Pipe coiling machine

A coil machine and chuck technology, applied in the field of pipe fittings processing machinery, can solve the problems of unadjustable coil length, inconvenient coil disassembly, poor coil quality, etc., achieve simple structure, improve coil quality, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

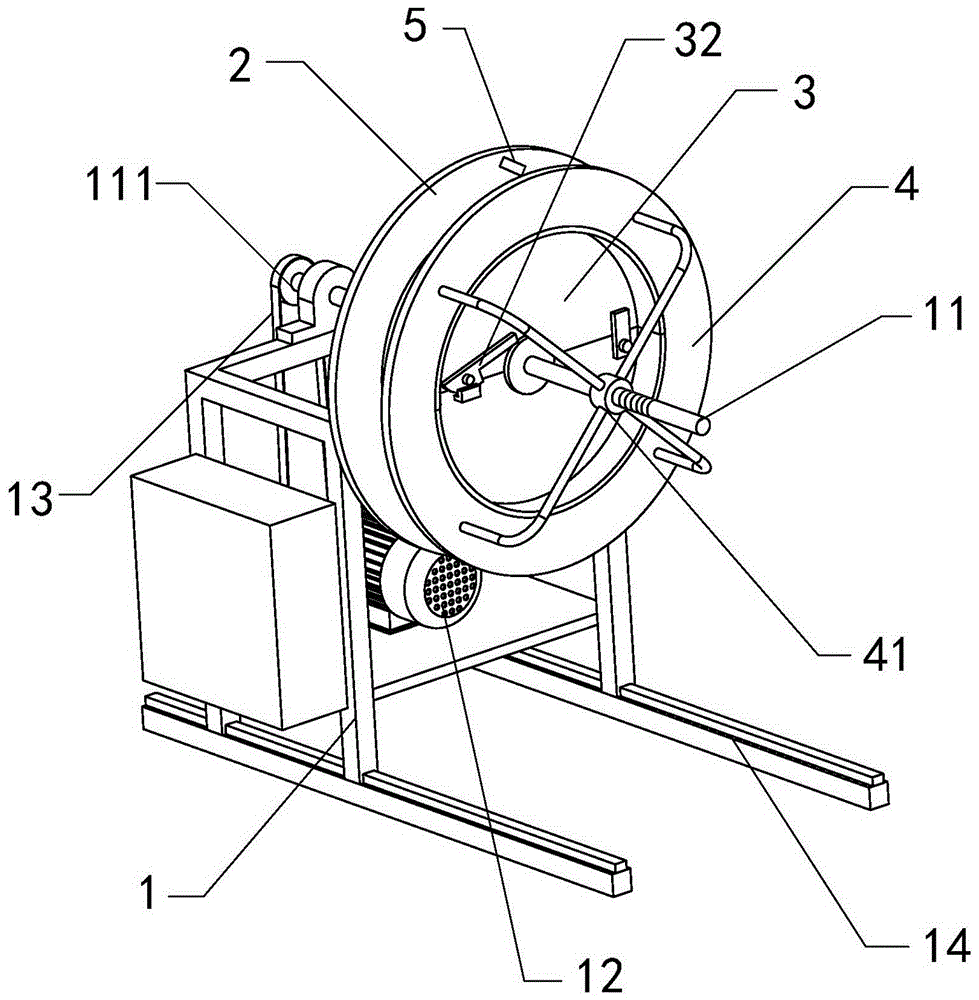

[0027] according to figure 1 , figure 2 As shown, a coil machine includes a bracket 1, a rotating shaft 11 is arranged on the bracket 1, and the rotating shaft 11 is sequentially provided with: a fixed disk 2 fixed on the rotating shaft 11, and a utility model composed of two half-discs assembled together. The inner chuck 3 for adjusting the size of the inner ring and the movable disc 4 sleeved on the rotating shaft 11 and slides along the rotating shaft 11 to adjust the distance from the fixed disc 2 .

[0028] Through the rotation of the rotating shaft 11, the steel pipe is wound on the inner chuck 3 to complete the bending, the distance between the movable disk 4 and the fixed disk 2 can be controlled, and the length of the coil pipe and the diameter of the inner chuck 3 can be easily loaded and unloaded.

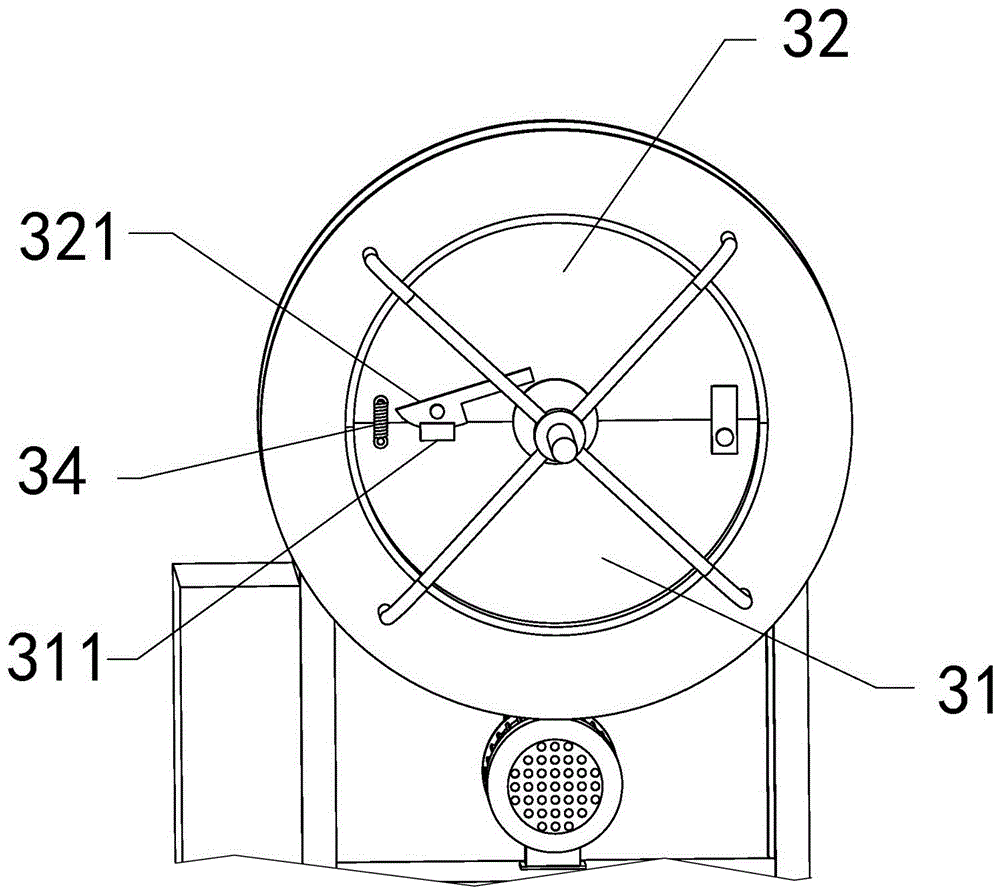

[0029] The inner chuck 3 comprises a first chuck 31, a second chuck 32 and a diameter adjusting device 33, and the first chuck 31 and the second chuck 32 are hinged ne...

Embodiment 2

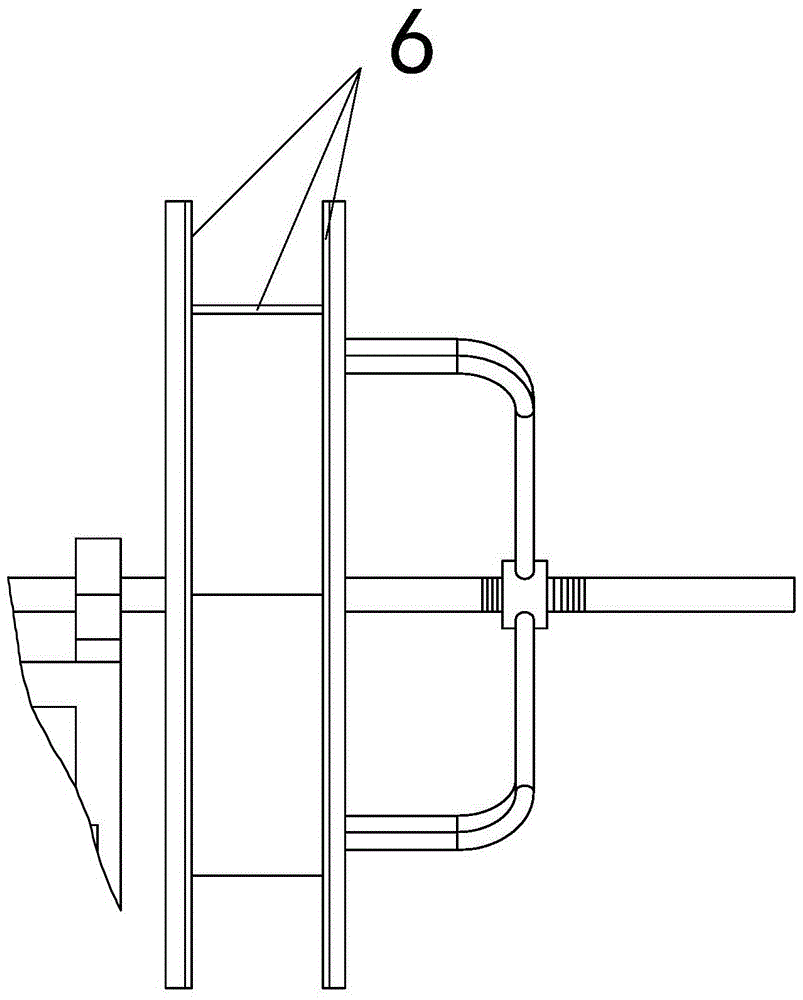

[0036] The difference from the above-mentioned embodiment 1 is that, according to image 3 As shown, the outer peripheral surface of the inner chuck 3 and the surface of the fixed plate 2 and the moving plate 4 close to the inner chuck 3 are provided with a buffer layer 6 to protect the steel pipe.

Embodiment 3

[0038] The difference from the first embodiment above is that a slide rail 14 is provided at the bottom of the support 1, which slides axially on the rotating shaft 11 to make the coil more uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com