Patents

Literature

41results about How to "Improve coiling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for preventing band-steel electrolyzing cleaner running from offset and coiling leakage

ActiveCN101029414AImprove deviationOvercoming Coil Overflow ChallengesElectrolysis componentsWork treatment devicesGround rollerPulp and paper industry

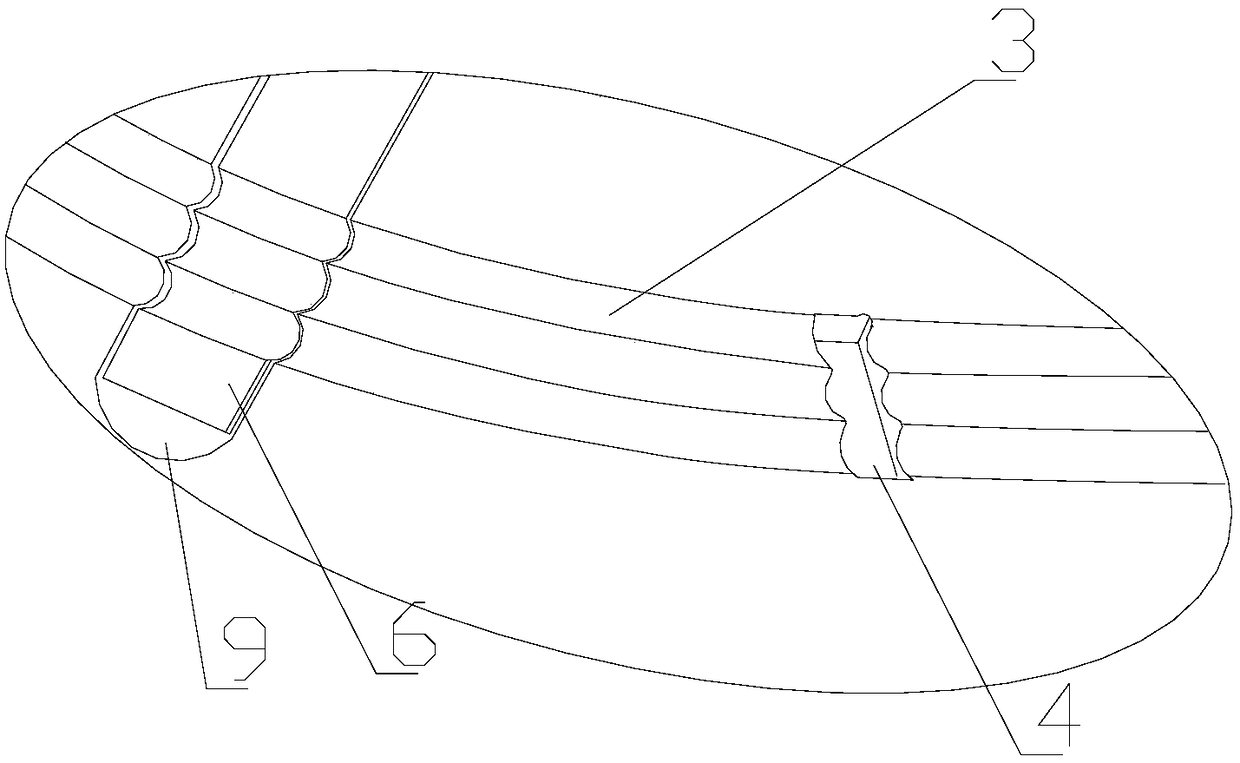

A method for preventing band steel electrolyzed cleaner set running from offset and overflow is optimized. The band steel electrolyzed cleaner set consists of unwind section, cleaning section and tension coiling section, roller's shaped is optimized designed. Cleaning section entrance, exist grounding roller and front steering roller of coiler adopt sinusoidal curved roller and medium projected, roller material is chromium plated on surface; front steering roller of silicon-coated slot for cleaning section contacting liquid, submerged roller of silicon-coated slot and submerged roller of spraying slot adopt sinusoidal curved roller and medium projected; roller-side rubber, ring-opening slot and rear steering roller of silicon-coated slot adopt planar roller, roller-side material, ring-opening slot, front steering roller of silicon-coated slot and coiling section roller are sinusoidal curved roller and medium projected, roller side is made of polyurethane urea ring-opening slot. It's simple and convenient.

Owner:BAOSHAN IRON & STEEL CO LTD

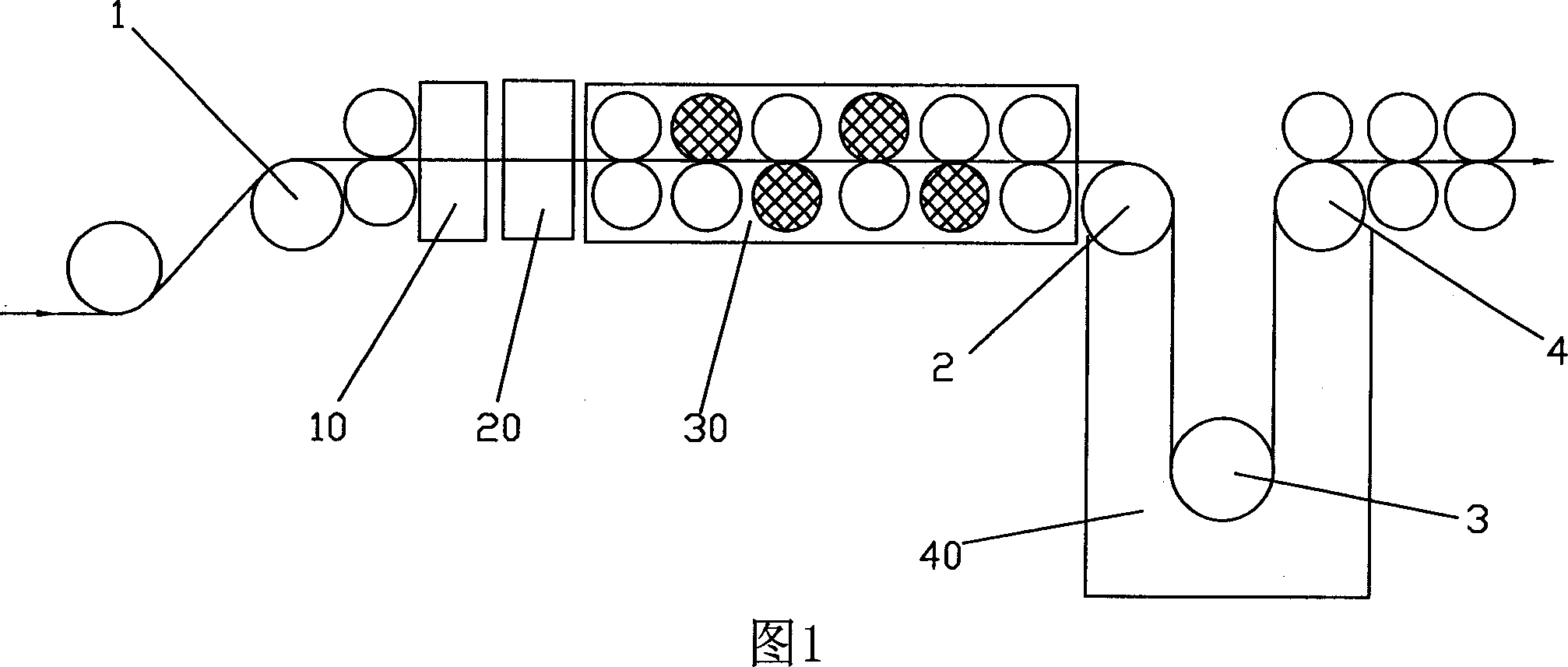

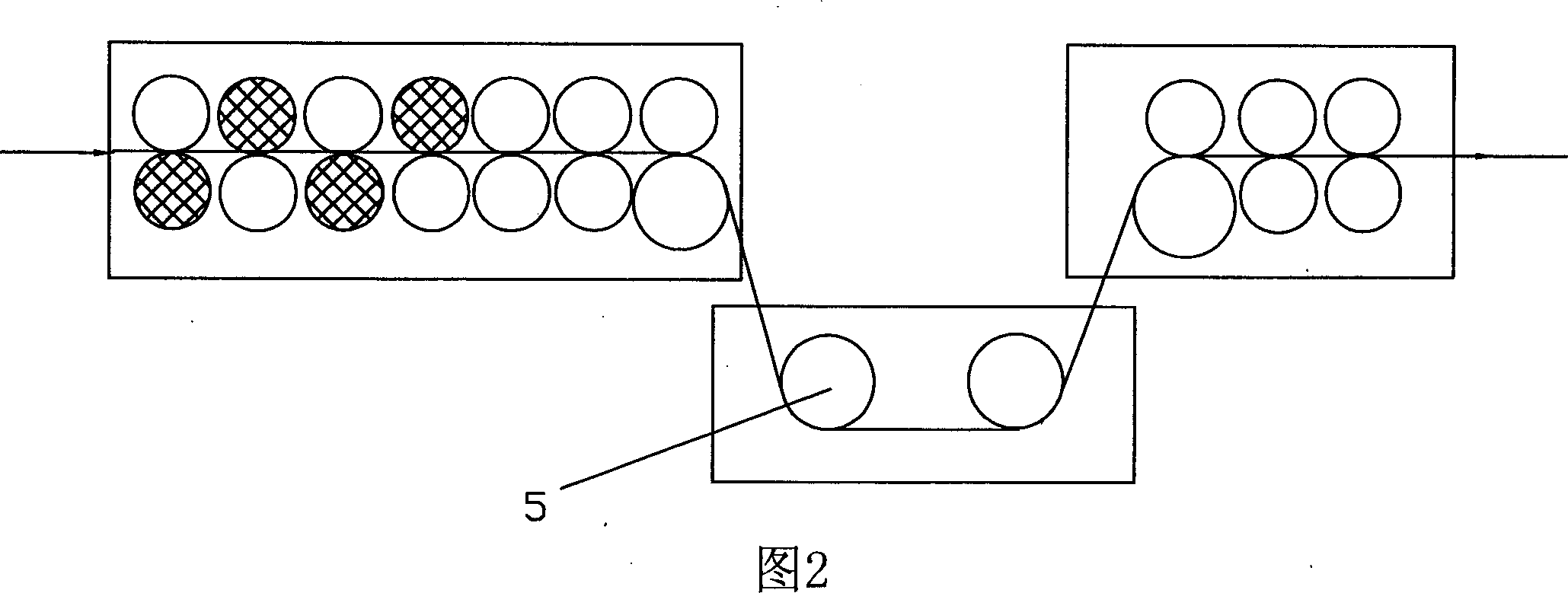

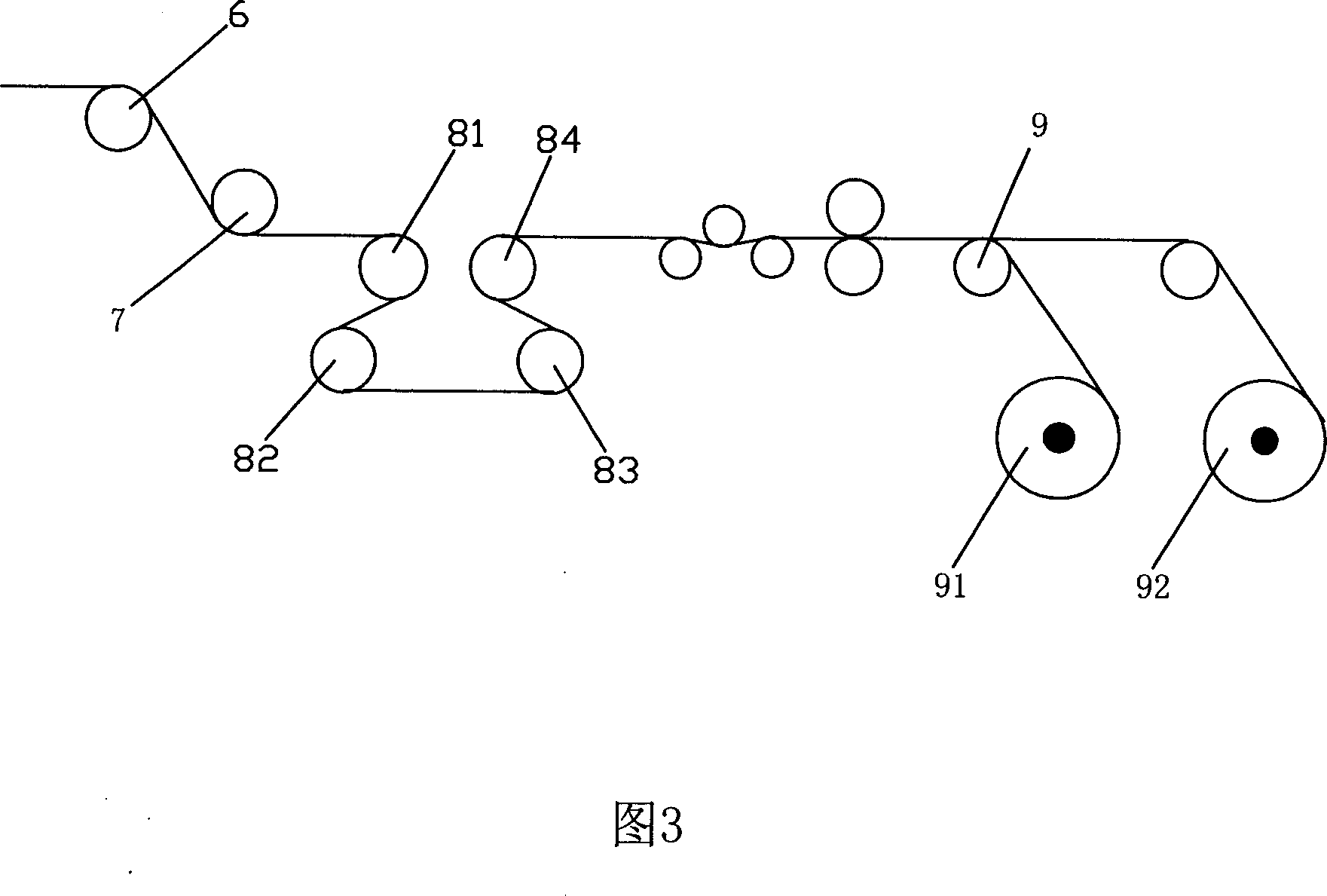

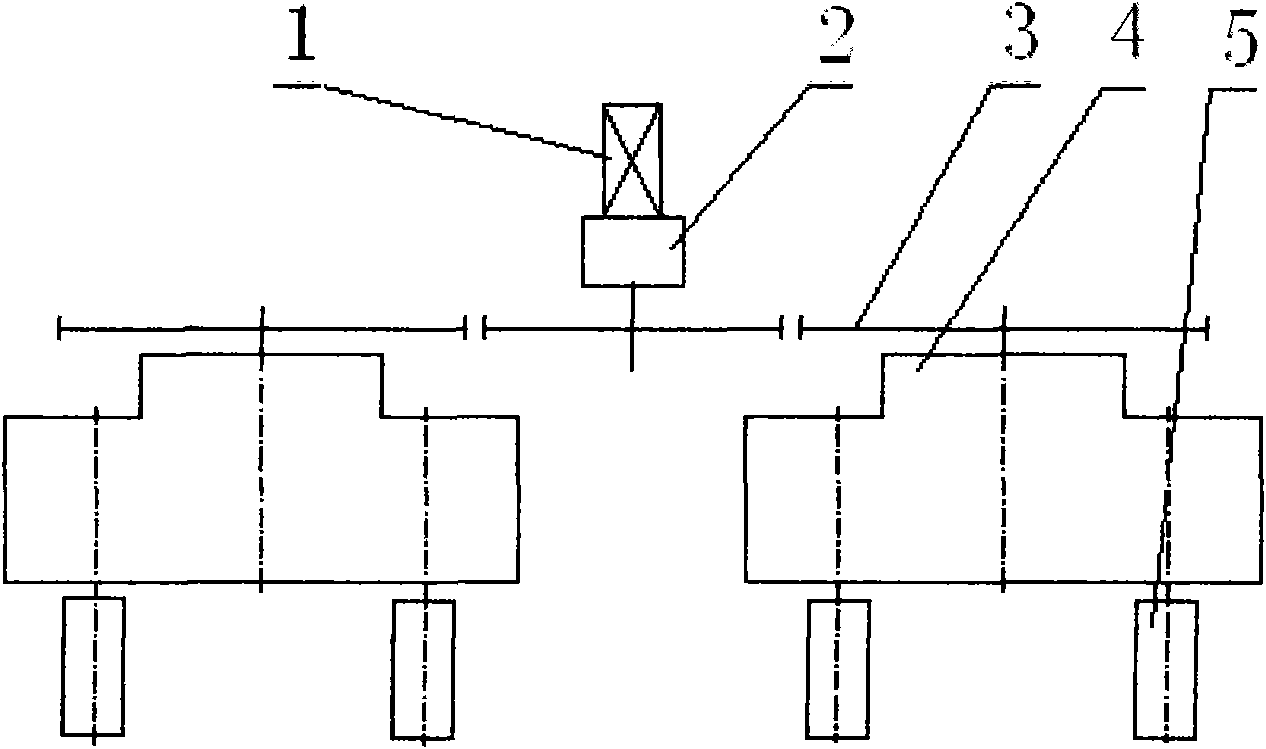

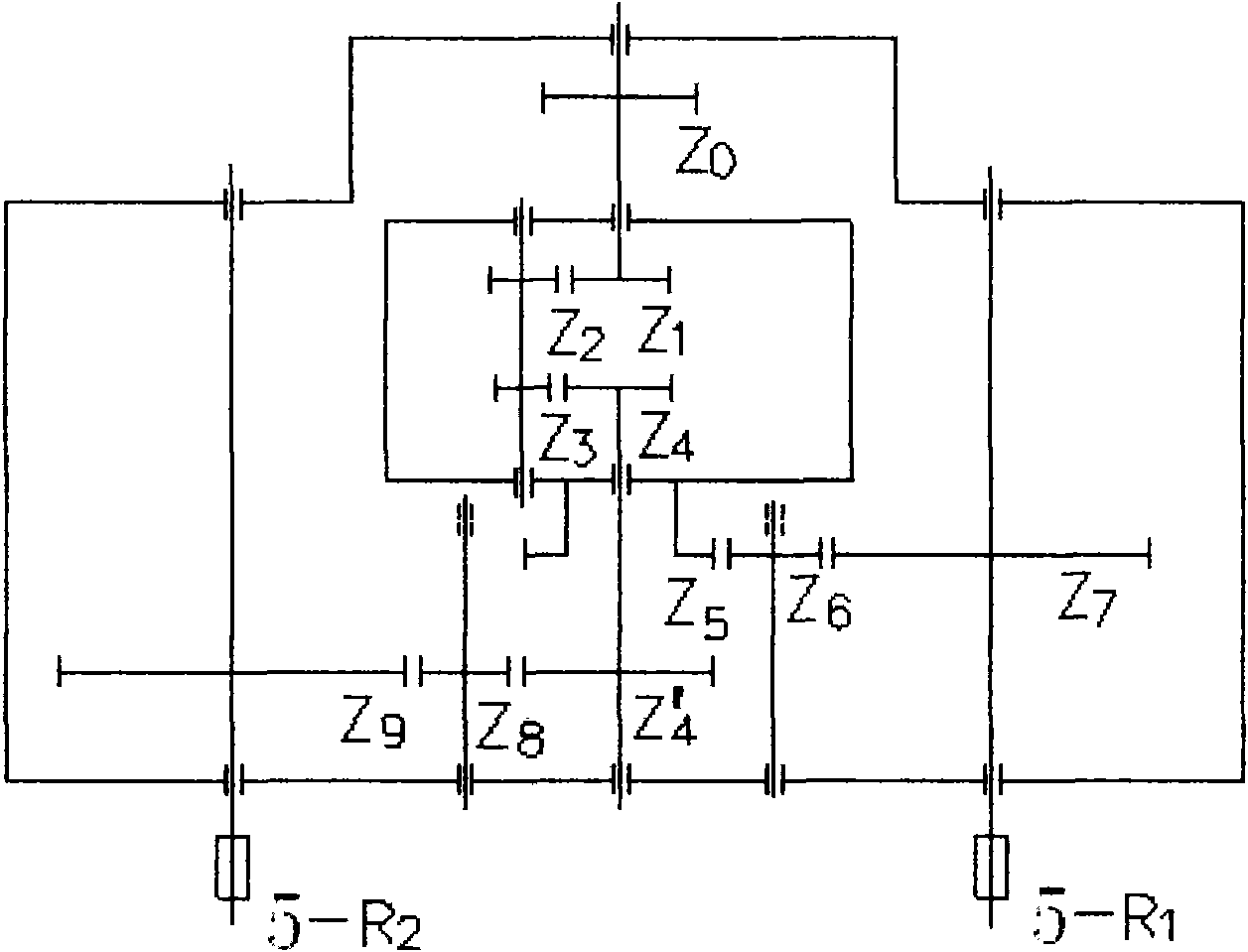

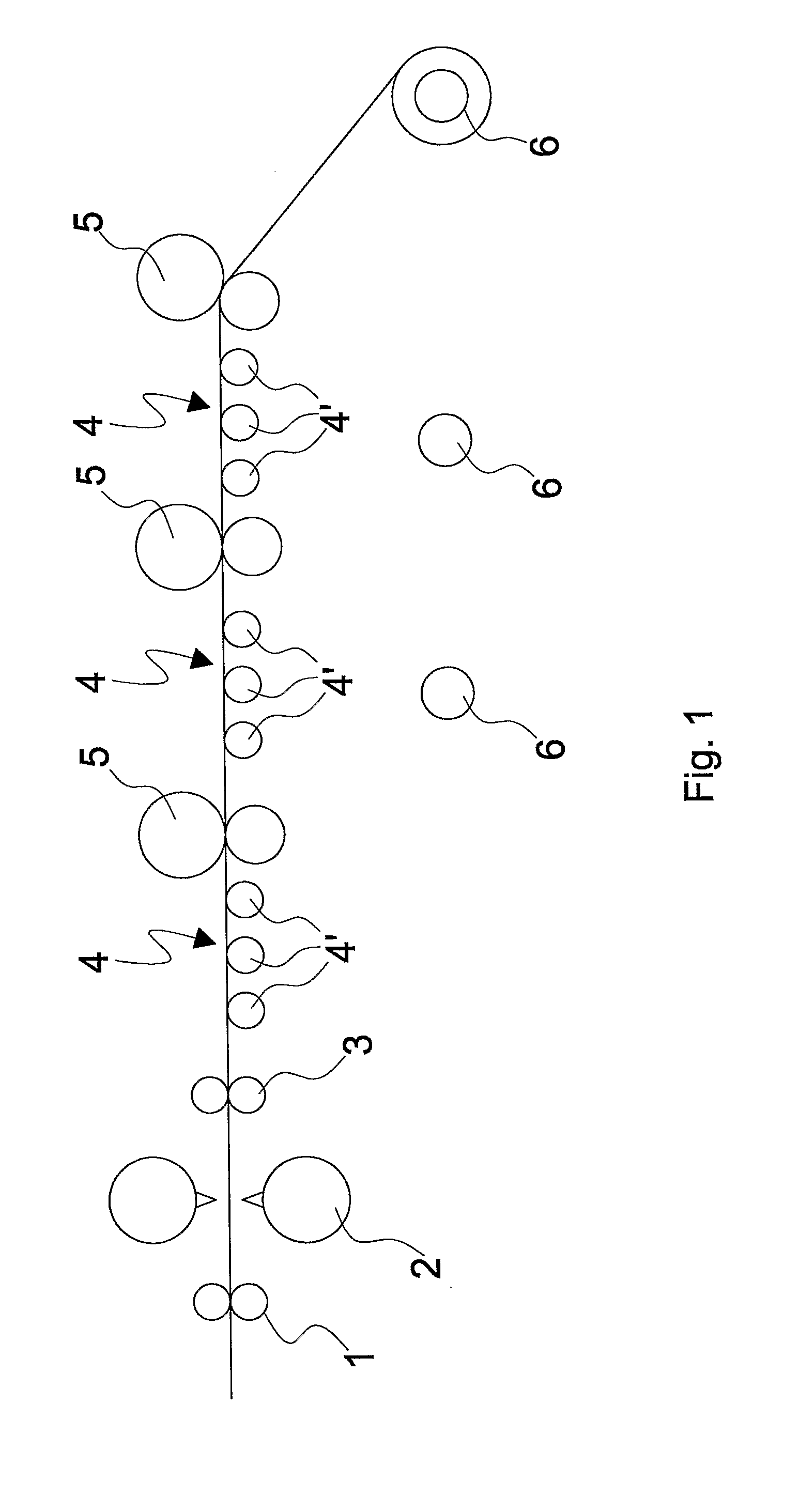

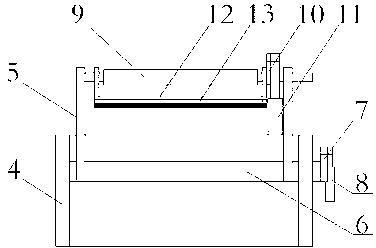

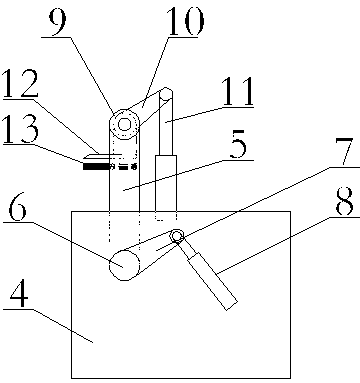

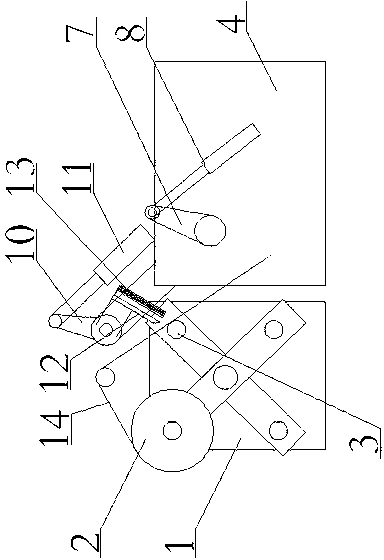

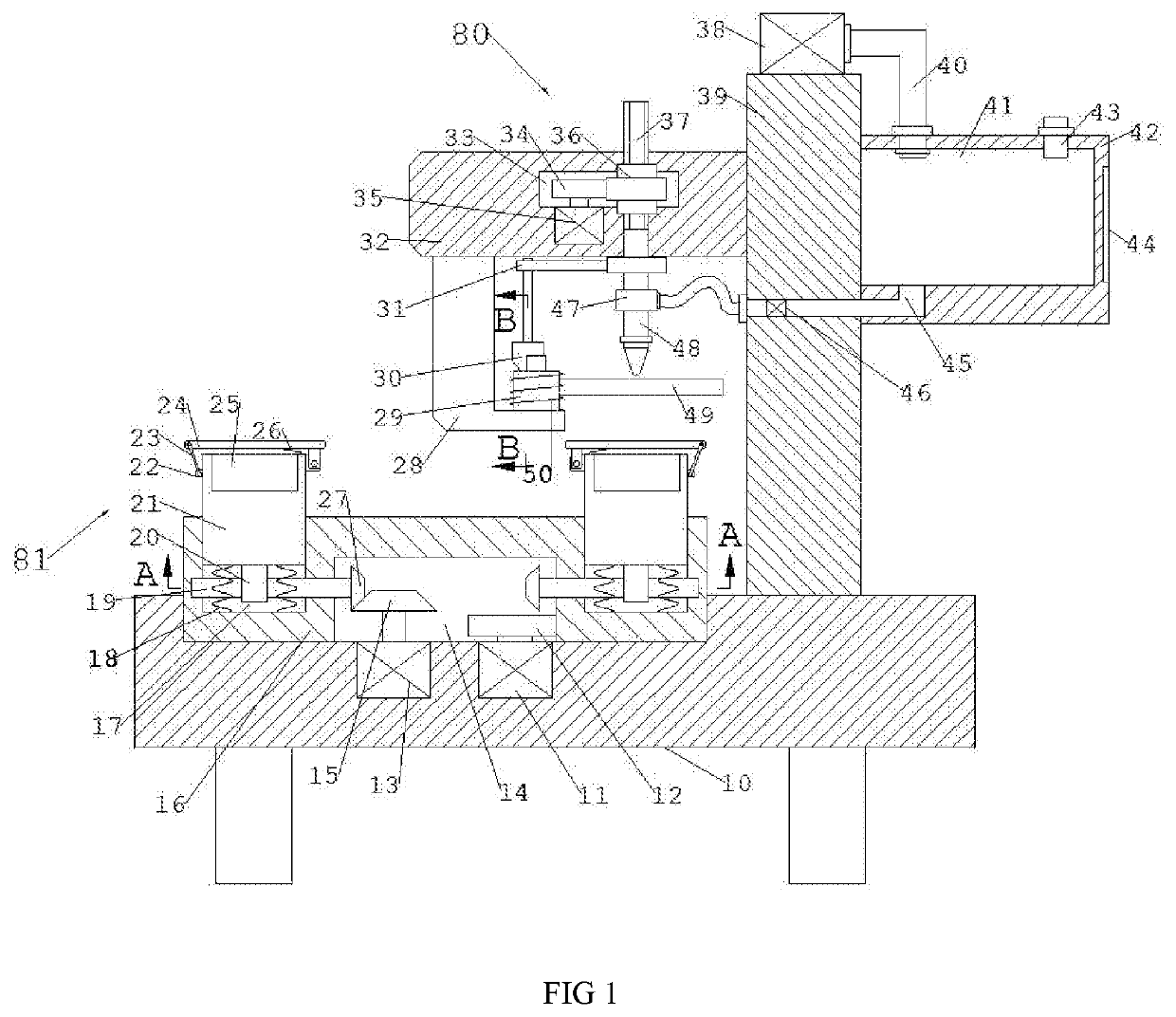

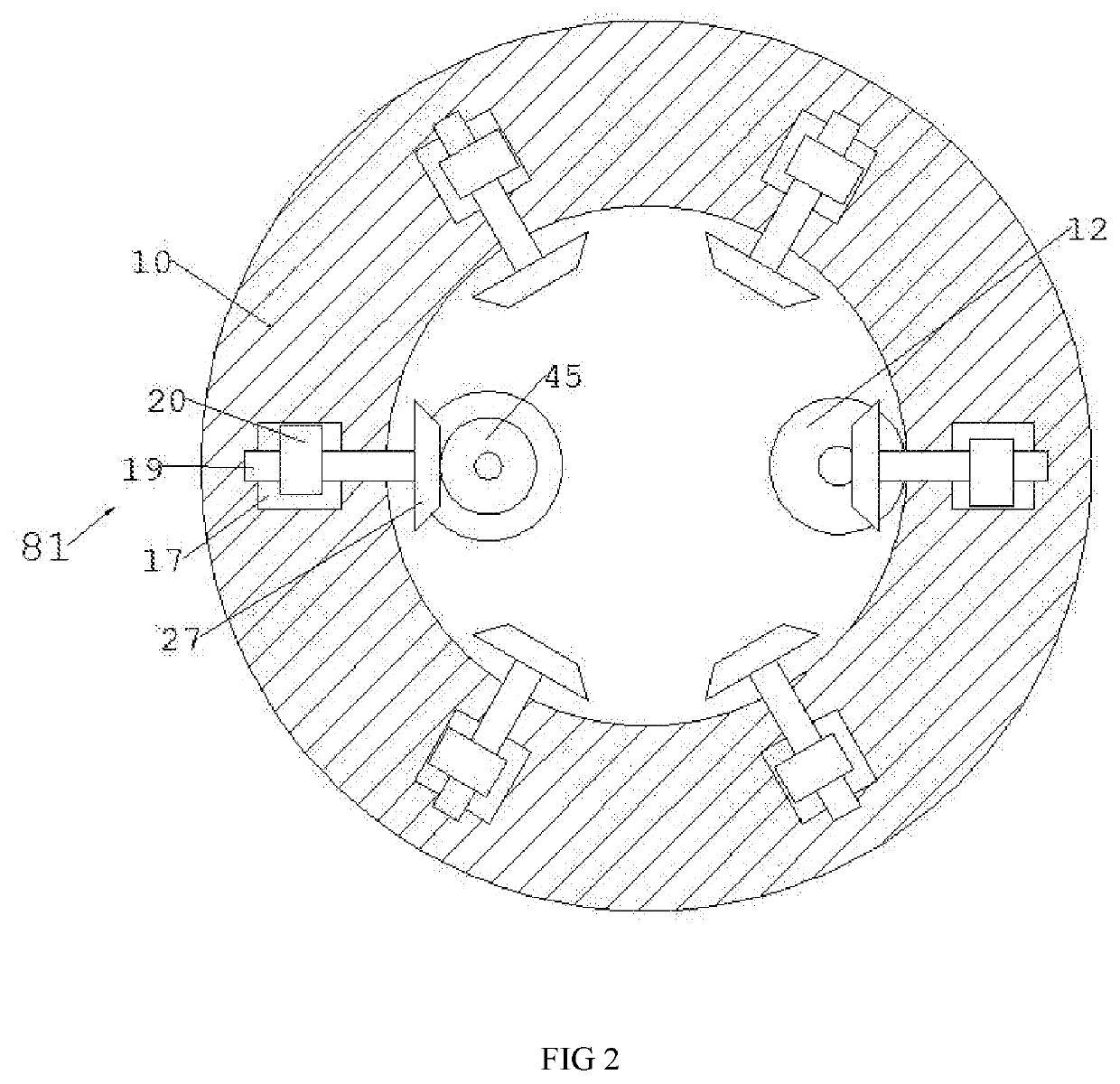

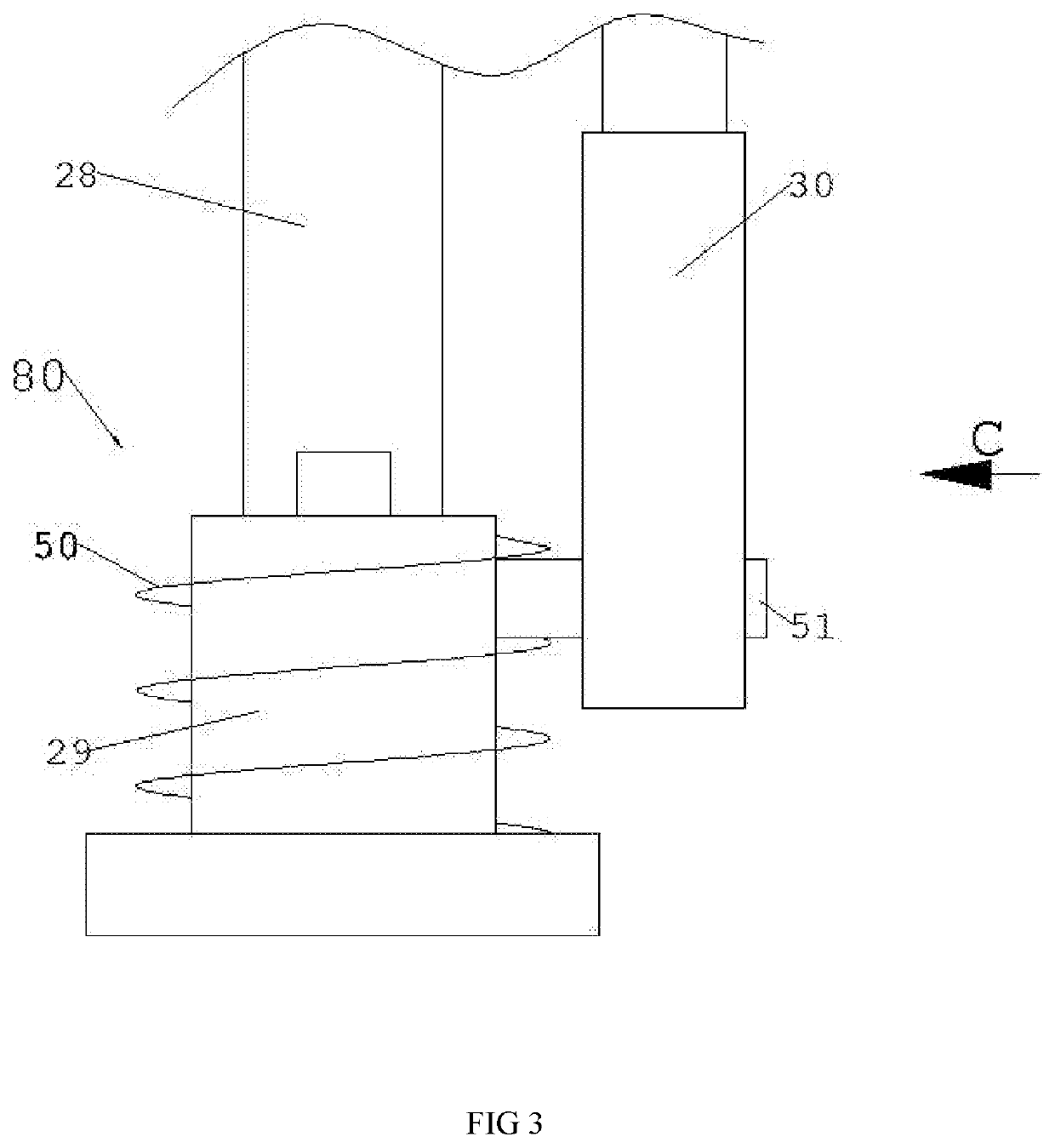

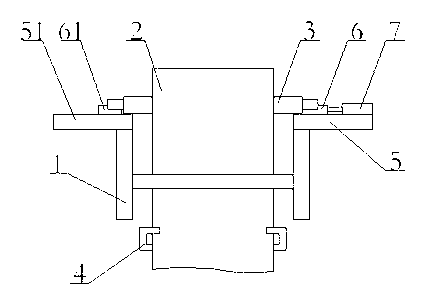

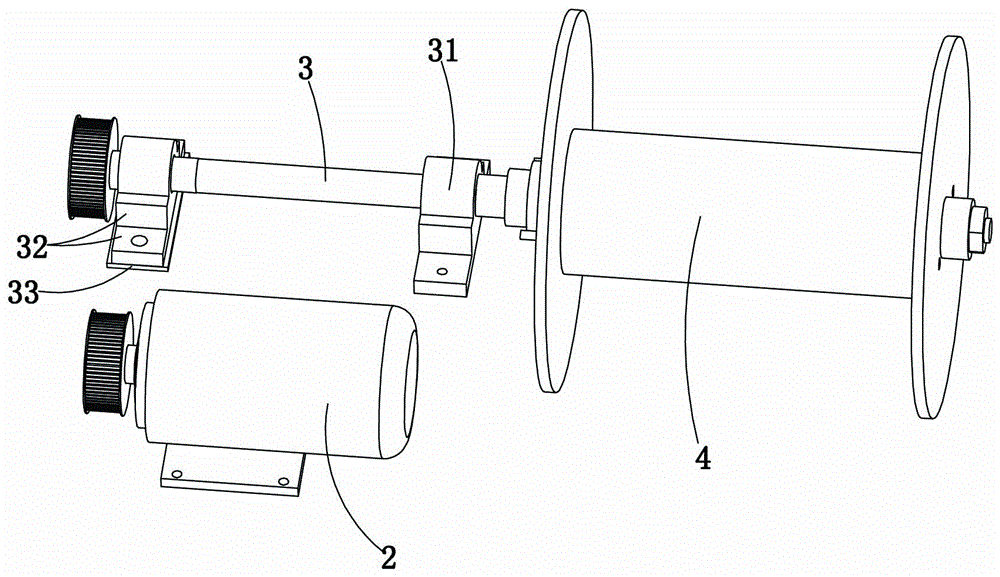

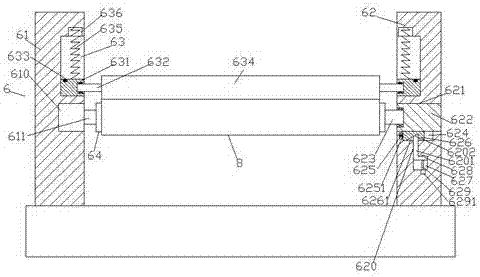

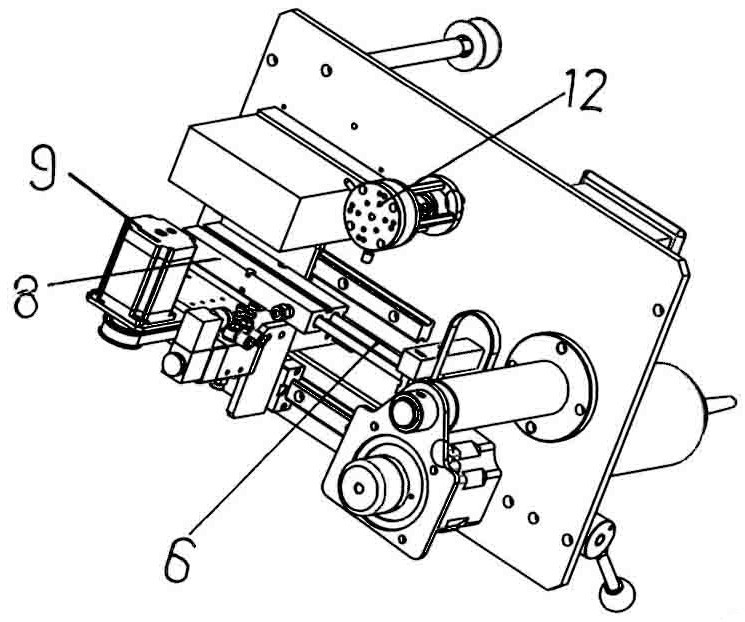

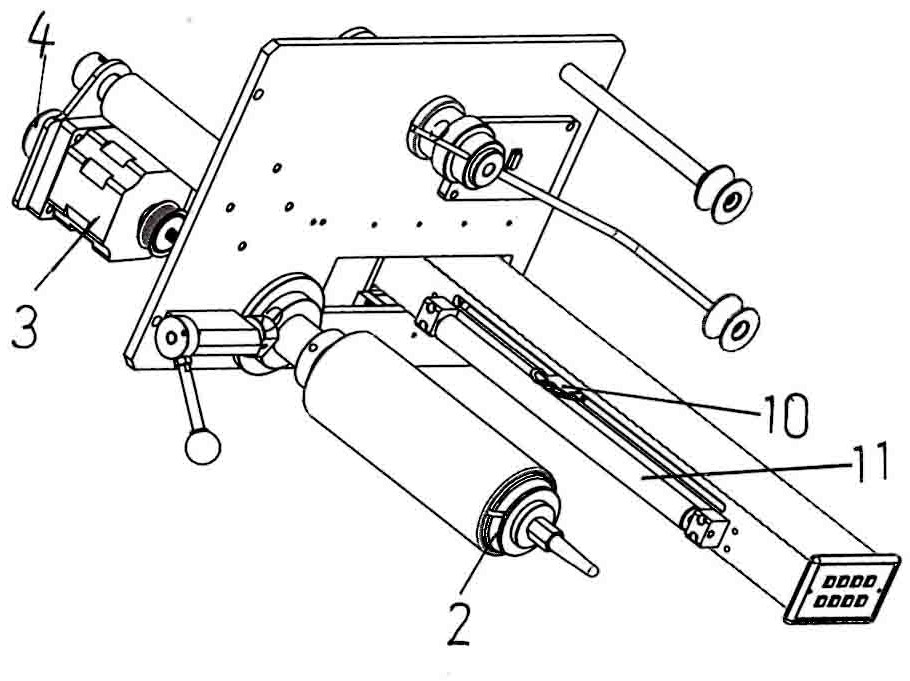

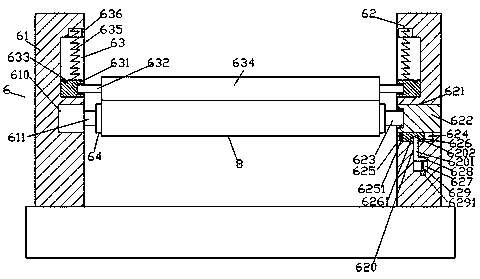

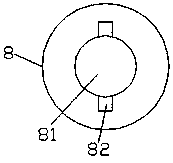

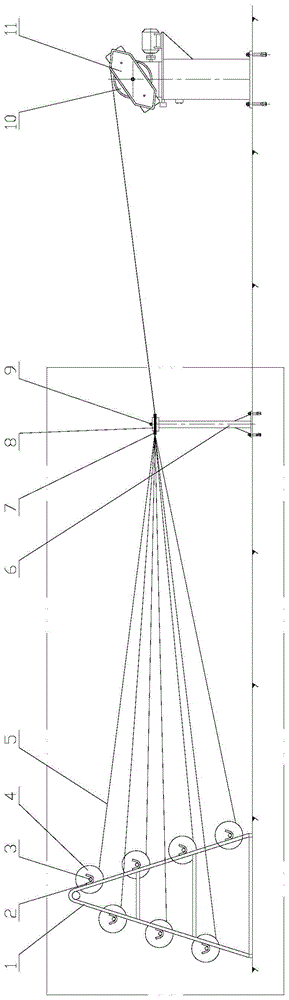

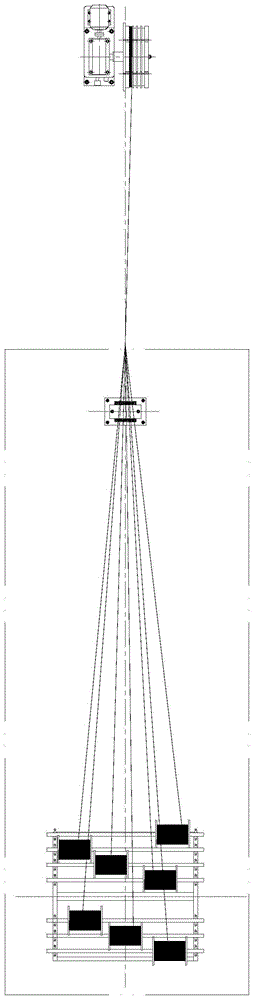

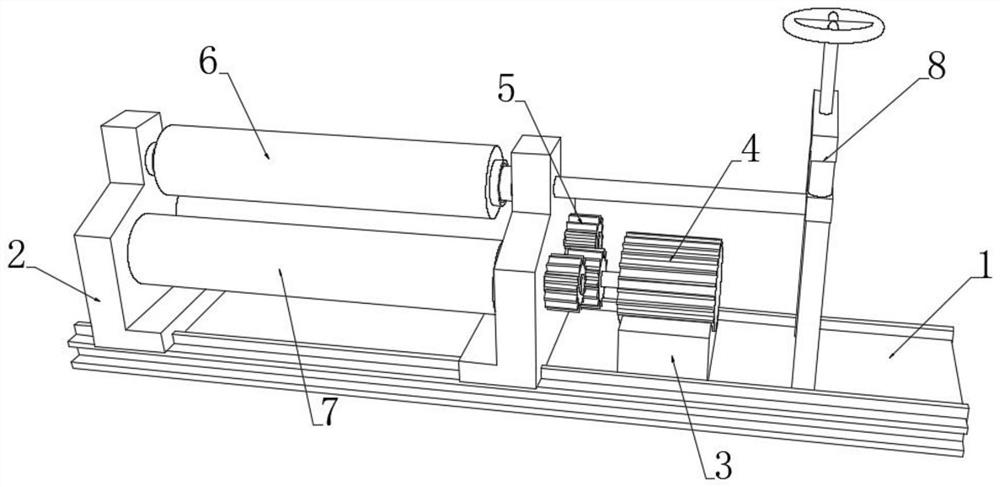

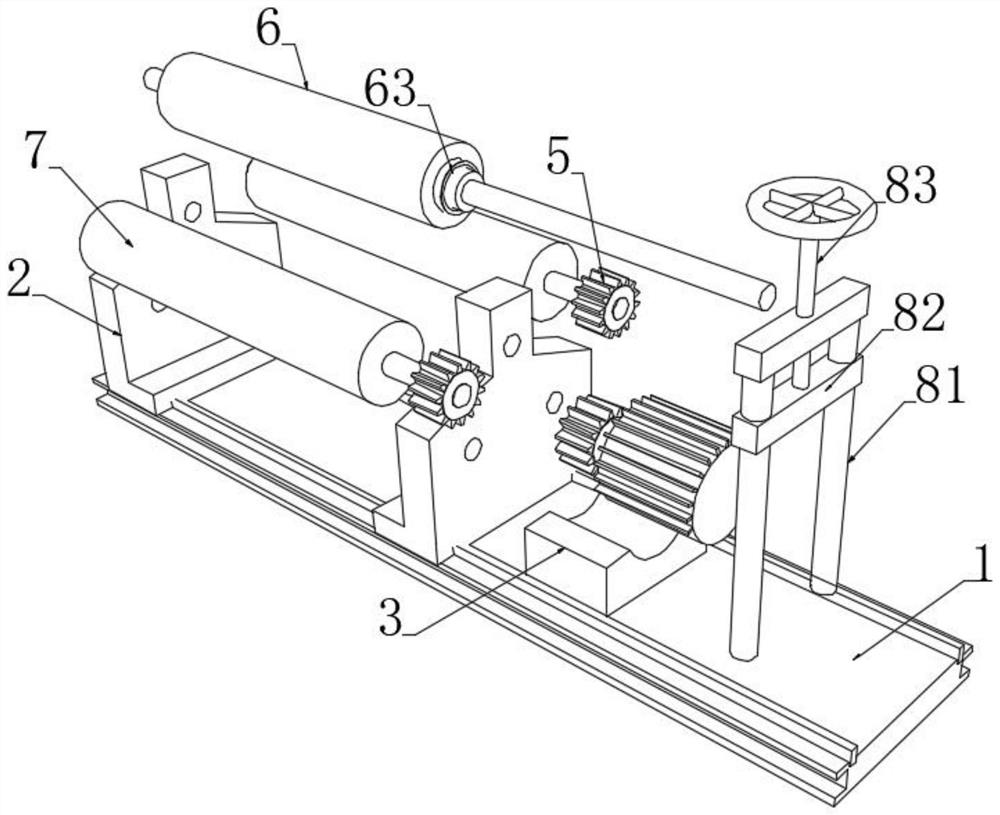

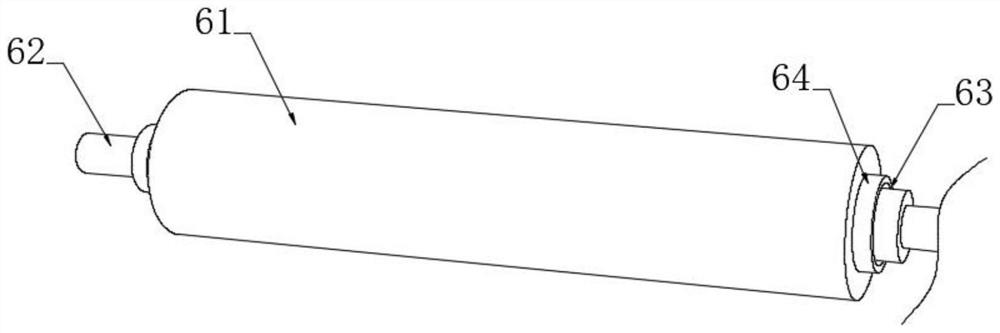

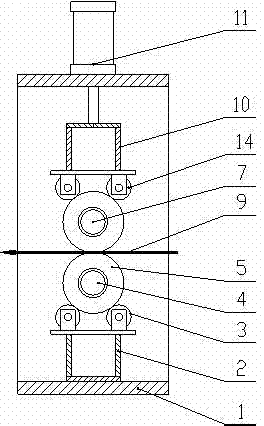

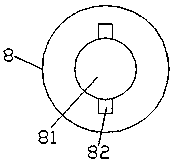

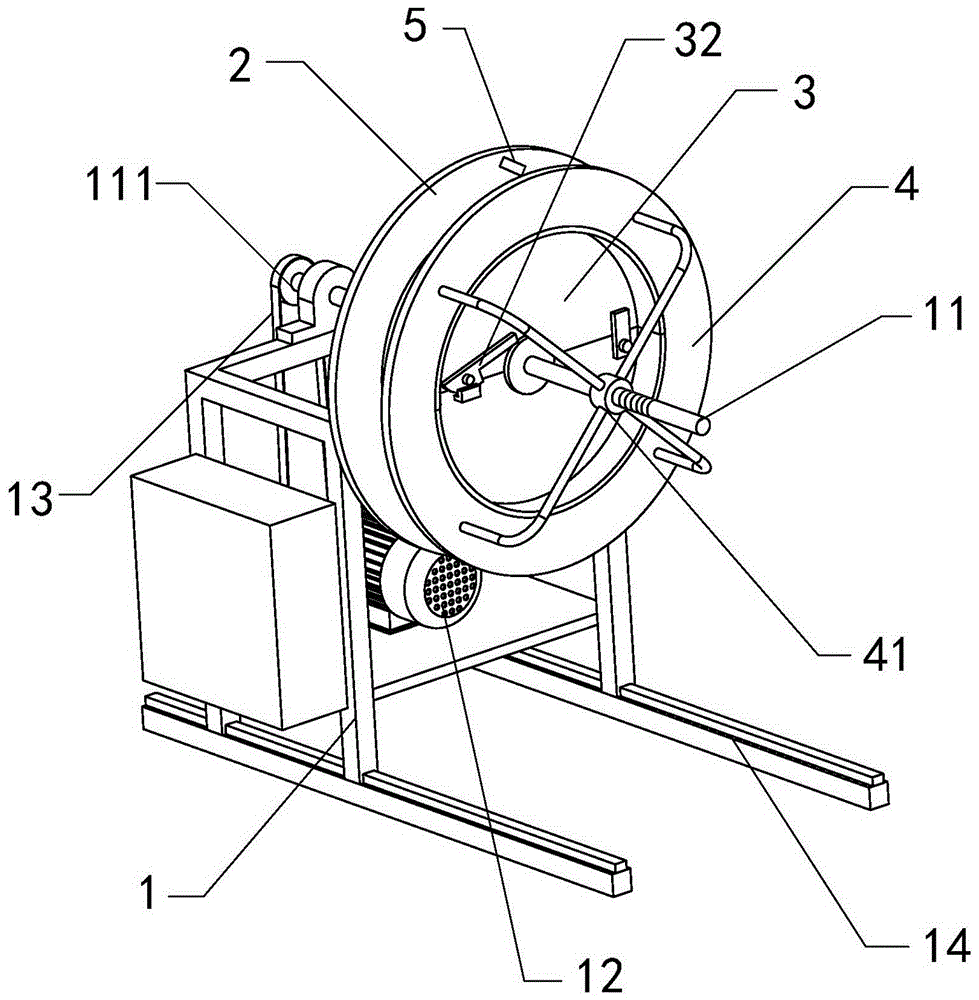

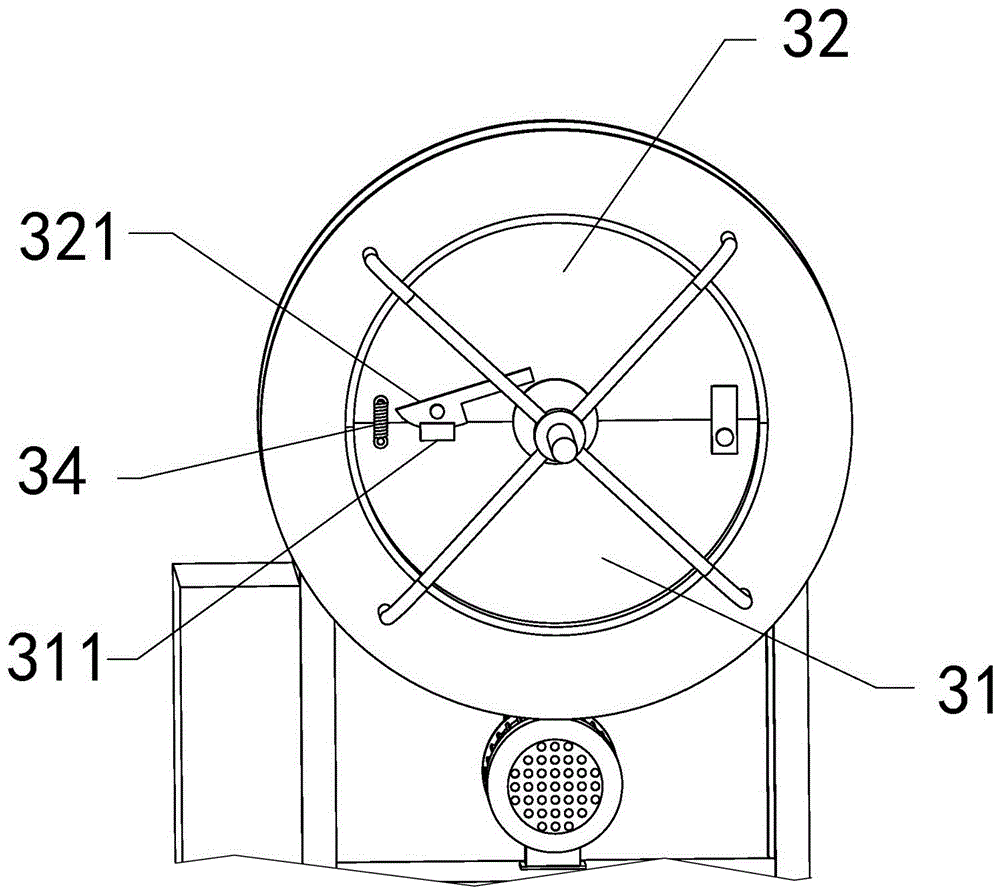

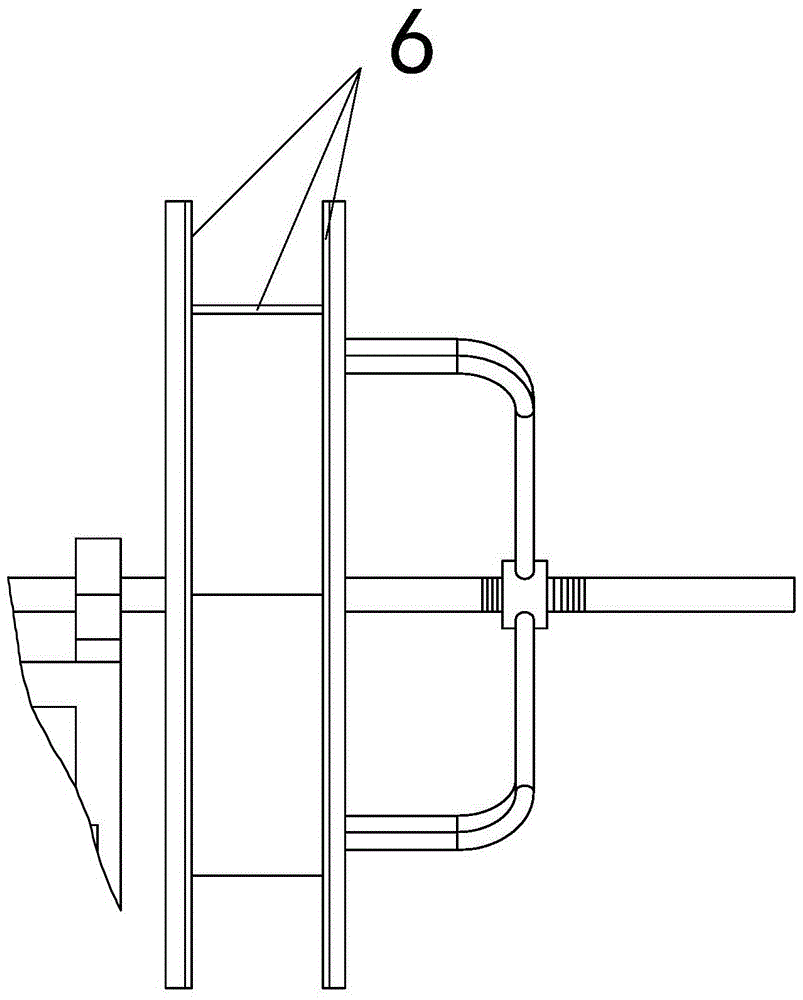

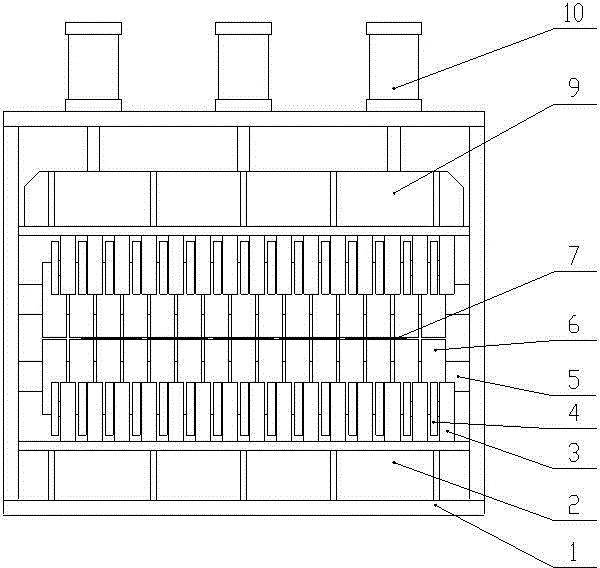

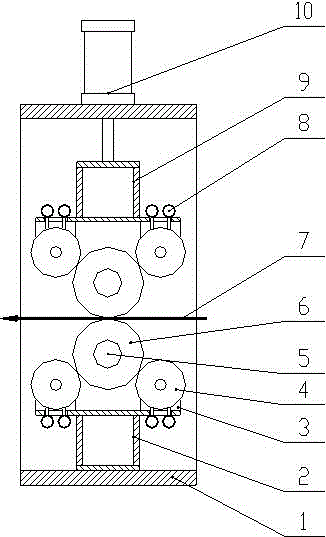

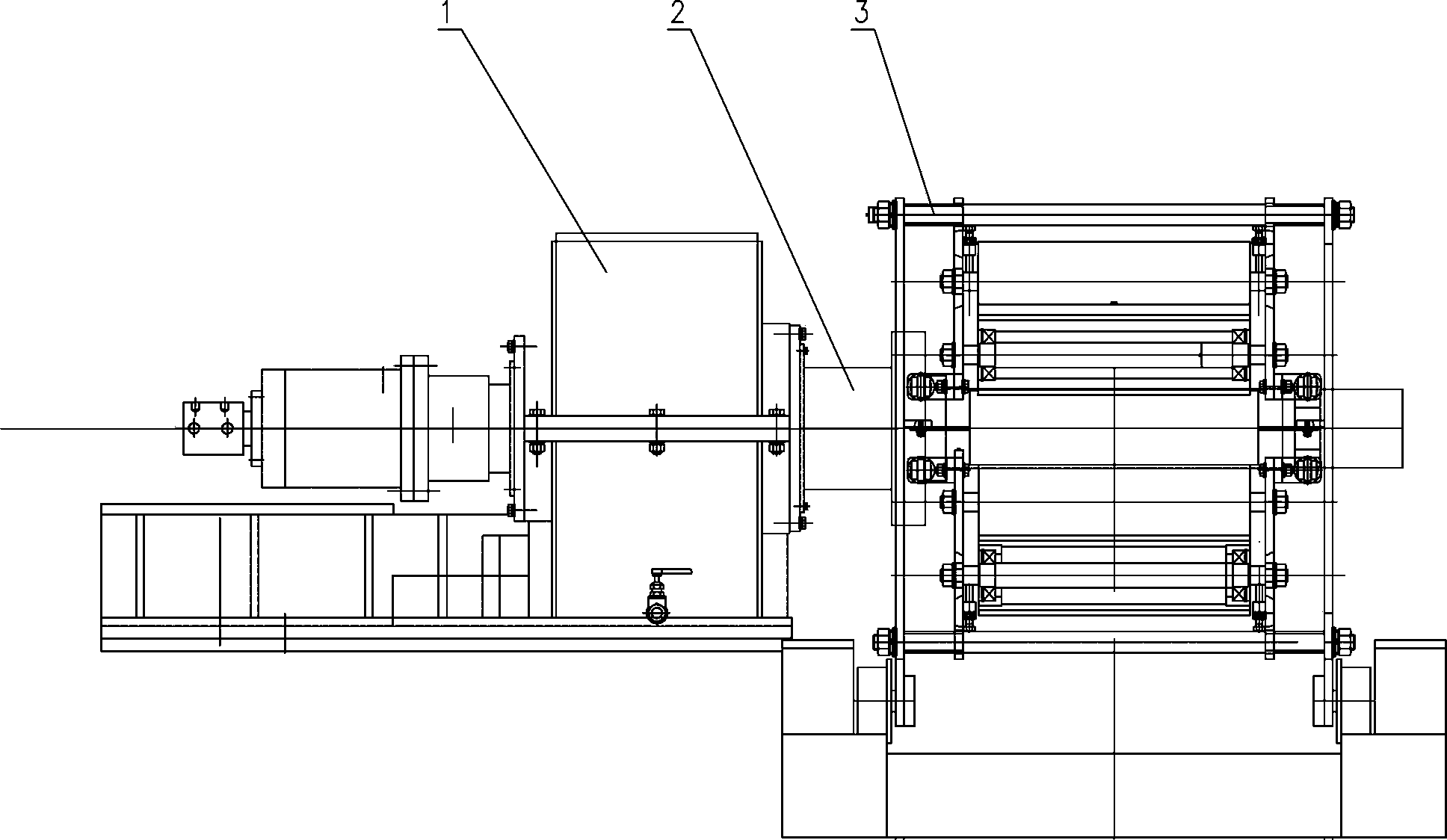

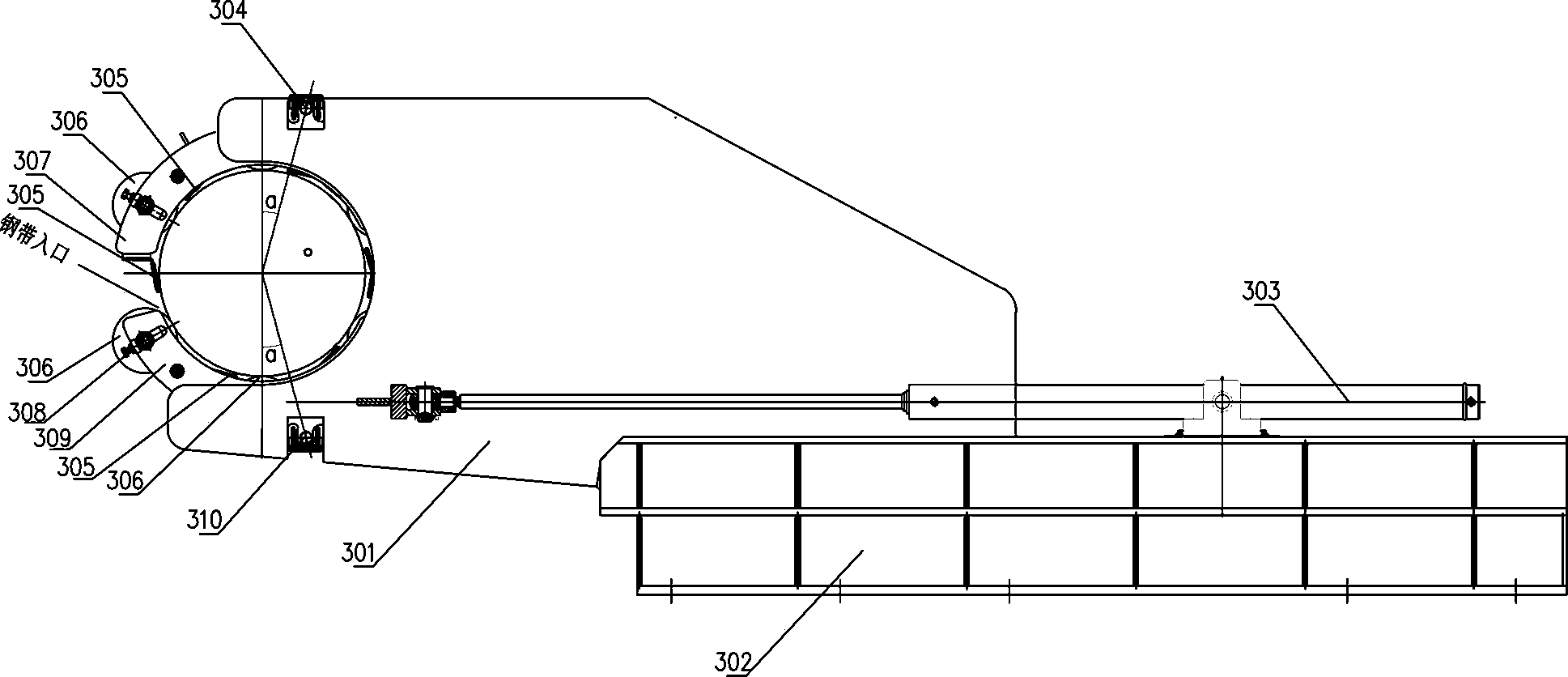

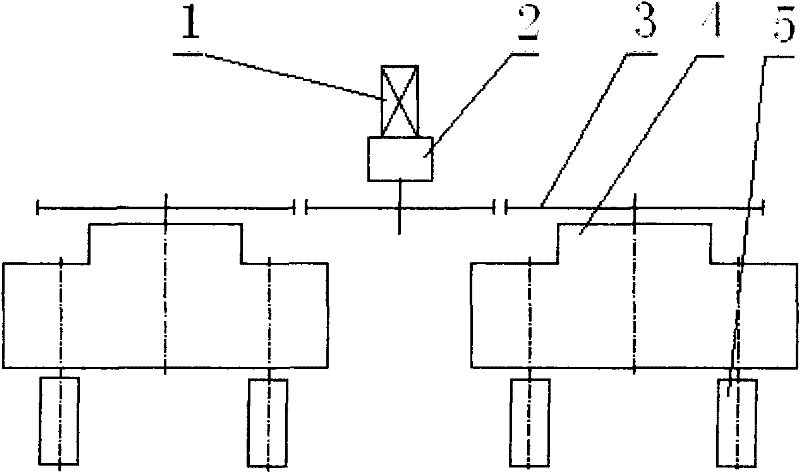

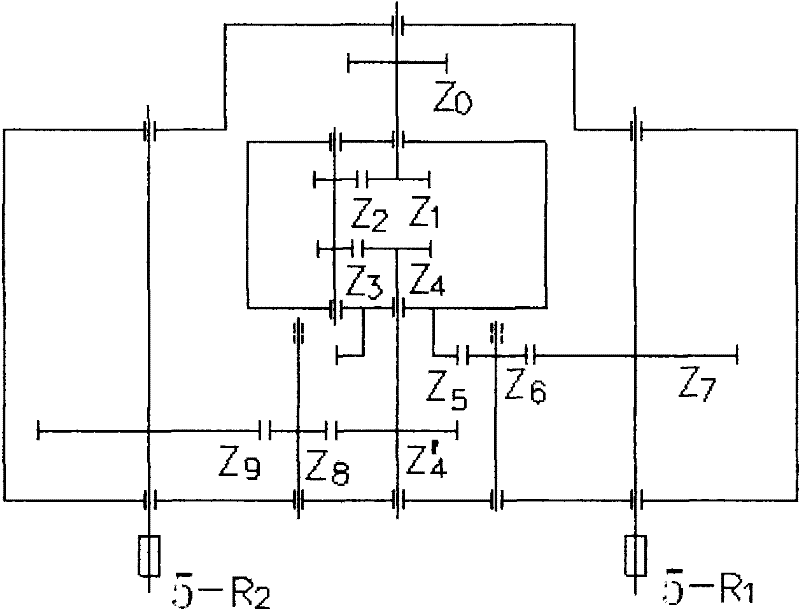

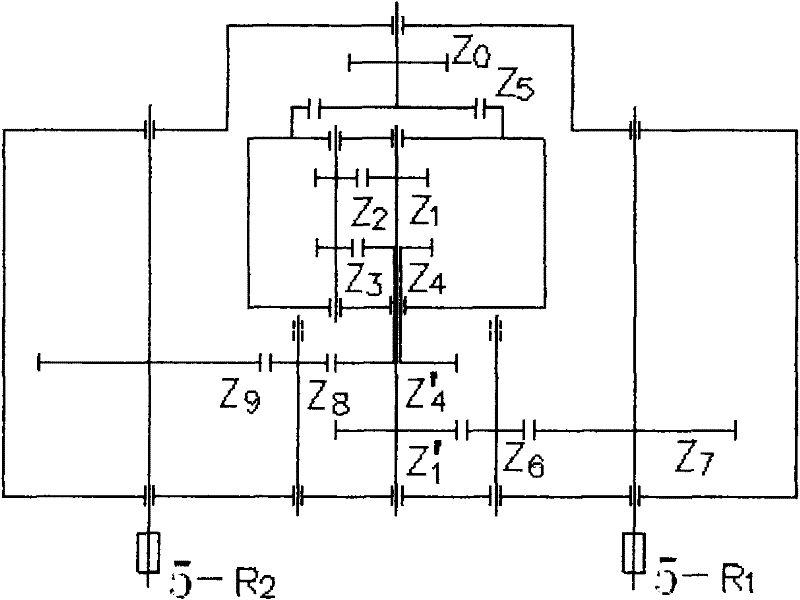

Driving mechanism of multi-head scroll recoiling machine

InactiveCN101559896AChanging the slitting and coiling processCompact layoutToothed gearingsShearing machinesReduction driveEngineering

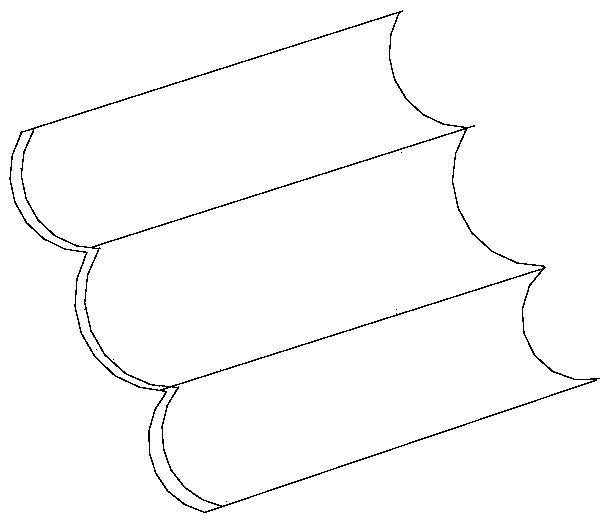

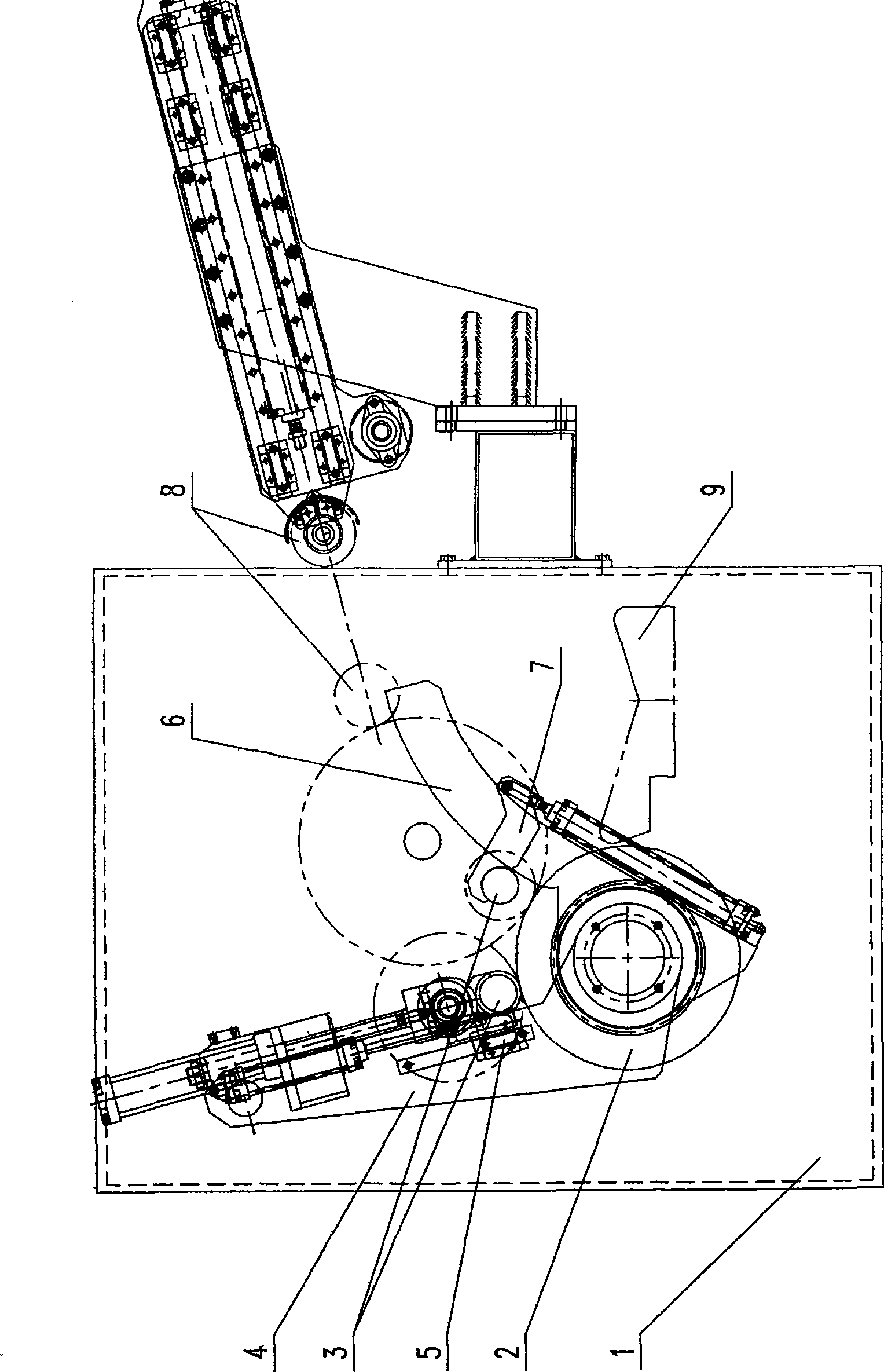

The invention relates to a mechanical transmission method, in particular to a driving mechanism of a multi-head scroll recoiling machine which satisfies special requirements of belt material coiling or cord winding. The driving mechanism comprises an electromotor and a decelerator. The driving mechanism is characterized in that an output shaft of the decelerator (2) which is connected with an electromotor (1) is engaged with a plurality of coupling transmission ladles (4) by a distribution gear (3); each transmission ladle (4) transmits kinetic moment and velocity to two scrolls (5) connected thereon; and rotation speed of each scroll can be self-adjusted according to length of the recoiled stripe. The driving mechanism changes traditional strip-by-stripe recoiling technique of belt material, thereby compacting machine unit distribution, reducing equipment investment, simplifying operation and improving recoiling quality. The driving mechanism further realizes flexible winding of multi-head cords.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

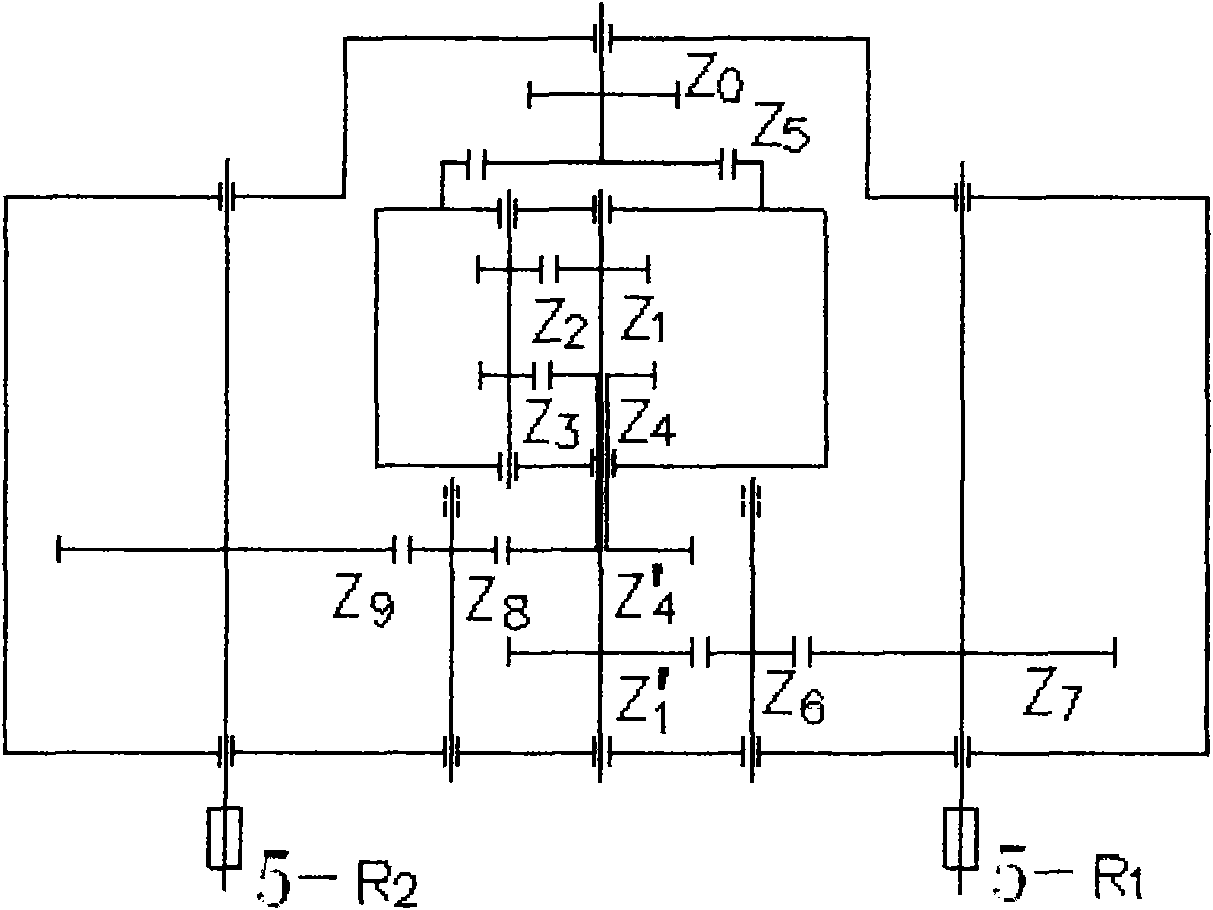

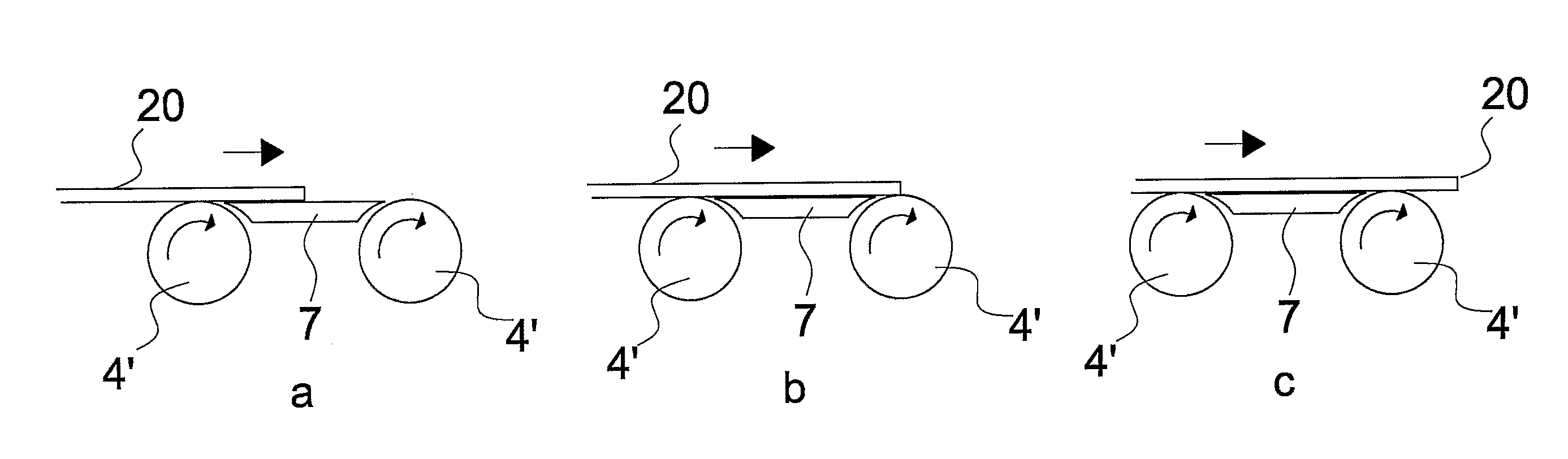

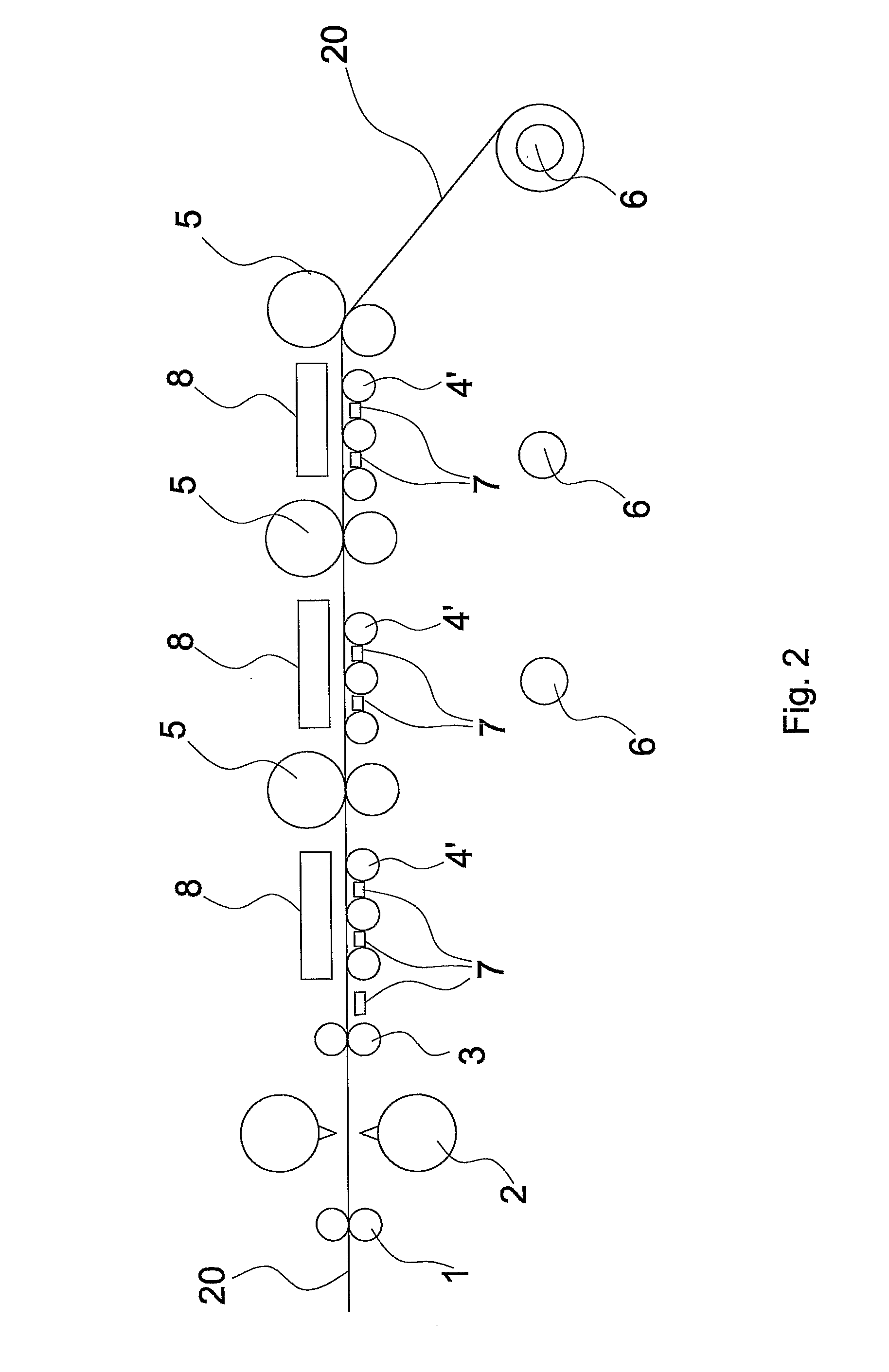

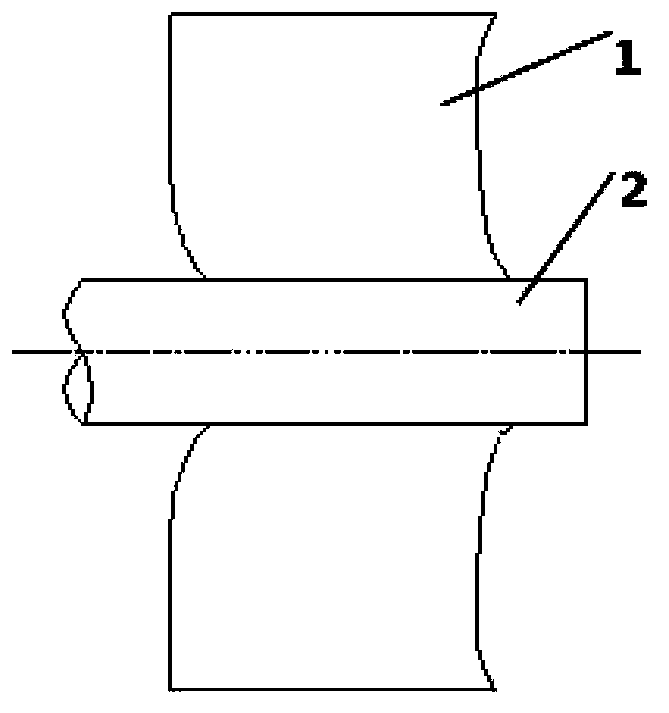

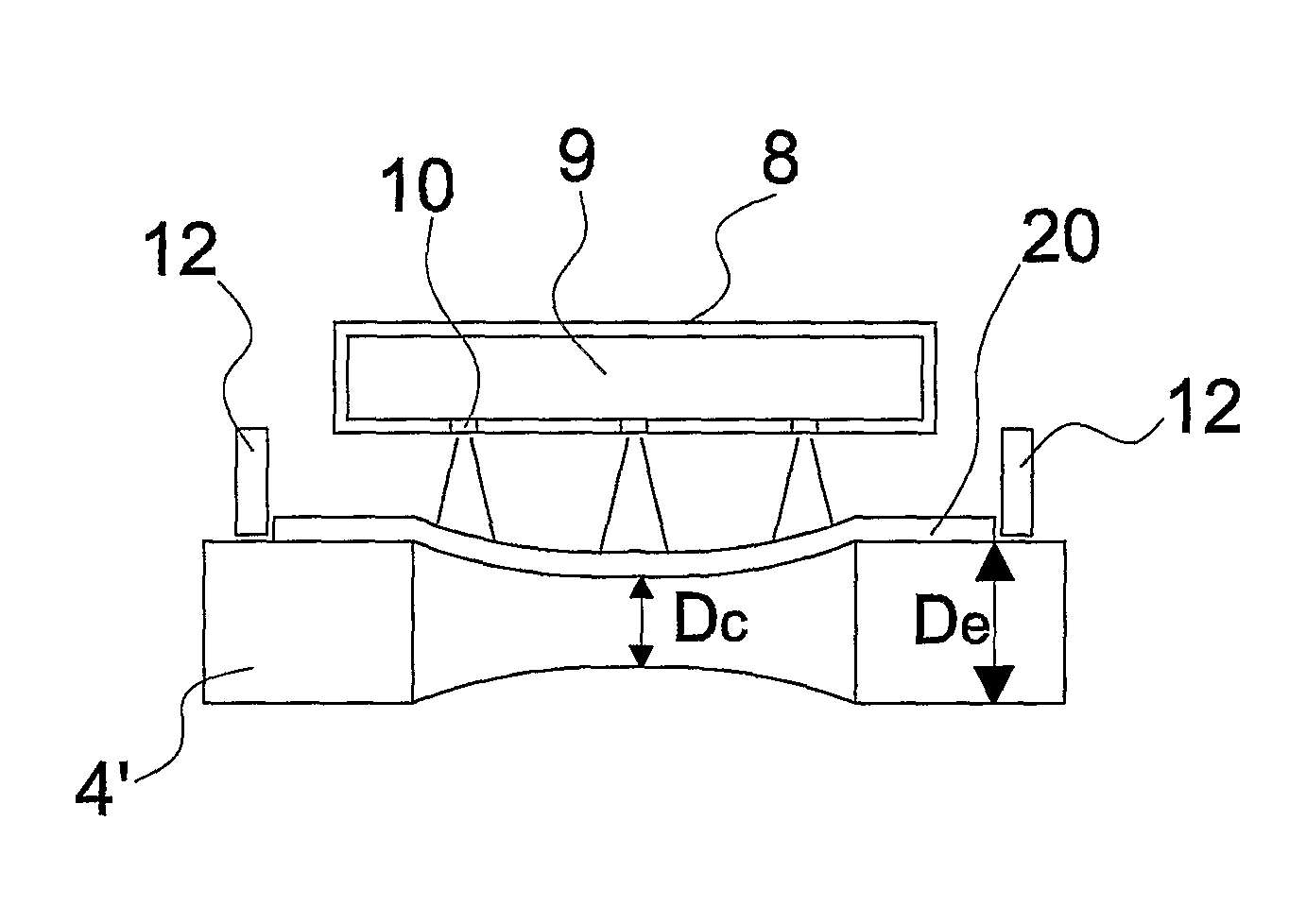

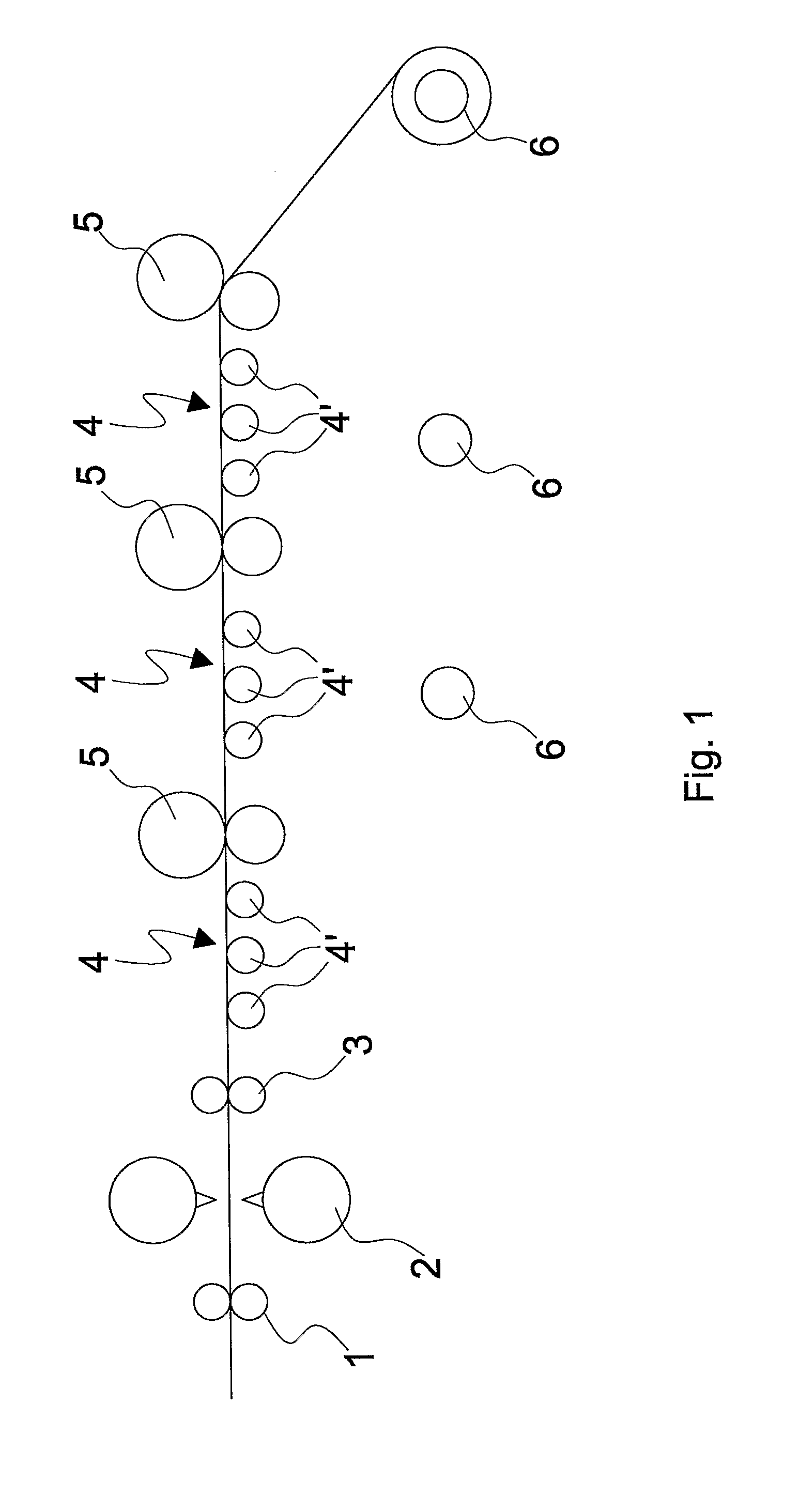

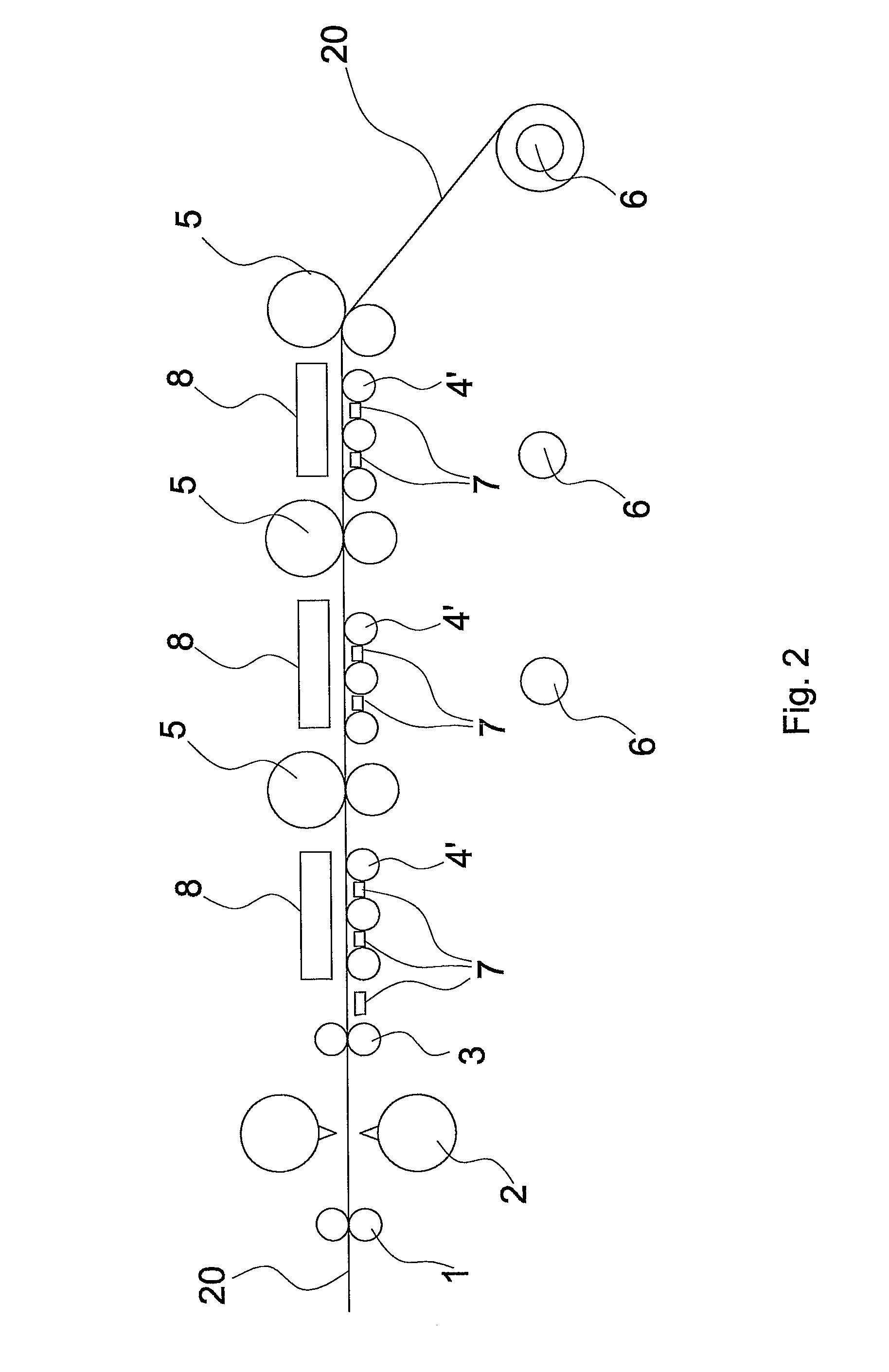

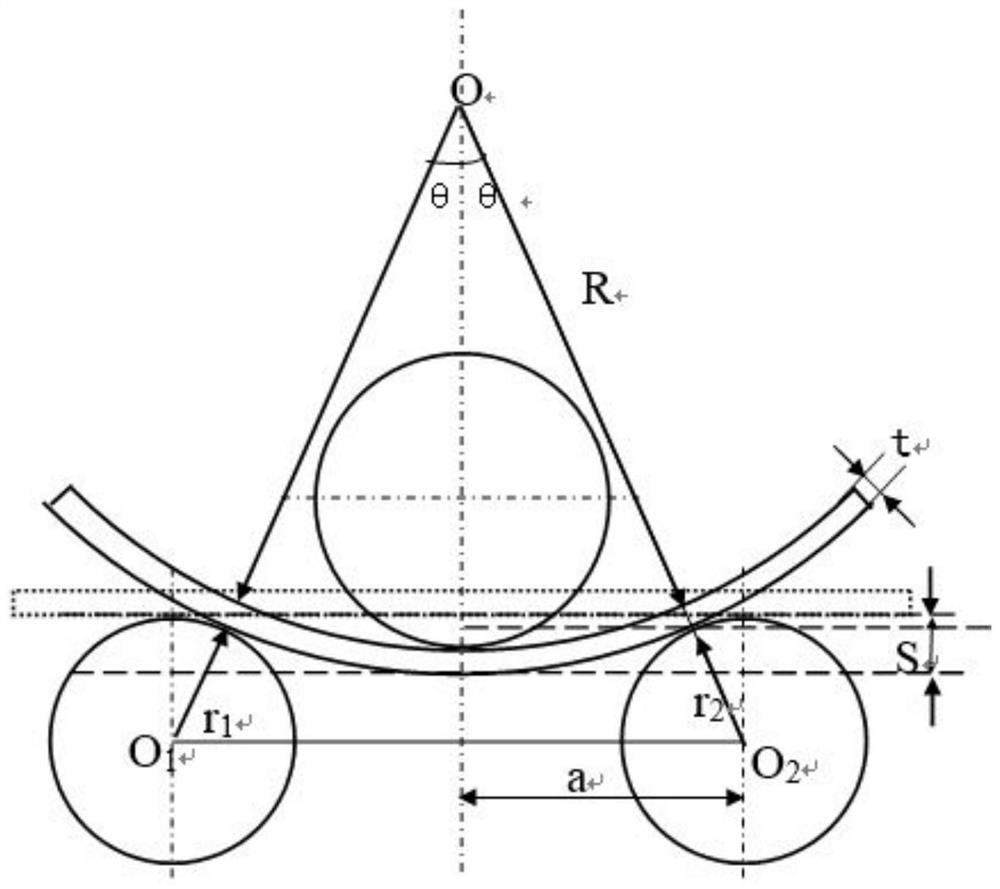

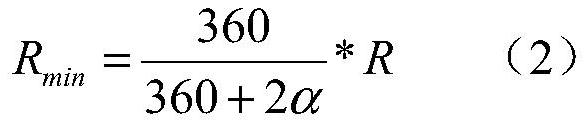

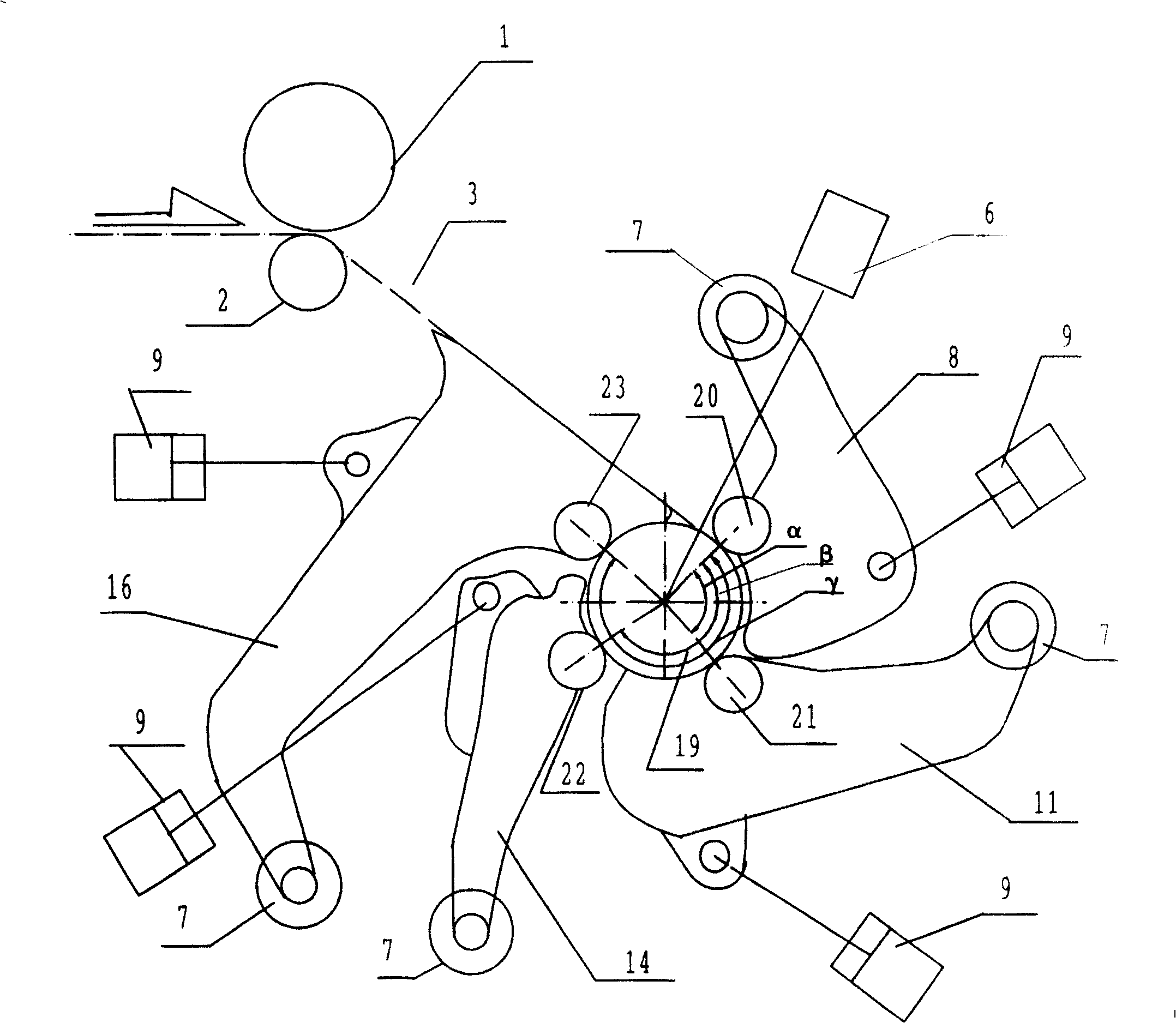

Guiding system for a metal strip at a rolling mill outlet

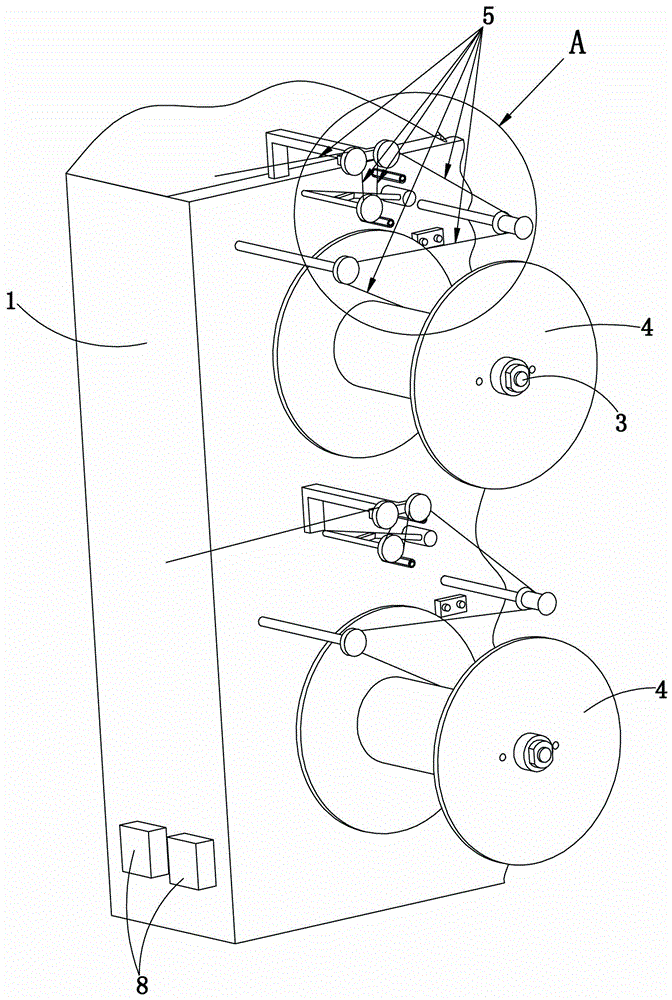

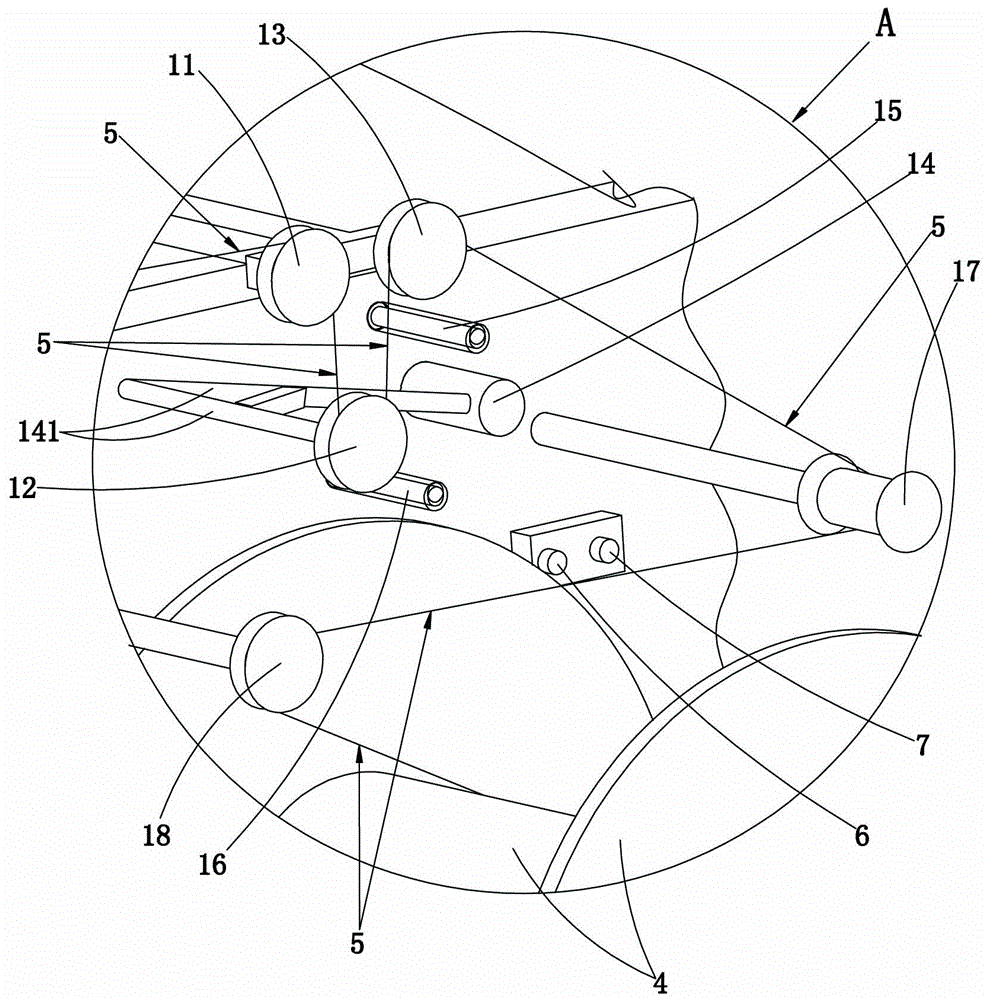

ActiveUS20100101294A1Improve coiling qualityGuiding/positioning/aligning arrangementsWork manipulationInstabilityAerodynamics

A roller guiding system for thin strips (20) at a rolling system outlet which allows a safe guiding without take-off and consequent tipping / folding of the head of the strip and without cobbles even at high feeding speeds. The system of the invention prevents the strip from impacting or sliding on the upper containment devices (8) or on the rollers (4′) by its upwards or downwards movement, thus avoiding possible damages to the surface, such as scratches or lines. Furthermore, such a guiding system acts on the mechanical-aerodynamic phenomenon which causes instability in the head moving by making a self-centering guiding system which is thus suitable for improving the winding quality of the coil itself.

Owner:DANIELI & C OFF MEC SPA

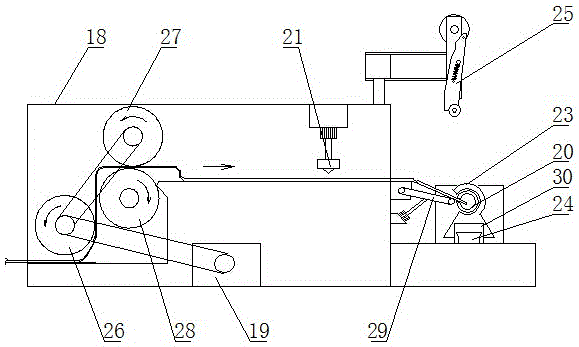

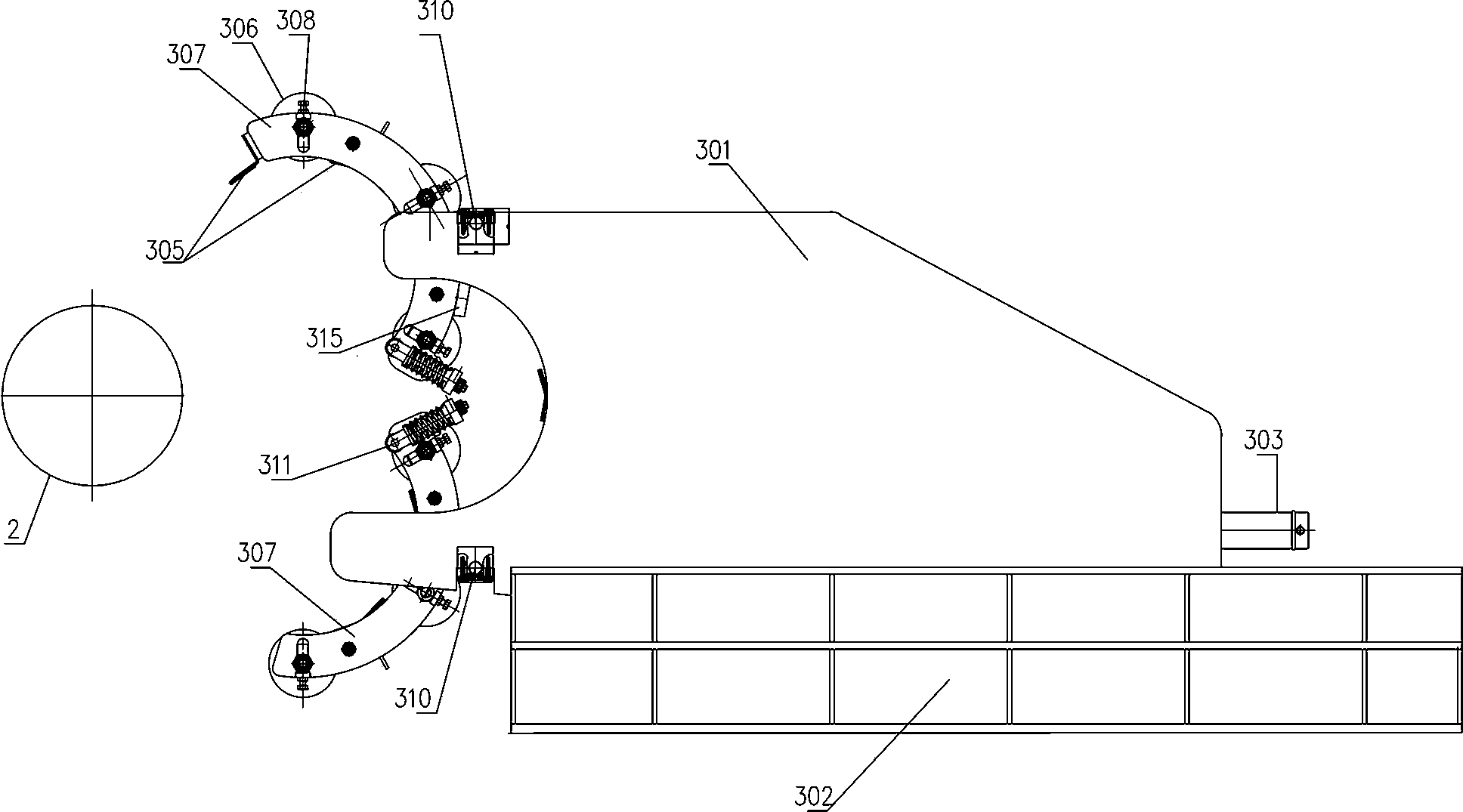

Winding, cutting and beginning device for coating machine

The invention relates to a winding, cutting and beginning device for a coating machine, which comprises a rotating mechanism and a cutting mechanism, wherein the rotating mechanism is arranged on the coating machine to be in a state rotationally corresponding to a receiving roller; and the cutting mechanism is arranged on the rotating mechanism to be in a state that while feeding to a feed roller, the coating machine for cutting is jointed with and feeds to another receiving roller. The winding, cutting and beginning device has the benefits that the structure is simple, the operation is convenient, stable cutting and winding can be performed, and the beginning of new winding is ensured to be level.

Owner:泰兴联创绝缘材料有限公司

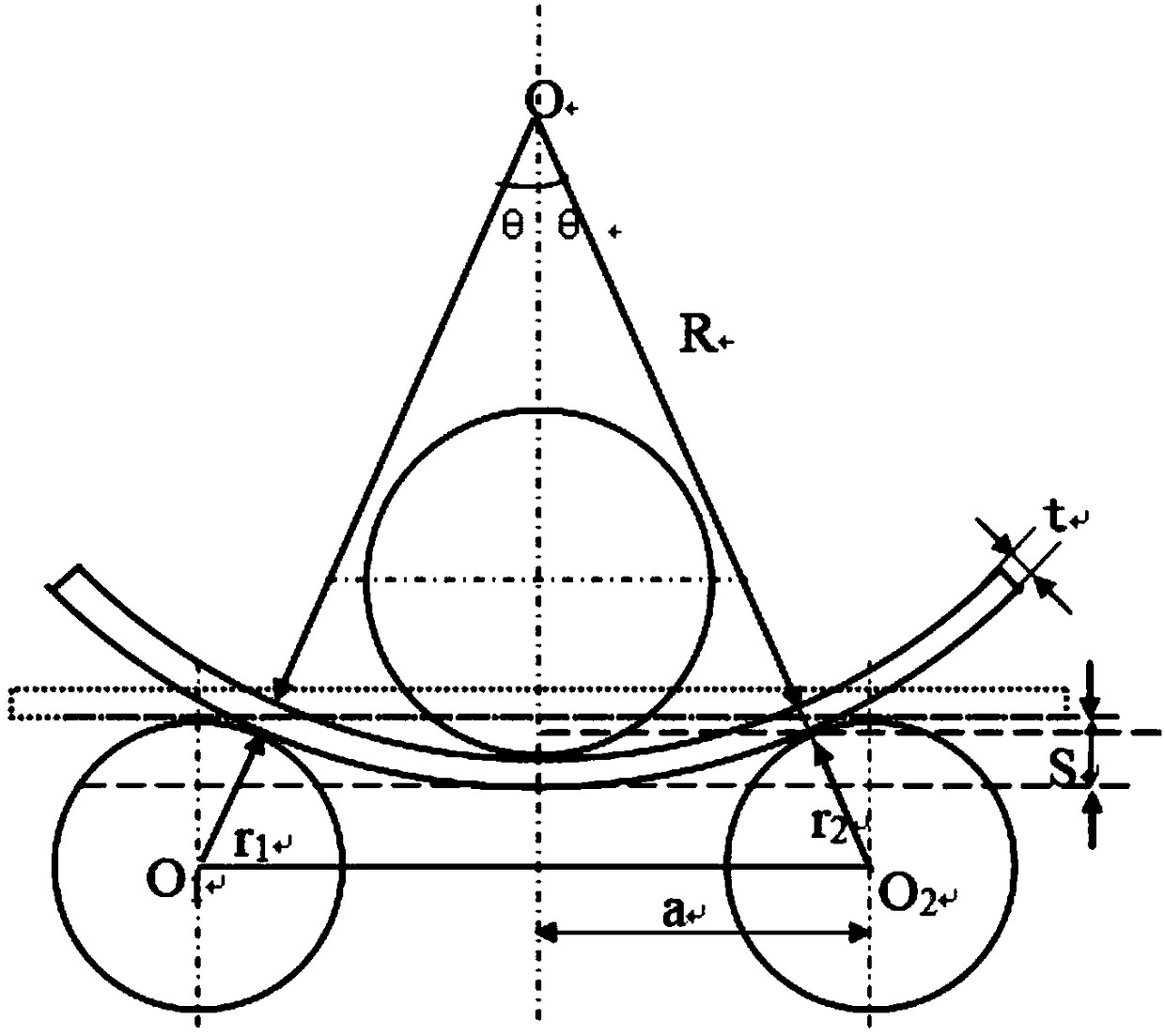

Machining process of high-strength steel coil pipe

The invention relates to a machining process of a high-strength steel coil pipe. The machining process of the high-strength steel coil pipe sequentially comprises the following steps of blanking, edgemilling and beveling, pre-bending, three-roller type plate rolling machine roller bending, straight seam welding and ring welding; before the plate rolling machine roller bending is carried out, theresilience of a steel plate is measured firstly, then the pipe coiling diameter is calculated when an actual pipe forming is carried out, the total lower displacement amount of an upper working rolleris calculated in the pipe coiling forming process, the pass displacement of the upper working roller is determined, and the pipe coiling machining is completed through a plurality of plate rolling; the pass displacement of the upper working roller is gradually decreased, and the first-pass displacement amount accounts for 50% or above of the total lower displacement amount, and the first three pass total displacement finishes 90% or above of the total lower displacement amount, and the upper working roller is basically in place when at least the antepenultimate pass is carried out. Accordingto the process, the displacement of the working roller can be effectively controlled, so that a high-strength steel plate with a proper size can prepare a dredging pipe with good straightness on a plate rolling machine, the gap of a pipe body does not exceed 3 mm at the end of the plate rolling, and welding can be carried out without circle rolling is performed, and the ovality of the pipe body isless than or equal to 2 mm.

Owner:CCCC TIANJIN DREDGING +1

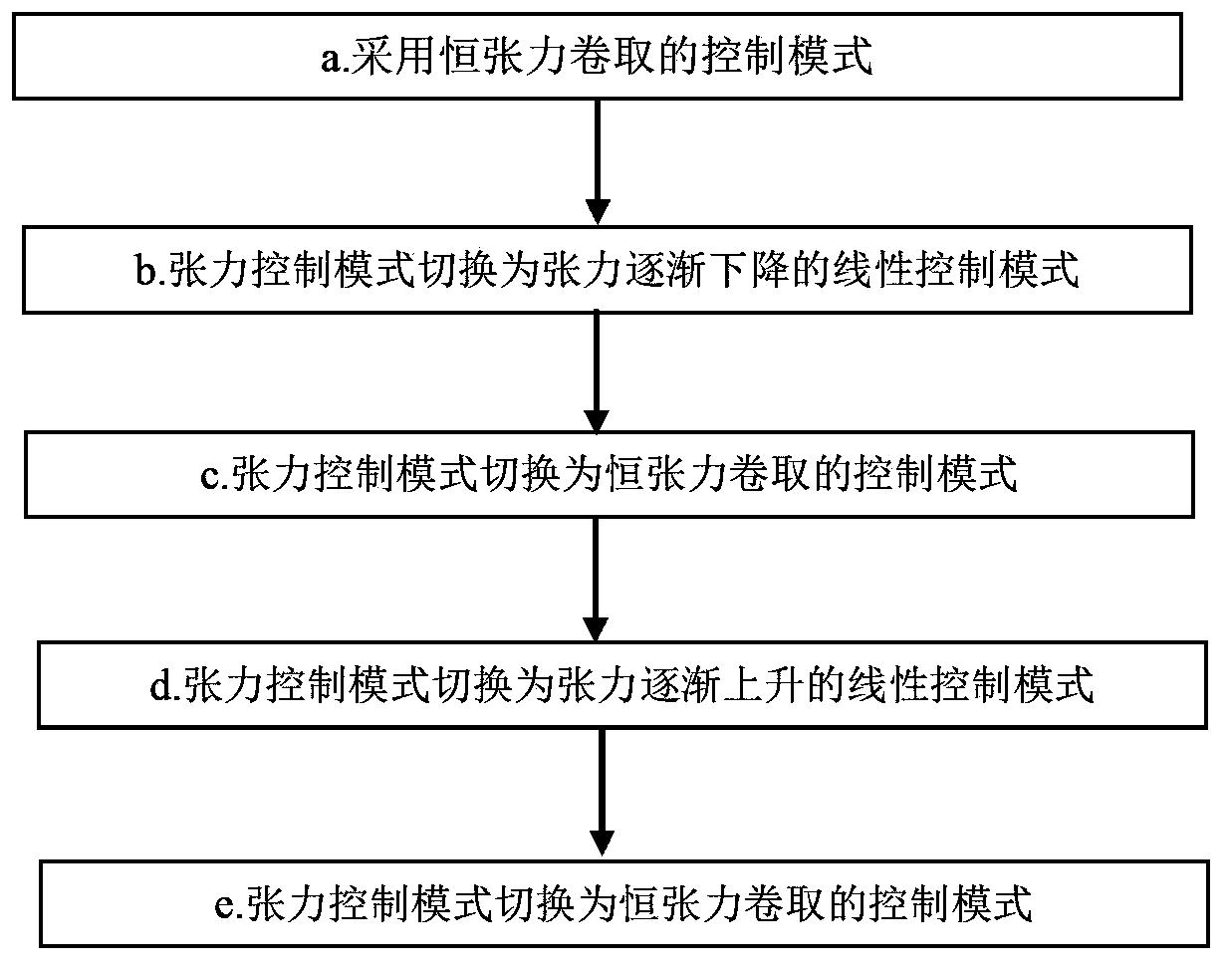

Coiling method of oriented silicon steel MgO coated steel coil

ActiveCN104342548AImprove coiling qualityAvoid quality problemsFurnace typesHeat treatment process controlLinear controlGradual increase

The invention relates to a coiling method of an oriented silicon steel MgO coated steel coil. The method comprises the following steps: 1, carrying out initial coiling on the steel coil on a coiler mandrel in a constant tension control coiling mode; 2, switching the tension control mode to a gradual decrease tension linear control mode; 3, switching the tension control mode to the constant tension control coiling mode; 4, switching the tension control mode to a gradual increase tension linear tension control mode; and 5, switching the tension control mode to the constant tension control coiling mode. The coiling method can effectively prevent the occurrence of coil collapse, inner and outer ring mandrel sideslip and other defects.

Owner:BAOSHAN IRON & STEEL CO LTD

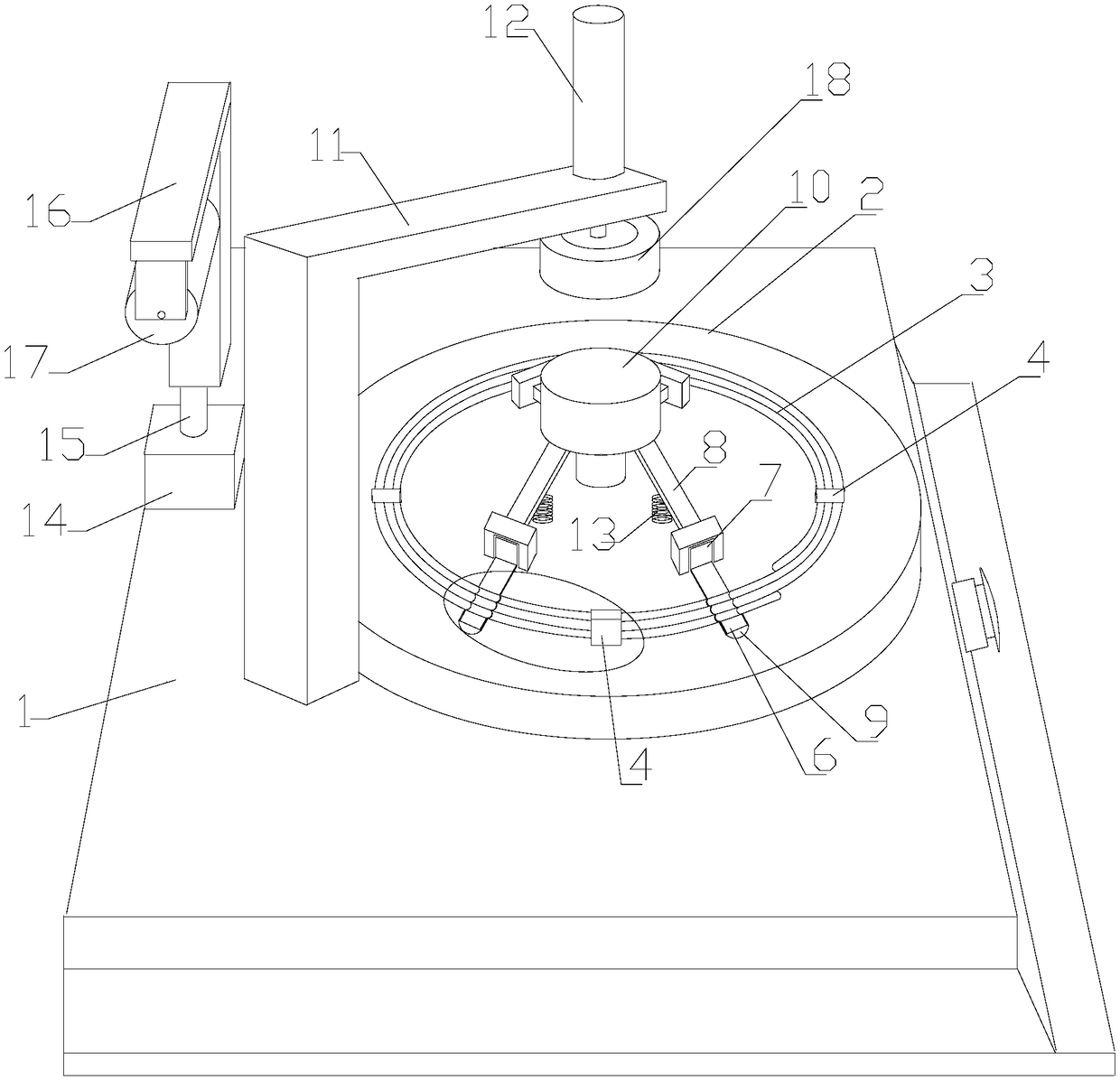

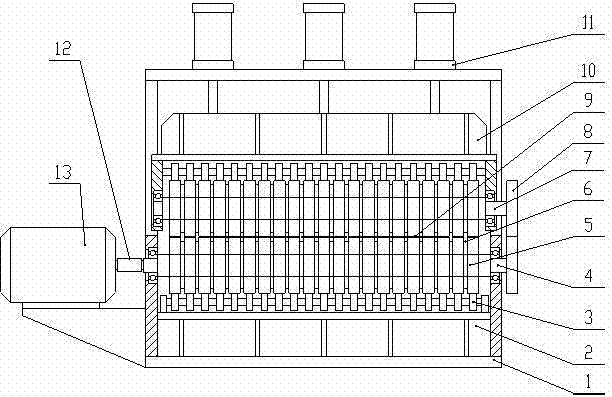

Electromagnetic coil dispenser for improving waterproof performance

InactiveUS20200179975A1Improve dispensing efficiencyImprove coiling qualityLiquid surface applicatorsSpraying apparatusGear wheelElectric machine

The present invention discloses a method for improving the solenoid dispensing water resistance, comprising a base, said base top surface of the fixed mounting support column slidably mounted threaded rod of the boom, the bottom of the threaded rod fixedly mounted may coil for dispensing of the dispensing head, when the dispensing start lifting the motor, the lifting motor drives a first gear, a first gear rotatably drives the second gear, the second gear rotates the threaded rod may be down to the coil dispensing improved dispensing manner, increasing the efficiency of dispensing can be generated after a significant reduction dispensing bubbles, to improve the quality of the coil, glue extrusion by pressurizing the way, bubbles in the glue are deposited After the dispensing is completed, use the vibration method to shake the air bubbles in the coil to make the coil have better quality.

Owner:LIAN JINWEI

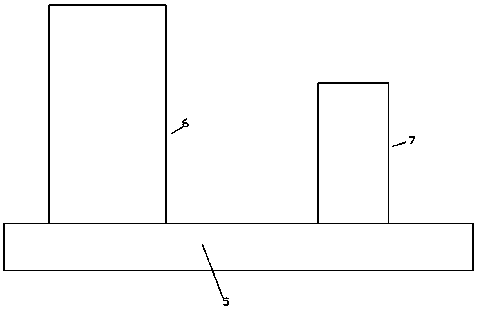

Coiled membrane deviation correcting device

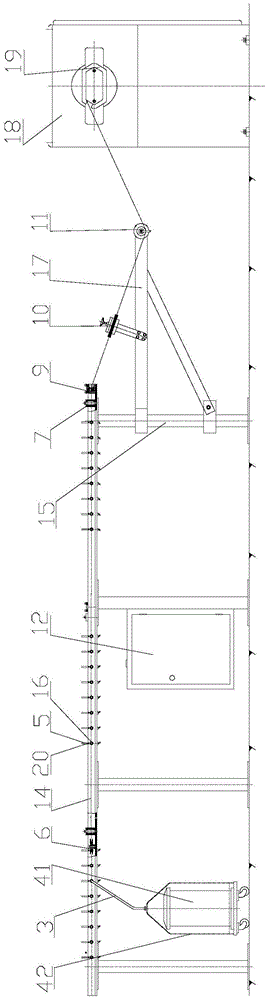

InactiveCN103303723AImprove coiling qualitySatisfy the use of coilingWebs handlingEngineeringMechanical engineering

The invention relates to a coiled membrane deviation correcting device which comprises a coiling roller mounted on a rack and used for coiling a coiled membrane, wherein a width position detection head is arranged on the rack corresponding to the side of the coiled membrane in an adjustable fixing state; an adjusting cylinder and two sliding adjusting bases are all mounted on the rack; two ends of the coiling roller are respectively connected with the two sliding adjusting bases; any one end or two ends of the coiling roller are connected with the adjusting cylinder to be in the state that the coiling roller is driven by the adjusting cylinder to slide in the axial direction; and the width position detecting head is connected with the adjusting cylinder. A deviation signal is detected by employing the width position detecting head, the coiling roller is driven by the sliding adjusting base to move in the axial direction so as to realize the deviation correction operation of the membrane, the coiled membrane deviation correcting device is simple in structure, stable in membrane conveying, free of hidden damage danger and capable of effectively correcting the deviation correction problem in the membrane conveying process and improving the coiling quality.

Owner:泰兴联创绝缘材料有限公司

Automatic pipe coiling machine

The invention relates to an automatic pipe coiling machine. A motor is fixed below a platform, a rotary table is arranged on the platform, and an output shaft of the motor is connected with the centerof the rotary table; a spiral gradual groove is formed in the rotary table, clamping buckle grooves are formed in the spiral gradual groove, clamping buckles can be embedded in the clamping buckle grooves, and the surface of each clamping buckle and the spiral gradual groove form a continuous groove shape; a downward-press bounce mechanism is arranged on the rotary table and comprises three or more elastic parts, each elastic part comprises a low segment, a fixed segment and a high segment, and each fixed segment is fixed on the rotary table; each low segment extends into the spiral gradual groove, through holes for containing the low segments are formed in the spiral gradual groove, the surface of each low segment and the spiral gradual groove form a continuous groove shape, and a downward-press block is fixed to the end of each high segment; a support is fixed on the platform, a downward-press air cylinder is fixed on the support, the retractable end of the downward-press air cylinder is downwards connected with an upward-press block, and the upward-press block is located over the downward-press block. By means of the automatic pipe coiling machine, automatic pipe coiling can beachieved, and the pipe coiling quality is high.

Owner:INNOVEX MEDICAL CO LTD

Method and apparatus for reducing coiling resistance of coiler

ActiveCN101439810AReduce the chance of damageReduce coiling resistanceWebs handlingEngineeringLife time

The invention provides a method and device for reducing reeling resistance of a reeling machine. The prior reeling device is unreasonable in structure, and can generate larger resistance in the reeling process. The technical proposal of the invention comprises: a structural shape of a second holding frame in the prior reeling device is improved from the original straight line type to the parabola type, so that the forced directions of a reeling wheel are separated to reduce the reeling resistance. The method and the device have the advantages that the parabola type holding frame replaces the straight line type holding frame, force applied to the face is partially separated to the holding frame, thereby avoiding the force from being completely applied to the reeling wheel, reducing the reeling resistance, effectively utilizing dynamic force, reducing probability of damaging the reeling wheel, improving reeling quality and prolonging service life of the equipment.

Owner:SHANGHAI FORWARD MASCH CO LTD

Constant tension winding device for nylon zipper drawn yarn

InactiveCN106115357ASolve manual adjustment of tension valueRealization of constant tension windingFilament handlingLower limitYarn

The invention relates to a constant tension winding device for nylon zipper drawn yarn. The constant tension winding device comprises a rack, motors and spindles, the motors and the spindles are assembled on the rack, and the motors drive the spindles to rotate and accordingly drive I-shaped barrels on the spindles to rotate; a left fixed wheel, a right fixed wheel, a tension resistor, an upper limiting column, a lower limiting column and a steering wheel are further fixedly assembled on the rack; an oscillating bar is fixedly assembled on the tension resistor, and an oscillating wheel is assembled on the oscillating bar; the oscillating bar oscillates between the upper limiting column and the lower limiting column, and the oscillating wheel is arranged below the left fixed wheel and the right fixed wheel; the drawn yarn sequentially passes the left fixed wheel, the oscillating wheel, the right fixed wheel and the steering wheel and then is wound on the I-shaped barrels. According to the constant tension winding device for the nylon zipper drawn yarn, the winding tension value can be automatically adjusted, constant tension winding is achieved, and the influence of production operation personnel human factors on the winding quality is reduced; the tension value of winding positions can be controlled one by one, the drawn yarn winding quality is improved, and movement of the winding process is smooth; and thus the winding efficiency and the product quality are improved.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

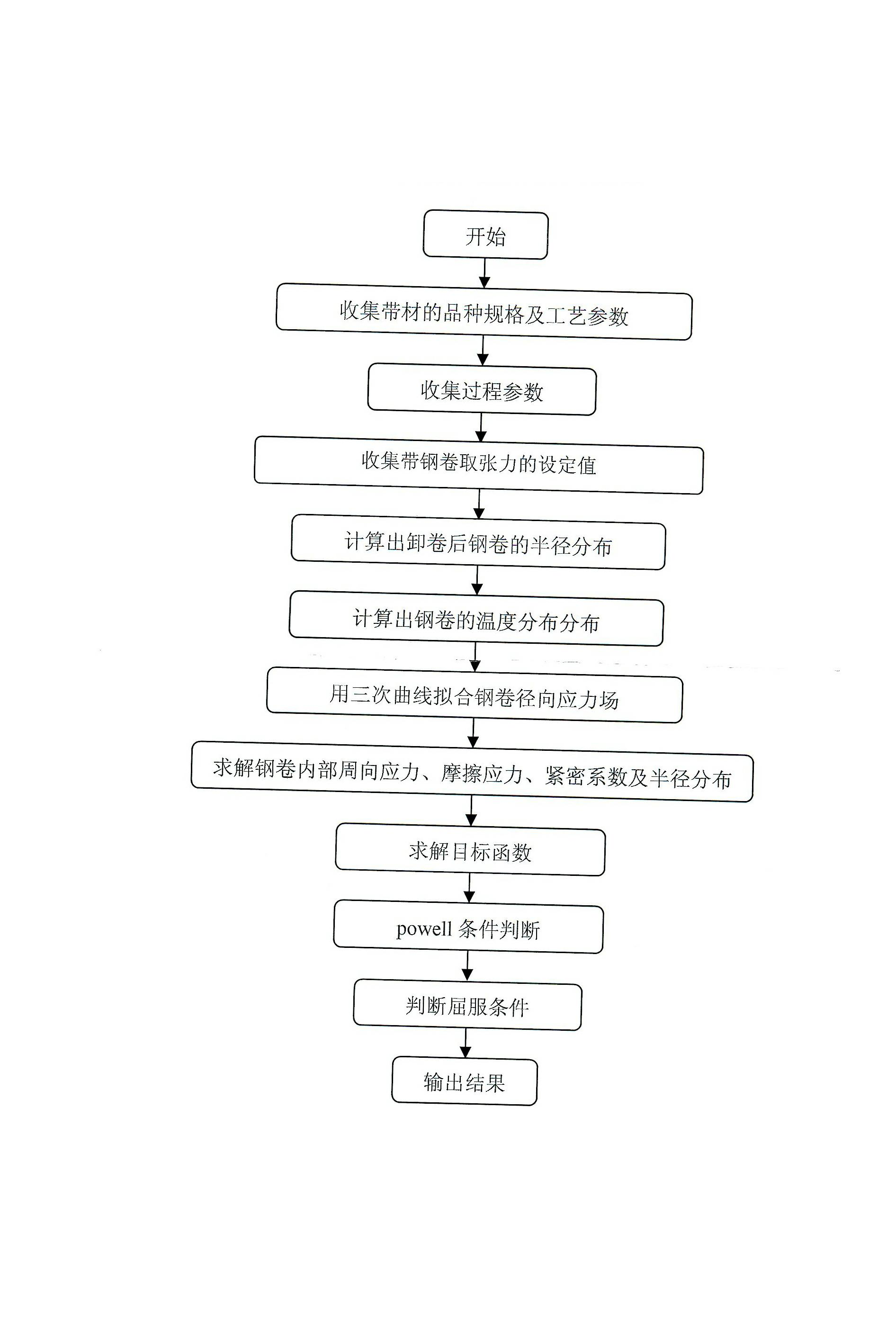

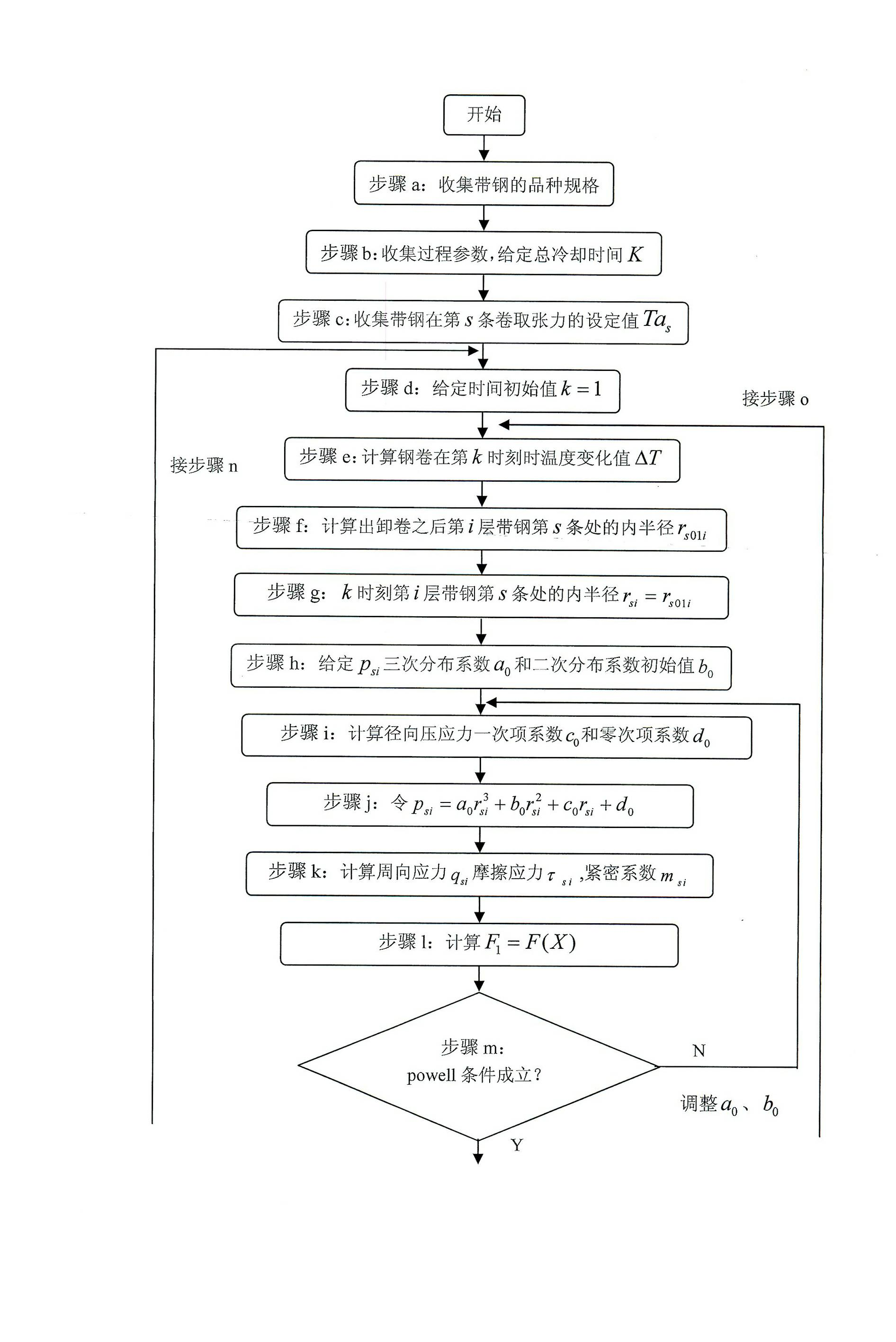

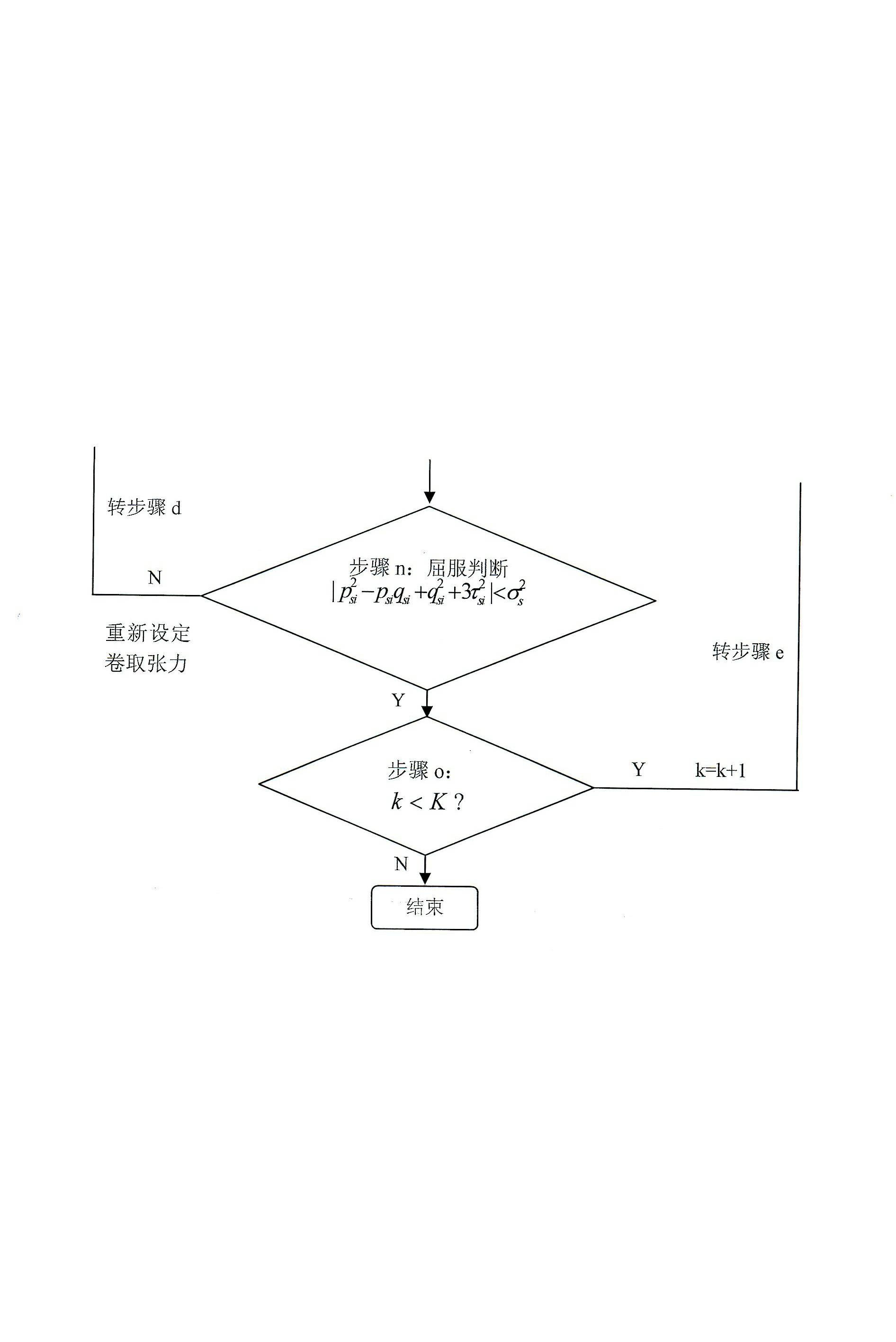

Method for forecasting and controlling additional shape waves in steel coil unloading and cooling process

InactiveCN102629124AImprove coiling qualityImprove qualityTotal factory controlProgramme total factory controlRadial stressMetallurgy

The invention discloses an integrated control method for additional shape waves in a steel coil unloading and cooling process. According to the method, features of devices and technologies in a steel coil coiling process are fully combined, anisotropy of the steel coil is considered for the first time, and a polynomial curve fitting mode is adopted to set a radial stress distribution of the inside of the steel coil, and then a circumferential stress, a friction stress and compactness coefficients of the interior of the steel coil are deduced. A rapid calculation method for thermal stress in the steel coil unloading and cooling process is established by means of a yield condition judgment. The method has the advantages that by means of a solving of a stress field of the steel coil cooling, and possible additional shape waves in the steel coil cooling process are forecasted, thereby by means of adjusting coiling process, producing of the additional shape waves of the steel coil can be controlled and the steel coil coiling quality can be improved.

Owner:唐山市榕泽钢材加工有限公司

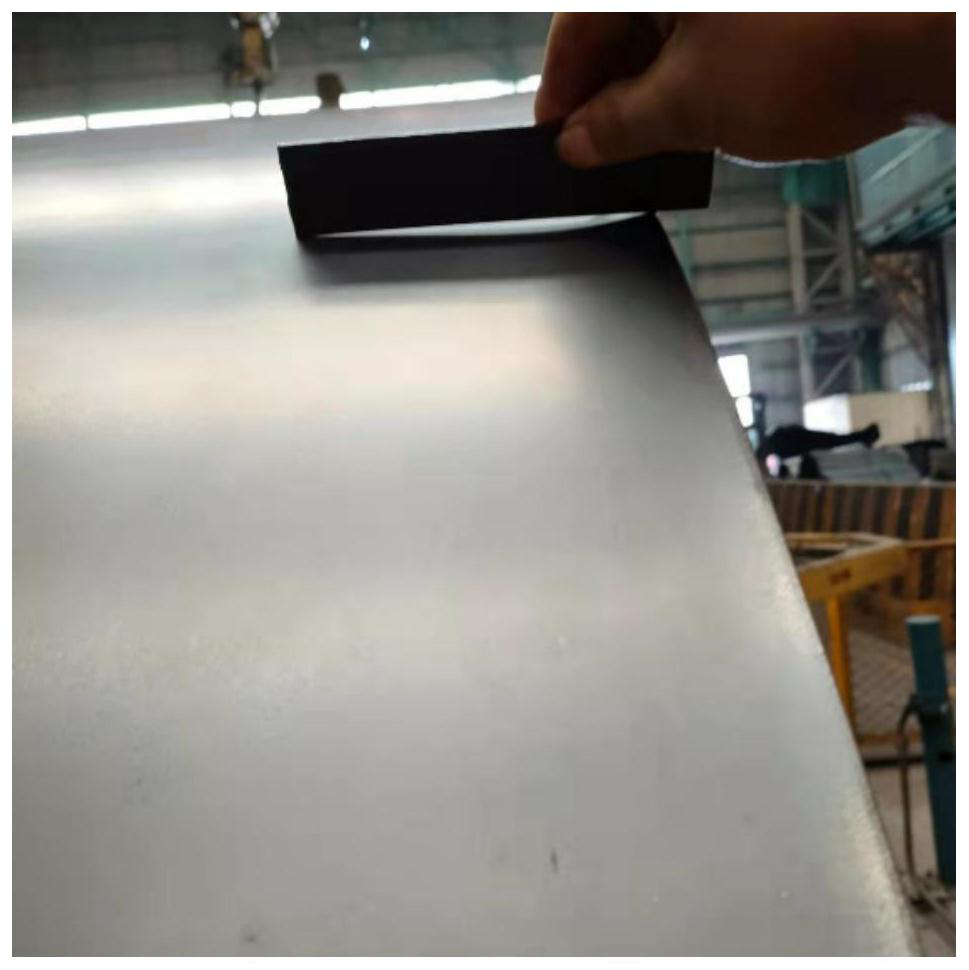

Method for improving flanging of thin strip steel coil

ActiveCN113953479AInvolves process controlAffect solidificationDesign optimisation/simulationProcess efficiency improvementMathematical modelStrip steel

The invention belongs to the field of thin-strip continuous casting, and relates to an edge quality control technology of thin strip steel produced through thin-strip continuous casting, in particular to a production control method for improving flanging of a thin-strip continuous casting thin strip steel coil. By controlling the H content of continuous casting molten steel and the baking time of various refractory materials before casting, the H content of the molten steel in a molten pool in the continuous casting process of thin strip steel is controlled, the heat conduction efficiency between the molten steel on the edge of the molten pool and a crystallization roller is improved, the thickness of a blank shell obtained by molten steel solidification is increased, and the influence of static pressure of the molten steel on the edge thickness of the continuous casting thin strip steel is reduced. Meanwhile, by measuring the difference value between the maximum value and the minimum value of the thickness of the thick area of the edge area of the thin strip steel, a mathematical model of the edge pressure of the crystallization roller and the difference value is established, and the control value of the edge pressure of the crystallization roller is adjusted in real time. The problem of flanging of the strip steel coil in the thin-strip continuous casting thin strip steel production process can be solved, so that the edge quality of the thin strip steel coil and the product percent of pass are improved.

Owner:SHAGANG GROUP +2

Cable equipment

ActiveCN107128742ASpeed up the processQuick installationFilament handlingCoil procedureEngineering

Owner:HUNAN DEYI ELECTRIC

Guiding system for a metal strip at a rolling mill outlet

Owner:DANIELI & C OFF MEC SPA

Processing technology of high-strength steel coiled pipe

The invention relates to a machining process of a high-strength steel coil pipe. The machining process of the high-strength steel coil pipe sequentially comprises the following steps of blanking, edgemilling and beveling, pre-bending, three-roller type plate rolling machine roller bending, straight seam welding and ring welding; before the plate rolling machine roller bending is carried out, theresilience of a steel plate is measured firstly, then the pipe coiling diameter is calculated when an actual pipe forming is carried out, the total lower displacement amount of an upper working rolleris calculated in the pipe coiling forming process, the pass displacement of the upper working roller is determined, and the pipe coiling machining is completed through a plurality of plate rolling; the pass displacement of the upper working roller is gradually decreased, and the first-pass displacement amount accounts for 50% or above of the total lower displacement amount, and the first three pass total displacement finishes 90% or above of the total lower displacement amount, and the upper working roller is basically in place when at least the antepenultimate pass is carried out. Accordingto the process, the displacement of the working roller can be effectively controlled, so that a high-strength steel plate with a proper size can prepare a dredging pipe with good straightness on a plate rolling machine, the gap of a pipe body does not exceed 3 mm at the end of the plate rolling, and welding can be carried out without circle rolling is performed, and the ovality of the pipe body isless than or equal to 2 mm.

Owner:CCCC TIANJIN DREDGING +1

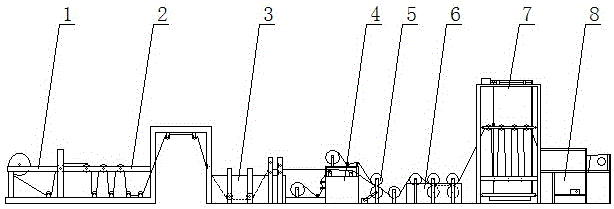

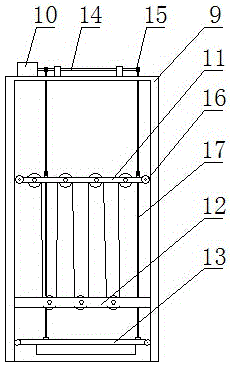

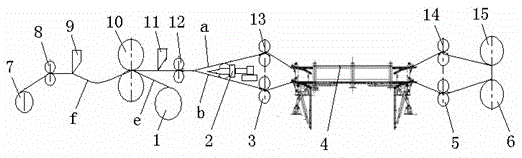

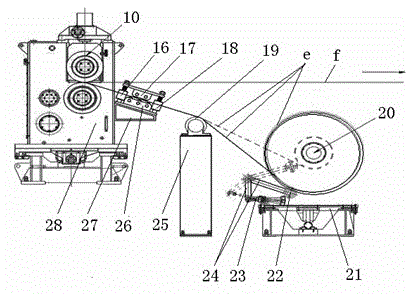

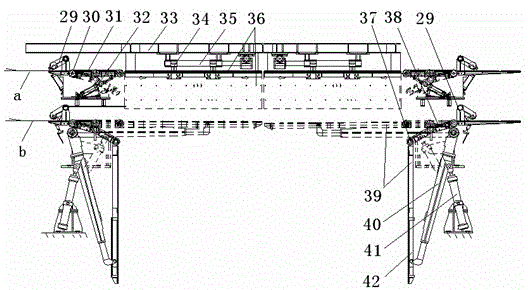

All-in-one machine for producing elastomer modified asphalt waterproof coiled material

InactiveCN105128505ASimple structureCompact structureLamination plant layoutLamination ancillary operationsElastomerBituminous waterproofing

The invention relates to an all-in-one machine for producing an elastomer modified asphalt waterproof coiled material, and belongs to the field of waterproof coiled material production devices. The all-in-one machine comprises a support for disposing a base material, a stretching device, an elastomer modified asphalt coating device, a film laminating device, extrusion pair rollers, a cooling and cutting device, a storage device and a rolling-up device, the storage device is formed by a frame, a lifting motor, a movable rack, a fixed rack and a weight body, the top of the frame is fixedly provided with the lifting motor, the frame below the lifting motor is movably provided with the movable rack through guiding wheels, and the frame below the movable rack is fixedly provided with the fixed rack. The all-in-one machine has the advantages of simple and compact structure, and small occupied area, solves the problems of complex structure of present waterproof coiled material production devices, and large worker labor intensity and low production efficiency of artificial coiling especially needed in the last process, and is of positive significance to improve the enterprise's production efficiency, reduce the worker labor intensity and improve the quality of the coiled material.

Owner:HUBEI YONGJIA WATERPROOF TECH CO LTD

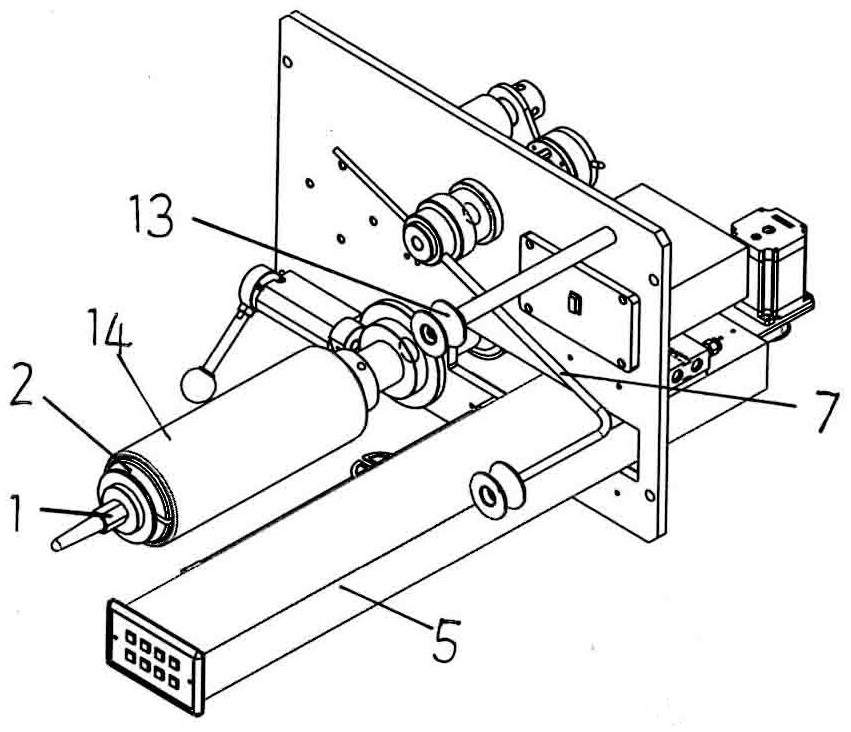

Large diameter polymer monofilament take-up device

The invention discloses a large-diameter polymer monofilament coiling device, which comprises a main shaft driven by a main servo motor, a bobbin sleeved on a bobbin tensioning fixture installed on the main shaft, and a rotary encoder is arranged on the main servo motor; The reciprocating mechanism assembly is installed on the linear guide rail through the fixed bracket, the linear guide rail is installed on the panel, and the side of the reciprocating mechanism assembly opposite to the main shaft is equipped with a pressure rod; one side of the cylinder is fixed on the panel, and the cylinder is connected to the reciprocating assembly mechanism , to push the reciprocating assembly mechanism and the pressure rod to move back and forth; the reciprocating servo motor is installed on the panel, and the reciprocating servo motor drives the reciprocating movement of the reciprocating paddle, and the reciprocating paddle is provided with a guide wire groove; Swing rod, tension sensor and angle sensor are installed on the tension swing rod to sense the tension of the monofilament and the rotation angle of the tension swing rod; the main yarn device is installed on the panel. The invention has high reliability, high transmission efficiency, saves energy consumption, and greatly improves the coiling quality of large-diameter monofilament.

Owner:NANTONG NTEC MONOFILAMENT TECH CO LTD

a cable device

ActiveCN107128742BAutomatic control workSpeed up the processFilament handlingCoil procedureEngineering

Owner:HUNAN DEYI ELECTRIC

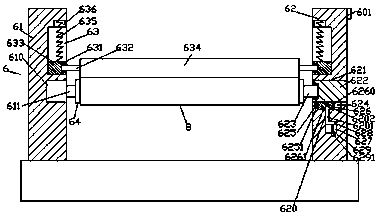

Auxiliary wire transmission equipment for stator winding machine

ActiveCN104993658BImprove coiling qualityReduced impact on performance stabilityManufacturing dynamo-electric machinesWinding machineSteering wheel

The invention discloses an auxiliary wire conveying device for stator winders which can reduce the work intensity and improve the winding quality and production efficiency. The auxiliary wire conveying device comprises a frame, feeding devices, a hose, an automatic stop probe device, a steering wheel, a vertical clustering steering device, a horizontal spring pressurization device, a de-oiling pressurization device, a guide clustering device, and an electric control device. The feeding devices are mounted at the two sides of the frame. The hose forms an electromagnetic wire output channel. When there is wire shortage or missing in the electromagnetic wire output channel, the automatic stop probe device triggers the electric control device to stop a winder. The steering wheel is used to steer each electromagnetic wire. The vertical clustering and steering device can cluster and steer a group of electromagnetic wires and preliminarily remove protective oil films on the surfaces of the electromagnetic wires. The horizontal spring pressurization device can cluster and apply tension to multiple groups of electromagnetic wires. The de-oiling pressurization device can de-oil and apply tension to multiple groups of electromagnetic wires. The guide clustering device can prevent multiple groups of electromagnetic wires from being out of a wire conveying track.

Owner:上海马拉松·革新电气有限公司

Circulating lubrication plate rolling machine

PendingCN114406054AQuality improvementImprove the lubrication effectShaping toolsEngineeringLubrication

The invention discloses a plate rolling machine capable of achieving circulating lubrication, and belongs to the technical field of plate rolling machines. According to the scheme, an upper rolling wheel is filled with lubricating liquid, and the lubricating liquid flows to a self-lubricating rotating shaft to lubricate the upper rolling wheel in the rotating process of the upper rolling wheel; meanwhile, redundant lubricating liquid is transferred to first-stage liquid collecting cavities in collecting rings on the two sides through a liquid storage channel formed in the self-lubricating rotating shaft, then the lubricating liquid is transferred to second-stage liquid collecting cavities in the rotating rings through guide pipes in the rotating rings, the lubricating liquid is guided into the upper rolling wheel through the second-stage liquid collecting cavities, and complete lubricating liquid circulation is formed; the lubricating effect is improved, the lubricating liquid is saved, meanwhile, the heat dissipation effect is improved, and the quality of produced rolled plates is further improved.

Owner:HT METALFORMING EQUIP MFG

Belt material non-destructive coiling tensioner

The invention relates to a belt material sub-section production line coiling tensioner, specifically to a belt material non-destructive coiling tensioner. The coiling tensioner comprises a frame, an upper main shaft, a lower main shaft, a plurality of inert rubber wheels and a plurality of frictional disks, wherein one end of the lower main shaft is connected with a motor, the motor is set in a reactive torque control mode, the motor outputs a torque reverse to a rotation direction of the lower main shaft, and the other end of the lower main shaft is in drive connection with the upper main shaft through a gear; the plurality of inert rubber wheels are uniformly distributed on the upper main shaft and the lower main shaft, the inert rubber wheels on the upper main shaft or the lower main shaft can rotate independently, the inert rubber wheels on the upper main shaft is opposite to the inert rubber wheels on the lower main shaft, and a channel for the belt material is formed between tworows of the inert rubber wheels; the frictional disks are arranged between the inert rubber wheels, the frictional disks rotate with the rotation of the upper main shaft or the lower main shaft, and end faces of the frictional disks are in frictional contact with the end faces of the inert rubber wheels; and a pressure apparatus for pressing the inert rubber wheels to compress the belt material tightly is arranged on the frame. With the tensioner, the problem of scratch is solved, and the coiling quality of the sub-section production line is improved.

Owner:HANGZHOU HENGLI CUTTING EQUIP

Rolling machine for hot-rolled sheets with excellent rolling assisting property

A hot-rolled sheet coiling machine with better coil-helping performance has a reel, coil-helping rollers, swinging arms for supporting said coil-helping rollers, and hydraulic cylinders for driving said swinging arms. It features that 1-3 coil-helping roller are additionally used for increasing the points to where the pressure is applied, so improving its coil-helping performance.

Owner:HEBEI IRON AND STEEL

Novel cable equipment

InactiveCN107697742ASpeed up the processQuick installationFilament handlingEngineeringElectric motor

Owner:王除仙

Pipe coiling machine

The invention relates to pipe fitting machining machinery, in particular to a pipe coiling machine. The pipe coiling machine comprises a bracket, wherein a rotating shaft is arranged on the bracket; a fixed disk fixed on the rotating shaft, an inner chuck which consists of two spliced half disks and is used for adjusting the size of an inner circle, and a movable disk which is arranged on the rotating shaft in a sleeving manner and slides along the rotating shaft to adjust a distance between the movable disk and the fixed disk are arranged on the rotating shaft in sequence; the inner chuck comprises a first chuck, a second chuck and a diameter adjustment device; and the position, close to the edge of the inner chuck, of the first chuck is hinged to the second chuck, so that the first chuck can rotate relatively to the second chuck. The pipe coiling machine disclosed by the invention is simple in structure and can be used for manufacturing coil pipes with different lengths; by the adoption of the pipe coiling machine, steel pipes are convenient to load and unload, and the operating speed is increased; and therefore, the production efficiency of the coil pipes is improved.

Owner:湖州水晶宫管业科技有限公司

Braking type non-damage coiling and tensioning machine

The invention relates to a striping production line reeling and tensioning machine, in particular to a braked strip zero damage reeling and tensioning machine. The reeling and tensioning machine comprises a frame, main shafts are respectively arranged on the upper and lower sides of the frame, a plurality of inert rubber wheels are uniformly arranged on the main shafts, the inert rubber wheels can independently rotate on the main shafts, the inert rubber wheels of the upper and lower rows are arranged corresponding to one by one, and a strip conveying passage is formed between the inert rubber wheels of the two rows; at least one of the upper and lower corresponding inert rubber wheels is provided with a braking device; and the frame is provided with a pressure device for pressing the inert rubber wheels to compact the strip. Through the reeling and tensioning machine, the scratch problem is solved, and the striping production line reeling quality is improved.

Owner:HANGZHOU HENGLI CUTTING EQUIP

Rubber roller auxiliary rolling machine and auxiliary rolling device

InactiveCN104044942AEasy to pass throughIncrease wrap angleWebs handlingEngineeringMechanical engineering

The invention provides a rubber roller auxiliary rolling machine and an auxiliary rolling device. The rubber roller auxiliary rolling machine comprises a base, wherein a main machine is slidably arranged on the base, a driving cylinder is fixedly arranged on the base, a piston rod of the driving cylinder is connected with the main machine, an upper swing arm and a lower swing arm are hinged to the main machine, a space for containing a coiling block is formed between the upper swing arm and the lower swing arm, a plurality of rubber rollers protruding the inner wall are movably arranged on each of the upper swing arm and the lower swing arm, and a plurality of guide plates are movably arranged among the rubber rollers and the outer side end of the upper swing arm. The invention provides the rubber roller auxiliary rolling machine and the auxiliary rolling device, and the rubber rollers arranged on the upper swing arm and the lower swing arm are used for replacing belt auxiliary rolling structures in the prior art, so that the structure is simplified, processing and manufacturing are convenient, and the maintenance is also very convenient. After the structure is adopted, the wrap angle of the coiling block is also increased, and the coiling quality is improved. The guide plates are arranged, so that interference to the ends of belt materials among the rubber rollers is overcome, and the full-wrap-angle compressing of the belt materials on the coiling block is realized.

Owner:OUDA YICHANG ELECTROMECHANICAL EQUIP

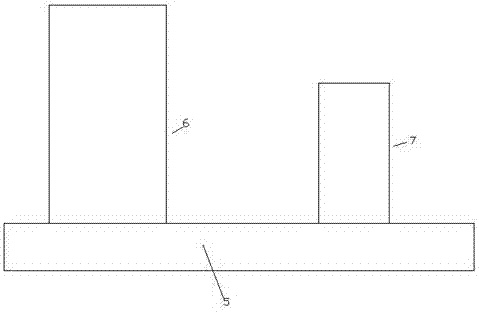

Driving mechanism of multi-head scroll recoiling machine

InactiveCN101559896BChanging the slitting and coiling processCompact layoutToothed gearingsShearing machinesReduction driveEngineering

The invention relates to a mechanical transmission method, in particular to a driving mechanism of a multi-head scroll recoiling machine which satisfies special requirements of belt material coiling or cord winding. The driving mechanism comprises an electromotor and a decelerator. The driving mechanism is characterized in that an output shaft of the decelerator (2) which is connected with an electromotor (1) is engaged with a plurality of coupling transmission ladles (4) by a distribution gear (3); each transmission ladle (4) transmits kinetic moment and velocity to two scrolls (5) connectedthereon; and rotation speed of each scroll can be self-adjusted according to length of the recoiled stripe. The driving mechanism changes traditional strip-by-stripe recoiling technique of belt material, thereby compacting machine unit distribution, reducing equipment investment, simplifying operation and improving recoiling quality. The driving mechanism further realizes flexible winding of multi-head cords.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Method for forecasting and controlling additional shape waves in steel coil unloading and cooling process

InactiveCN102629124BImprove coiling qualityImprove qualityTotal factory controlProgramme total factory controlRadial stressMetallurgy

The invention discloses an integrated control method for additional shape waves in a steel coil unloading and cooling process. According to the method, features of devices and technologies in a steel coil coiling process are fully combined, anisotropy of the steel coil is considered for the first time, and a polynomial curve fitting mode is adopted to set a radial stress distribution of the inside of the steel coil, and then a circumferential stress, a friction stress and compactness coefficients of the interior of the steel coil are deduced. A rapid calculation method for thermal stress in the steel coil unloading and cooling process is established by means of a yield condition judgment. The method has the advantages that by means of a solving of a stress field of the steel coil cooling, and possible additional shape waves in the steel coil cooling process are forecasted, thereby by means of adjusting coiling process, producing of the additional shape waves of the steel coil can be controlled and the steel coil coiling quality can be improved.

Owner:唐山市榕泽钢材加工有限公司

Device for trimming, shoveling and then coiling composite material plate

ActiveCN102581047BAvoid wear and tearAvoid scratchesMaterial accumulating devicesAuxillary arrangementsCircular discEngineering

Owner:YUNNAN HEAVY EQUIP MFG GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com