Anti-vibration plate and material transport device applying same

A technology for conveying devices and objects is applied in the field of anti-shake plates and object conveying devices applying the anti-shake plates, which can solve the problems of affecting the copying effect, breaking and coiling of the paper web, and needing energy consumption, so as to reduce the chance of object breaking. , The device is simple, the effect of preventing jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

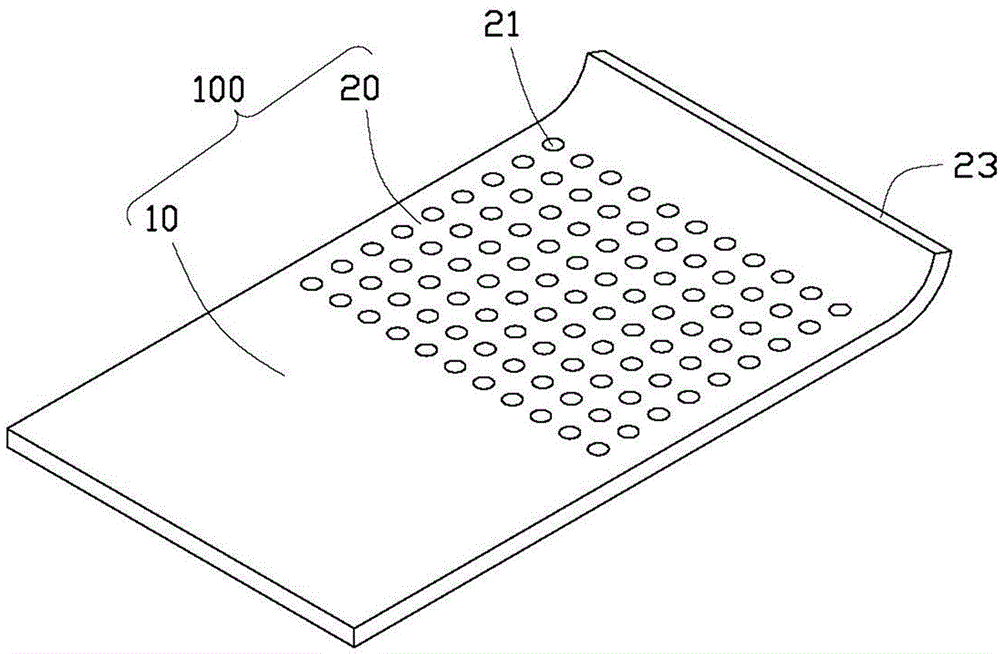

[0013] see figure 1 , the anti-shake plate 100 of the present invention is roughly a plate structure, which includes a first part 10 and a second part 20 integrally connected. The first part 10 is a plate structure. The second part 20 is also a plate structure with a plurality of through holes 21 defined therein. The shape of the through hole 21 is not limited, and may be a circular hole, a square hole, a rectangular hole, an oval hole, a triangular hole or other shapes.

[0014] The second portion 20 has an end portion 23, and the end portion 23 can be configured to have a certain curvature and be upturned.

[0015] The length ratio between the second part 20 and the first part 10 is (1:10)-(1:1).

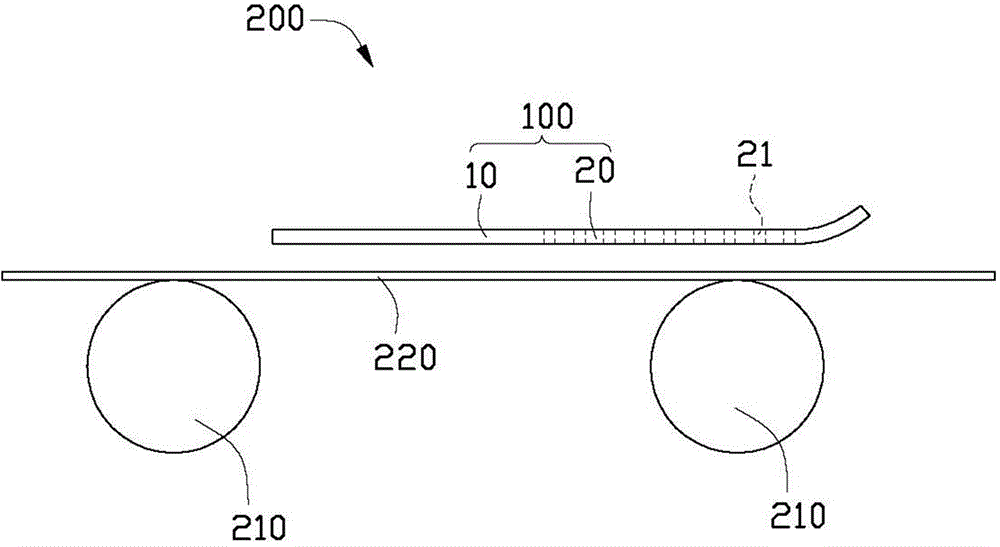

[0016] see figure 2 , an object conveying device using the above-mentioned anti-shake plate 100, the object is a light and thin sheet object, such as paper web, plastic film or cloth. This embodiment is described using a papermaking device 200 in the papermaking field. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com