Machining process of high-strength steel coil pipe

A processing technology and steel coil technology, which is applied in the field of high-strength steel coil tube processing technology, can solve the problems of not considering the springback of steel plates, difficult coil tube processing, and non-coil tube technology, so as to improve the efficiency and quality of tube making, reduce the Tensile stress, reduction of difficulty and effect of roll rounding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

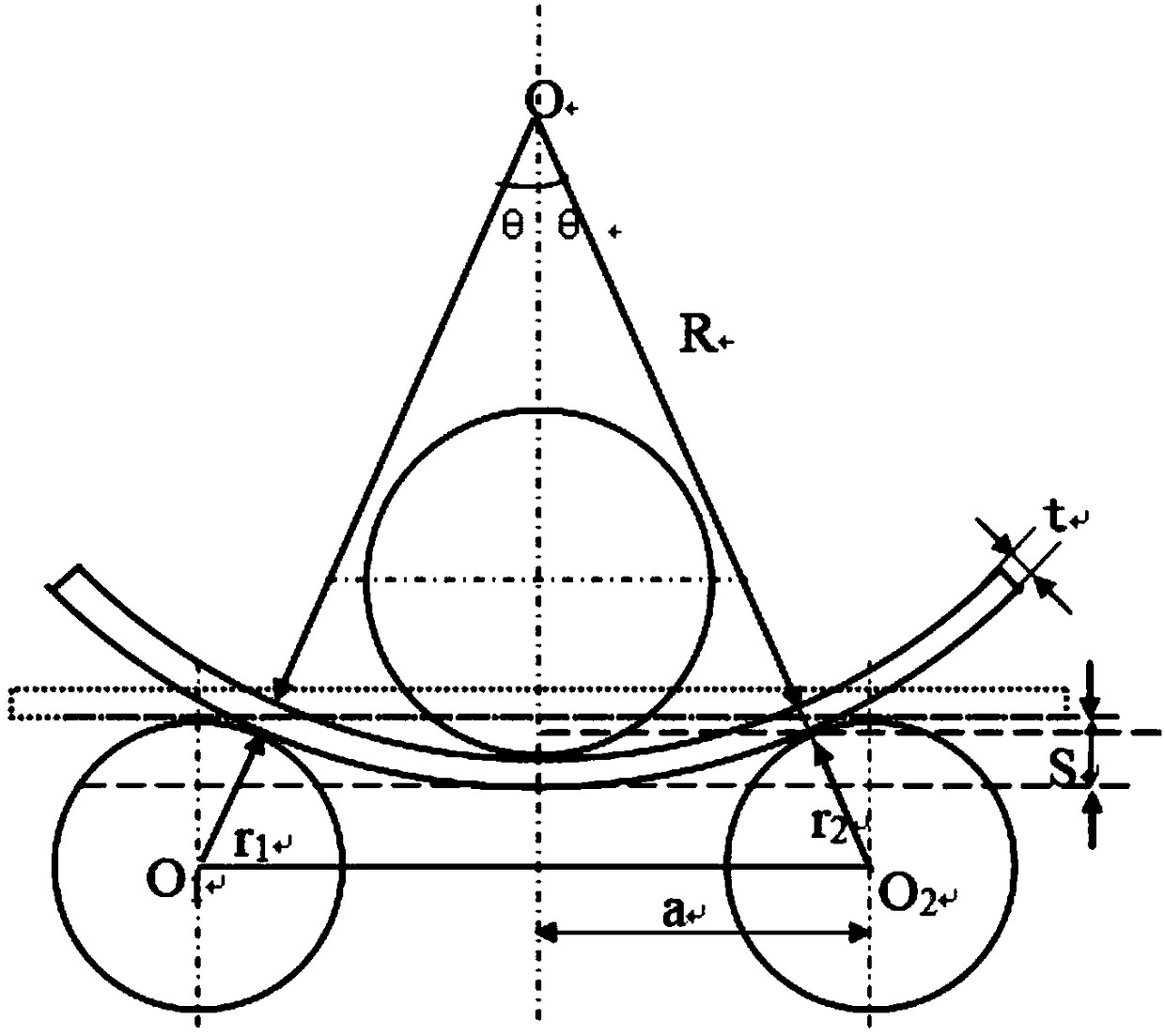

[0046] A 15mm thick steel plate with a yield strength of 1250MPa is used to make a steel pipe with an inner diameter of 850mm. The diameter of the working roll and the support roll of the three-roll plate rolling machine is 400mm, and the distance between the support rolls is 800mm. According to formulas 1 and 2, it is calculated that the total downward displacement of the work roll is 148.4mm when the 12° springback is considered, as shown in Table 1. The displacement of the work roll is only 140.4mm when the springback is not considered. Adjust the upper work roll The displacement amount is the method to control the diameter of the pipe body when rolling the pipe, and the larger displacement amount of the work roll can obtain the pipe body with a smaller diameter.

[0047] Table 1 Work roll displacement of 850mm diameter steel pipe made of high-strength steel plate

[0048]

[0049] Considering that even after repeated coiling, the steel plate still has a little springba...

Embodiment 2

[0054] A steel pipe with an inner diameter of 800mm is made of a 16mm thick high-strength steel plate with a yield strength of 1360MPa. The diameter of the working roll of the three-roller plate rolling machine is 550mm, the diameter of the support roll is 450mm, and the distance between the support rolls is 700mm. According to formulas 1 and 2, the total down-adjustment displacement of the work roll considering the 18° springback is 111.6 mm, as shown in Table 3 for details.

[0055] Table 3 Work roll displacement of 800mm diameter steel pipe made of high-strength steel plate

[0056]

[0057] Considering that even after repeated coiling, there is still a little rebound of the steel plate, the calculated total downward displacement of the work roll 111.6mm is rounded up to 112mm as the actual displacement of the work roll, and the coiling into a tube is completed in 7 passes. The distribution of the displacement of the roller table is shown in Table 4.

[0058] Table 4 C...

Embodiment 3

[0062] A steel pipe with an inner diameter of 900 mm is made of a 20 mm thick high-strength steel plate with a yield strength of 1360 MPa. The diameter of the working roll of the three-roller plate rolling machine is 550mm, the diameter of the support roll is 450mm, and the distance between the support rolls is 700mm. According to formulas 1 and 2, the total down-adjustment displacement of the work roll considering the 20° springback is 102.3mm, as shown in Table 5 for details.

[0063] Table 5 Work roll displacement of 900mm diameter steel pipe made of high-strength steel plate

[0064]

[0065] Considering that even after repeated coiling, there is still a little rebound of the steel plate, the calculated total downward displacement of the work roll 102.3mm is rounded up to 103mm as the actual displacement of the work roll, and the coiling into a tube is completed in 8 passes. The distribution of the displacement of the roller table is shown in Table 6.

[0066] Table 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com