Rapid winding rack for insulating rope

A technology of insulating ropes and coiling wires, which is applied in the field of coiling racks, can solve the problems of easy intertwining of wires, high labor intensity of coiling, and different coil lengths. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

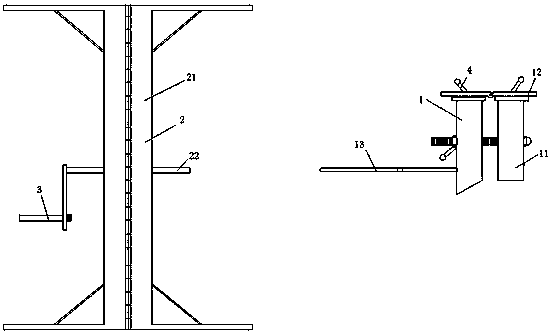

[0021] a kind of like figure 1 The insulating rope fast coiling stand shown in -2 includes a fixing part 1 and a coiling part 2, and the fixing part includes two supporting feet 11 and two supporting blocks 12, along the length of the two supporting blocks There are two long grooves in the direction, and the two support blocks are hinged together in the width direction. The two support feet are respectively suspended on the long grooves of the support block, and threaded holes are arranged on the two support feet along the direction of their cross section. The two supporting feet are connected by threaded connectors and locked with nuts. One of the supporting feet is also connected with a cross bar 13. The coil portion includes an I-shaped support 21, and the I-shaped support is The structure is composed of left and right halves with movable and detachable connections between the two halves. On the left side of the middle part of the bracket, there is a through hole that runs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com