A balance compensation chain suitable for wide-car elevators and its preparation process

A technology of preparation process and balance compensation, which is applied in mine lifting equipment, elevators, transportation and packaging, etc., can solve the problems of reducing the service life of products, not controlling the bending diameter, and compensating chain suspension systemic problems, so as to improve efficiency , improve the service life and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

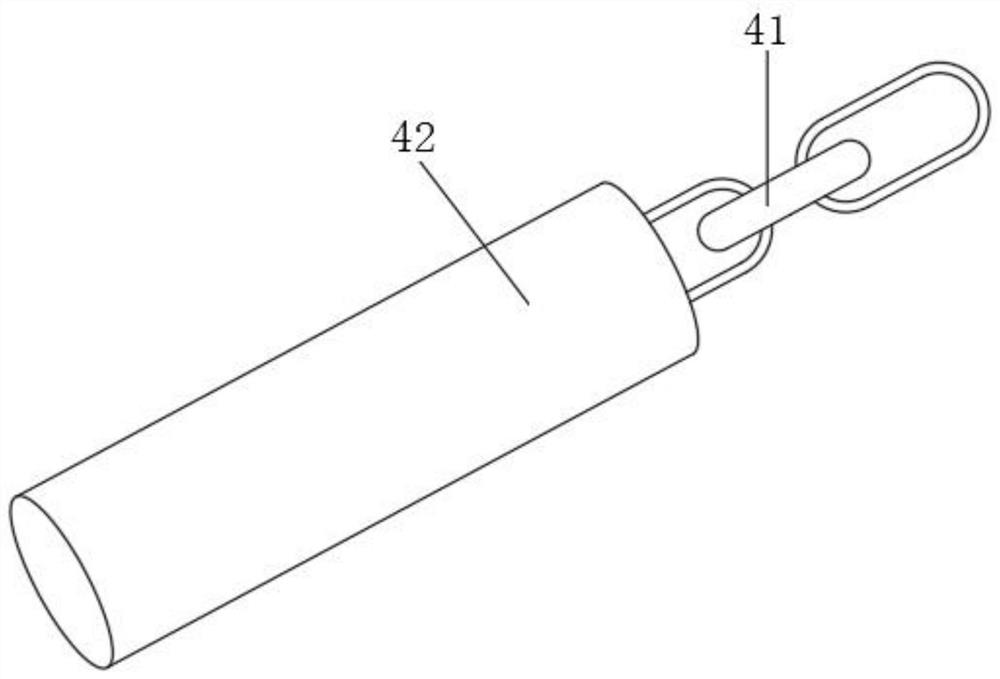

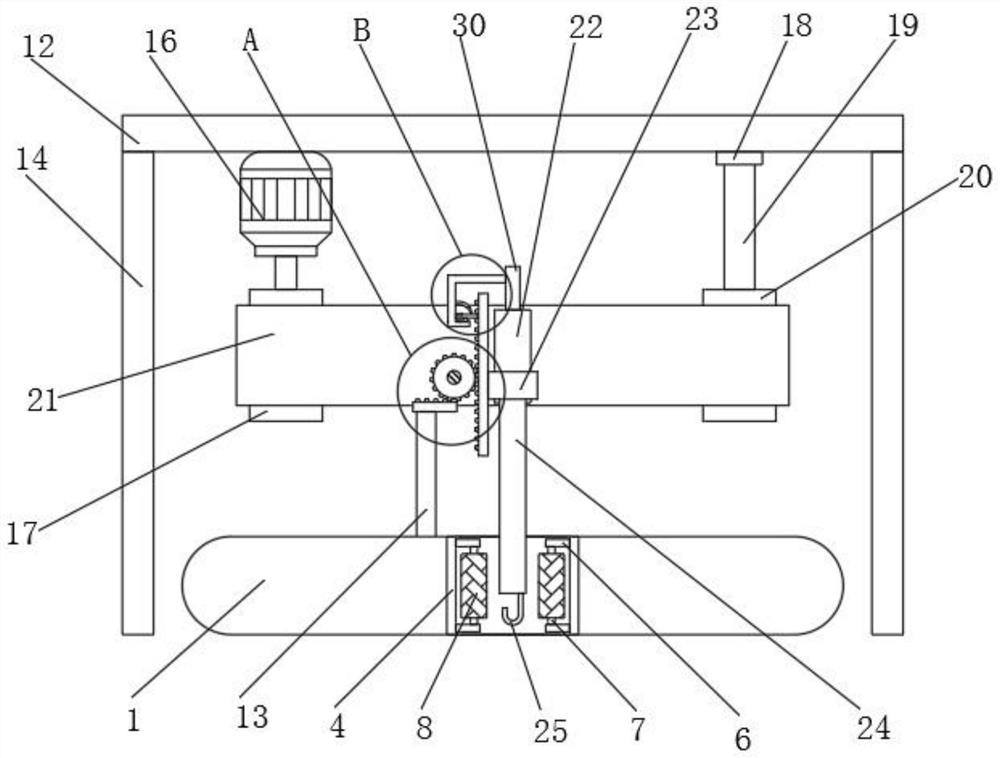

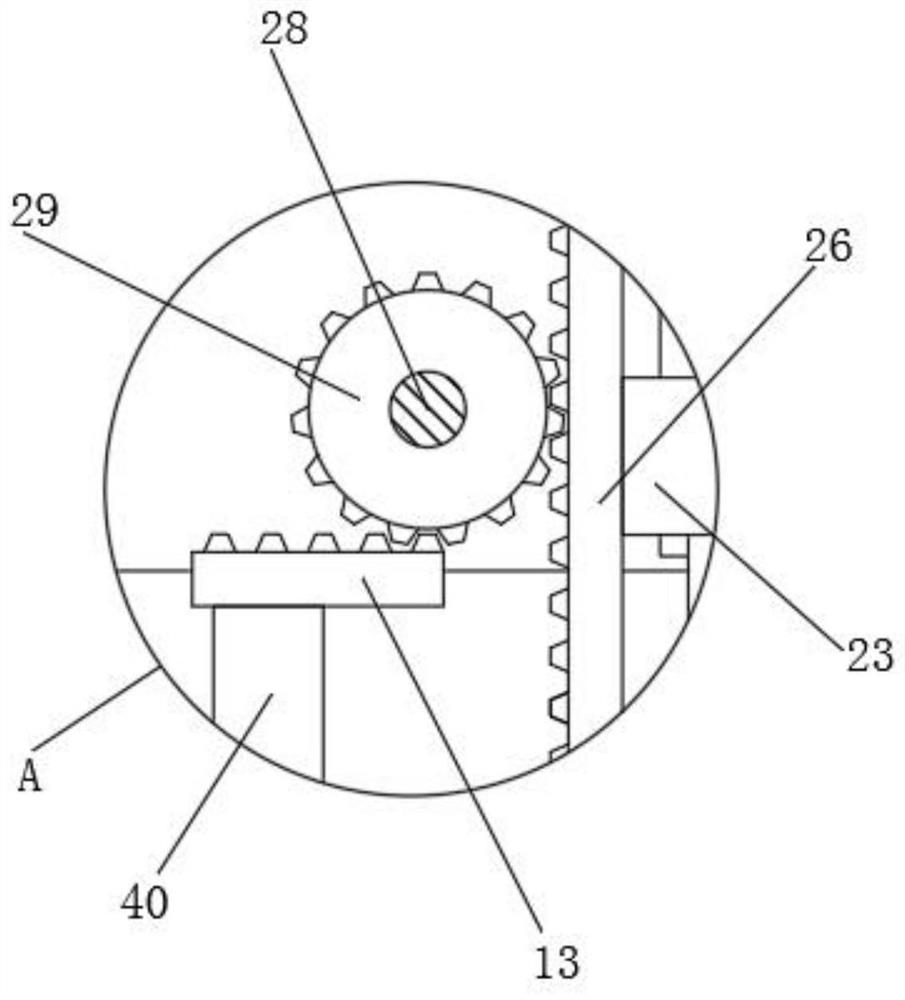

[0048] see figure 1 with Figure 10 , a kind of balance compensation chain applicable to wide car elevators and its preparation process, comprising a compensation chain chain 41, a suspension device and a preparation process, the outer wall of the compensation chain chain 41 is provided with an outer cladding layer 42, and the material of the outer cladding layer 42 is environmentally friendly Type polyvinyl chloride, the hardness of environment-friendly polyvinyl chloride material can reach Shore hardness 80-98, thereby improving the service life, the suspension device includes connecting rope 43 and connecting head 44, both ends of connecting rope 43 are fixedly connected with connecting head 44, the suspension device and the compensating chain chain 41 are used together.

[0049] The preparation process comprises the following steps:

[0050] S1. Take an appropriate amount of environmentally friendly polyvinyl chloride and put it into a single-screw extruder of the model ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com