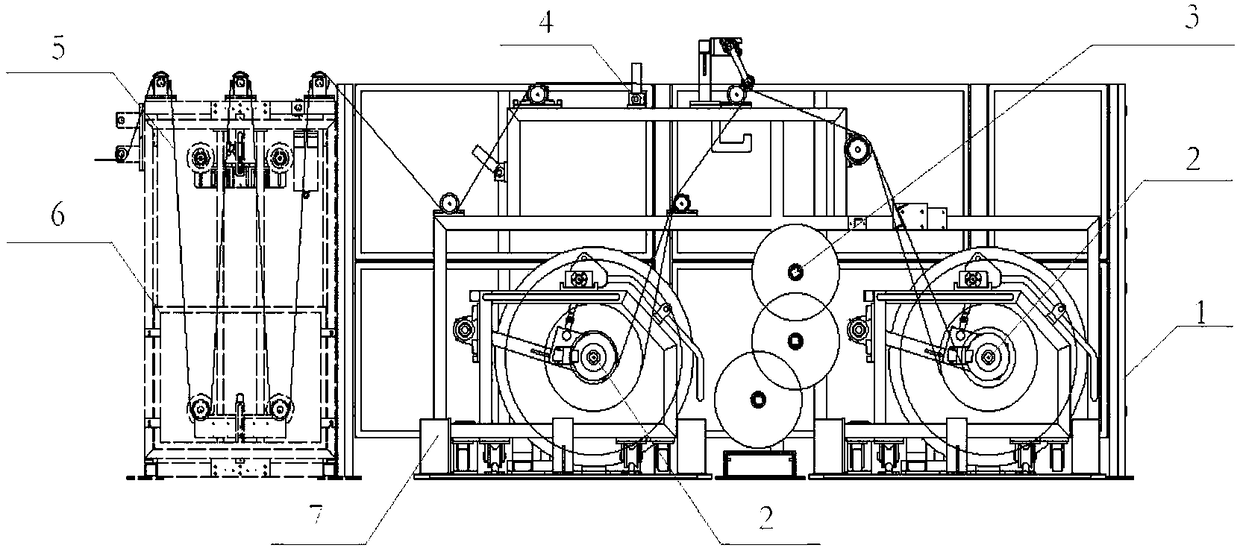

Device for coiling half-product zero-degree belted layer

A belt layer and semi-finished product technology, applied in the field of tire manufacturing equipment, can solve the problems of poor precision control, high mechanical noise, and long time-consuming, and achieve high control accuracy, low noise, and long time-consuming problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

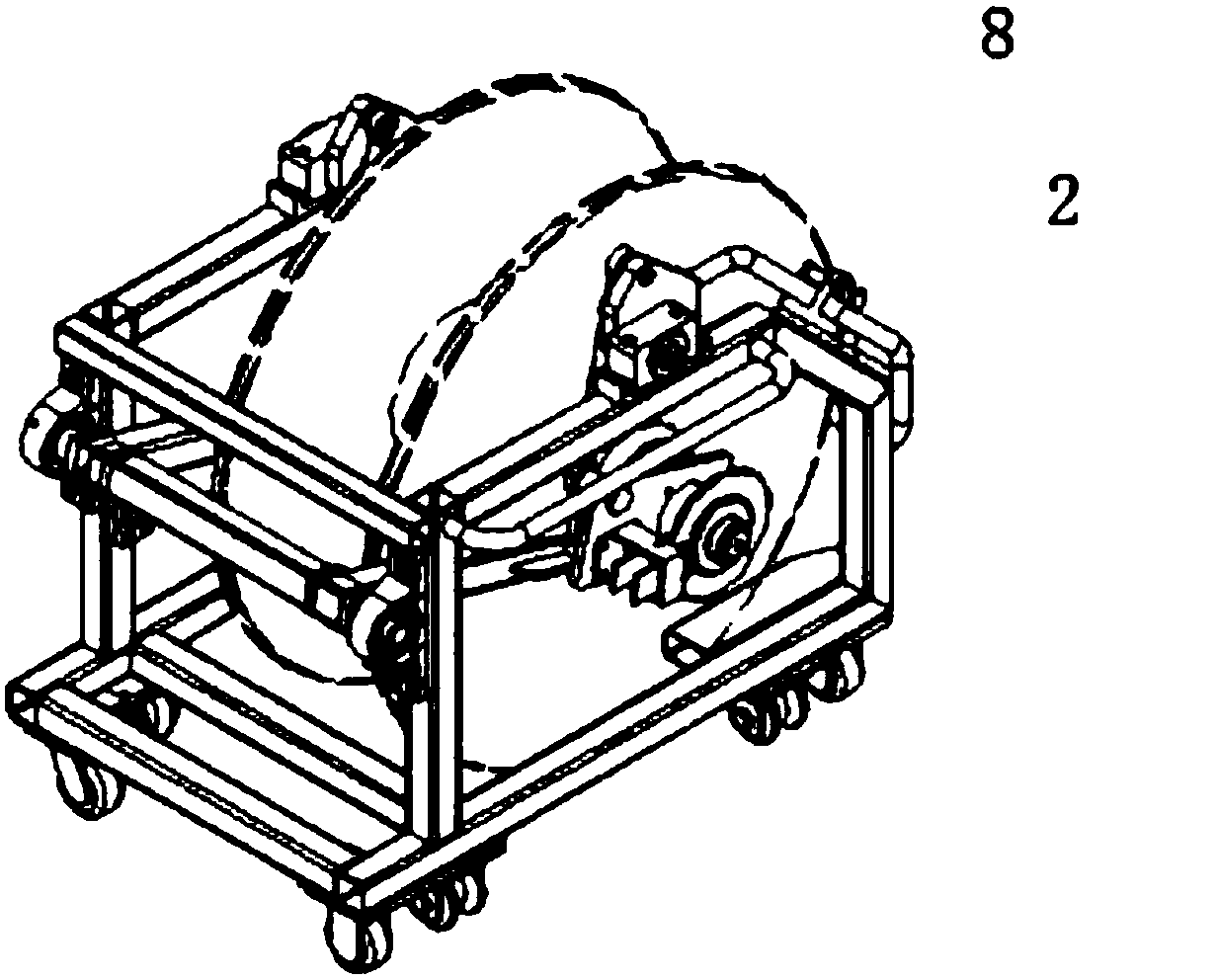

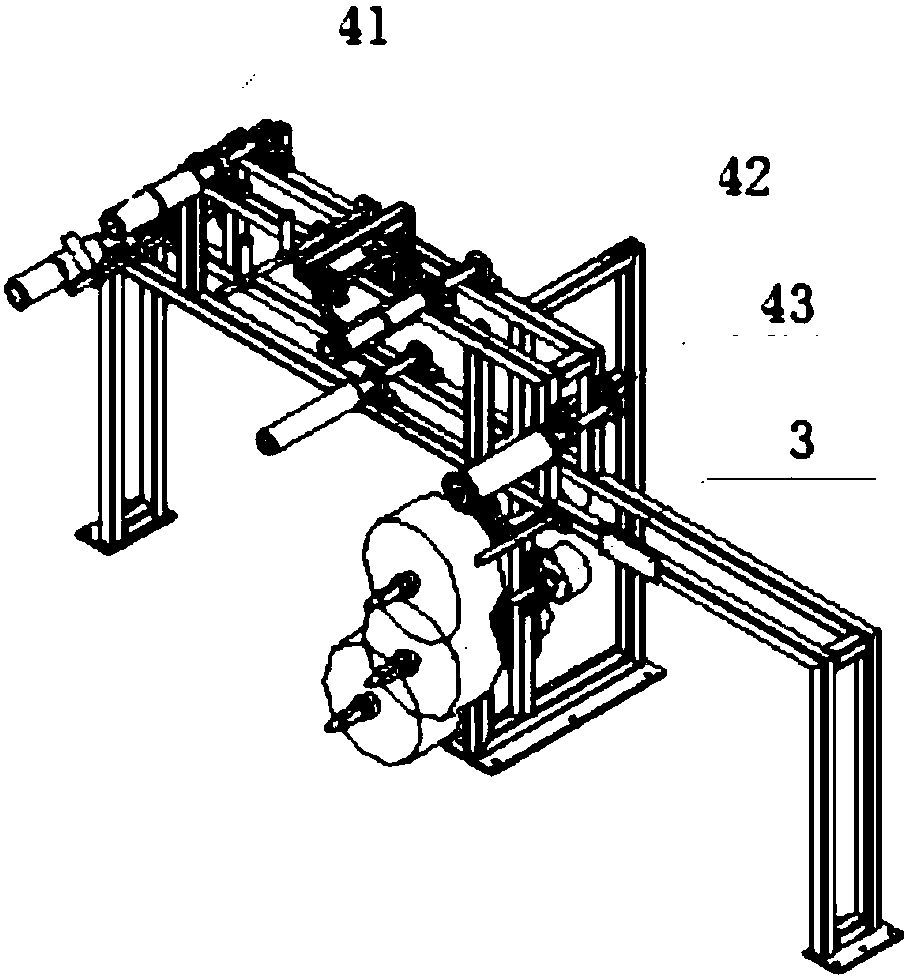

[0030] Specific implementation method: in actual use, the user puts the I-shaped wheel 8 on the fixed rod on the coiling trolley 2, and then the user turns the nut, and the rotation of the nut drives the baffle plate 71 to move forward, and the baffle plate 71 moves forward The movement drives the I-shaped wheel 8 to move forward along the fixed rod, and then clamps the I-shaped wheel 8, then stops turning the nut, and then the user pushes the coiling trolley 2 backwards, thereby causing the moving wheel on the coiling trolley 2 to Enter the track 72, and then cause the coiling trolley 2 to move backward along the track 72, the coiling trolley 2 moves backward and drives the I-shaped wheel 8 to move backward, and the I-shaped wheel 8 moves backward to contact with the chuck 75 , stop moving the coiling trolley 2, and then the user will pull out one end of the belt layer product 5 from the inside of the storage rack 6, and then pass the one end of the belt layer product 5 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com