Auxiliary wire transmission equipment for stator winding machine

A stator winding and wire transmission technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of not being able to meet the needs of large-capacity generators, increase the mental pressure of error prevention, and increase errors, so as to reduce the frequency , improve the quality of coiling, relieve the effect of working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing.

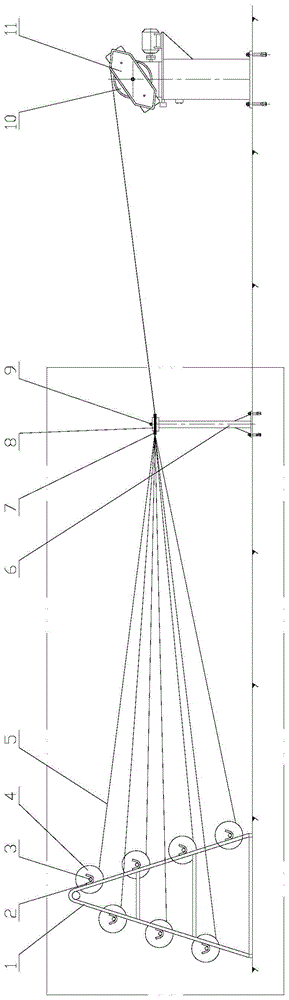

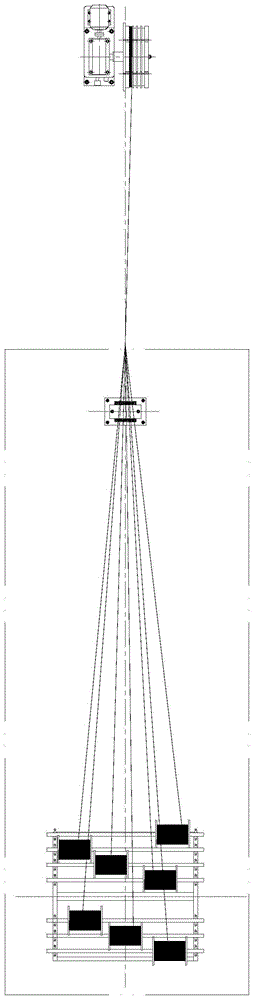

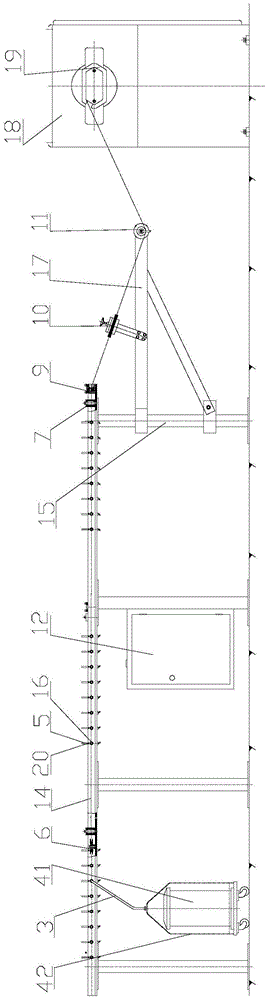

[0048] see Figure 2a with Figure 2b , the auxiliary wire feeding equipment of the stator winding machine of the present invention comprises a frame 8, a feeding device 1, a hose 3, a self-stop probe device 5, a steering wheel 6, a vertical cluster steering device 7, and a horizontal spring pressure device 9. Deoiling and pressurizing device 10, guiding and converging device 11 and electrical control device 12.

[0049] Frame 8 comprises a conveying flat plate 13, two side frames 14 and many pairs of uprights 15; The longitudinal direction of conveying flat plate 13 is provided with several pairs of transmission line areas at intervals; Corresponding to each transmission line area on two pieces of side frame 14 is opposite respectively On the upper surface of the two side frames 14, corresponding to each transmission line channel 16, a probe installation hole that is ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com