Method and apparatus for reducing coiling resistance of coiler

A technology of coiling machine and resistance, which is applied in the direction of coiling strips, transportation and packaging, and thin material processing, etc. It can solve the problems of loss of power, large resistance, and affecting coiling quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

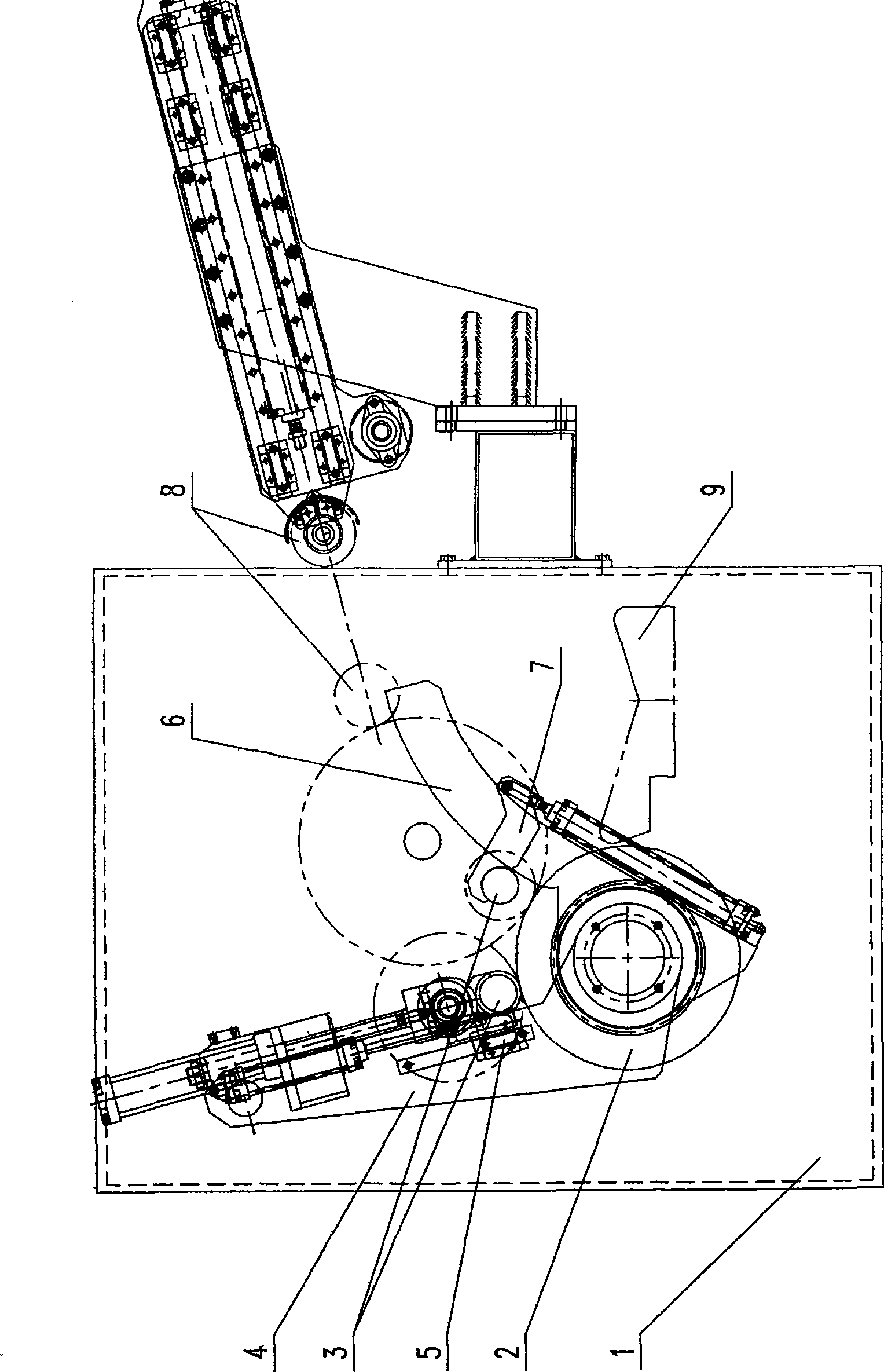

[0011] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

[0012] A coiling device in calendering equipment for producing plastic films with a width of 1500 mm, the device is composed of the structure according to the attached drawings, including: support wall 1, coiling wheel 2, winding mandrel 3, first cage 4, second A cage shaft pressing device 5 , a second cage 6 , a second cage shaft pressing device 7 , a second cage surface pressing device 8 and a platform 9 . Among them: the two ends of the coiling wheel 2 with a diameter of 450 mm and a wheel surface length of 1750 mm are fixed on the support wall 1 with an inner width of 2390 mm, and the first cage 4 and the parabolic second cage 6 are respectively fixed on the coiling wheel 2 When the coiling operation is performed, the coiling wheel 2 is rotated by an external power source, the first cage shaft pressurizing device 5 is fixed on the first cage 4, the press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com