Belt material non-destructive coiling tensioner

A non-damaging and tensioning technology, applied in the direction of coiling strip, thin material handling, transportation and packaging, etc., to improve the coiling quality and solve the effect of scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

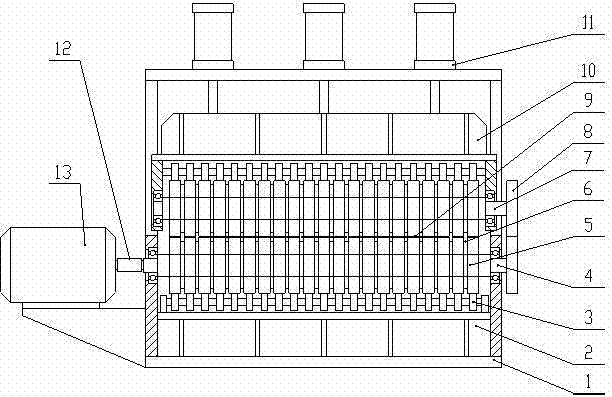

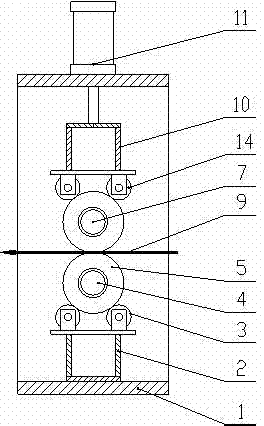

[0015] like figure 1 , figure 2 As shown, a coiling and tensioning machine without damage to the strip, the coiling and tensioning machine includes a frame 1, an upper main shaft 7, a lower main shaft 4, a plurality of inert rubber wheels 5 and a plurality of friction discs 6, and an upper main shaft 7 and the lower main shaft 4 are respectively arranged on the upper and lower sides of the frame 1 through bearings, and one end of the lower main shaft 4 is connected with a motor 13 through a coupling 12, and the motor 12 is set as an anti-torque control mode, and the output of the motor 13 is in the same direction as the rotation direction of the lower main shaft 4 In the opposite torque, the other end of the lower main shaft 4 is in transmission connection with the upper main shaft 7 through a gear 8 . The plurality of inert rubber wheels 5 are evenly distributed on the upper main shaft 7 and the lower main shaft 4, and the inert rubber wheels 5 are connected with the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com