Rolling machine for hot-rolled sheets with excellent rolling assisting property

A coiler and performance technology, applied in the field of sheet rolling, can solve the problems of unsatisfactory sheet and strip introduction performance and uniform winding performance, affecting the normal operation of the coiler and coiling quality, and failing to find a solution. Improve lead-in performance and uniform winding performance, facilitate smooth lead-in and standardize winding, and avoid stacking accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

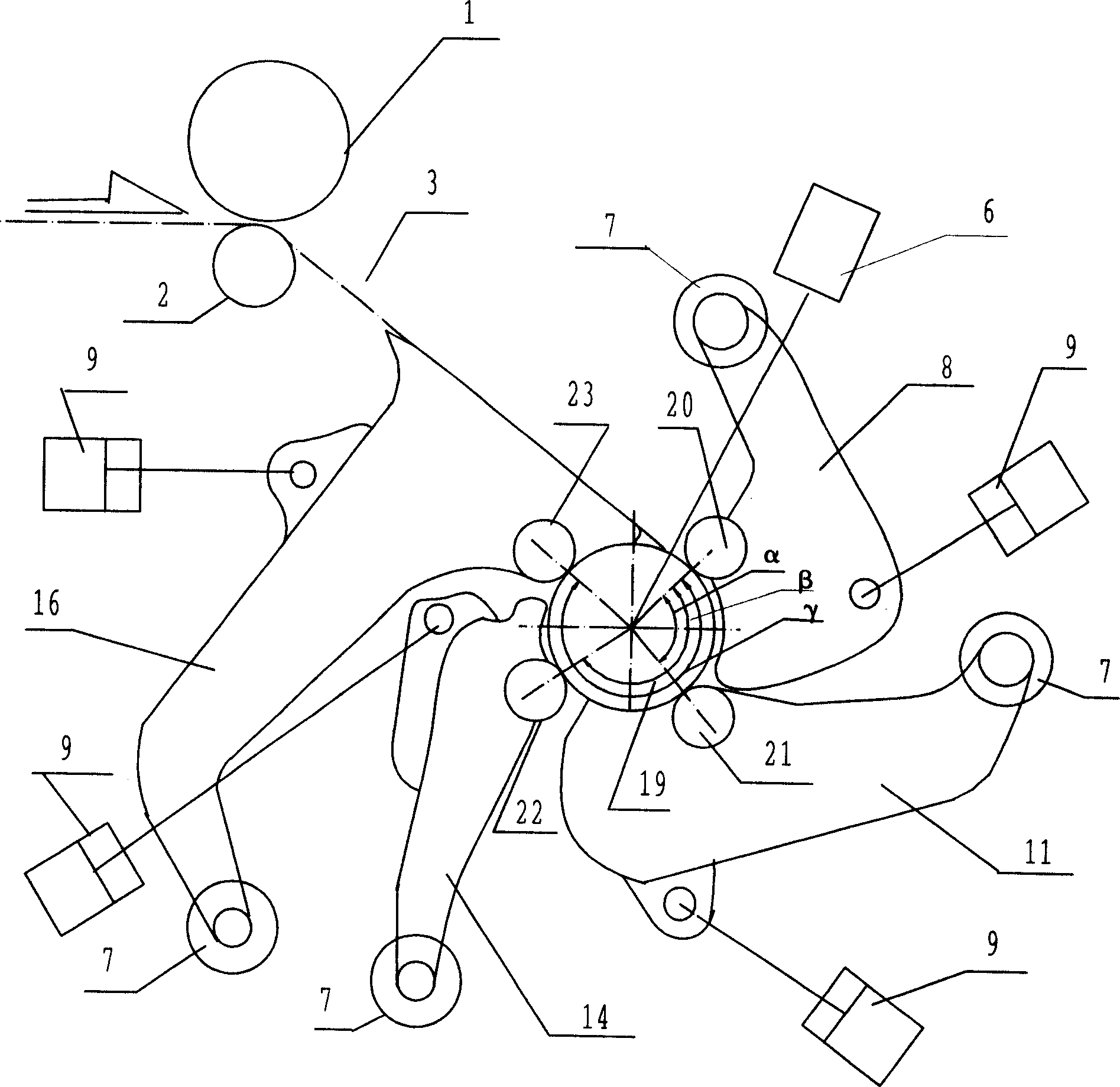

[0015] The contribution of the present invention to the prior art lies in changing the traditional three-point arrangement of the winding-helping rollers into an arrangement of more than three points. In the illustrated embodiment, a four-point arrangement is adopted, and the number of roll-helping rolls is four, respectively No. 1, 2, 3, and 4. The four roll-helping rolls 20, 21, 22, and 23 are distributed around the mandrel 19, and each A rolling roll is rotatably supported on a swing arm. One end of each swing arm is a hinged shaft end, and the other end is hingedly connected with the piston rod of the hydraulic cylinder. When reciprocating, the swing arm is driven to swing with the hinge shaft as the axis.

[0016] still see figure 1 . When the number of roll-assist rollers is four, the four roll-assist rolls should be reasonably distributed in a 360-degree circle. The specific position of each roll-assist roll should be combined with the arrangement of each swing arm, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com