Adhesive films and adhesive film cartridges

A technology of adhesive film and adhesive layer, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of sufficient productivity and high cost, and achieve the effect of excellent coilability and surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

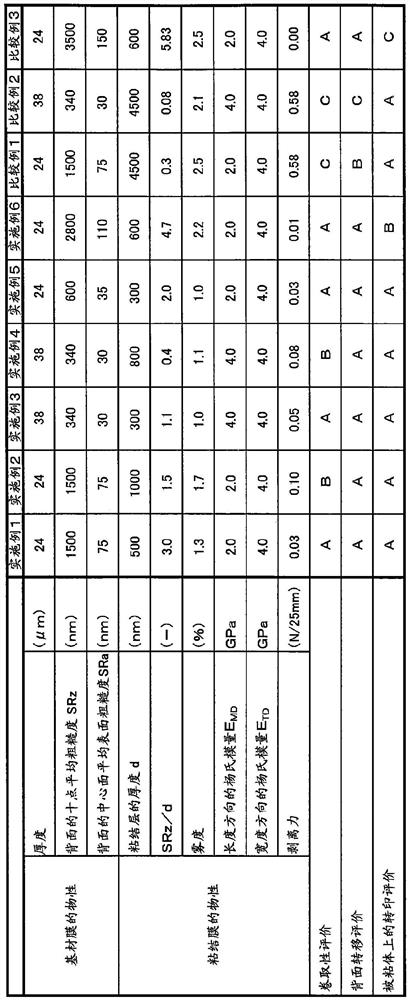

Embodiment 1

[0102] For the base film, crystalline polypropylene (manufactured by Prime Polymer Co., Ltd., TF850H, MFR: 2.9 g / 10 minutes, ratio of isotactic pentads (mesopentad): 0.94) was supplied to a uniaxial melt extrusion Machine, melt extrusion at 240°C, use a 60μm threshold (cut) sintered filter to remove foreign matter, discharge it to the casting drum whose surface temperature is controlled at 30°C, and use an air knife to make it tightly bonded to the casting drum. Thereafter, compressed air at a temperature of 30° C. and a pressure of 0.3 MPa was sprayed onto the uncooled drum surface of the sheet on the casting drum to cool it, thereby obtaining an unstretched sheet. Next, this sheet was preheated to 140° C. using ceramic rolls, and stretched 4.6 times in the longitudinal direction of the film between rolls at 140° C. provided with a peripheral speed difference. Next, the ends are held by clips and introduced into a tenter-type stretching machine, preheated at 170°C for 3 secon...

Embodiment 2

[0105] In Example 1, except that the thickness of the adhesive layer was 1000 nm, the adhesive film was directly wound up for 1000 m by the same method as in Example 1 (without passing through a release film) to obtain an adhesive film tube. Although no wrinkling occurs when the tube is taken up, some air bites in. Table 1 shows the properties and evaluation results of the adhesive film.

Embodiment 3

[0107] In Example 1, the PET film (manufactured by Toray Co., Ltd., T60 (38 μm) was used as the base film, and the thickness of the adhesive layer was 300 nm. In addition, the same method as in Example 1 was used to directly bond the adhesive film ( In the case of not passing through the release film), it was wound up for 1000 m to make an adhesive film tube. Wrinkles, air bite, etc. did not occur when the tube was wound up, and the appearance was good. The physical properties and evaluation results of the adhesive film are shown in the table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com