Circulating lubrication plate rolling machine

A technology of circulating lubrication and plate rolling machine, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of plate rolling machine vibration and backtracking, affecting product quality, and limiting machine performance, so as to reduce severe wear and improve Heat dissipation effect, effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

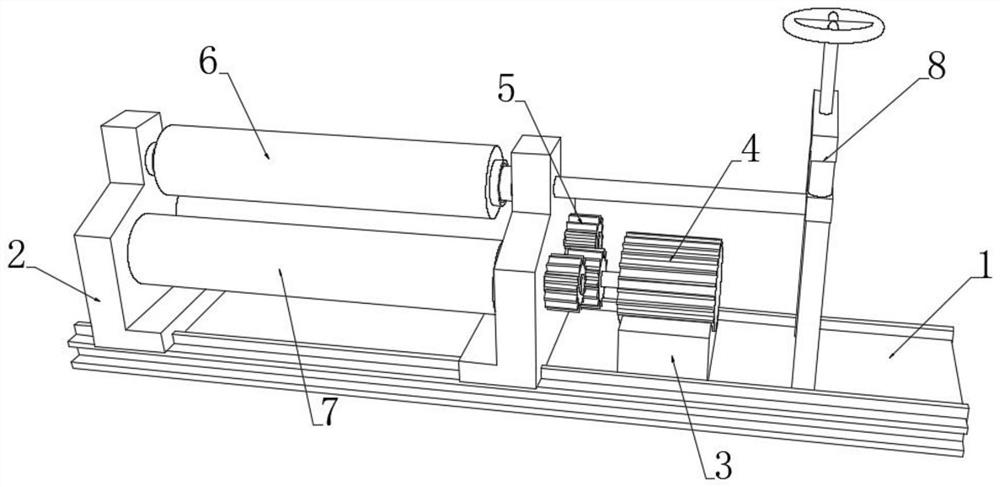

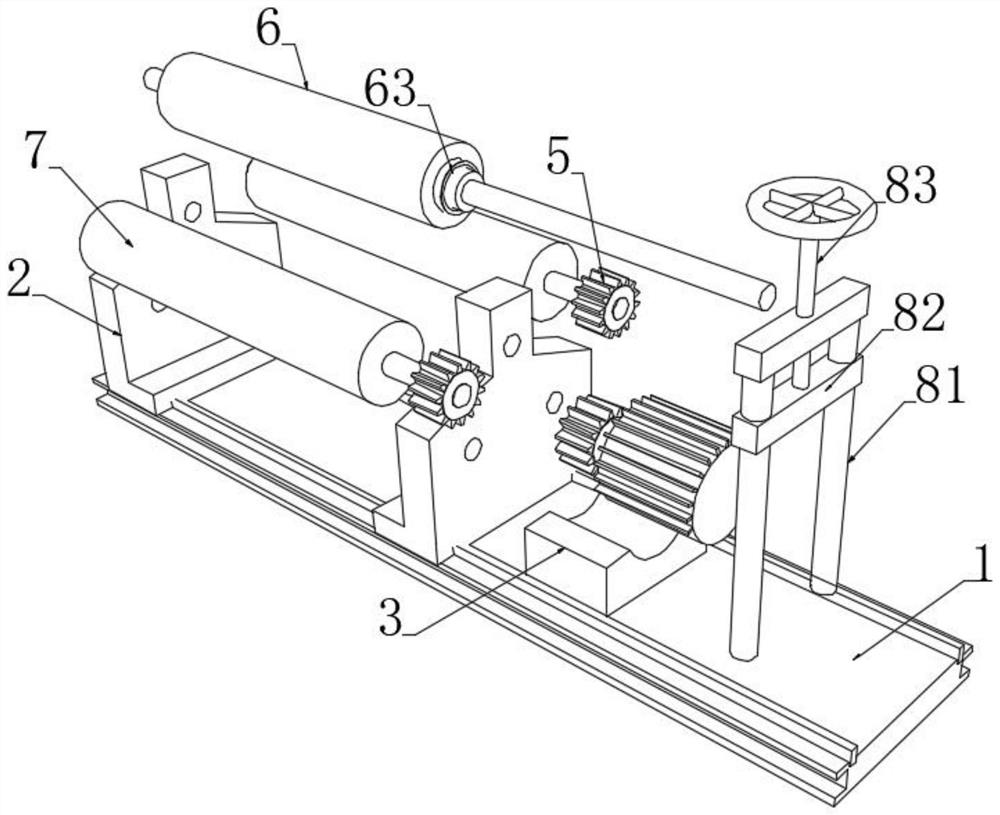

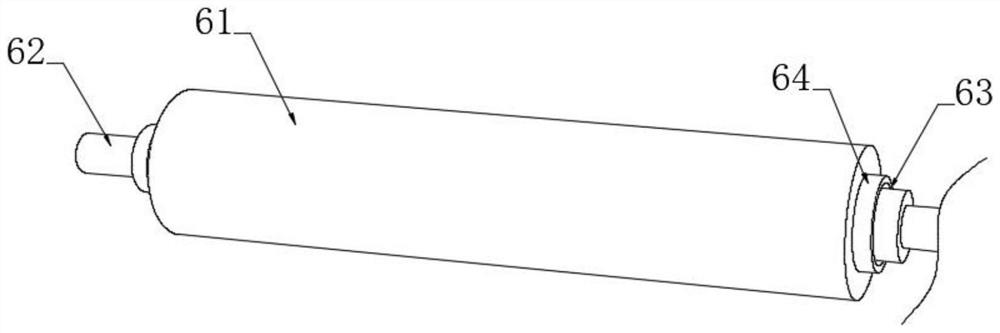

[0039] see Figure 1-7, a plate rolling machine with circulating lubrication, including a base 1, a pair of roller bearings 2 are arranged on the base 1, a pair of driving rollers 7 are arranged between the pair of roller bearings 2, and the driving rollers 7 include a middle The rotating shaft and the external rolling wheel, the rotating shaft runs through the right side roller shaft support 2 and extends to its outside, the right end of the rotating shaft is provided with a damping gear 5, the upper end of the base 1 is provided with a motor support 3, and the motor support 3 is provided with The motor 4, the output end of the motor 4 is provided with a driving gear corresponding to the position of the buffer gear 5, and the upper end between a pair of roller bearings 2 is provided with a circulating self-lubricating roller shaft 6, and the circulating self-lubricating roller shaft 6 includes a self-lubricating roller shaft in the middle. The rotating shaft 62 and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com