Release film for ceramic green sheet production

A ceramic green sheet and mold release film technology, which is applied in the direction of manufacturing tools, capacitor manufacturing, ceramic molding machines, etc., can solve the problems of low protrusion density, large protrusions, pinholes, etc., and achieve good coilability and prevent pinholes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0195] (Preparation of Easy Slip Coating Liquid 1)

[0196] An easy-slip coating liquid 1 having the following composition was prepared.

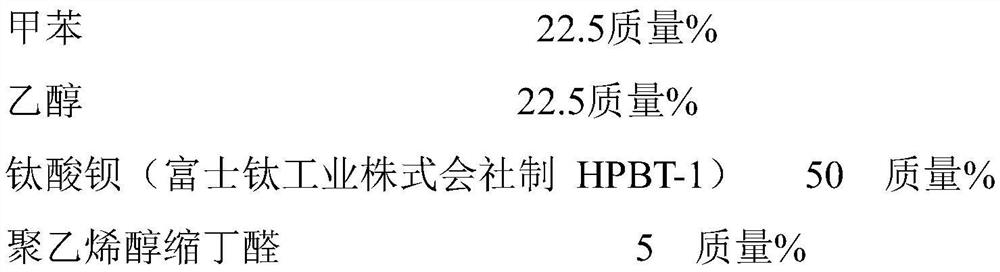

[0197] (Easy Slip Coating Liquid 1)

[0198]

[0199]

[0200] (Manufacture of polyester film)

[0201] As a film raw material polymer, a PET resin pellet (PETII) having an intrinsic viscosity (solvent: phenol / tetrachloroethane=60 / 40) of 0.62 dl / g and substantially no inorganic particles was used under a reduced pressure of 133 Pa. , and dried at 135°C for 6 hours. Then, it was supplied to an extruder, melt-extruded into a sheet form at about 280 degreeC, and was quenched and solidified on the rotating cooling metal roll which kept the surface temperature at 20 degreeC, and the unstretched PET sheet was obtained.

[0202] The unstretched PET sheet was heated to 100° C. with a heated roll set and an infrared heater, and then stretched 3.5 times in the longitudinal direction by a roll set having a peripheral speed difference to obtai...

Embodiment 2

[0210] Except having changed the easy-slip coating liquid 1 to the following easy-slip coating liquid 2, it carried out similarly to Example 1, and obtained the mold release film for ultrathin-layer ceramic green sheet manufacture.

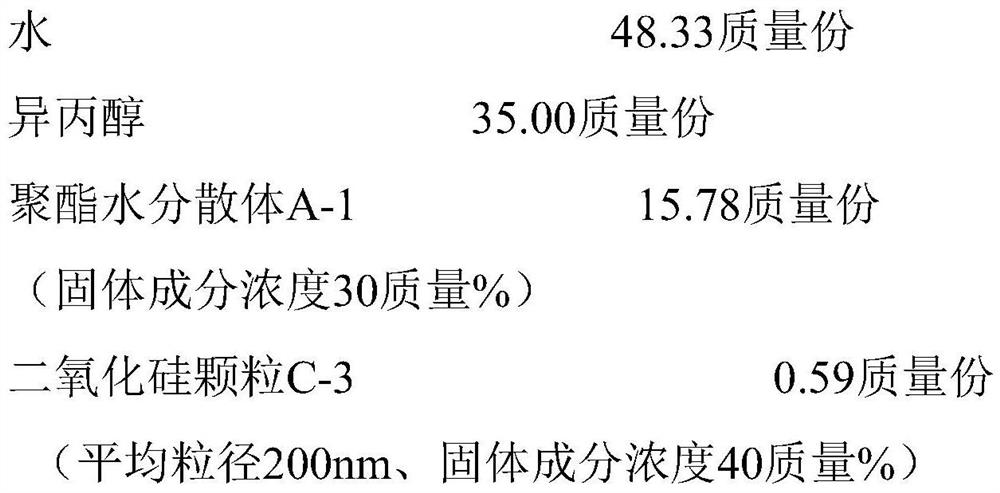

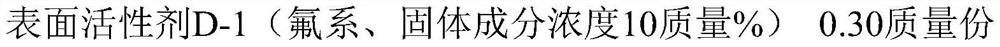

[0211] (Easy Slip Coating Liquid 2)

[0212]

Embodiment 3

[0214] Except having changed the easy-slip coating liquid 1 to the following easy-slip coating liquid 3, it carried out similarly to Example 1, and obtained the release film for ultrathin-layer ceramic green sheet manufacture.

[0215] (Easy slip coating solution 3)

[0216]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com