Transparent conductive film and touch panel

一种透明导电性、透明导电层的技术,应用在绝缘载体上的导电层、电路、电气元件等方向,能够解决薄膜处理性差、透明导电性薄膜卷曲、表面凹凸形成不充分等问题,达到处理性优异、透明性及外观特性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] (Preparation of Coating Composition)

[0107] Prepare a resin solution as follows: a resin solution containing a resin composition for forming surface irregularities by phase separation and a resin component including a photopolymerization initiator at a solid content concentration of 60% by weight in a mixed solvent of methyl ethyl ketone and methyl isobutyl ketone (trade name "Lucifral NAB-007" manufactured by Nippon Paint Co., Ltd.).

[0108] Acrylic fine particles (trade name "BMSA-18GN" manufactured by Sekisui Plastics Co., Ltd. (average particle diameter: 0.8 μm)) were dispersed in methyl isobutyl ketone, and the dispersion was mixed with the aforementioned resin solution to prepare A coating composition containing 0.1 part by weight of acrylic fine particles per 100 parts by weight of a resin component and having a solid content concentration of 40% by weight.

[0109] (Formation of cured resin layer)

[0110] Using a bar coater, the aforementioned coating compos...

Embodiment 2

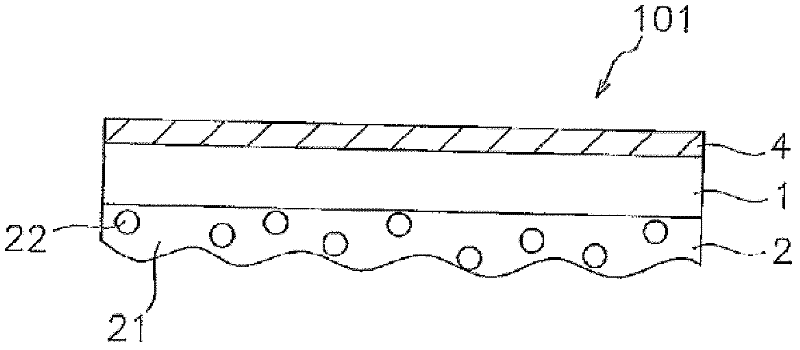

[0115] In Example 1, except that the thickness of the cured resin layer was changed to 2.7 μm, it was formed in the same manner as in Example 1. figure 1 A transparent conductive film in the stacked form shown.

Embodiment 3

[0117] In Example 1, except that the thickness of the cured resin layer was changed to 1.1 μm, the same method as in Example 1 was formed. figure 1 A transparent conductive film in the stacked form shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com