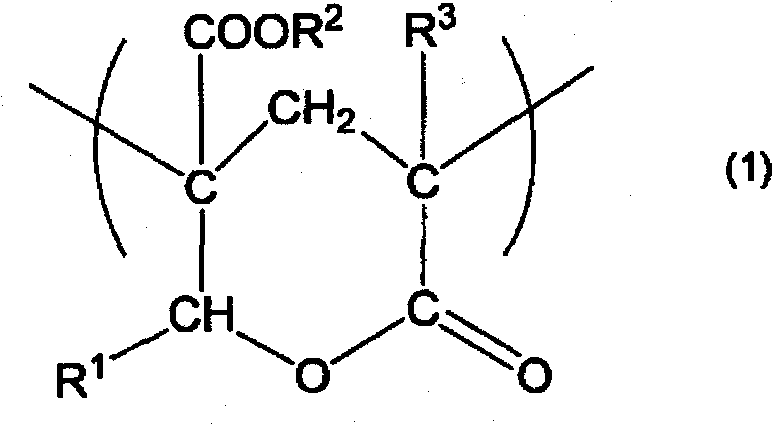

Polarizer-protecting film, and polarizing plate and image display device each comprising polarizer-protecting film

InactiveCN102112899AInhibit adhesionGood coiling effectSynthetic resin layered productsPolarising elementsColloidal silicaAcrylic resin

Disclosed is a polarizer-protecting film which rarely causes blocking during the take-up of the film and thereby has excellent take-up properties. The polarizer-protecting film comprises a (meth)acrylic resin film and a highly adhesive layer composed of a highly adhesive agent composition comprising a urethane resin and microparticles. Preferably, the microparticles comprise colloidal silica.

Owner:NITTO DENKO CORP +1

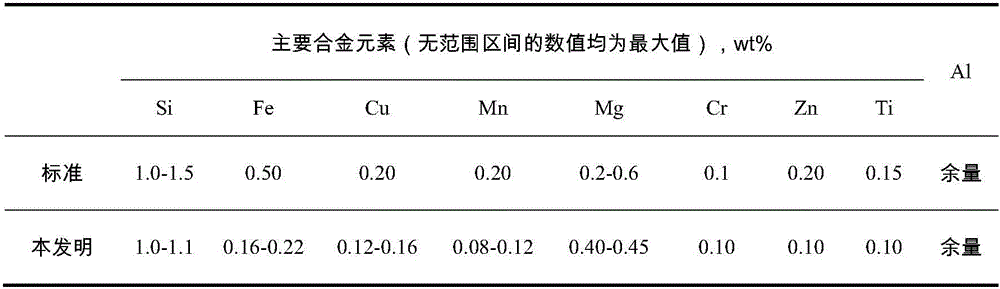

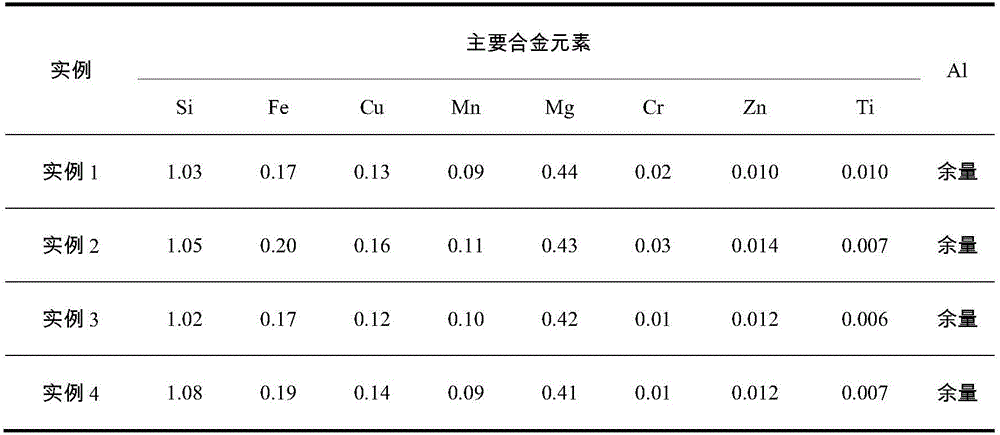

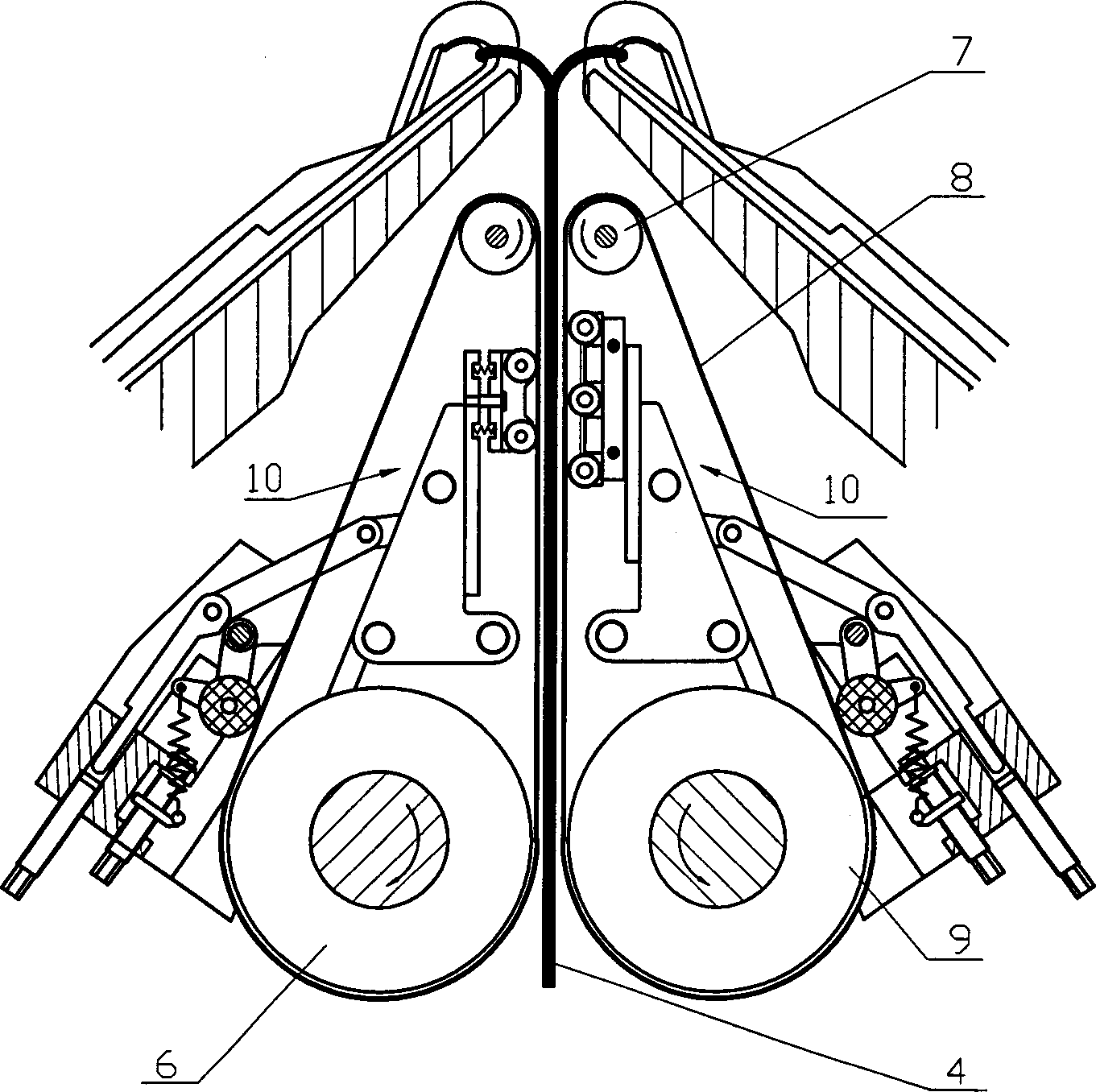

Aluminum alloy sheet and production method thereof

InactiveCN105925858AExcellent formability and mechanical propertiesImproved coiling performanceChemical compositionHardness

The invention discloses a 6016-series aluminum alloy sheet for a vehicle body and a production method thereof. The aluminum alloy sheet comprises the following chemical components in percentage by mass: 1.0-1.5% of Si, 0-0.50% of Fe, 0-0.20% of Cu, 0-0.20% of Mn, 0.25-0.60% of Mg, 0-0.10% of Cr, 0-0.10% of Zn, 0-0.10% of Ti, and the balance of Al. The production method comprises the steps of batching-smelting-converter-furnace side refining-standing-casting-sawing-surface milling-ingot homogenization-hot rolling-intermediate annealing-cold rolling-electrospark frosting-finished product cold rolling-solid solution quenching-drawing correction-Ti / Zr passivation-preageing-finished product coiling. The aluminum alloy sheet can provide a high-grade vehicle body sheet to users, improves the yield in punching, reduces the vehicle manufacturer cost, improves the formability and the baking hardness of aluminum alloy sheets, and is broad in market prospect and prominent in economic benefit.

Owner:SHANDONG NANSHAN ALUMINUM +1

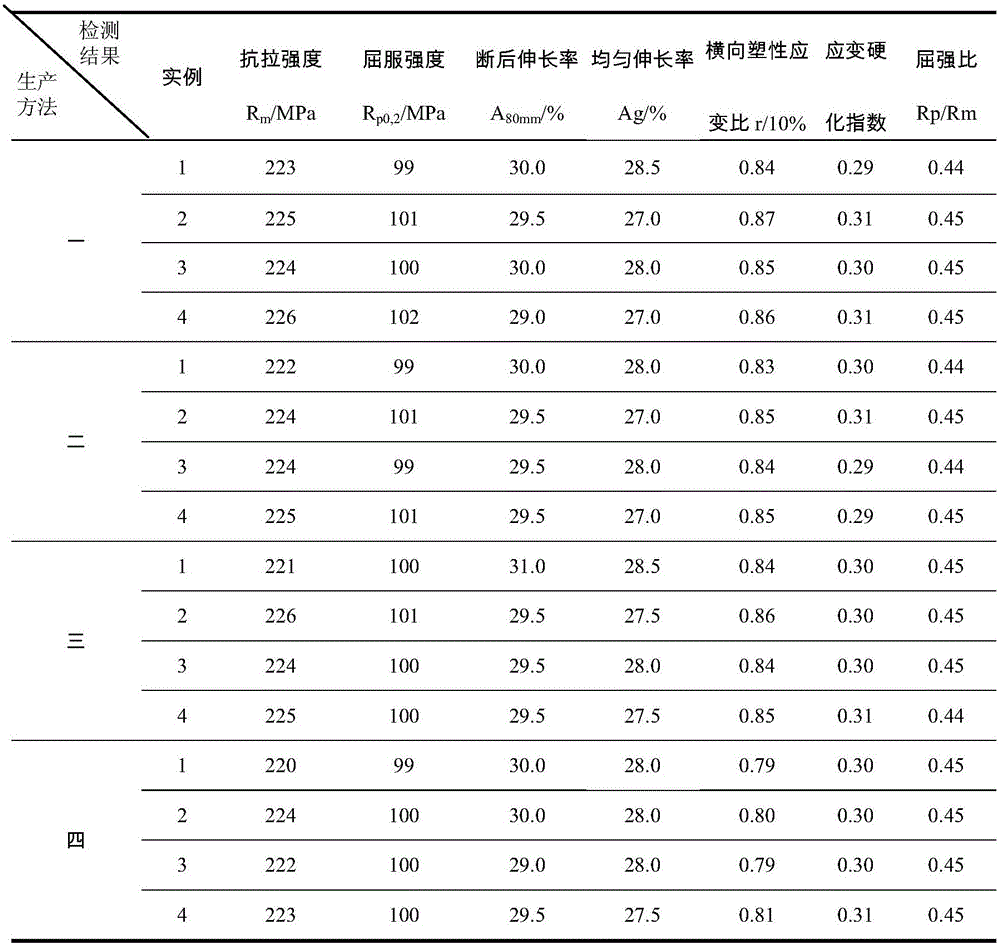

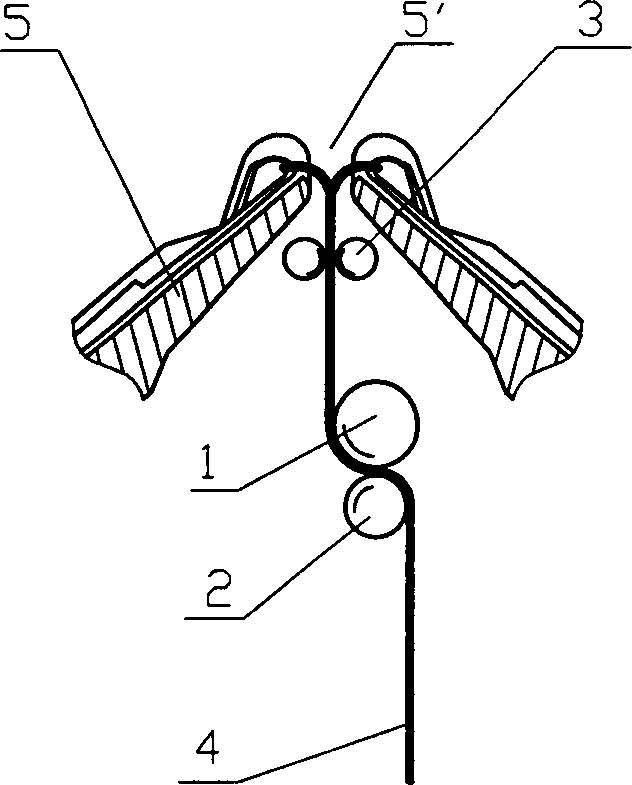

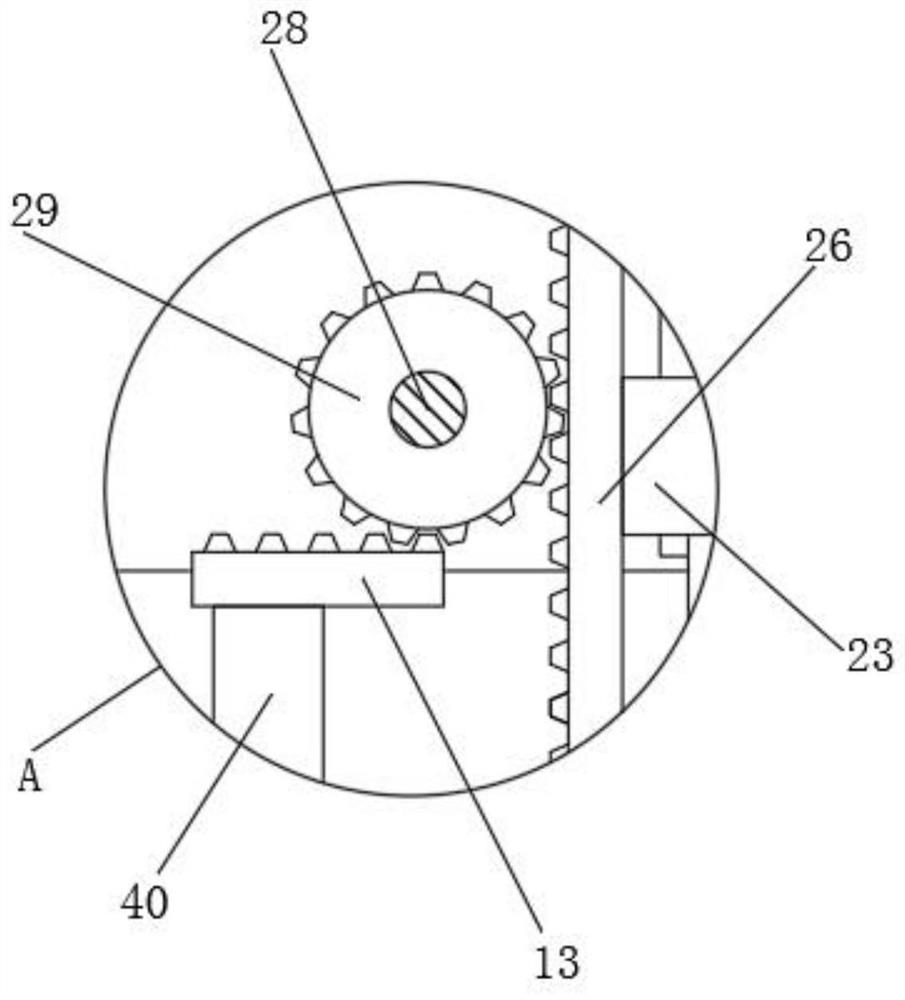

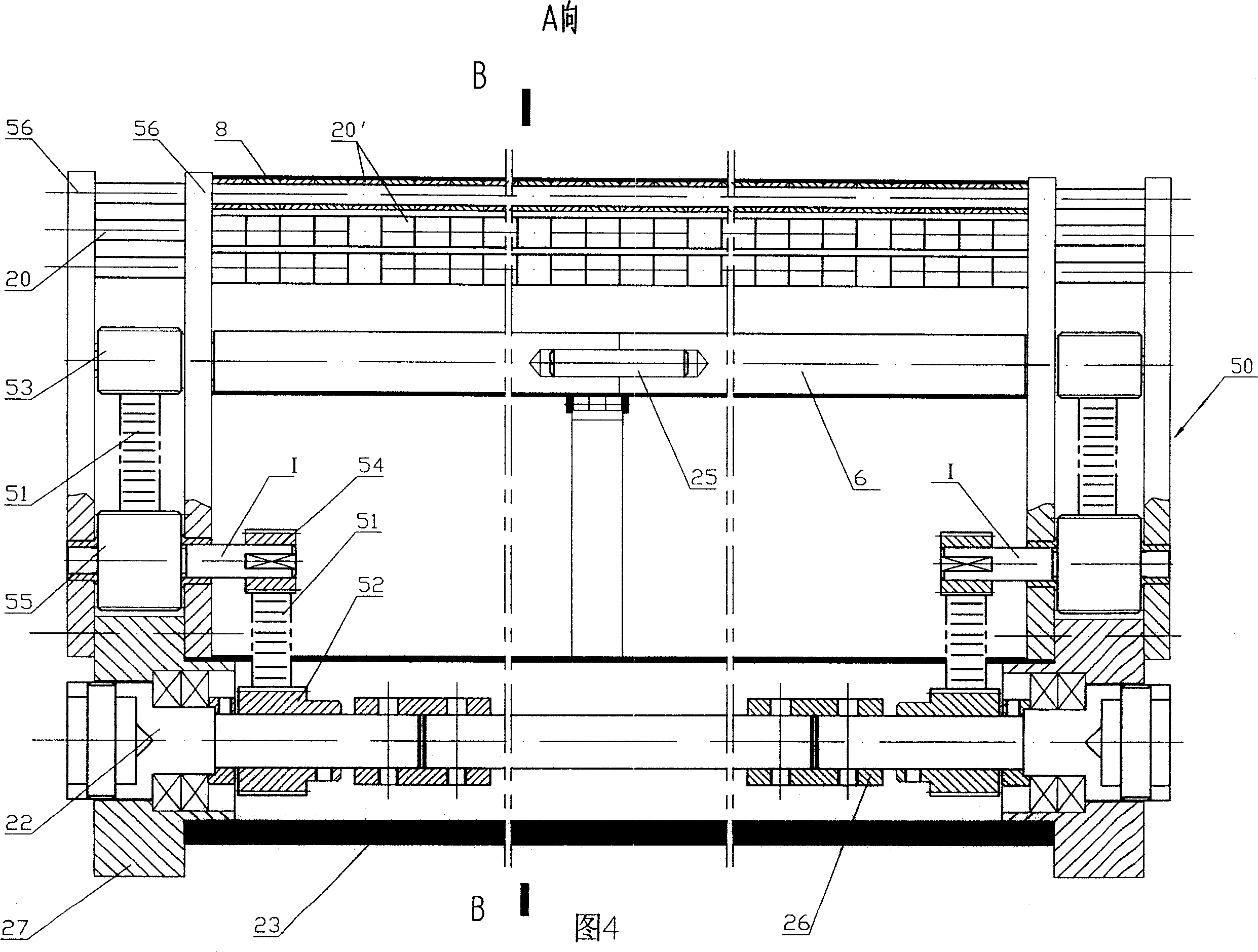

Line belt coiling unit for braiding flat-bed machine

A rolling-up device of conveying belt in flat-knitting machine, which contains small roller, small roller axle, large roller axle, rolling-up belt, two driving axle, two groups of belt driving mechanism, several matched press-wheel acting adjusting mechanism and press-wheel fixing adjusting mechanism. Said invention has advantages of automatic adjusting rolling-up gap, small size, fine rolling-up effect, easyinstallation and adjustment, simple structure, and low cost.

Owner:冯加林

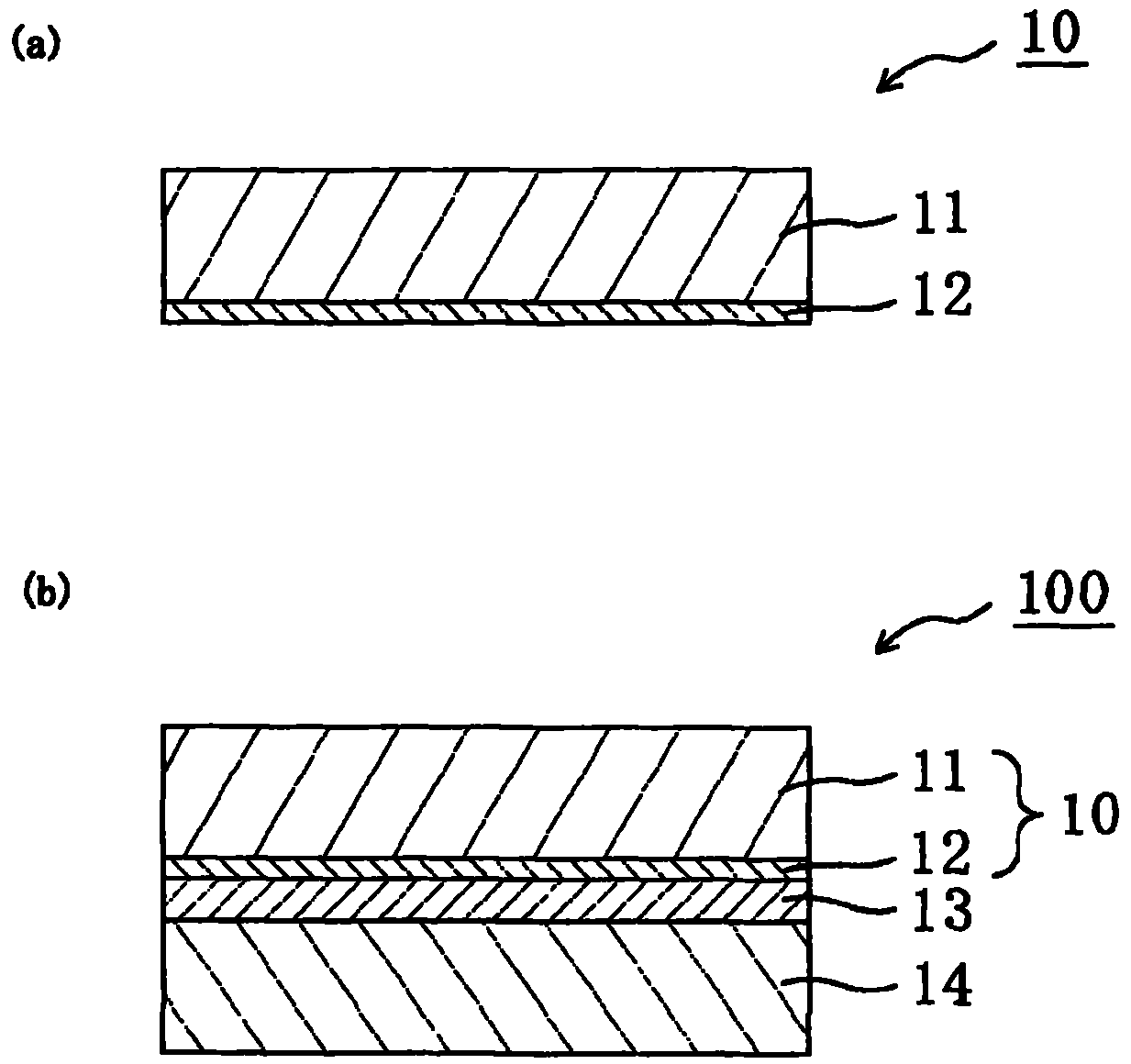

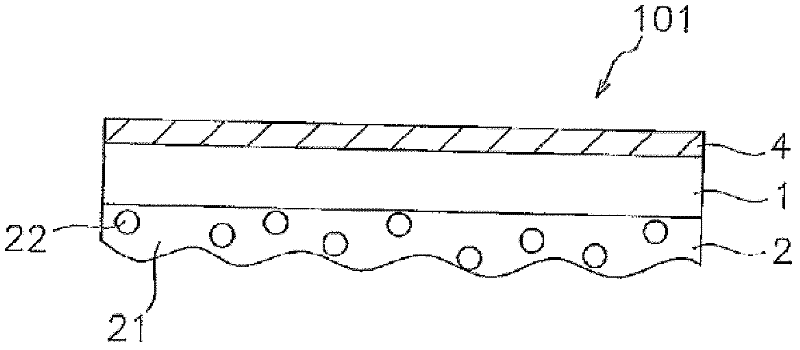

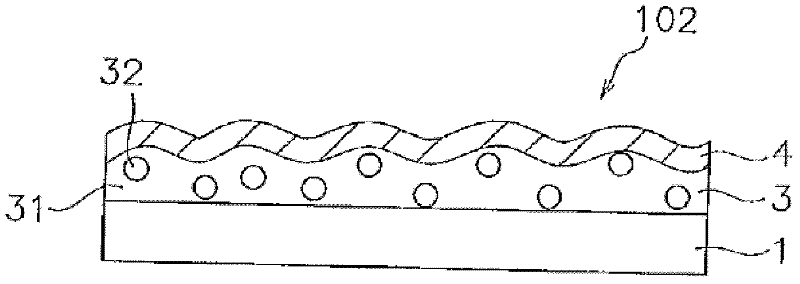

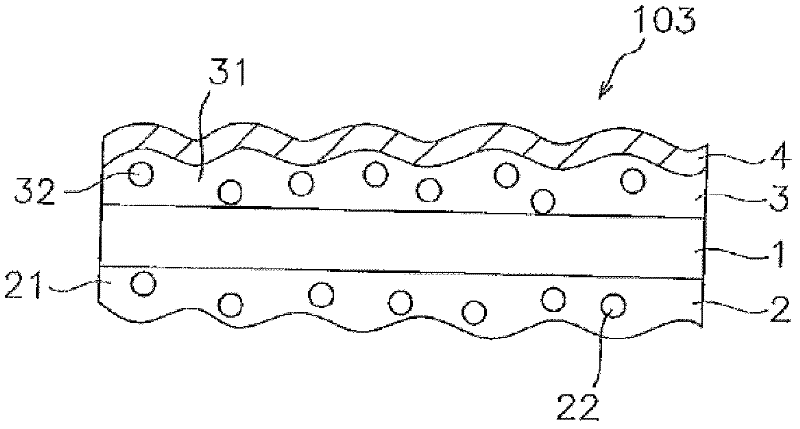

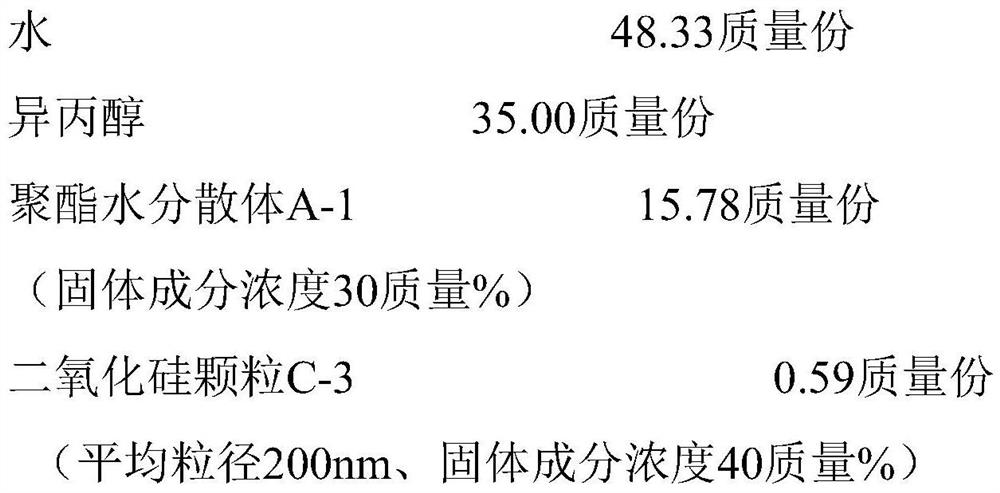

Transparent conductive film and touch panel

ActiveCN102682876AHigh transparencyImprove featuresConductive layers on insulating-supportsSynthetic resin layered productsPolymer substrateSolid content

The invention provides a transparent conductive film and a touch panel, the transparent conductive film has a blocking resistance and has a good transparency and an appearance characteristic. The transparent conductive film has a transparent polymer substrate and a transparent conductive layer on one main surface of the transparent polymer substrate. A cured resin layer with surface irregularities is formed: at least one of: between the transparent polymer substrate and the transparent conductive layer; and on the main surface opposite to the surface with the transparent conductive layer formed thereon of the transparent polymer substrate. The cured resin layer is preferably 1 [mu]m or more and 3 [mu]m or less in thickness and preferably contains a resin composition containing at least two components that undergo phase separation based on a difference in physical properties and 0.01 to 5 parts by weight of fine particles to 100 parts by weight of the solid content of the resin composition. The particle size of the fine particles is preferably 25 to 80% of the thickness of the cured resin layer.

Owner:NITTO DENKO CORP

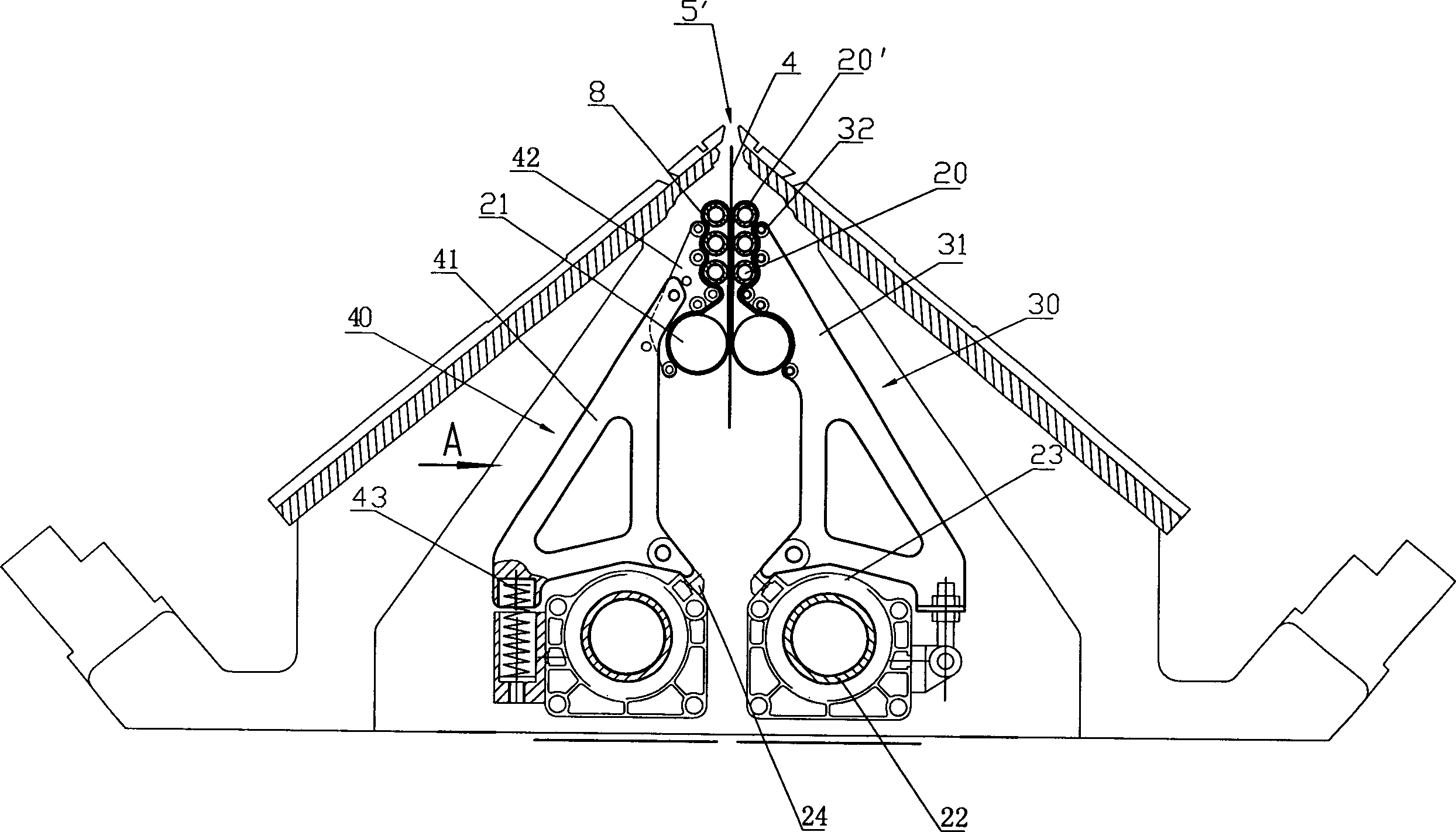

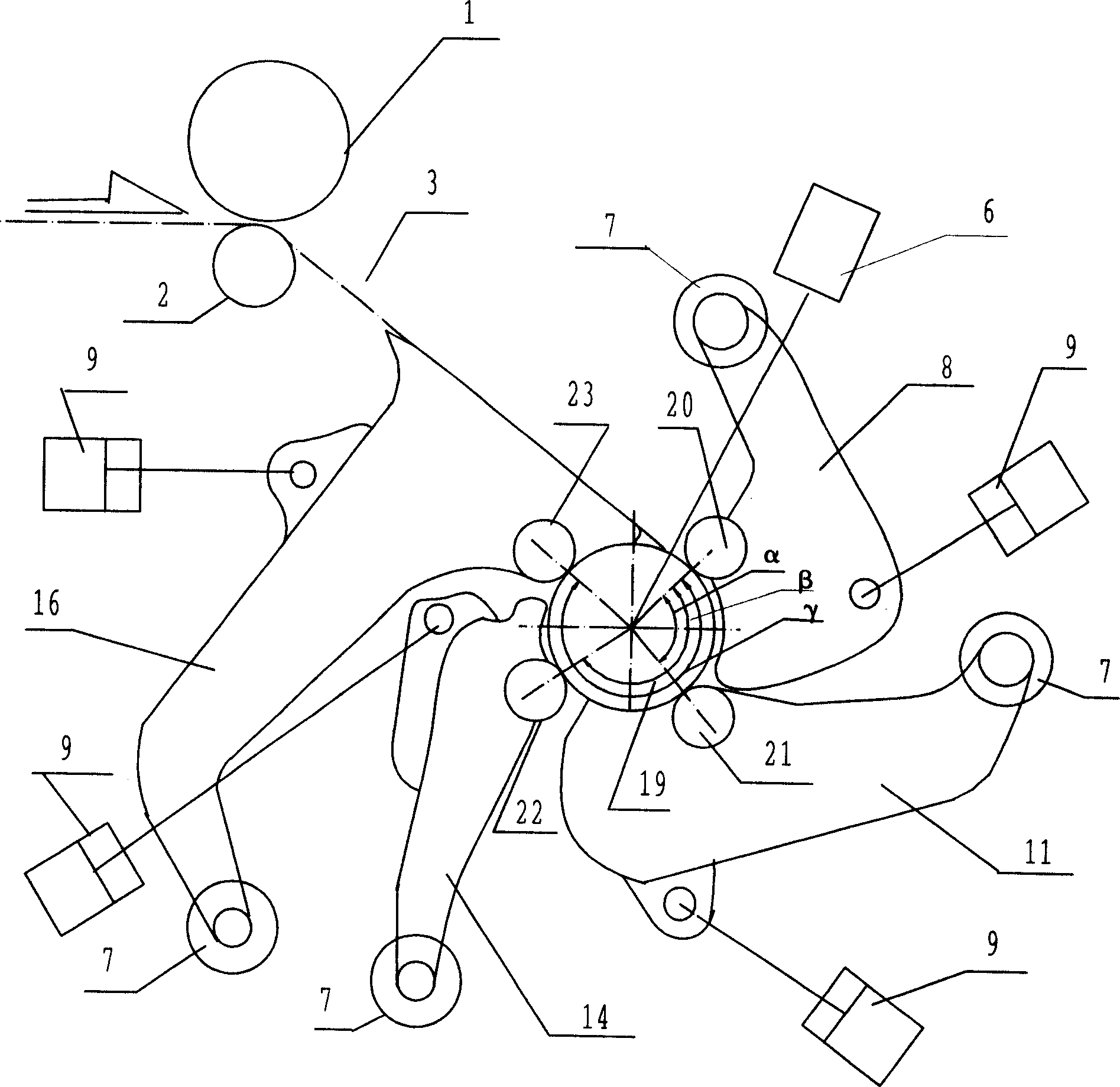

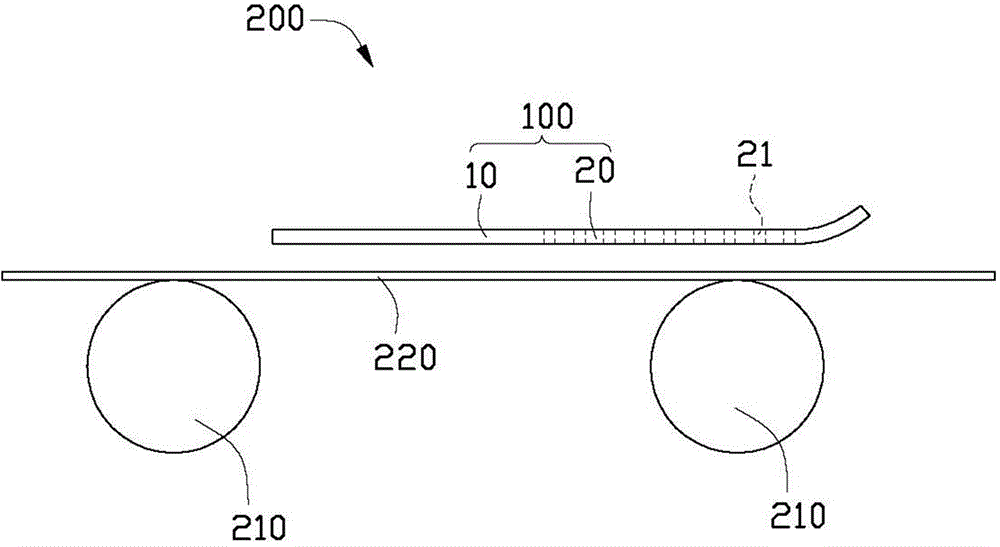

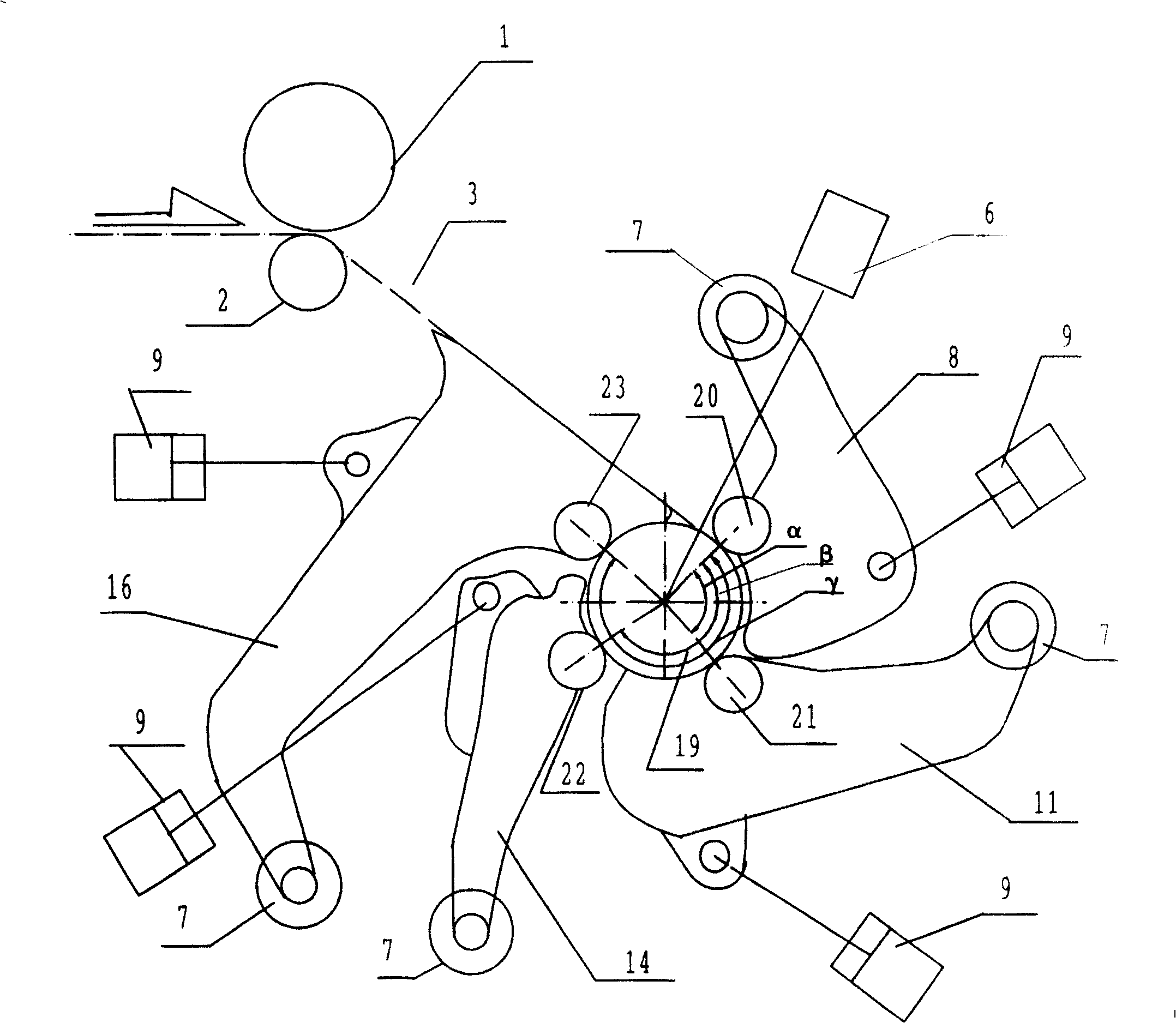

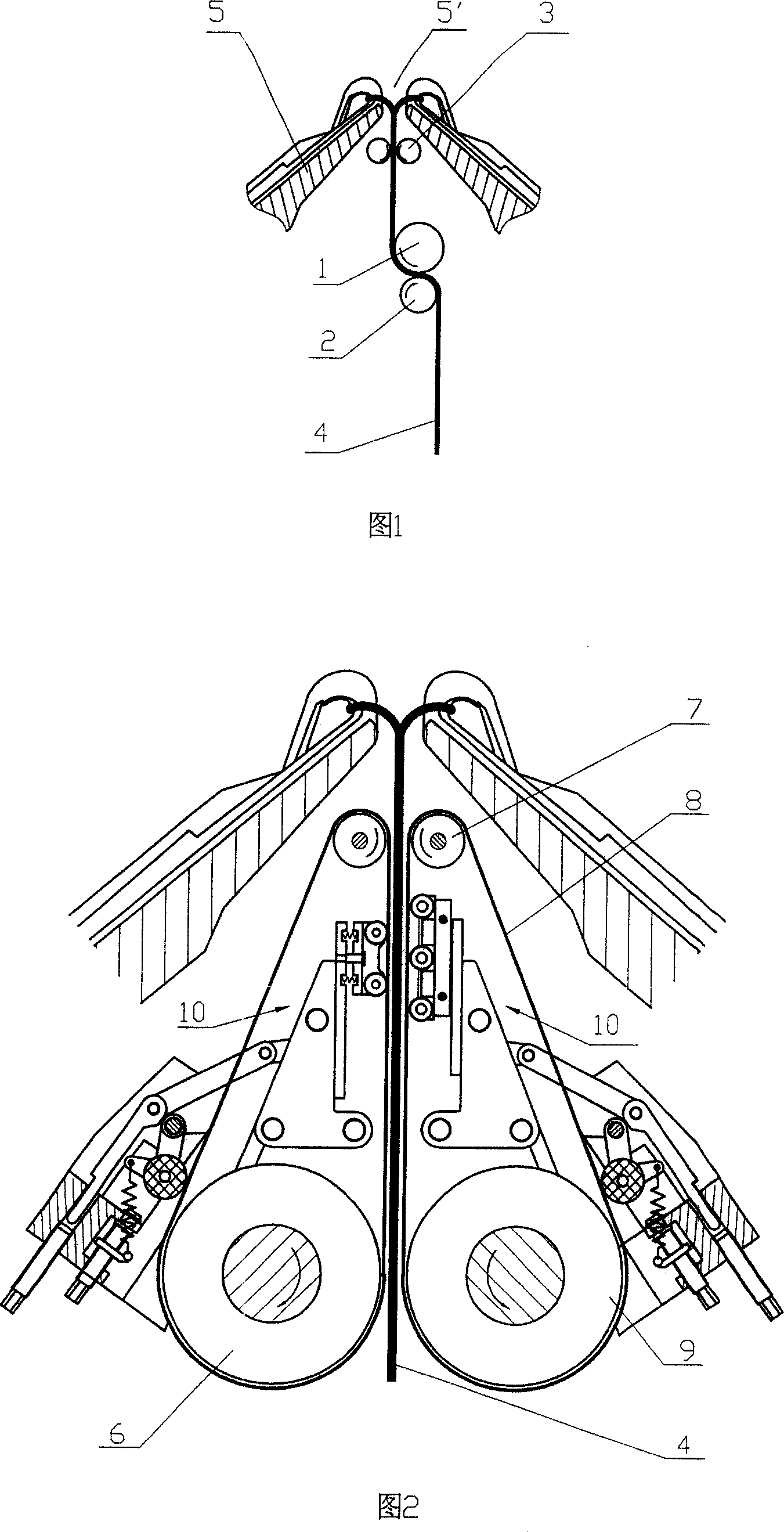

Rolling machine for hot-rolled sheets with excellent rolling assisting property

ActiveCN1903467AImproved lead-in performance and uniform winding performancePrevent unwindingManufacturing lineEngineering

A hot-rolled sheet coiling machine with better coil-helping performance has a reel, coil-helping rollers, swinging arms for supporting said coil-helping rollers, and hydraulic cylinders for driving said swinging arms. It features that 1-3 coil-helping roller are additionally used for increasing the points to where the pressure is applied, so improving its coil-helping performance.

Owner:HEBEI IRON AND STEEL

Preparation method of HOY spring wire

InactiveCN105648552AGood coiling effectImprove performanceMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterEngineering

The invention discloses a preparation method of an HOY spring wire. The method comprises the steps that 1, polyester chips are pretreated; 2, the polyester chips are melted into a spinning fluid through a screw extrusion machine; 3, the spinning fluid is pressed into a spinning component and sprayed out through a spinneret plate, and tows are formed in a spinning window; 4, the tows are subjected to cross air cooling, oiling, bundling and antistatic treatment and then further cooled through a spinning channel, wherein the cross air blasting speed is 0.5-0.9 m / s; 5, the cooled tows pass through a pre-interlacing device to enable the oil uniform saturability to be better, wherein six pre-interlaced nozzles are arranged, and the pre-interlaced pressure is 0.8-2 kg; 6, the tows are stretched through a godet at a high speed, nodes are made through a main interlacing device, and then winding formation is achieved through a high-speed winder, wherein the W / D speed is 5,900-7,900 m / min. According to the preparation method of the HOY spring wire, the number of traditional pre-interlaced nozzles is decreased to six, the pre-interlaced pressure is decrased to 1.0 kg, the cross air blasting speed is decreased to 0.7 m / s, and the spinning wheel speed is decreased to 5,900-7,900 m / min; under the technological conditions, the obtained HOY spring wire is good in winding effect and excellent in performance.

Owner:SUZHOU LONGJIE SPECIAL FIBER

Preparation method of cast iron roller of pinch roll of recoiler

The invention relates to a preparation method of a cast iron roller of a pinch roll of a recoiler. The preparation method comprises the following steps that 2.5-3.6 percent by weight of C, 0.5-5.0 percent by weight of Ni, 0.1-3.8 percent by weight of Cr, 1.0-3.0 percent by weight of Si, 0.2-2.7 percent by weight of Nb, 0.5-3.5 percent by weight of Mn, 0.1-2.2 percent by weight of Mo, 0.1-1.2 percent by weight of Cu, 0-1.7 percent by weight of W, less than 0.05 percent by weight of P, less than 0.06 percent by weight of S and the balance of Fe are melted at 1,450 DEG C in an induction melting electric furnace to obtain a melt; the melt is superheated to 1,500-1,550 DEG C, and is thermally insulated for 20-30 min, slag on the surface of the melt is removed, and the temperature of the melt is regulated to 1,400-1,450 DEG C; 0.5 percent of Si when the melt is discharged from the induction melting electric furnace; the melted solution is poured in a preheated centrifugal casting mold for casting; and the cast is cooled and solidified to obtain the alloy cast iron roller. The alloy cast iron roller is heat-resistant, wear-resistant, and is long in service life, and low in cost; and moreover, steel is not stuck on the alloy cast iron roller.

Owner:湖北精利机电科技有限公司

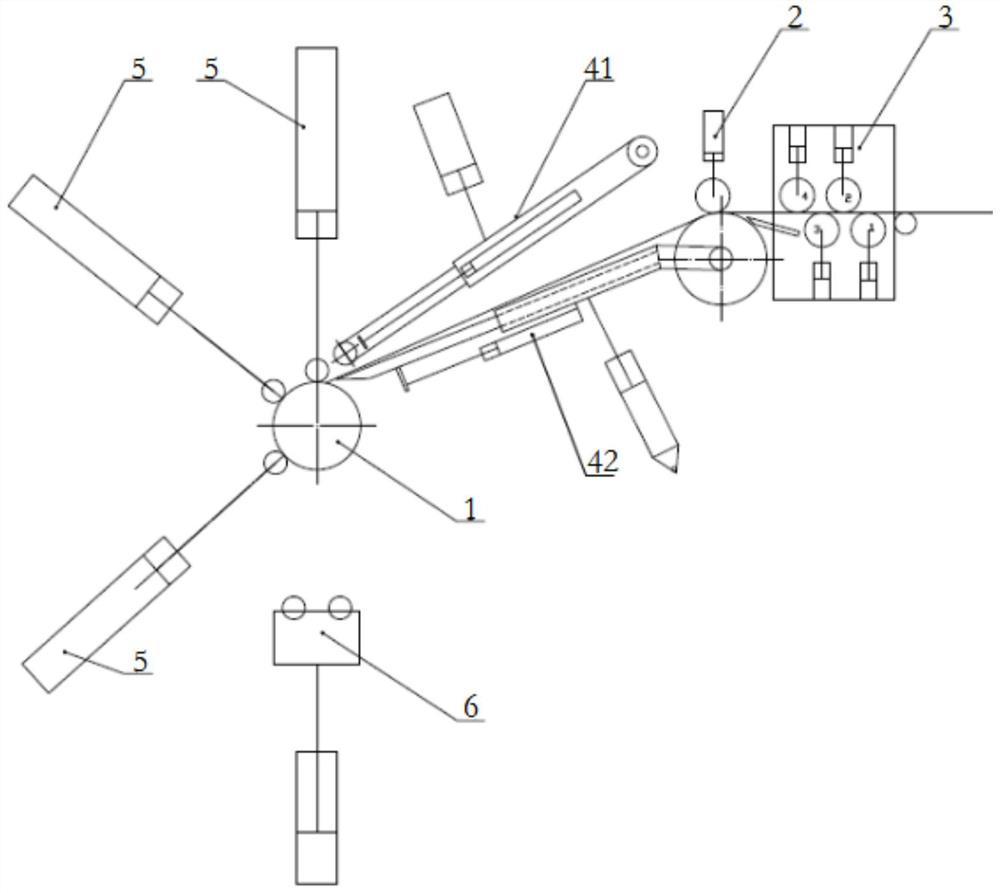

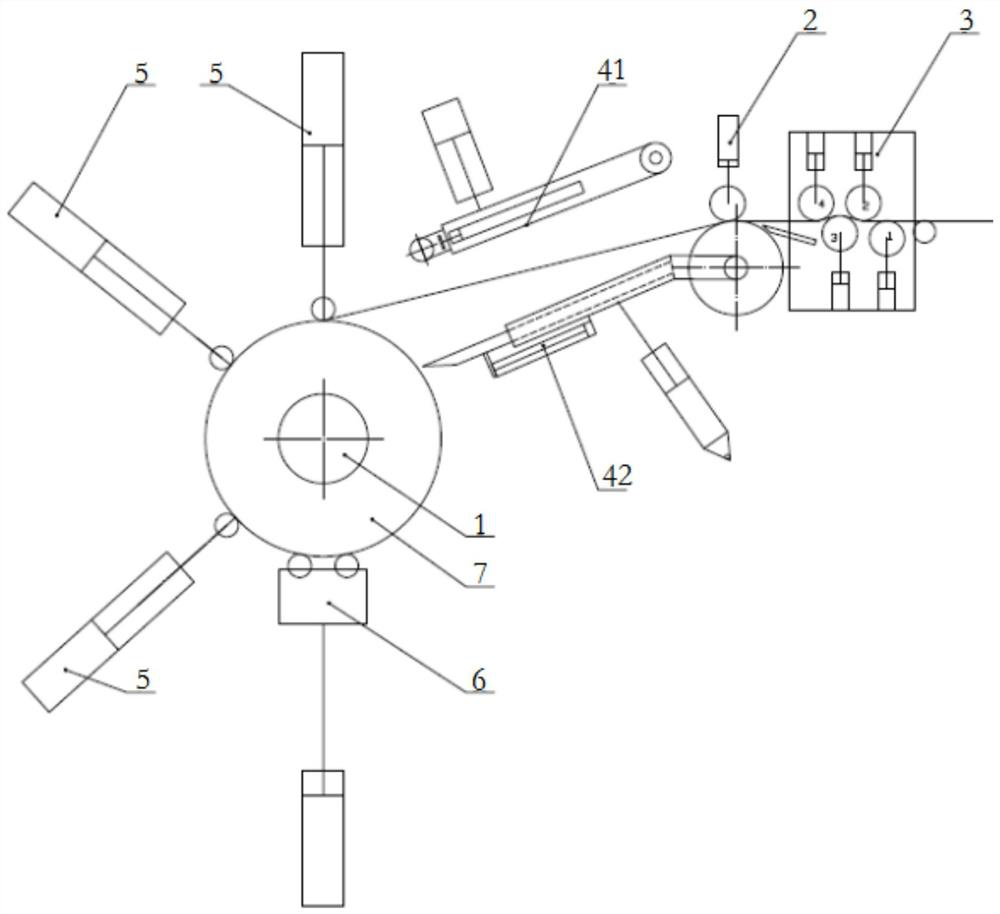

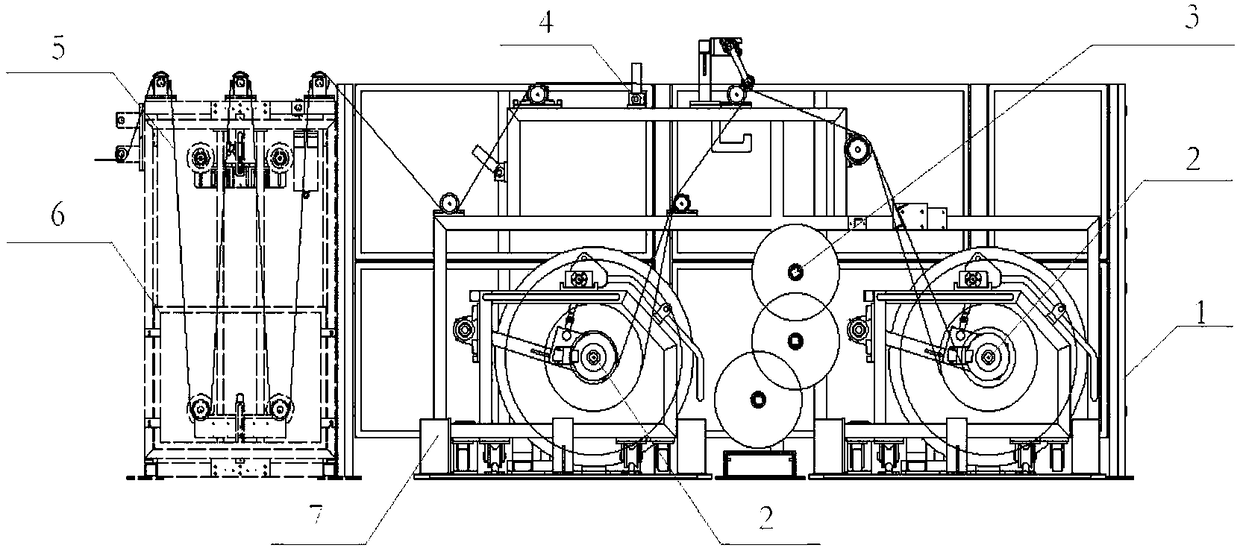

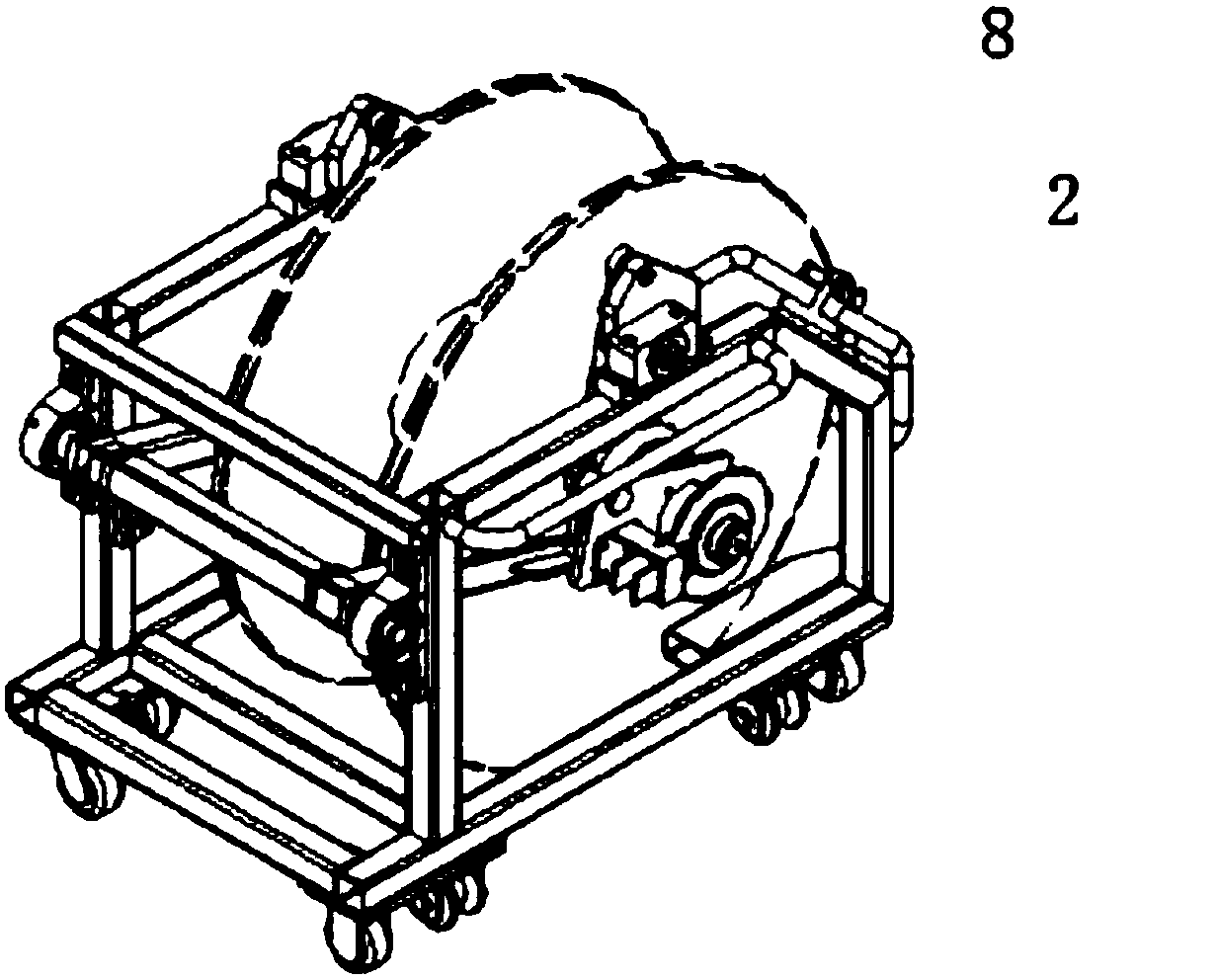

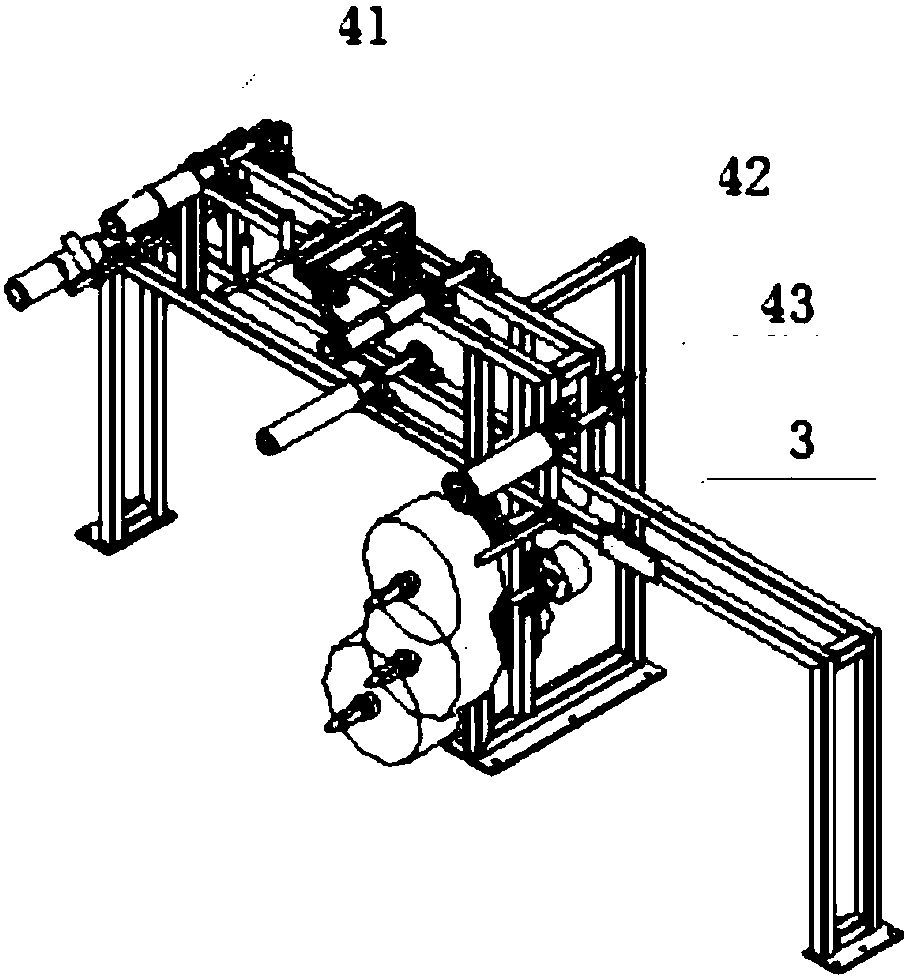

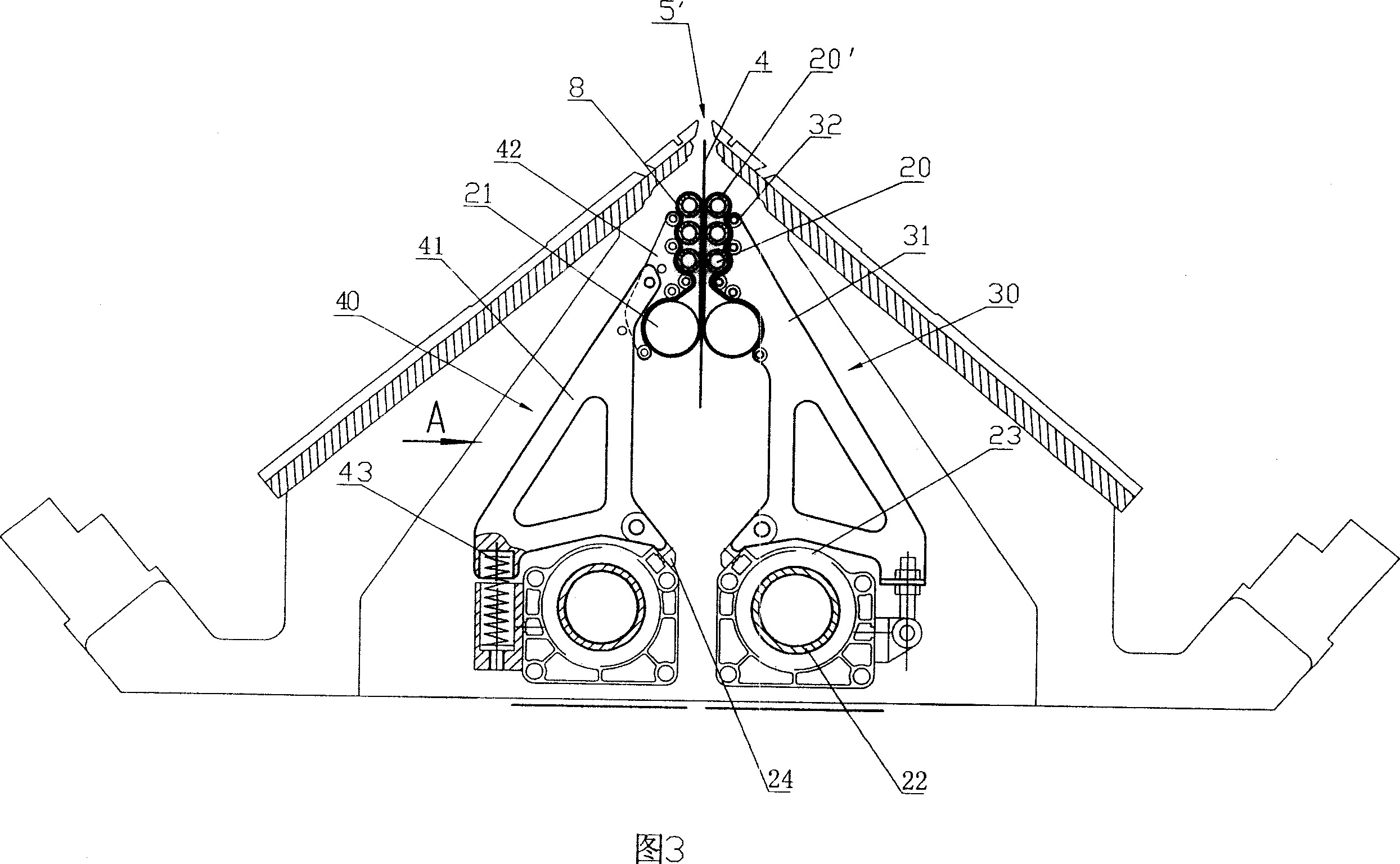

Strip steel coiling system, high-strength steel coiling method and high-strength steel production line

The invention relates to a strip steel coiling system, a high-strength steel coiling method based on the strip steel coiling system and a high-strength steel production line adopting the strip steel coiling system. The coiling system comprises a coiling machine, a steering pinch roller and a coil unloading vehicle. The steering pinch roller is connected with the coiling machine through a strip penetrating guide plate, and a bending machine is arranged on the feeding side of the steering pinch roller; and at least one auxiliary pressing roller is arranged around a winding drum of the coiling machine, the axial directions of the auxiliary pressing rollers are parallel to the axial direction of the winding drum, and the auxiliary pressing rollers are provided with auxiliary pressing roller driving units so as to have working positions in rolling contact with a steel coil and standby positions away from the steel coil. The bending machine can straighten strip steel at the initial stage ofcoiling to prevent the strip penetrating guide plate from being damaged, the strip steel is made to generate plastic deformation at the final stage of coiling, rear tension can be provided for coiling, and bounce of the outer-ring strip steel can be reduced; and the auxiliary pressing rollers can enable the strip steel to be attached to the winding drum / steel coil in the coiling process, the winding effect of the strip steel is improved, and the problem that when high-strength steel and other steel types are wound, bumps exist near a jaw can be avoided.

Owner:WISDRI ENG & RES INC LTD

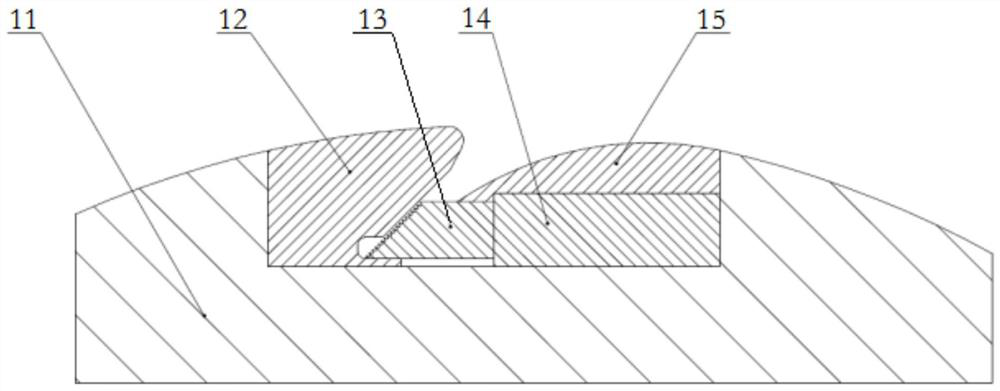

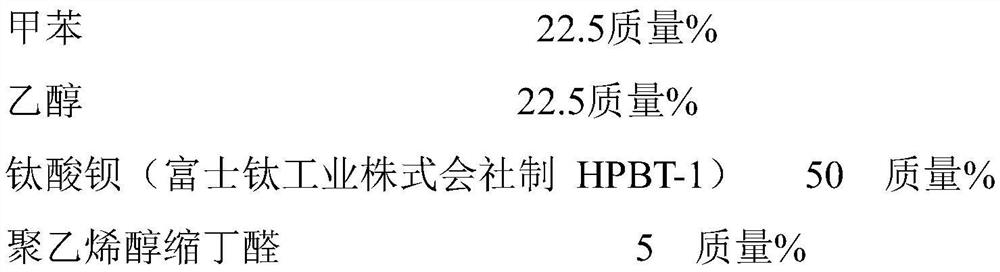

Release film for ceramic green sheet production

ActiveCN109070383BGood coiling effectSynthetic resin layered productsCeramic shaping apparatusPolyesterAccessibility

[Problem] To provide an excellent release film for producing a ceramic green sheet that can achieve both good winding performance and prevention of pinholes, partial thickness unevenness, etc. even when the ceramic green sheet is thinned. [Solution] A release film for producing ceramic green sheets, which uses a polyester film substantially free of particles as a base material, has a release coating layer on one surface of the base material, and has a release coating layer on the other surface. There is an easy-slip coating layer containing particles on it, the area surface average roughness (Sa) of the easy-slip coating layer is not less than 1nm and not more than 25nm, the maximum protrusion height (P) is not less than 60nm and not more than 500nm, and the average of the contour unit The width (RSm) is 10 μm or less.

Owner:TOYOBO CO LTD

Fe-based amorphous alloy material and method of producing the same

InactiveCN101509106BImprove performance indicatorsHigh saturation magnetizationChemical compositionAlloy

The invention provides an amorphous alloy material with Fe as the main component and a preparation method thereof. The amorphous alloy material of the invention comprises the chemical components with the following parts by weight: Fe: 91.0-93.5; Si: 5.2-6.6; B: 2.5-3.3; Cr: 0.05-0.25; Cu: 0.010-0.030; and C: 0.05-0.20. The Fe-based amorphous alloy belt material has simple design in components, and good mechanical property and fine processability of the material; moreover, yield is over 90%. In addition, the manufactured Fe-based amorphous alloy belt material has high comprehensive magnetic property; and coreloss of a transformer manufactured by the amorphous alloy material is greatly reduced. The Fe-based amorphous alloy belt material enjoys wide application and low use cost and serves tosave energy and protect the environment.

Owner:北京晶鑫联合新材料科技有限公司

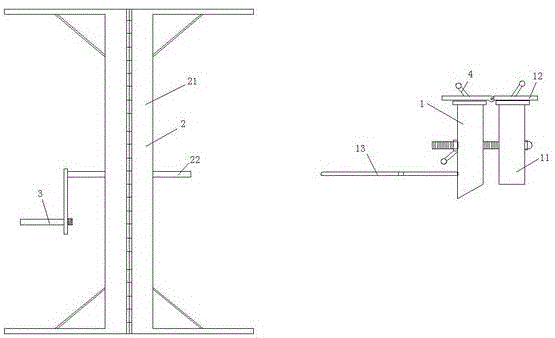

Device for coiling half-product zero-degree belted layer

The invention provides a device for coiling a half-product zero-degree belted layer. The device for coiling the half-product zero-degree belted layer comprises a first guide roller, a machine frame rack, a second guide roller, a baffle, a track, a pull rod, a cylinder, a chuck and a driving motor. The first guide roller and the second guide roller are arranged at the front end of the machine framein an assembled mode. The first guide roller is arranged on the left side of the second guide roller, the chuck is mounted at the front end of the driving motor in an assembled mode, and the pull rodis arranged on the lower side of the chuck. The cylinder is fixed to the rear end of the pull rod, the cylinder is arranged on the left side of the driving motor, the track is arranged on the left side of the pull rod, and the baffle is arranged on the left side of the track. The design has high control precision, low noise, convenient use and operation, high control precision and improves the coiling effect.

Owner:HANGZHOU CHAOYANG RUBBER

Release film for producing ceramic green sheet

ActiveCN109070383AGood coilingAvoid pinholesSynthetic resin layered productsCeramic shaping apparatusPolyesterMetallurgy

Provided is an excellent release film for producing a ceramic green sheet, the release film being capable of attaining both satisfactorily suitability for winding and prevention of pinholes, local thickness unevenness, etc., even when forming a ceramic green sheet having a reduced thickness. The release film for producing a ceramic green sheet comprises a substrate that is a polyester film containing substantially no particles, a release coating layer formed on one surface of the substrate, and an easy-to-slip coating layer formed on the other surface and containing particles, wherein the easy-to-slip coating layer has an average surface region roughness (Sa) of 1-25 nm, a maximum projection height (P) of 60-500 nm, and an average roughness-curve-element length (RSm) of 10 [mu]m or less.

Owner:TOYO TOYOBO CO LTD

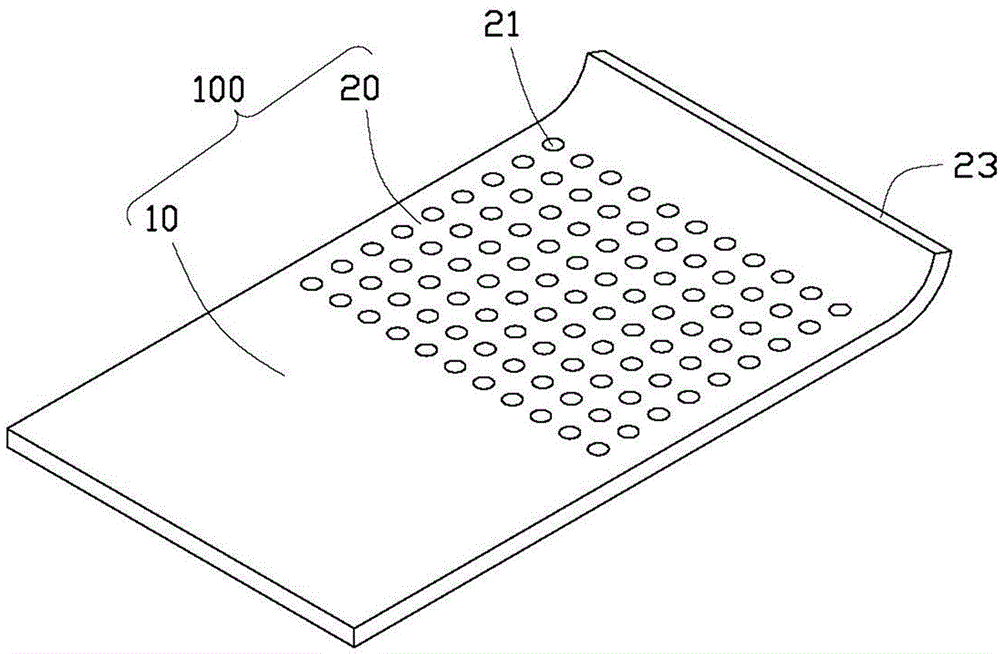

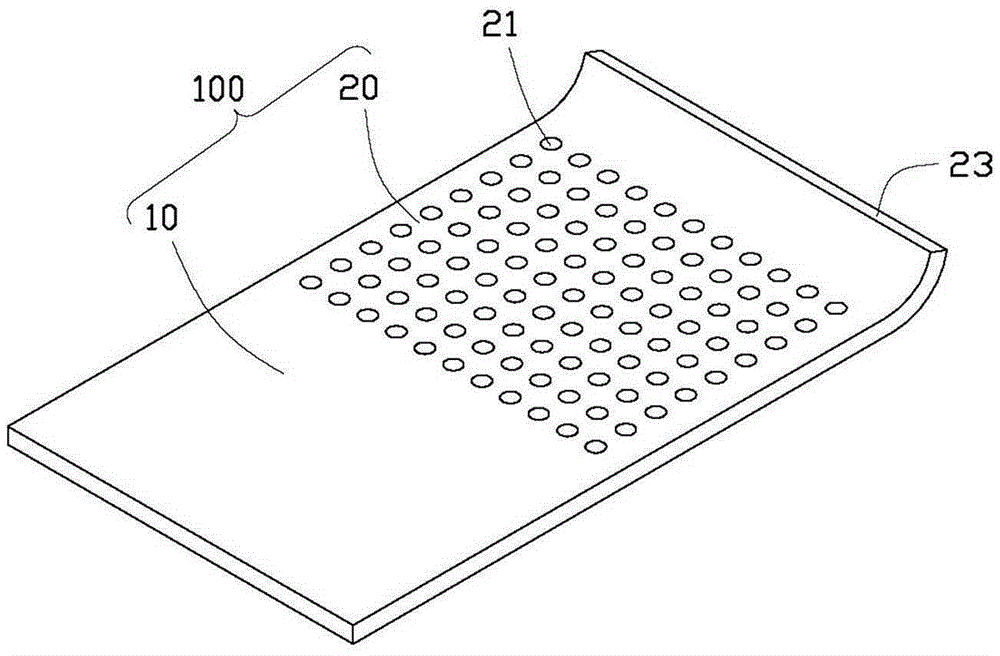

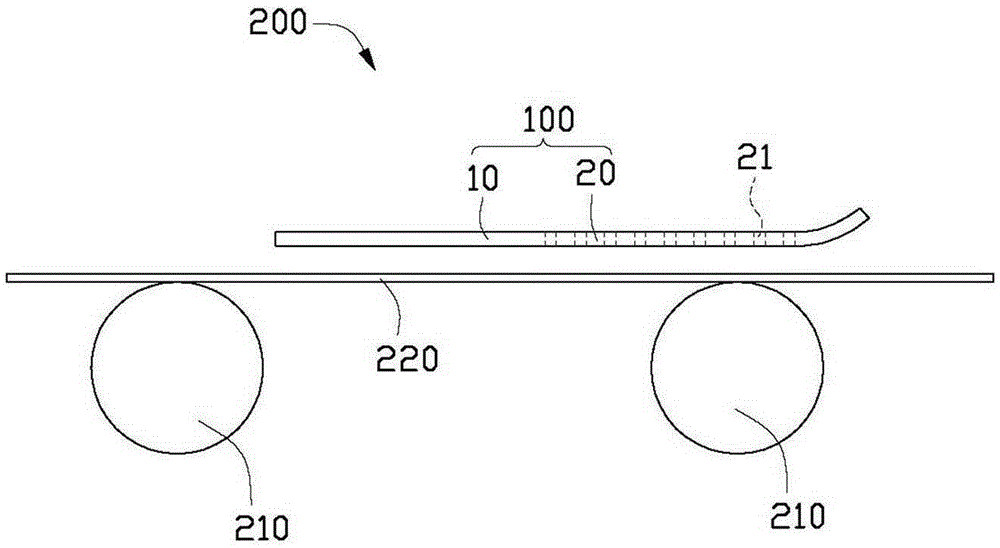

Anti-vibration plate and material transport device applying same

The invention provides an anti-vibration plate which is roughly of a platy structure comprising a first portion and a second portion, wherein the first portion and the second portion are integrally connected, and various through holes are arranged on the second portion. The invention further provides a material transport device applying the anti-vibration plate. By the aid of the anti-vibration plate, vibration range and vibration frequency of materials are reduced during high-speed moving of materials, so that a transportation process is more stable and fracture of the materials occurs less. In addition, the anti-vibration plate is free of power consumption, simple in structure, assembling, adjusting and maintenance, quite low in cost, more energy-saving and environment-friendly and capable of effectively preventing vibration of the materials. Multiple anti-vibration plates can be mounted at various positions during the whole transportation.

Owner:GOLD HONG YE PAPER

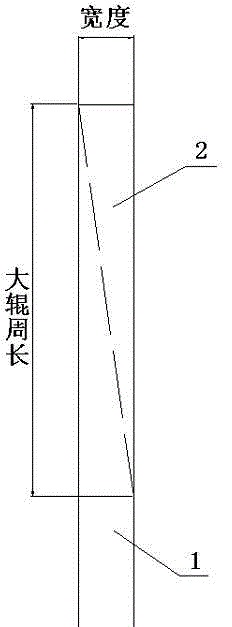

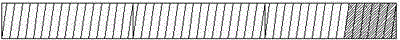

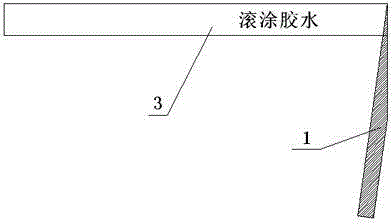

Large roll of net roll for paper forming net inspection and its wrapping method

The invention discloses a net reel large roller for examining a papermaking forming fabric, wherein all the surface of the net reel large roller is evenly packed with a specific flat belt, and a paste face of the flat belt is pasted onto the surface of the large roller through glue. The invention further discloses a packing method of the net reel large roller for examining the papermaking forming fabric, wherein the packing method comprises the following steps of: cutting a corner of which the length is equal to the perimeter of the large roller and the width is equal to the width of the specific flat belt from one end of the glazed specific flat belt; coating the glue on a paste face between the large roller and the glazed specific flat belt in a rolling way; and pasting from one corner of the glazed specific flat belt and one side of the large roller, and coating the glue by the large roller in a rolling way till the surface of the large roller is completely packed with the glazed specific flat belt. According to the net reel large roller, the glazed specific flat belt is evenly packed on the surface of the large roller, and a glaze of the glazed specific flat belt faces out, so that the damage of the large roller to the forming fabric can be effectively reduced.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

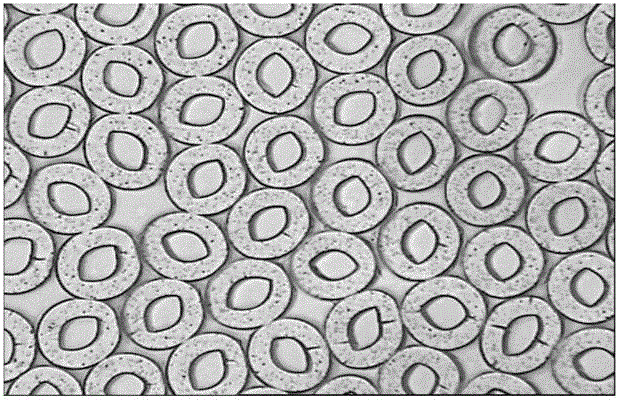

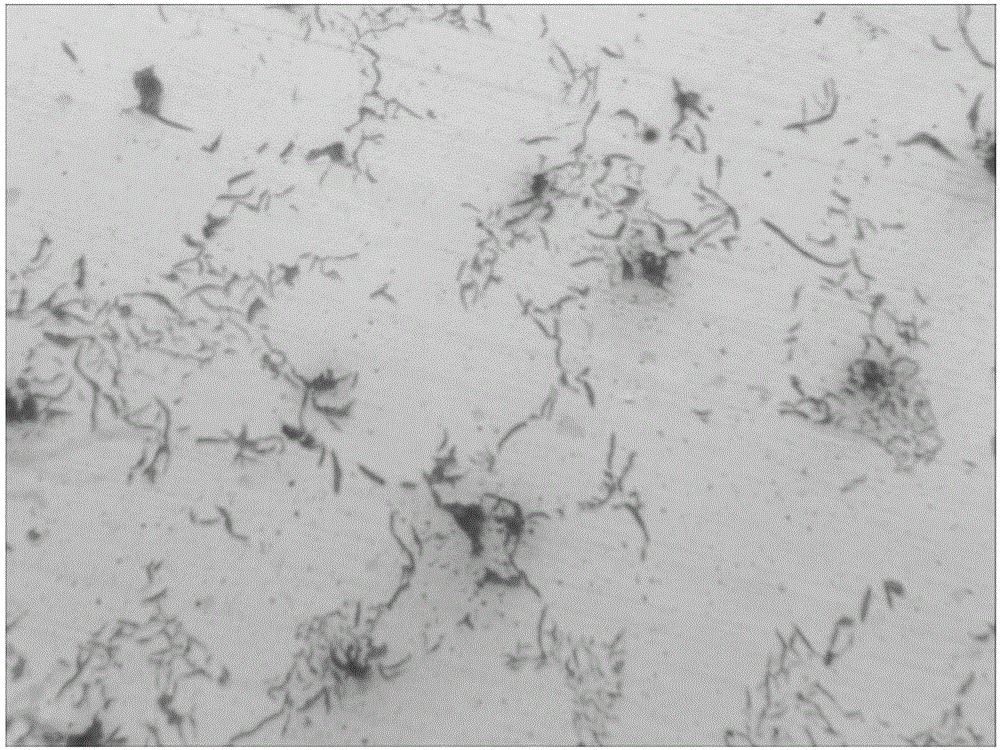

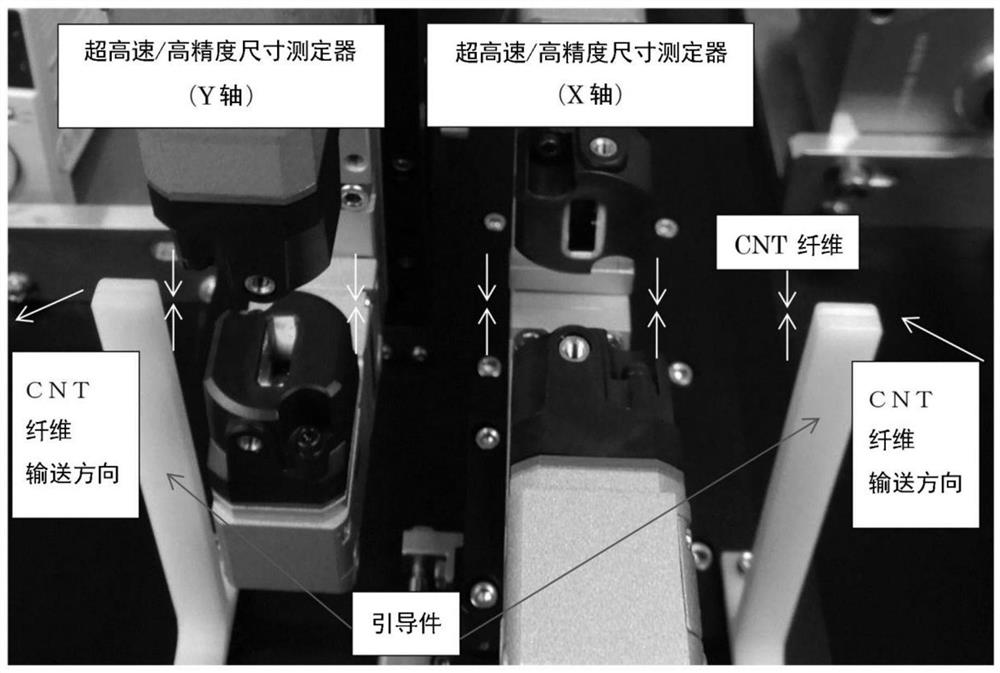

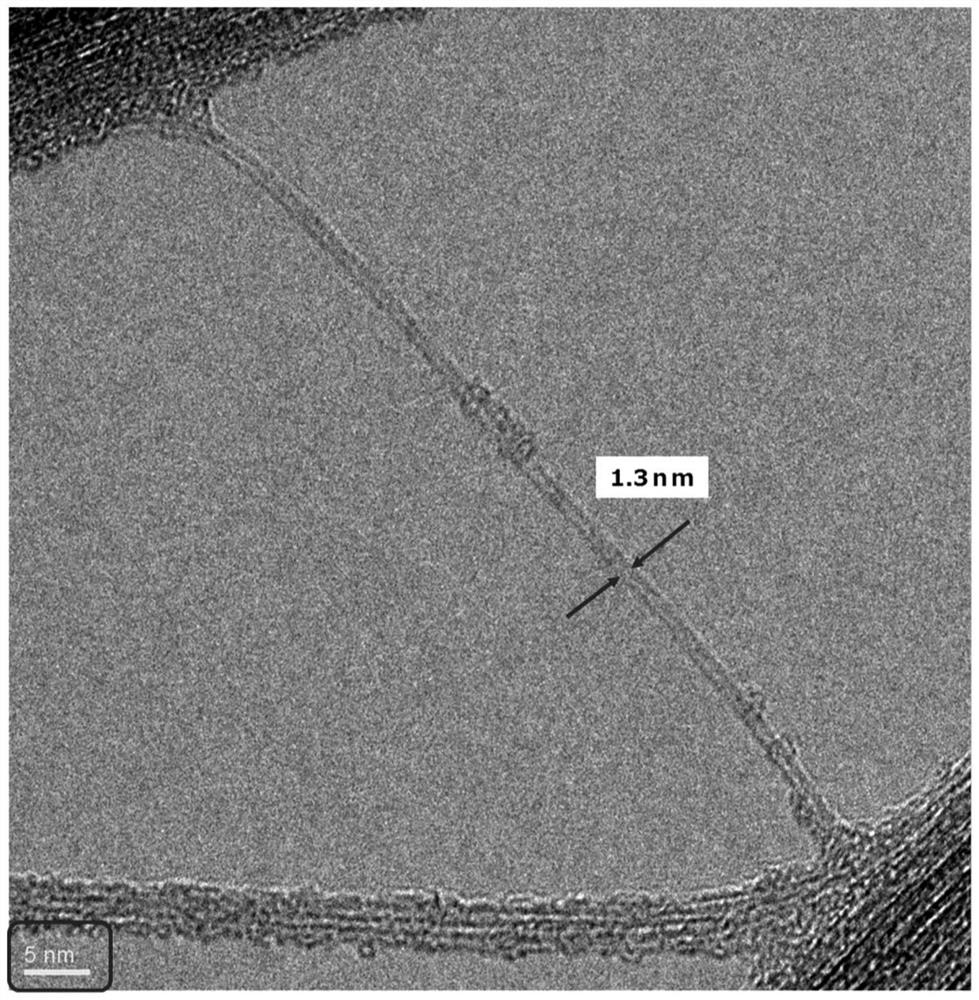

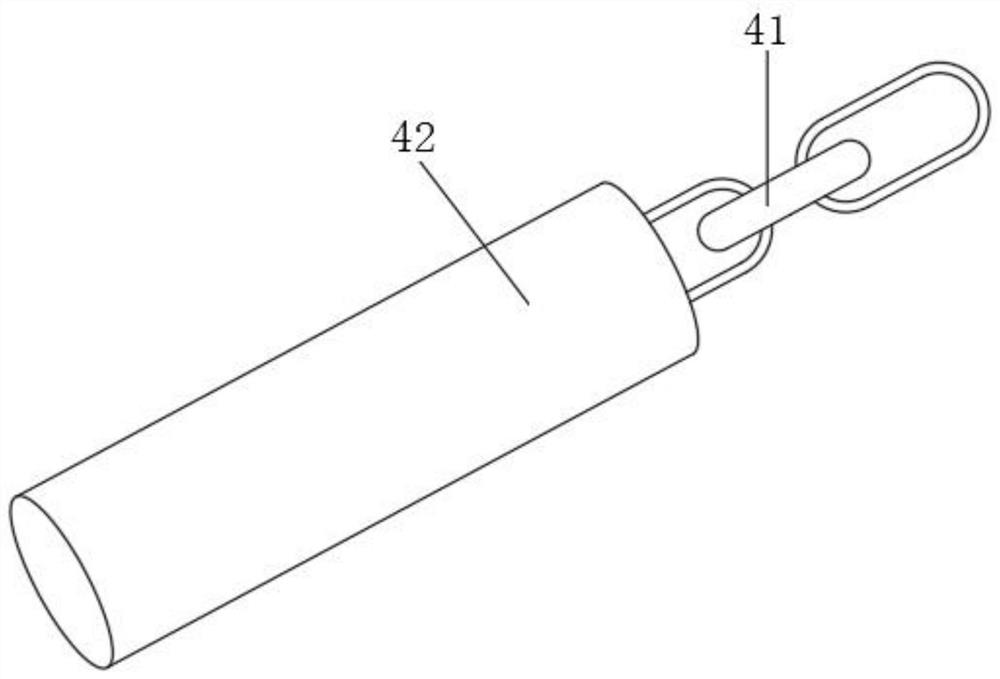

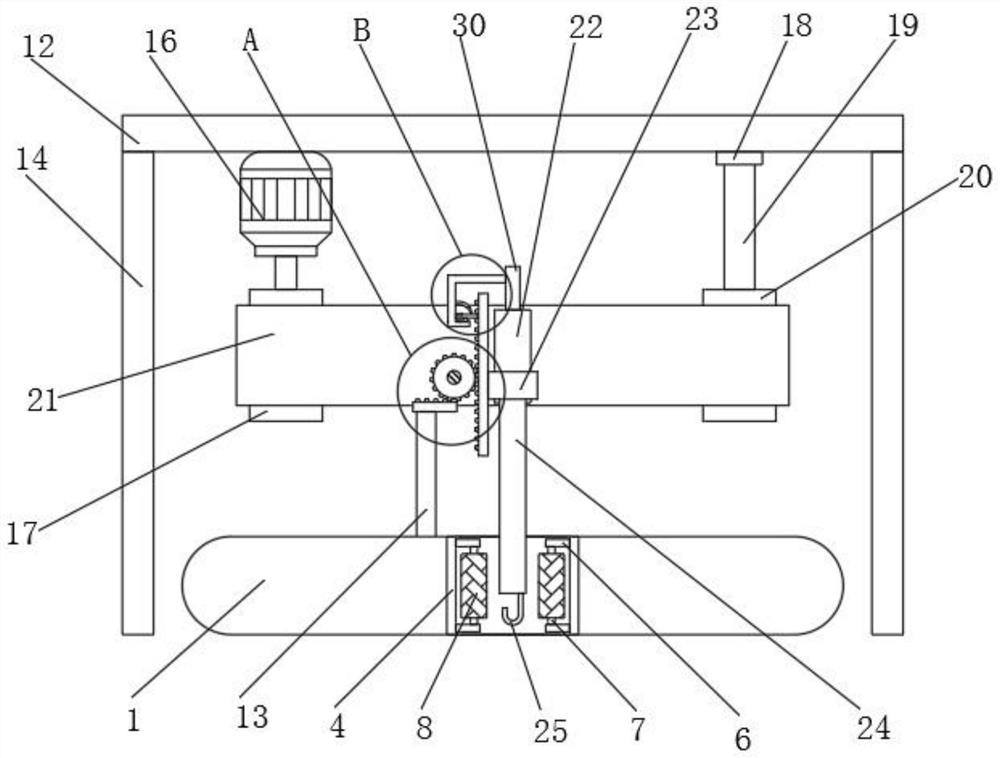

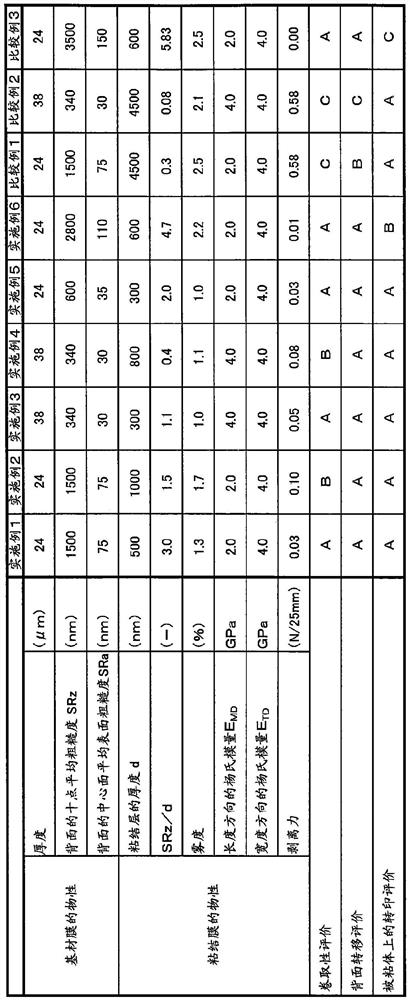

Fiber composed of carbon nanotubes and its production method

ActiveCN111201343BGood coiling effectImprove the winding effectMaterial nanotechnologyInorganic material artificial filamentsFiberPolymer science

We provide: CNT fibers made of aligned carbon nanotubes (CNTs), which are thin, have little unevenness in thickness, have good windability during coil processing, and have excellent electrical conductivity. The present invention relates to CNT fibers composed of carbon nanotubes (CNTs) and a method for producing the CNT fibers, wherein the thickness of the CNT fibers is 0.01 μm to 3 mm, and the unevenness of the thickness is 0.2 or less in terms of coefficient of variation, in terms of roundness The distribution ratio a is 40% or more and the distribution ratio b is 70% or more, and the production method includes the following steps: a spinning step, discharging an aqueous dispersion containing carbon nanotubes (CNT) and a surfactant to an organic solvent containing In the coagulation bath, the CNT aggregation structure in the shape of a filament is obtained; and, in the pulling step, the obtained CNT aggregation structure is continuously pulled from the coagulation bath at a line speed higher than the discharge line speed.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

A balance compensation chain suitable for wide-car elevators and its preparation process

ActiveCN111531841BExtended service lifeIncrease bend diameterElevatorsMine liftsPolyvinyl chlorideControl theory

Owner:JIANGSU XINGHUA RUBBER BELT

Anti-shake plate and object conveying device using the same

The invention provides an anti-vibration plate which is roughly of a platy structure comprising a first portion and a second portion, wherein the first portion and the second portion are integrally connected, and various through holes are arranged on the second portion. The invention further provides a material transport device applying the anti-vibration plate. By the aid of the anti-vibration plate, vibration range and vibration frequency of materials are reduced during high-speed moving of materials, so that a transportation process is more stable and fracture of the materials occurs less. In addition, the anti-vibration plate is free of power consumption, simple in structure, assembling, adjusting and maintenance, quite low in cost, more energy-saving and environment-friendly and capable of effectively preventing vibration of the materials. Multiple anti-vibration plates can be mounted at various positions during the whole transportation.

Owner:GOLD HONG YE PAPER

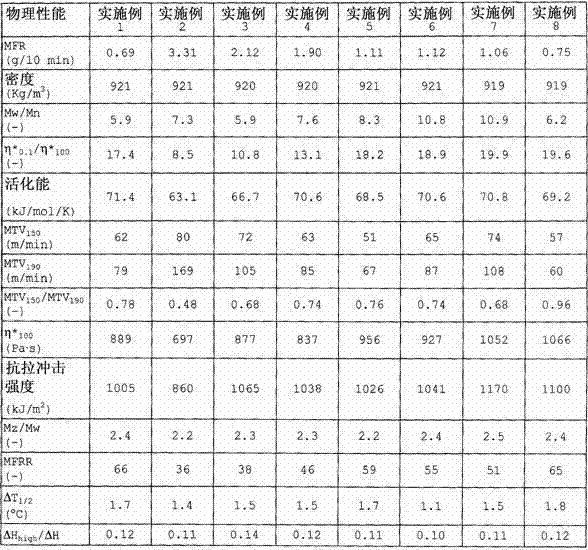

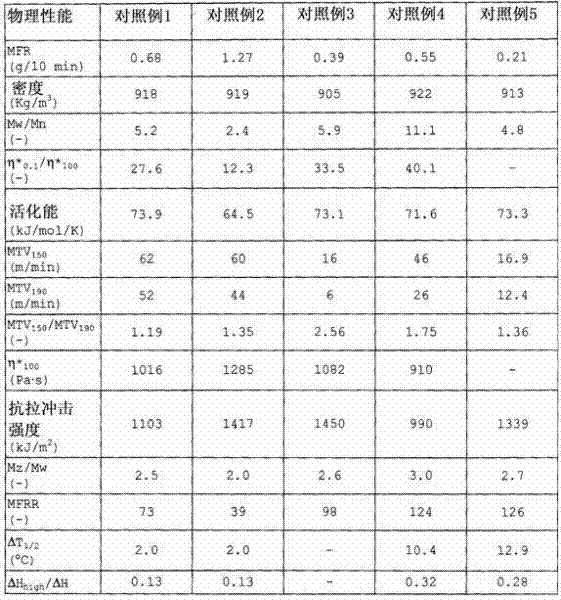

Ethylene-a-olefin copolymer

Provided is an ethylene-a-olefin copolymer that has a monomer unit based on ethylene and a monomer unit based on C3-20 a-olefin. Said ethylene-a-olefin copolymer has a melt flow rate between 0.01 and 100 g / 10 min, a density between 860 and 970 kg / m , a molecular weight distribution between 5.5 and 12, and a flow activation energy between 50 and 100 kJ / mol. Letting the maximum take-up velocity of the provided copolymer at 150 DEG C be MTV150 and the maximum take-up velocity at 190 DEG C be MTV190, MTV150 is at least 40 m / min and is less than MTV190.

Owner:SUMITOMO CHEM CO LTD

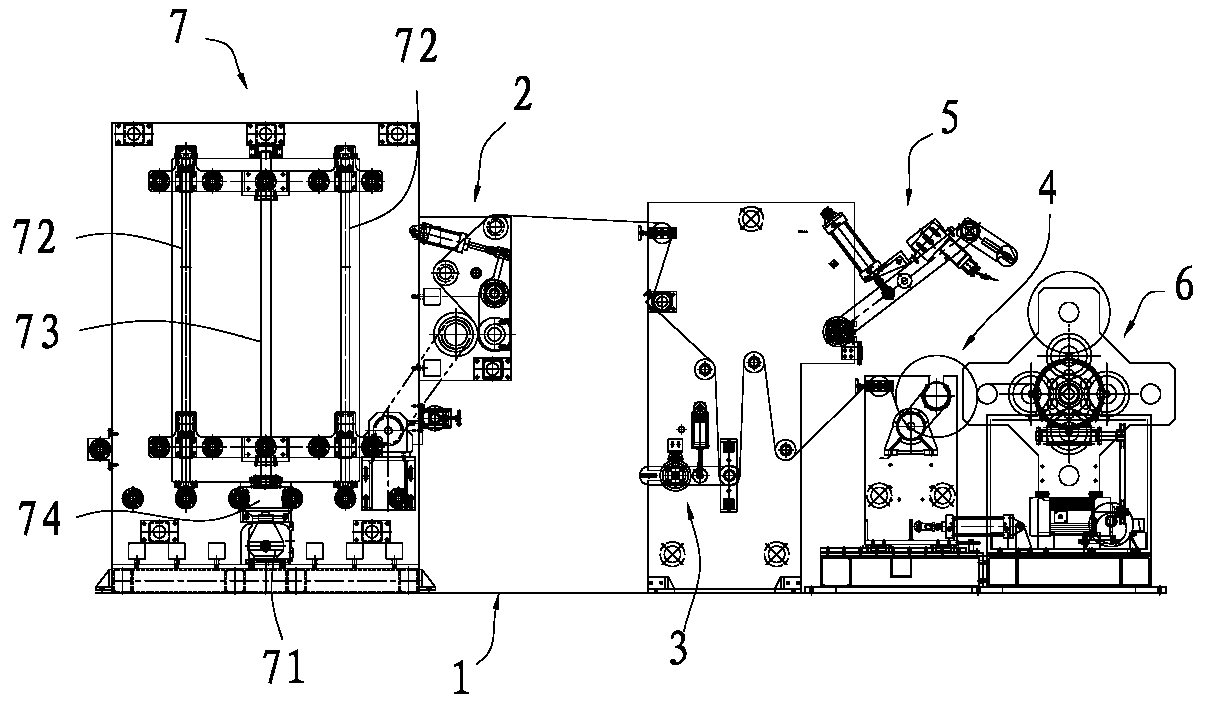

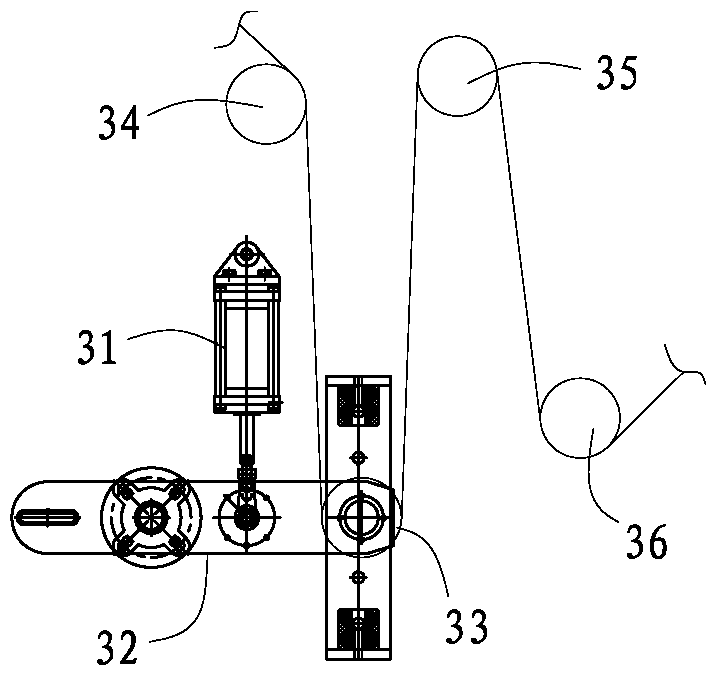

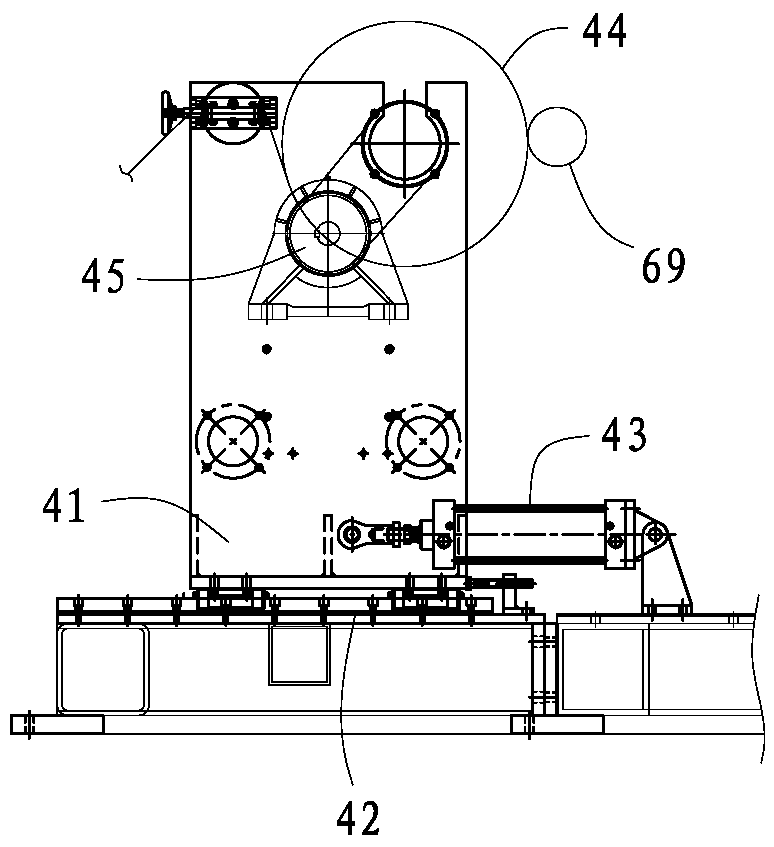

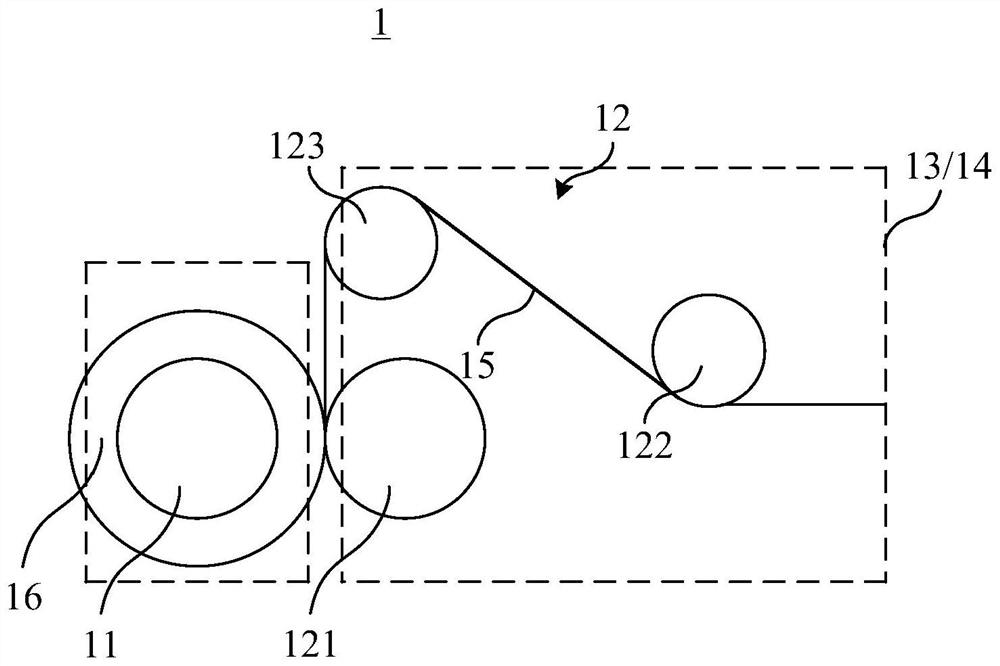

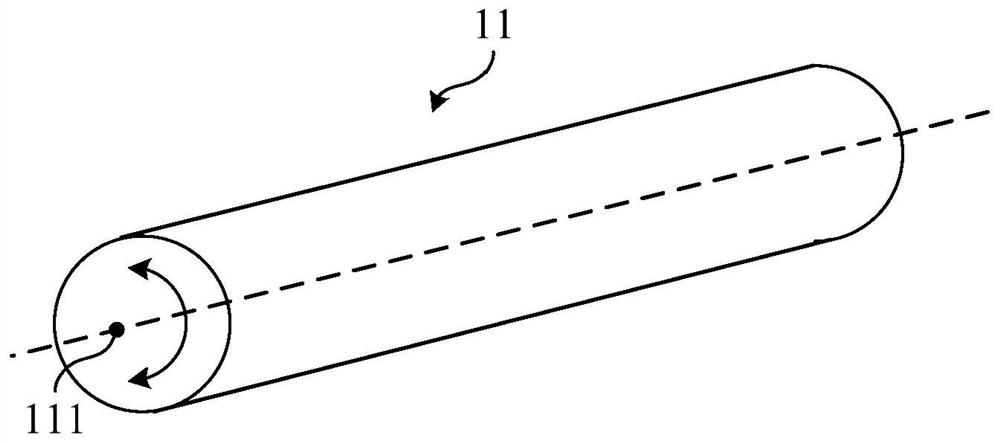

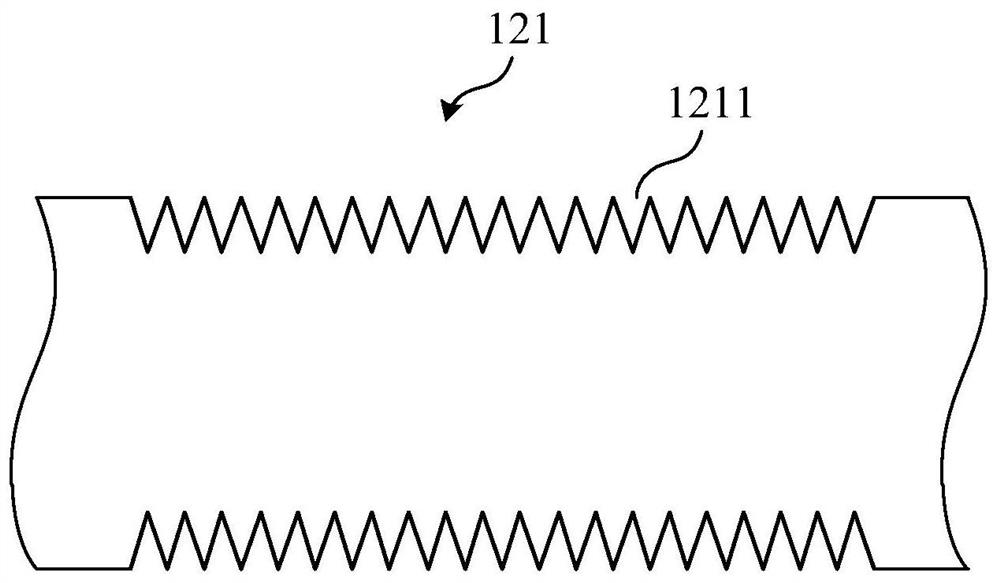

Multi-station automatic center surface coiler

ActiveCN105035812BIngenious structural designSave time changing rollsWebs handlingWinding machineProduction line

The invention discloses a multi-station full-automatic center surface recoiling machine. The multi-station full-automatic center surface recoiling machine comprises a machine frame, a traction wheel set, a floating roller set, a pressing wheel set and a recoiling and turning mechanism, wherein the traction wheel set, the floating roller set, the pressing wheel set and the recoiling and turning mechanism are sequentially arranged on the machine frame. A film breaking cutter mechanism is arranged at the position, corresponding to the position between the pressing wheel set and the recoiling and turning mechanism, of the machine frame. The multi-station full-automatic center surface recoiling machine is ingenious in structural design, and multiple recoiling stations are reasonably arranged. When roll replacement needs to be conducted, the recoiling and turning mechanism turns so that new recoiling shafts can be parallel to a pressing wheel, the film breaking cutter mechanism is started to cut off a film, the new round of recoiling work is started while recoiling is started, the roll replacement time is effectively saved, and the work efficiency is greatly improved. Meanwhile, during winding, under the cooperation of the pressing wheel set, pressure is effectively kept constant, stability is high, the bubble removal effect is greatly enhanced, the recoiling effect is good, and the product quality is ensured. In addition, a film storage set is additionally arranged, a whole production line does not need to halt during roll replacement, and the production efficiency is improved to a great extent.

Owner:DONGGUAN TURUI MECHANICS

Paper roll winding system and paper roll winding method

ActiveCN108861771BAdjust coiling tightnessReduce appearance of paper defectsWebs handlingRolling paperPaper production

The invention relates to the technical field of paper production and processing, and discloses a paper roll winding system and method. The paper roll winding system comprises a paper winding roller and a functional roller assembly. The same side ends of the paper winding roller and the functional roller assembly are separately connected to an operation platform, and the other same side ends of thepaper winding roller and the functional roller assembly are separately connected to a transmission platform. The functional roller assembly comprises a paper pressing roller, a stretching roller anda reverse acting roller. The axial directions of the paper winding roller, the paper pressing roller and the reverse acting roller are parallel to each other. The paper winding roller is capable of rotating around a central shaft of the paper winding roller to wind a paper roll, and the paper pressing roller is capable of abutting against and holding the surface of the paper roll wound by the paper winding roller and applying pressure to adjust the winding tightness of the paper roll. The stretching roller and the reverse acting roller are used for stretching a paper web before the paper web reaches the paper winding roller. In this way, the paper roll winding system and method can improve the winding effect of the paper roll.

Owner:GOLD EAST PAPER JIANGSU

Rolling machine for hot-rolled sheets with excellent rolling assisting property

A hot-rolled sheet coiling machine with better coil-helping performance has a reel, coil-helping rollers, swinging arms for supporting said coil-helping rollers, and hydraulic cylinders for driving said swinging arms. It features that 1-3 coil-helping roller are additionally used for increasing the points to where the pressure is applied, so improving its coil-helping performance.

Owner:HEBEI IRON AND STEEL

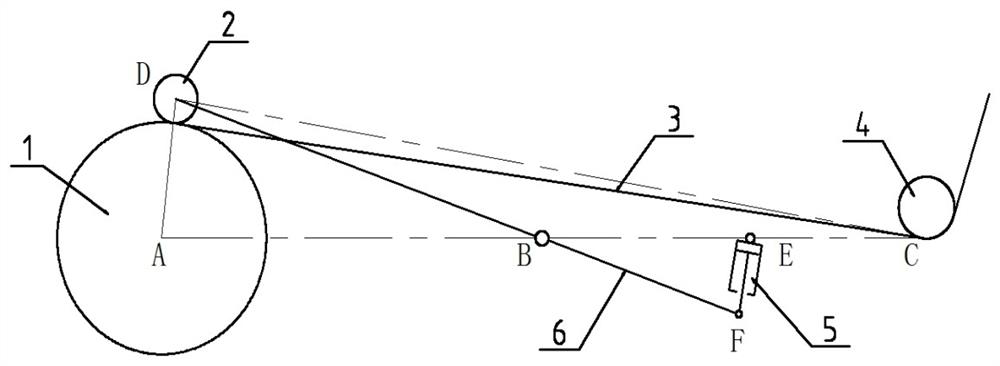

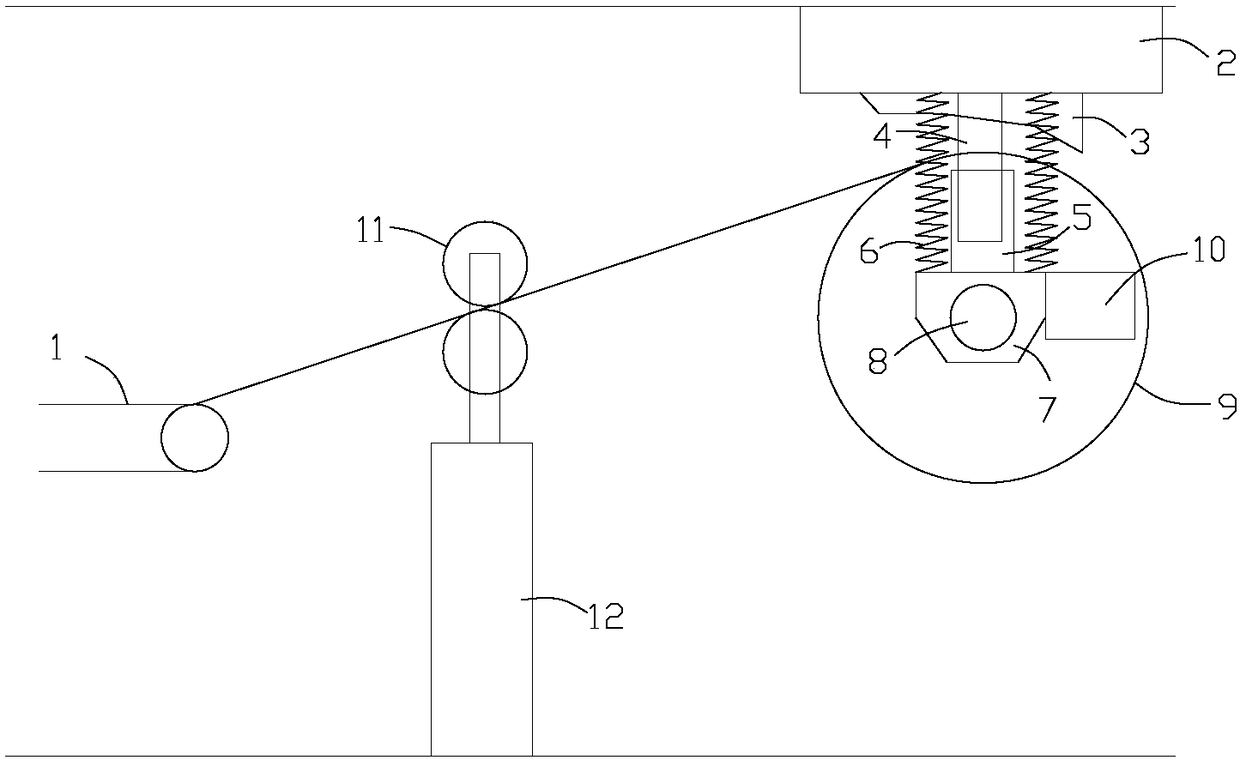

Coiled material ironing roller device of high-speed cold-rolling mill

PendingCN111889539AGood coiling effectConstant pressure control system simplifiedControl systemEngineering

Provided is a coiled material ironing roller device of a high-speed cold-rolling mill. A coiled material is tightened by a corner wrapping roller and then wound on a winding roller, and an ironing roller is disposed at one end of a lever; a projection point B of a rotary axis of the lever, a projection point A of an axis of the winding roller and a projection point C of the coiled material at a position away from a tangent of the corner wrapping roller are located on the same straight line; a projection point of an axis of the ironing roller is D; and in terms of length, AB=BC, and DB=AB+L, wherein L is less than or equal to 80 mm and greater than or equal to 35 mm. With a moving trajectory of a winding and cutting point as an object of study, the ironing roller can relatively constantly press the position 3-5 cm away from the winding and cutting point, thereby realizing the aim of the optimum coiled material winding effect. A constant pressure mechanism can exert constant pressure onthe coiled material by the ironing roller only by shaking an oil cylinder to output constant thrust, thereby simplifying a constant pressure control system of the ironing roller device.

Owner:洛阳泰盟机械制造有限公司

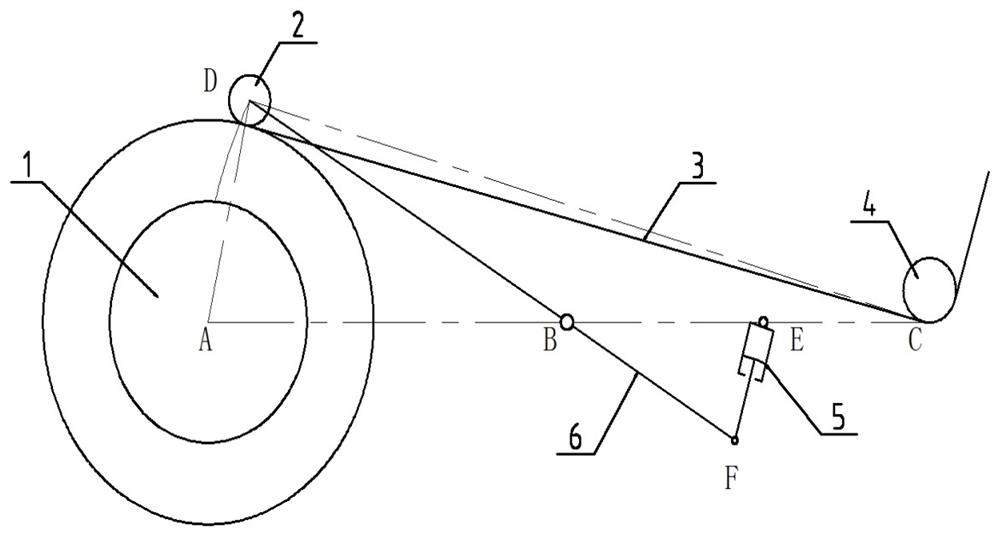

Adhesive films and adhesive film cartridges

ActiveCN107849399BImprove surface smoothnessEasy to slideFilm/foil adhesivesPolymer scienceBond line

The present invention is an adhesive film in which an adhesive layer is provided on one side of the base film, the ten-point average roughness SRz of the back side of the base film (the surface not provided with the adhesive layer) is 3000 nm or less, and the thickness d of the adhesive layer is below 3000nm. The present invention provides an adhesive film that is excellent in surface smoothness, and also excellent in sliding properties, handling properties, and winding properties.

Owner:TORAY IND INC

Preparation method of cast iron roller for pinch roller of coiler

The invention relates to a preparation method of a cast iron roller of a pinch roll of a recoiler. The preparation method comprises the following steps that 2.5-3.6 percent by weight of C, 0.5-5.0 percent by weight of Ni, 0.1-3.8 percent by weight of Cr, 1.0-3.0 percent by weight of Si, 0.2-2.7 percent by weight of Nb, 0.5-3.5 percent by weight of Mn, 0.1-2.2 percent by weight of Mo, 0.1-1.2 percent by weight of Cu, 0-1.7 percent by weight of W, less than 0.05 percent by weight of P, less than 0.06 percent by weight of S and the balance of Fe are melted at 1,450 DEG C in an induction melting electric furnace to obtain a melt; the melt is superheated to 1,500-1,550 DEG C, and is thermally insulated for 20-30 min, slag on the surface of the melt is removed, and the temperature of the melt is regulated to 1,400-1,450 DEG C; 0.5 percent of Si when the melt is discharged from the induction melting electric furnace; the melted solution is poured in a preheated centrifugal casting mold for casting; and the cast is cooled and solidified to obtain the alloy cast iron roller. The alloy cast iron roller is heat-resistant, wear-resistant, and is long in service life, and low in cost; and moreover, steel is not stuck on the alloy cast iron roller.

Owner:WUHAN SUOLITE TECH

Release film for ceramic green sheet production

ActiveCN110997258BGood coiling effectStacked capacitorsSynthetic resin layered productsPolyesterInorganic particle

[Problem] To provide a mold release film for producing ceramic green sheets that is excellent in both good windability and prevention of pinholes and partial thickness unevenness even when the ceramic green sheets are thinned. [Solution] A mold release film for producing ceramic green sheets, which uses a polyester film substantially free of inorganic particles as a base material, has a mold release coating layer on one surface of the base material, and is released from the mold by the above-mentioned mold release. In the nanoindentation test on the coating layer, the elastic modulus of the film measured from the surface on the opposite side to the substrate in the release coating layer is 2.0 GPa or more, and the other surface of the substrate has An easy-slip coating layer containing particles, the area of the easy-slip coating layer having an average surface roughness (Sa) of 1 nm or more and 25 nm or less, a maximum protrusion height (P) of 60 nm or more and 500 nm or less, and an average width of contour cells (RSm) is 10 μm or less.

Owner:TOYOBO CO LTD

Insulated rope fast winding frame

The invention discloses a rapid winding rack for an insulating rope. A fixation part comprises two supporting legs and two supporting shoes. Each supporting shoe is provided with an elongated slot; the two supporting shoes are hinged together in a width direction; the two supporting legs respectively pass through the elongated slots suspended on the supporting shoes; each supporting leg is provided with threaded holes along the cross section direction of the supporting leg; the two supporting legs are connected by adopting a threaded connector and are locked by using a nut; one of the two supporting legs is also connected with a cross bar; a winding part comprises an I-shaped support; the I-shaped support is of an integrated structure or a structure which consists of a left half and a right half and is formed by movably and detachably connecting the left half and the right half. The rapid winding rack for the insulating rope disclosed by the invention is lighter in total body mass, higher in strength and is easy to carry. By adopting the adjustable fixation part, the requirement on an installation occasion is low, and the fixation part can be installed in various occasions, and therefore, the rapid winding rack for the insulating rope is convenient to install. By adopting an adjustable crank, the radius of rotation can be conveniently changed, so that the moment of rotation is increased to achieve a labor-saving effect.

Owner:STATE GRID CORP OF CHINA +2

An industrial canvas winding device

ActiveCN106044325BPlay a flattening effectSimple structureWebs handlingEngineeringMechanical engineering

The invention discloses an industrial canvas coiling device. The device comprises a conveying belt, a fixed top frame is arranged on the outer side of the tail end of the conveying belt, a canvas pressing limiting plate is arranged on the lower side of the fixed top frame, a fixed rod is arranged at the position, below the canvas pressing limiting plate, of the fixed top frame, the fixed rod is sleeved with a movable cylinder, rotating shaft mounting heads are arranged at the lower end of the movable cylinder, a rotating shaft is connected between the two rotating shaft mounting heads, a coiling disc is fixedly mounted on the rotating shaft, the movable cylinder is fixedly connected with the fixed top frame through a tension spring, a pair of parallel guide rods are arranged between the tail end of the conveying belt and the fixed top frame, and the parallel guide rods are fixed to a lifting base; and the coiling disc can automatically descend along with increasing of the amount of coiled canvas, after the coiling disc is taken away, automatic resetting is achieved, arrangement of a drive mechanism is omitted, the structure is simplified, and the cost is reduced. Along with automatic descending of the coiling disc, the canvas pressing limiting plate can continuously flatten the canvas, the good coiling effect is ensured, and arrangement of the parallel guide rods further ensure the coiling effect.

Owner:ANHUI HUAYE ADVANCED MATERIALS CO LTD

Line belt coiling unit for braiding flat-bed machine

A rolling-up device of conveying belt in flat-knitting machine, which contains small roller, small roller axle, large roller axle, rolling-up belt, two driving axle, two groups of belt driving mechanism, several matched press-wheel acting adjusting mechanism and press-wheel fixing adjusting mechanism. Said invention has advantages of automatic adjusting rolling-up gap, small size, fine rolling-up effect, easyinstallation and adjustment, simple structure, and low cost.

Owner:冯加林

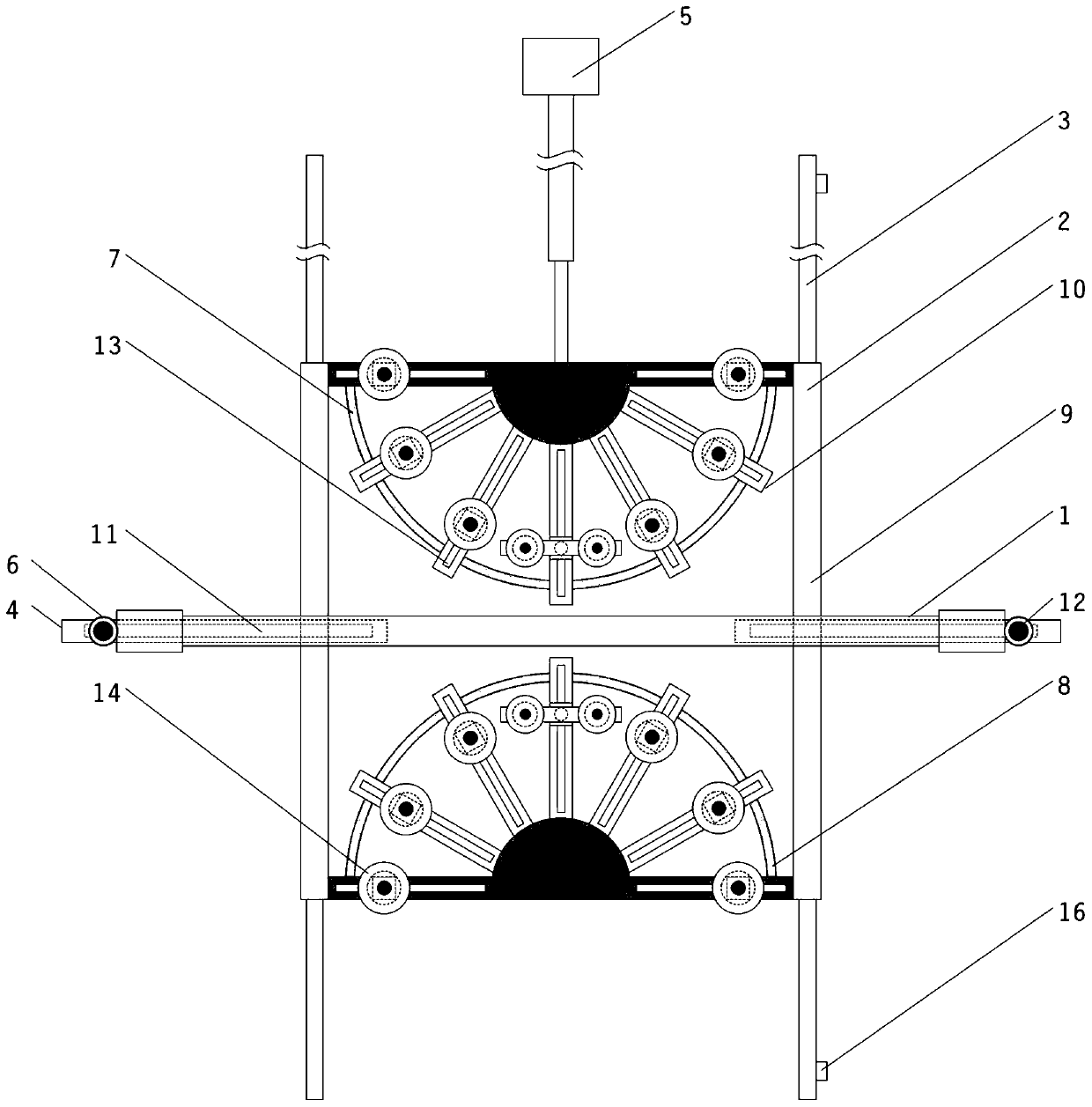

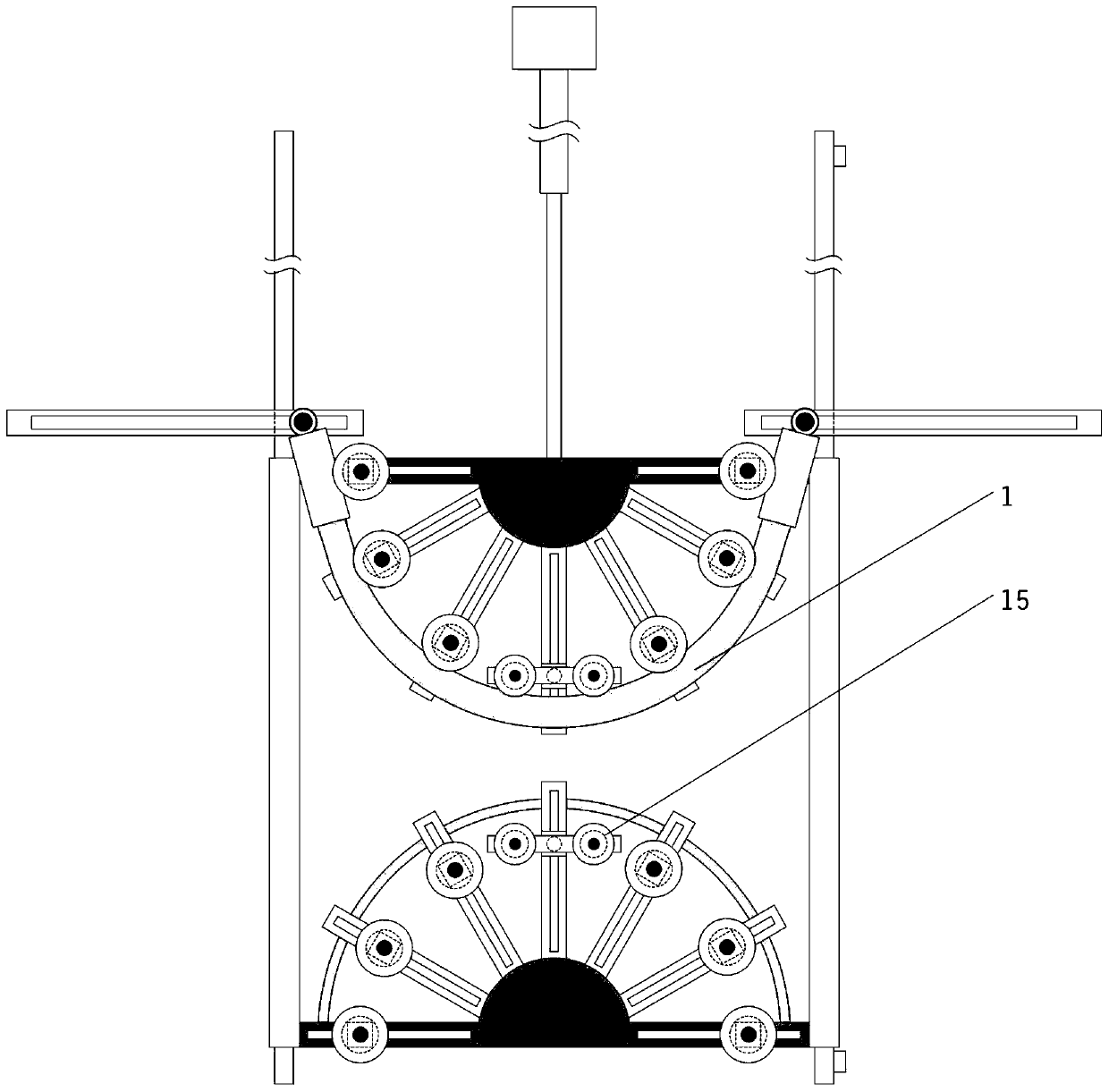

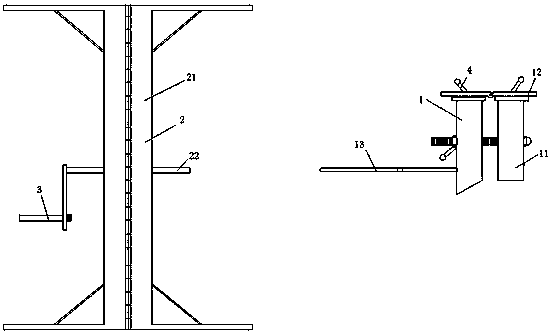

Reinforced plastic composite coiled tubing coiling performance detection testing machine and detection method

PendingCN111504808AReduce labor intensityHigh degree of automationStrength propertiesCircular discTest efficiency

The invention discloses a reinforced plastic composite coiled tubing coiling performance detection testing machine and a detection method. The testing machine comprises a sliding vehicle, a track, sample joint guide rails and a traction system, the upper half portion of the sliding trolley is a first coiling device, the lower half portion of the sliding trolley is a second coiling device, and thefirst coiling device and the second coiling device are each provided with a plurality of roller track frames. The number of the sample joint guide rails is two, the sample joint guide rails are vertically arranged above supports on the two sides of the sliding trolley respectively, a reinforced plastic composite coiled tubing sample is installed on the sample joint guide rails in a sliding mode and slides on the sample joint guide rails in cooperation with the reinforced plastic composite coiled tubing sample through sliding of the sliding trolley, and the sample is coiled on the first coilingdevice or the second coiling device. According to the testing machine and the detection method provided by the invention, the field working condition can be simulated; moreover, the testing machine is simple and convenient to operate and high in test efficiency, can form any size to simulate different disc pipe frame scrolls, can replace a large number of existing disc pipe frame real objects, saves the test cost and laboratory space, and is easy to evaluate the coiling performance of the reinforced plastic composite continuous pipe.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Rapid winding rack for insulating rope

The invention discloses a rapid winding rack for an insulating rope. A fixation part comprises two supporting legs and two supporting shoes. Each supporting shoe is provided with an elongated slot; the two supporting shoes are hinged together in a width direction; the two supporting legs respectively pass through the elongated slots suspended on the supporting shoes; each supporting leg is provided with threaded holes along the cross section direction of the supporting leg; the two supporting legs are connected by adopting a threaded connector and are locked by using a nut; one of the two supporting legs is also connected with a cross bar; a winding part comprises an I-shaped support; the I-shaped support is of an integrated structure or a structure which consists of a left half and a right half and is formed by movably and detachably connecting the left half and the right half. The rapid winding rack for the insulating rope disclosed by the invention is lighter in total body mass, higher in strength and is easy to carry. By adopting the adjustable fixation part, the requirement on an installation occasion is low, and the fixation part can be installed in various occasions, and therefore, the rapid winding rack for the insulating rope is convenient to install. By adopting an adjustable crank, the radius of rotation can be conveniently changed, so that the moment of rotation is increased to achieve a labor-saving effect.

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com