Rubber roller auxiliary rolling machine and auxiliary rolling device

A technology of rubber rollers and coiling aids, which is applied in the directions of coiling strips, transportation and packaging, thin material processing, etc. It can solve the problems of difficult installation and debugging, the failure of the whole equipment to work normally, and high processing precision requirements, and achieve convenience The effects of processing and manufacturing, easy maintenance, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

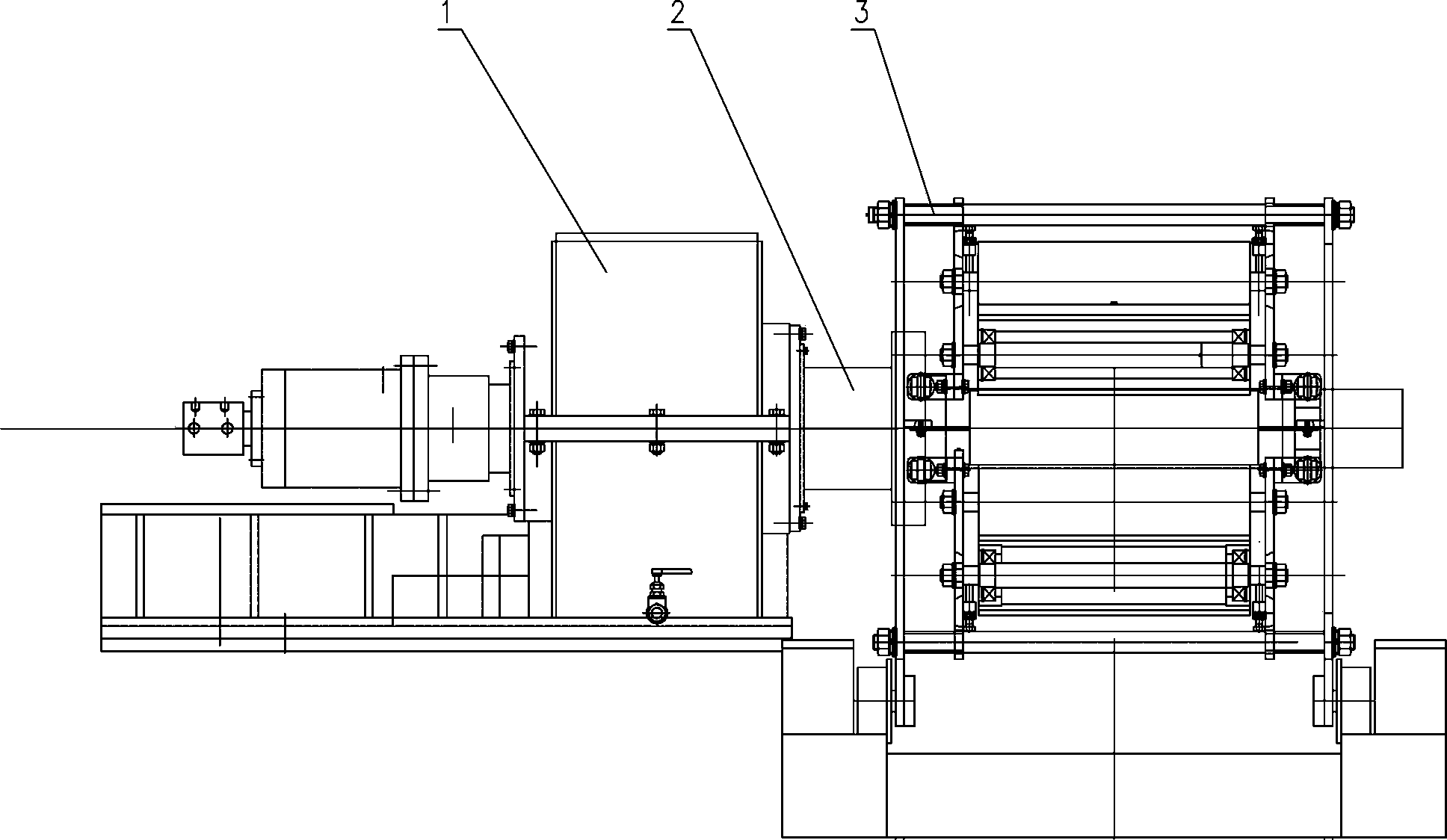

[0030] Such as figure 1 Among them, the coiler 1 is located on one side of the auxiliary coiler 3, the reel 2 is installed on the coiler 1, and the reel 2 is driven to rotate by the coiler 1. Utilize the coiler 3 to tightly hold the reel 2, so that the steel strip is tightly wound on the reel.

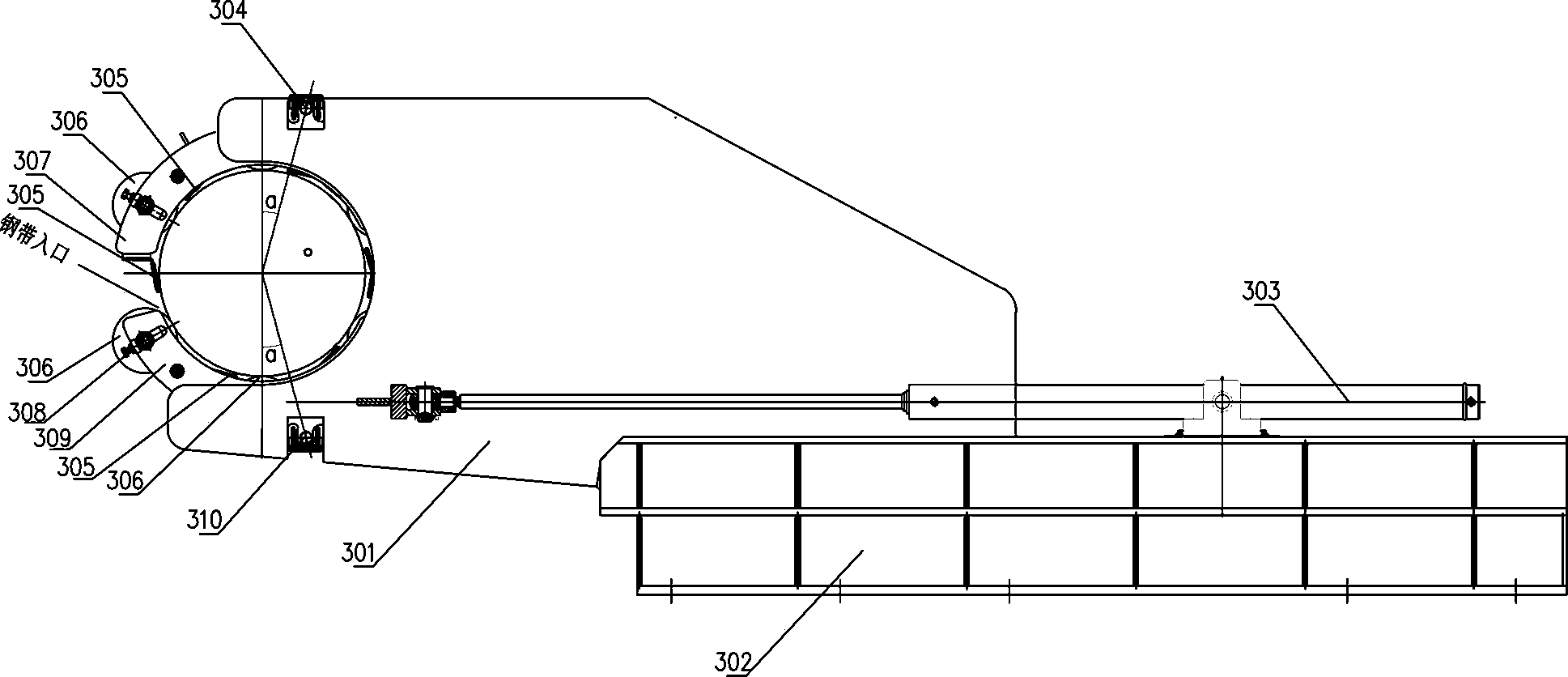

[0031] Such as figure 2 , 3 Among them, a rubber roller rolling machine includes a base 302, a host 301 is slidably installed on the base 302, a drive cylinder 303 is fixedly installed on the base 302, and the piston rod of the drive cylinder 303 is connected to the host 301; The expansion and contraction of the cylinder 303 drives the main machine 301 to reciprocate on the base 302. The driving cylinder 303 can be a hydraulic cylinder or an air cylinder, which is also the power mechanism of the present invention. Preferably, the main machine 301 slides horizontally, but for occasions with special requirements, It is also feasible for the host 301 to slide along an inclined surface...

Embodiment 2

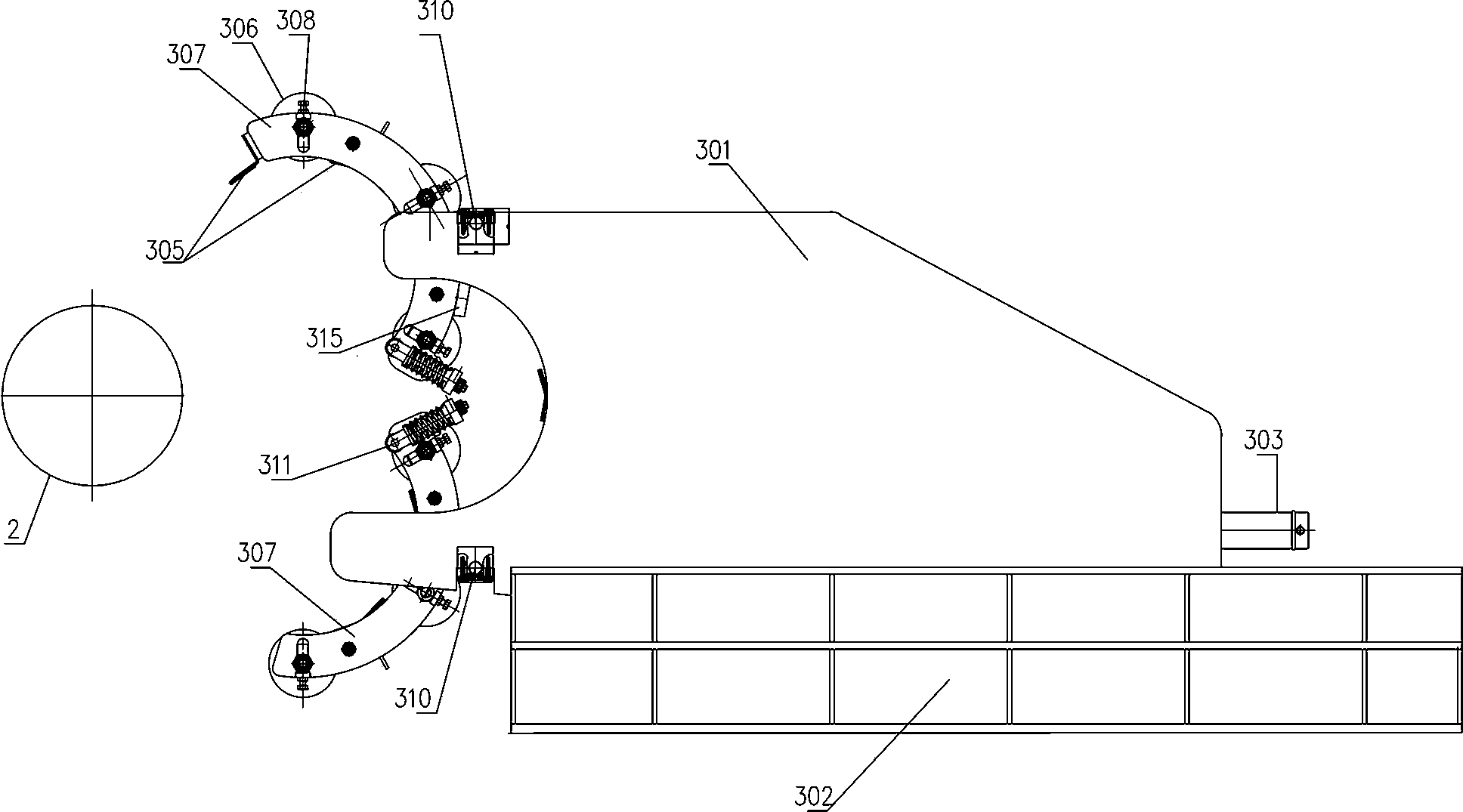

[0042] Such as Figure 2~4 Among them, a roll-assisting device is a roll-assisting structure that can be used alone, and it includes an upper swing arm 307 and a lower swing arm 309 that are hingedly connected to the main machine 301, and an upper swing arm 307 and a lower swing arm 309 are formed between the upper swing arm 307 and the lower swing arm 309 to accommodate rolls. In the space of cylinder 2, a plurality of rubber rollers 306 protruding from the inner wall are movably installed on the upper swing arm 307 and the lower swing arm 309, and a plurality of guide plates are movably installed between the rubber rollers 306 and on the outer end of the upper swing arm 307 305; in this example, the upper swing arm 307 and the lower swing arm 309 can be driven independently by a driving device, such as a gear mechanism, an air cylinder or a hydraulic cylinder, to complete the opening and closing action.

[0043] preferred as image 3 Among them, an extension section 313 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com