Line belt coiling unit for braiding flat-bed machine

A technology of coiling device and conveyor belt, applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of large debugging workload, high manufacturing requirements, complex structure and installation process, etc., and achieve convenient installation and debugging, even pulling The effect of pulling force and good coiling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

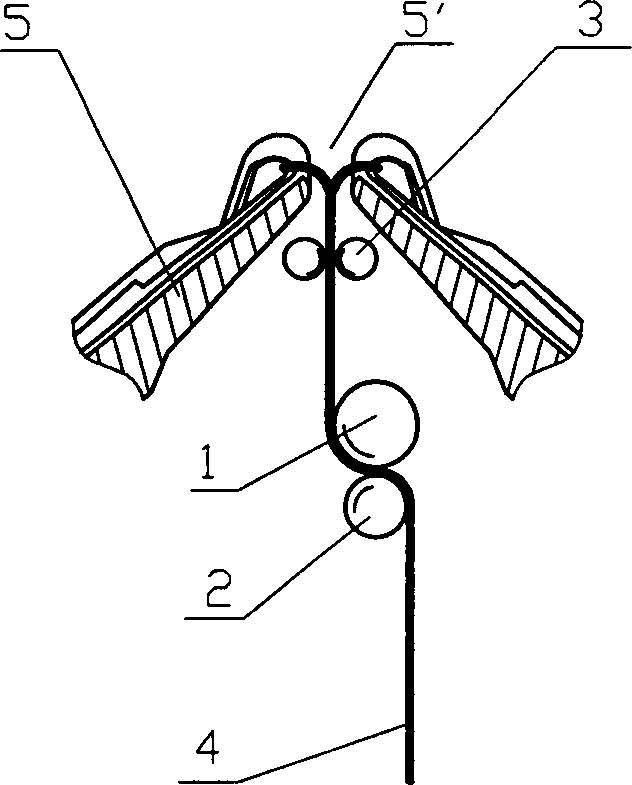

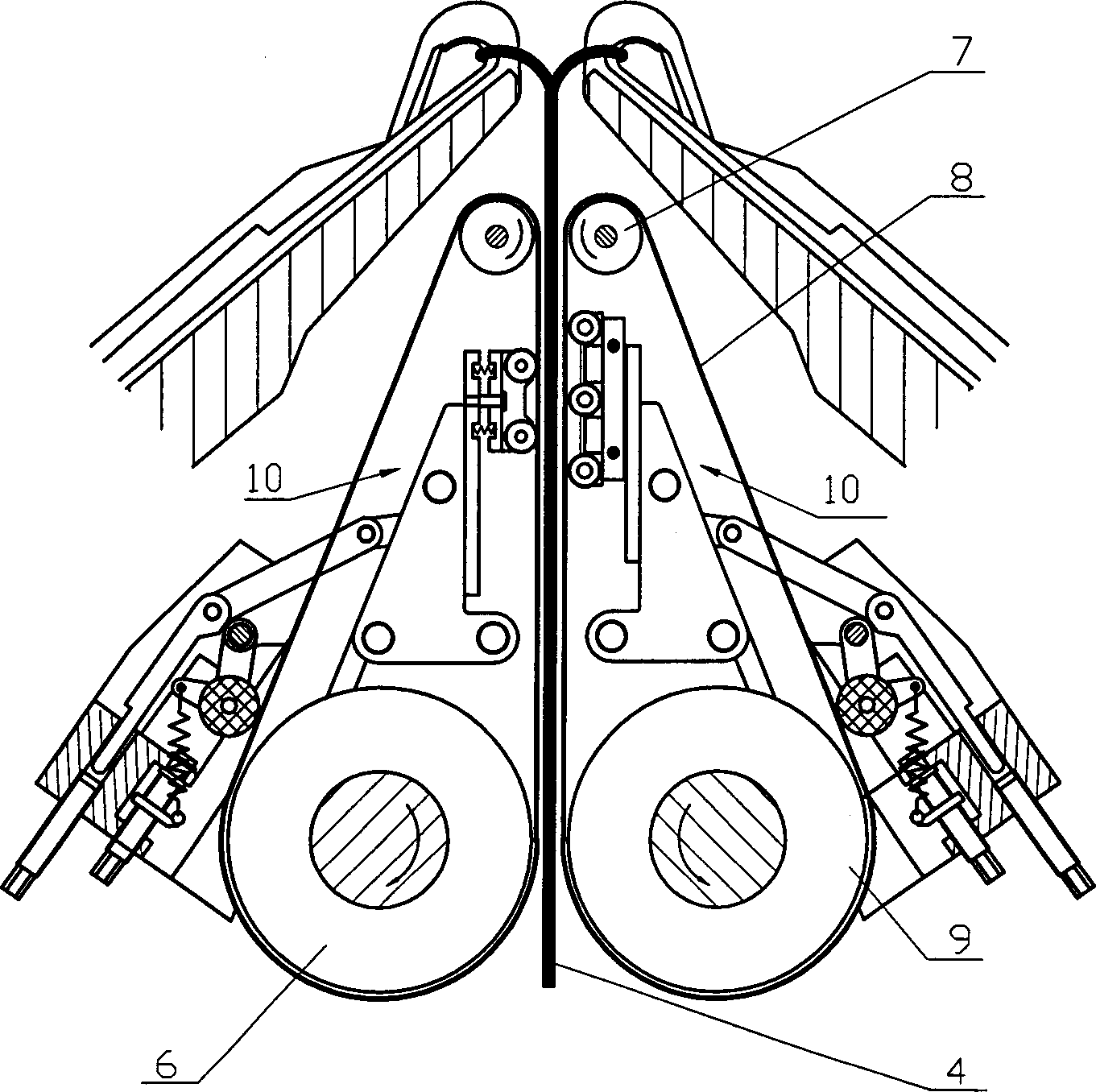

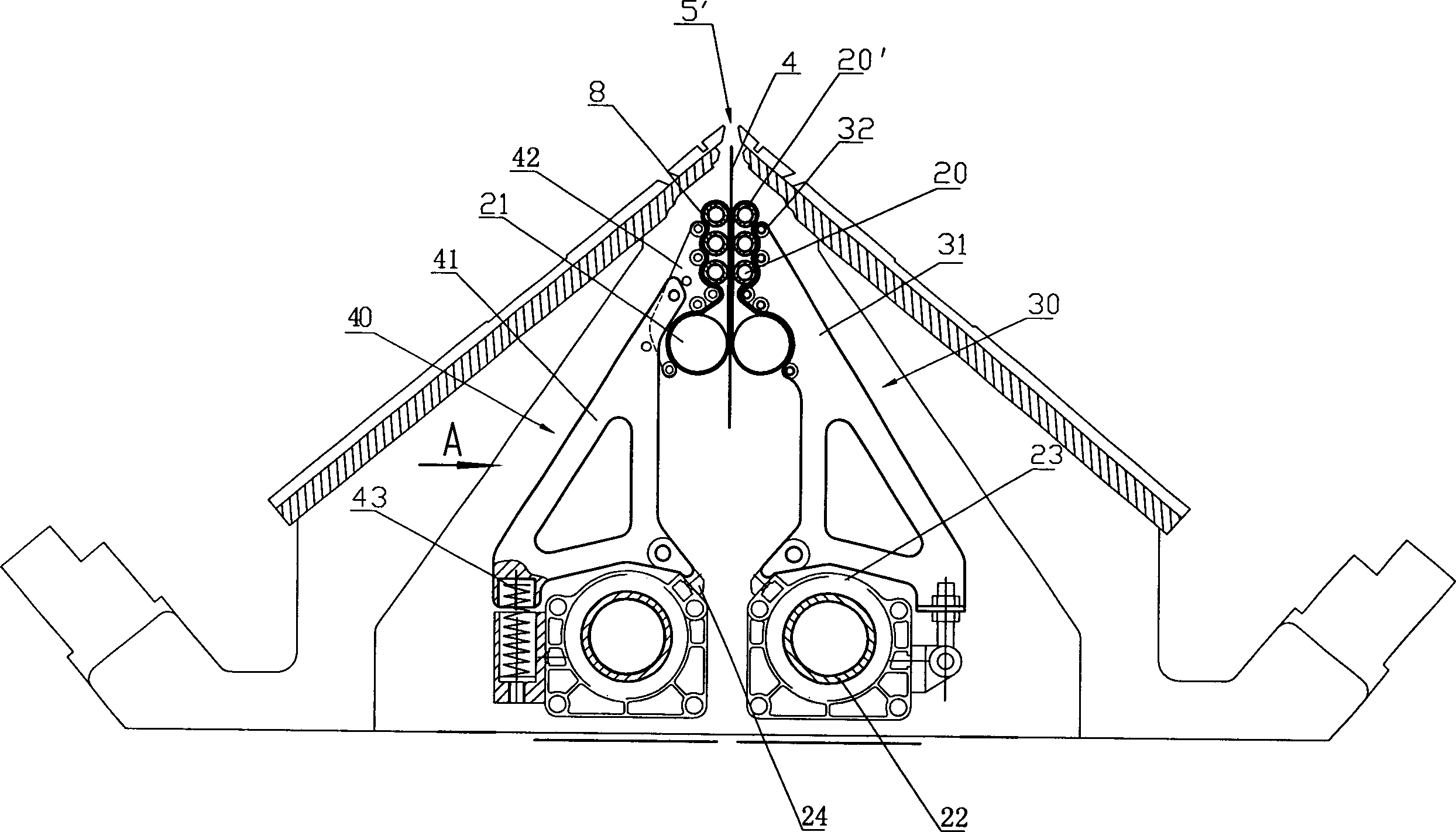

[0022] control image 3 , the overall structure of the device of the present invention is small, thereby can be placed in the position very close to the barrel mouth. Six small roller shafts 20 are arranged in the form of an array of two rows and three rows at the center of the lower side of the barrel mouth. Each small roller shaft 20 is connected with 36 small roller shafts 20' that can rotate around it. The two large roller shafts 21 are symmetrical Placed on the lower side of the above-mentioned small roller shafts arranged in an array, two rolls of cloth belts 8 respectively enclose a row of three small rollers 20' and the large roller shaft 21 on the same side. The pressure roller movable adjustment mechanism 40 and the pressure roller fixed adjustment mechanism 30 are respectively crimped on the outside of a row of small rollers 20 and the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com