Aluminum alloy sheet and production method thereof

A production method and an aluminum alloy technology are applied to the 6016 series aluminum alloy sheet for automobile body and the production field thereof to achieve the effects of eliminating poor paint hardening, reducing costs and achieving significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

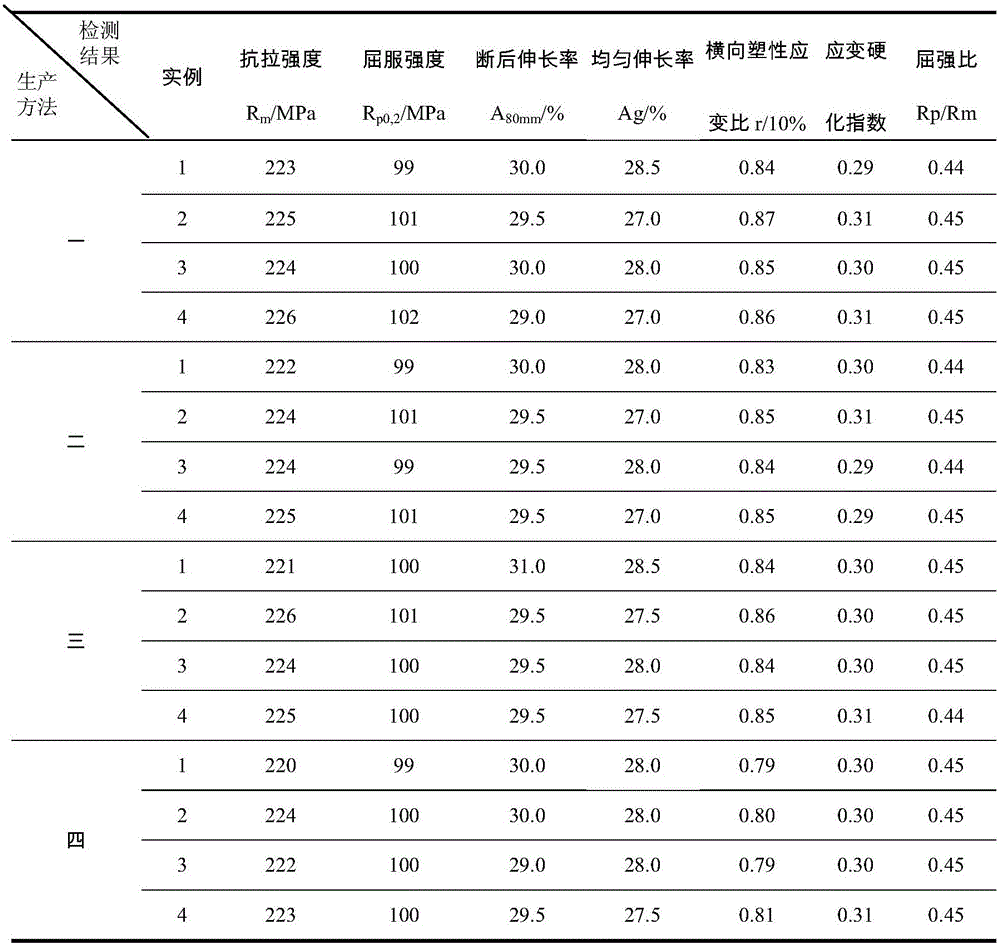

Examples

Embodiment Construction

[0024] The invention discloses an aluminum alloy thin plate, whose chemical composition and mass percentage are: Si 1.0-1.1%, Fe 0.16-0.22%, Cu 0.12-0.16%, Mn 0.08-0.12%, Mg 0.45-0.45%, Cr 0-0.10%, Zn 0-0.10%, Ti 0-0.10%, the balance being Al. . The production method of the present invention includes: batching → smelting → converter → furnace side refining → standing → casting → sawing → milling → ingot homogenization treatment → hot rolling → intermediate annealing → cold rolling → EDM texturing → cold Rolled product → solution quenching → tension straightening (permanent deformation rate) → Ti / Zr passivation → pre-aging → finished coil.

[0025] The present invention will be further described below in conjunction with some specific examples.

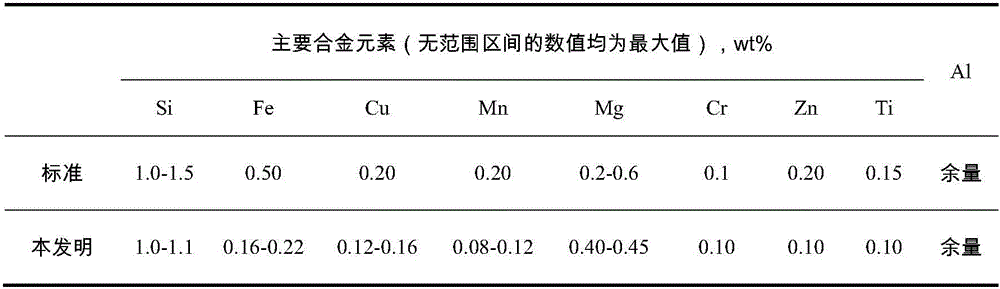

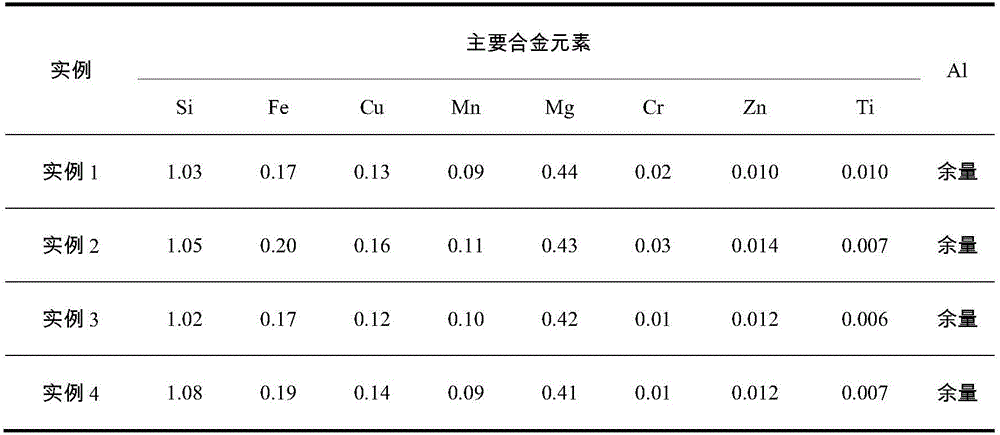

[0026] A kind of 6016 alloy sheet for automobile body, its chemical composition and mass percentage are shown in Table 1.

[0027] Table 1 The measured value of the alloy composition (wt%)

[0028]

[0029] One of the production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com