Strip steel coiling system, high-strength steel coiling method and high-strength steel production line

A technology for high-strength steel and strip steel, applied in the field of high-strength steel production lines, can solve the problems of difficult bundling of strip steel, high resilience, and accidents, so as to improve the coiling effect, reduce the rebound force, and avoid bulging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

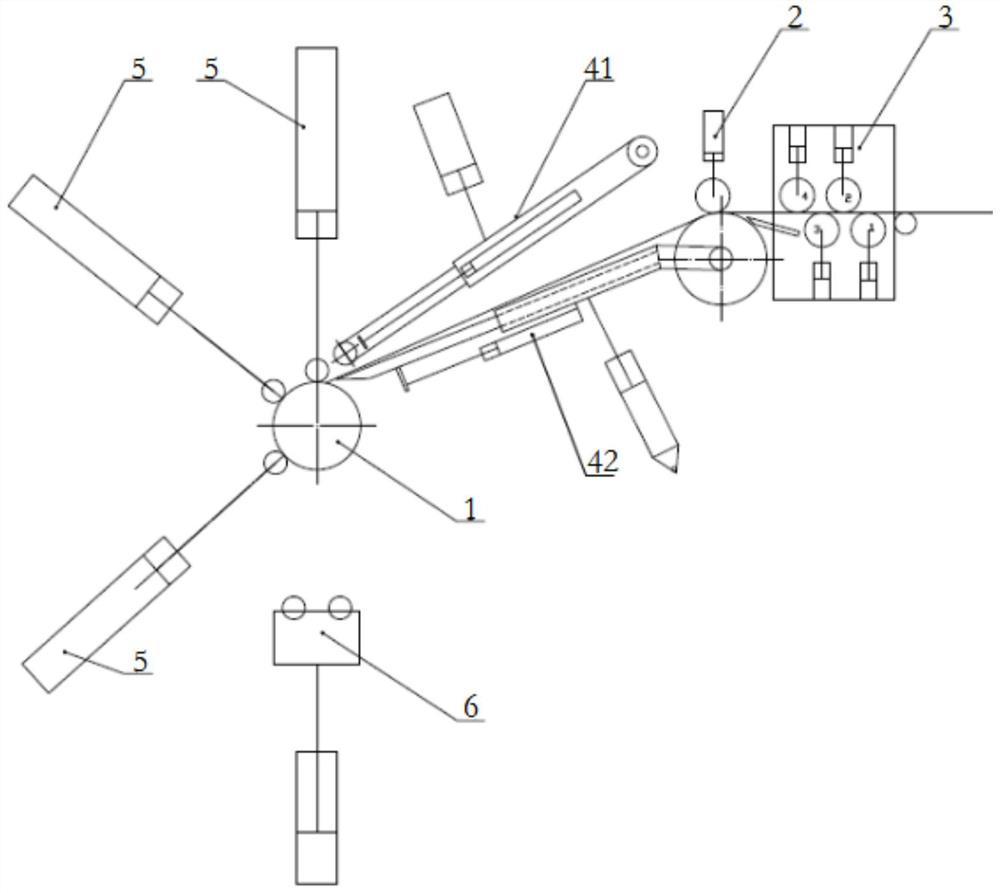

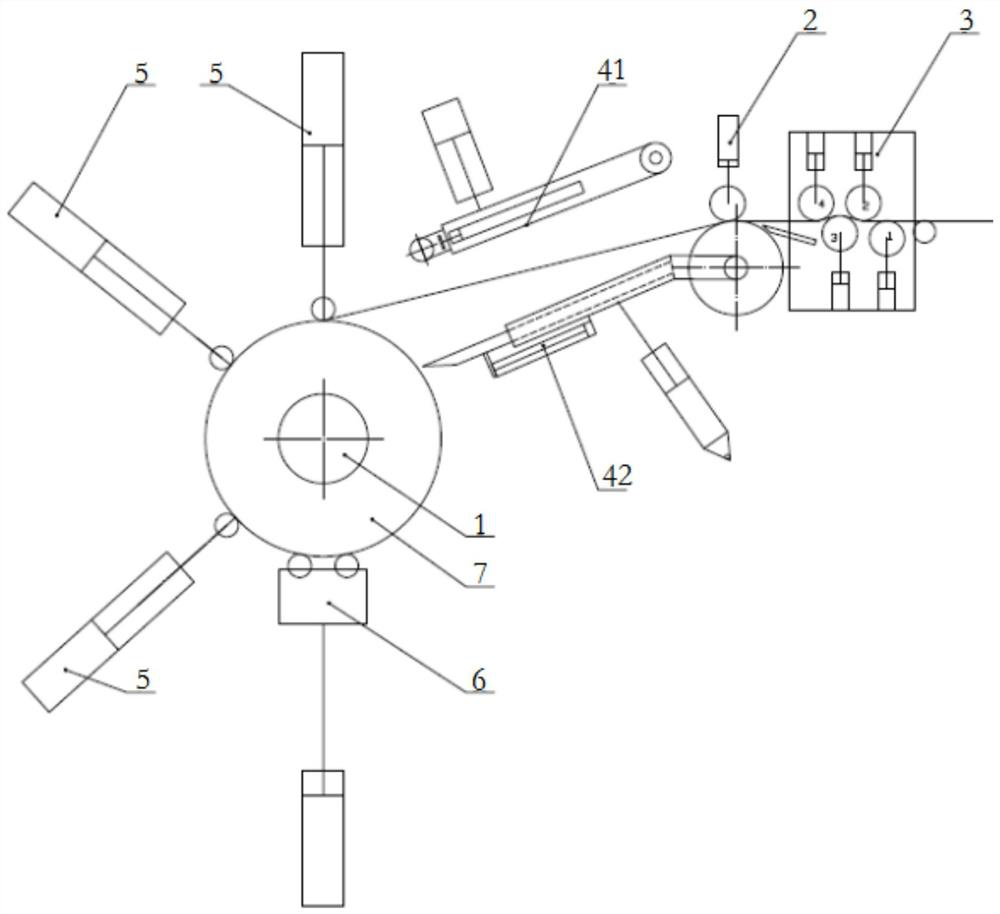

[0033] Such as figure 1 with figure 2 , the embodiment of the present invention provides a strip coiling system, including a coiler, a steering pinch roller 2 and an unloading car 6, the steering pinch roller 2 is connected with the coiler through a threading guide plate, so The incoming side of the steering pinch roller 2 is provided with a bending machine 3, and at least one auxiliary pressing roller 5 is arranged around the reel 1 of the coiler, and the axial direction of the auxiliary pressing roller 5 is in line with the reel. 1 is parallel to the axial direction, and the auxiliary pressing roller 5 is configured with a driving unit of the auxiliary pressing roller 5 so as to have a working position in rolling contact with the steel coil 7 and a standby position away from the steel coil 7 .

[0034] The coiler, the steering pinch roller 2 and the coil unloading car 6 are all conventional equipment in the field, and the specific structure will not be repeated here.

[0...

Embodiment 2

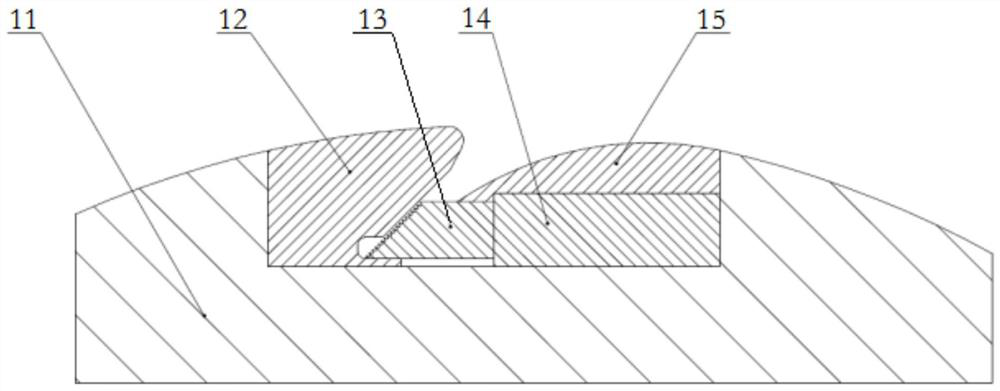

[0043] The embodiment of the present invention provides a winding jaw, which can be used on the reel 1 in the first embodiment above as the reel 1 jaw.

[0044] Such as image 3 , the jaws include a sector plate 11, a groove is formed on the sector plate 11, a fixed jaw plate 12 is provided on one side of the groove wall and a movable jaw plate is provided in the groove 13 and a jaw drive unit 14 for driving the movable jaw plate 13 close to or away from the fixed jaw plate 12, the other side of the groove is provided with an outlet guide plate 15, and the fixed jaw plate 12 is provided with an outlet guide plate 15. The jaw steel surface of the jaw plate 12 is inclined and its outer end is positioned at the side of its inner end close to the outlet guide plate 15. The space enclosed by the mouth plate 12 gradually expands from inside to outside.

[0045] Wherein, preferably, the above-mentioned jaw driving unit 14 is a hydraulic cylinder, adopting a hydraulic jaw can increa...

Embodiment 3

[0052] An embodiment of the present invention provides a high-strength steel coiling method, using the strip coiling system provided in the first embodiment above to coil the high-strength steel strip, and the method includes:

[0053] a. If figure 1 In the early stage of coiling, the bending machine 3 is used to straighten the strip steel, so as to prevent the strip steel from warping or bowing to damage the strip guide plate, and to make the strip steel, especially the high-strength steel, enter the clamp of the reel 1 smoothly and accurately. Mouth; The specific straightening operation has been mentioned in the above-mentioned embodiment one, and will not be repeated here.

[0054] The steel strip is guided to the reel 1 by the turning pinch roller 2 and the threading guide plate, which is a conventional operation in the art, and will not be described in detail here;

[0055] The jaws of the reel 1 clamp the strip steel, and the diameter of the reel 1 expands to establish ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com