Flexible plate packaging apparatus and application method

A flexible board and board technology, applied in transportation and packaging, coiling strips, climate sustainability, etc., can solve the problems of inability to maintain winding tension and low work efficiency, reduce manual labor, prevent Unwinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

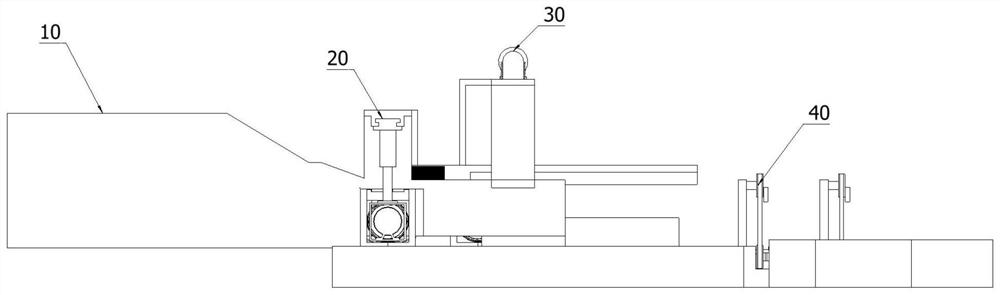

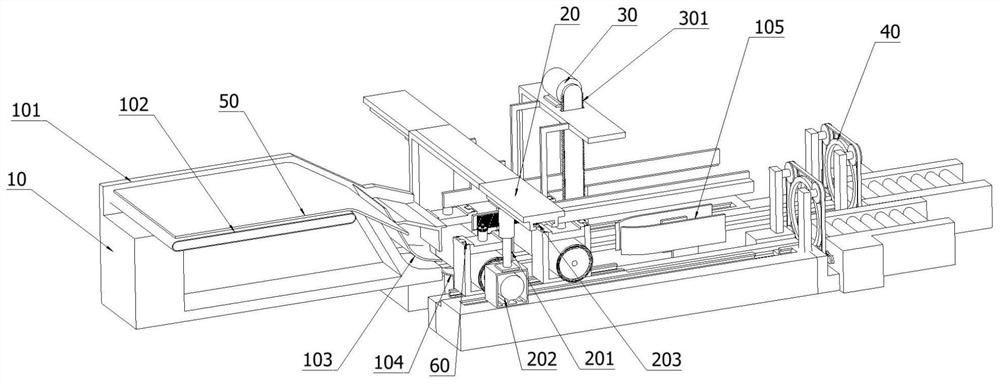

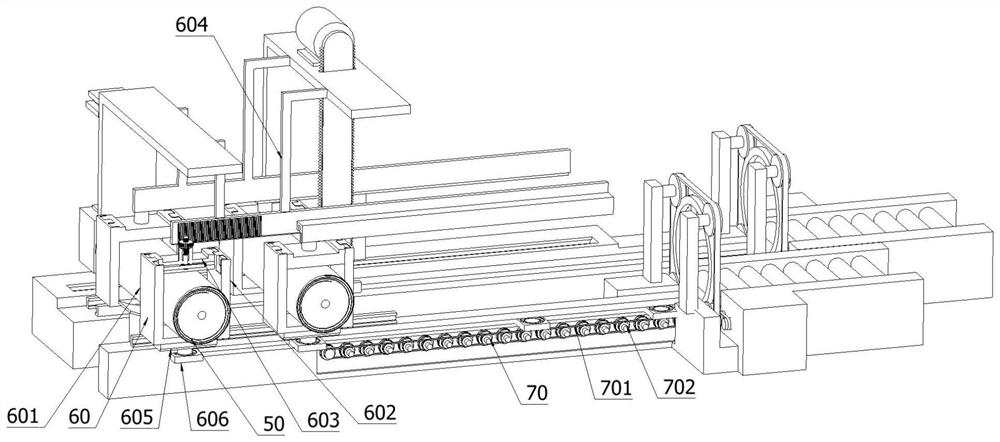

[0045] Such as figure 1 , 2 As shown, this embodiment discloses a flexible board 50 material packaging device, including: a body 10, the body 10 is arranged on a plane, the body 10 includes: a feeding track 101, the feeding track 101 is arranged on a plane, and the feeding track 101 surface is provided with groove, and the right side of feeding track 101 is provided with guide track, and guide track is connected with feed track 101; In the groove, the search book feeding conveyor belt 102 is flexibly connected with the feeding track 101, and the feeding conveyor belt 102 is used to transport the flexible board 50; the unloading channel 103, the unloading channel 103 is arranged inside the feeding track 101, the lower The material channel 103 is arranged on the inside of the feeding track 101 as an inclination, and the inside of the material channel 103 is hollow; the supporting plate 104, the supporting plate 104 is arranged on the right side of the material channel 103, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com