Driving mechanism of multi-head scroll recoiling machine

A technology of transmission mechanism and multi-head coil, which is applied in transmission devices, gear transmission devices, mechanical equipment, etc., can solve the problems of increasing the number of coiling motors, large equipment investment, and scratches on the surface of the strip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

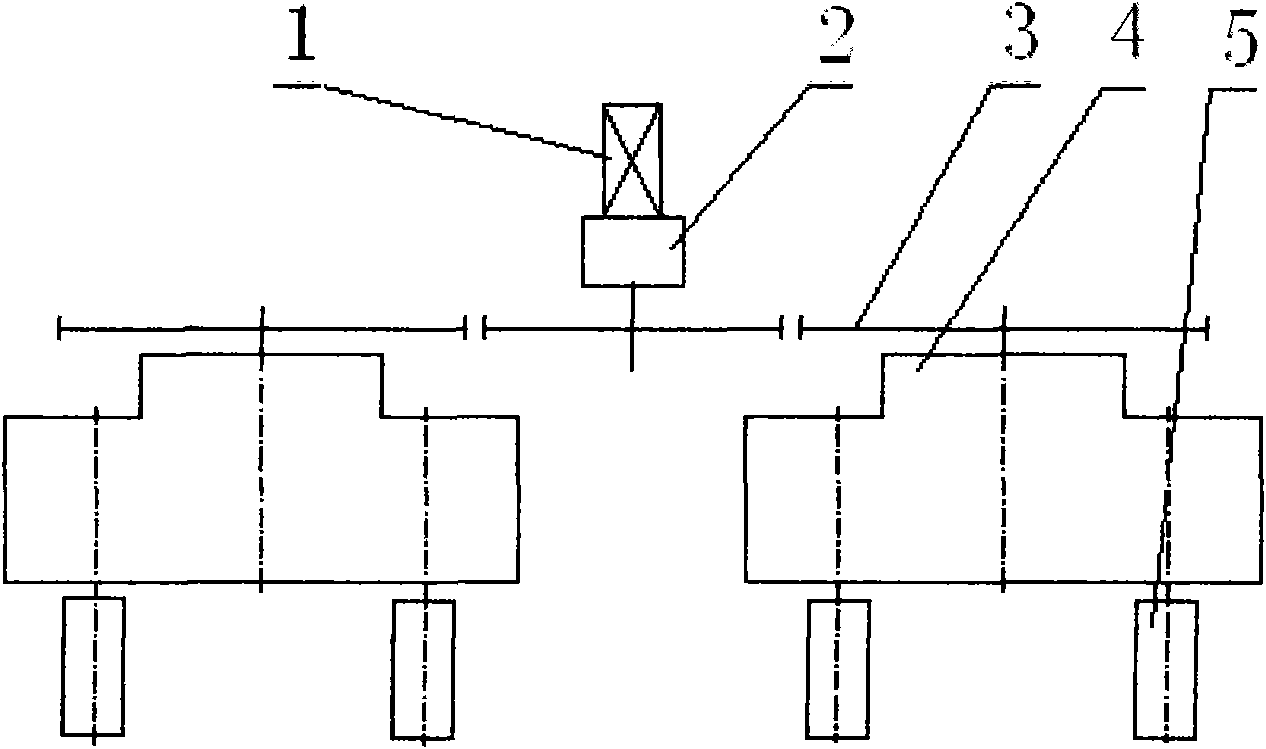

[0022] Example figure 1 As shown, this mechanism is in the form of full mechanical gear transmission, and a motor is used to drive multiple reels to run simultaneously. The output shaft of the reducer 2 connected to a motor 1 meshes with two coupling transmission packages 4 through the distribution gear 3, and each coupling transmission package 4 transmits the power torque and speed to the two reels 5 connected to it.

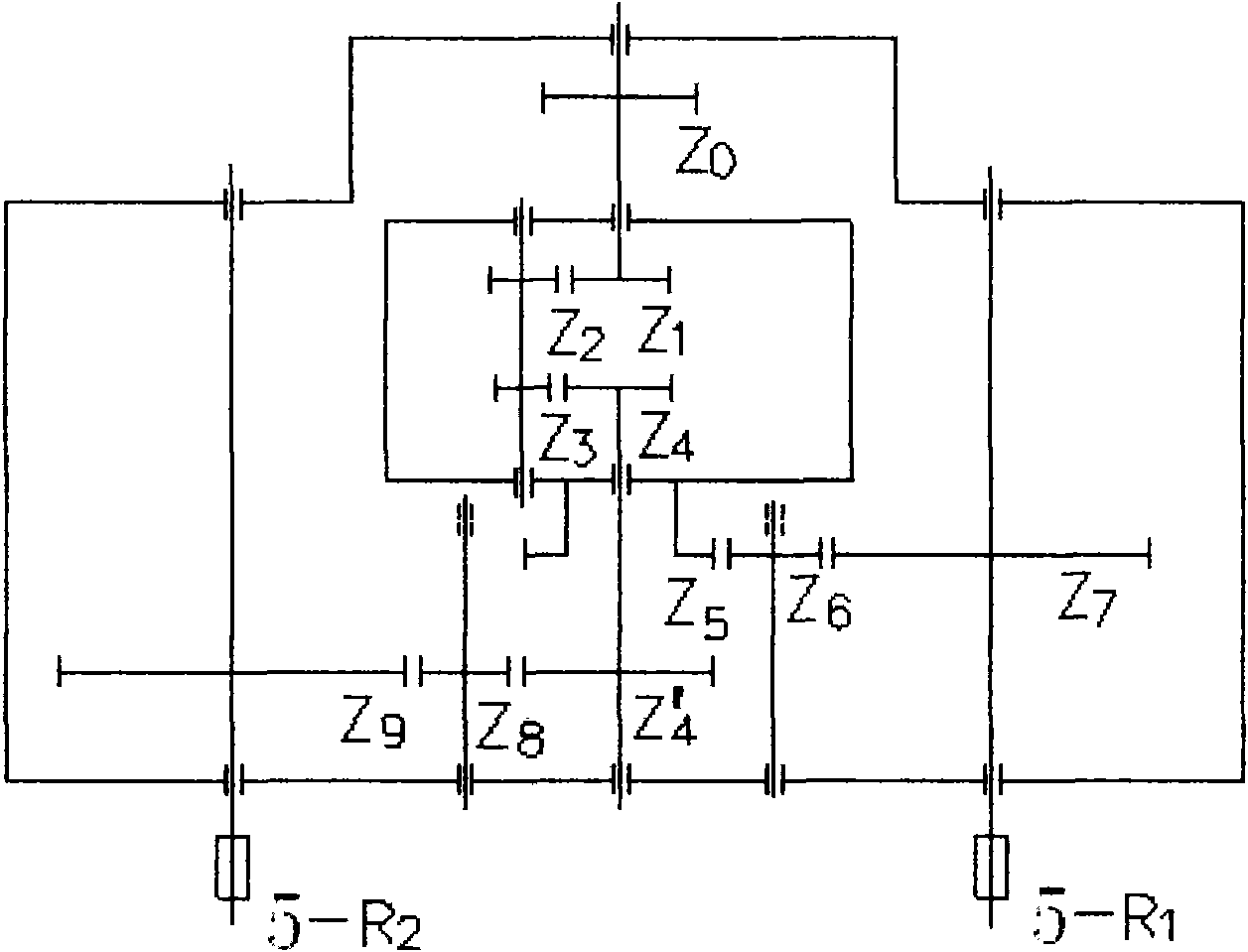

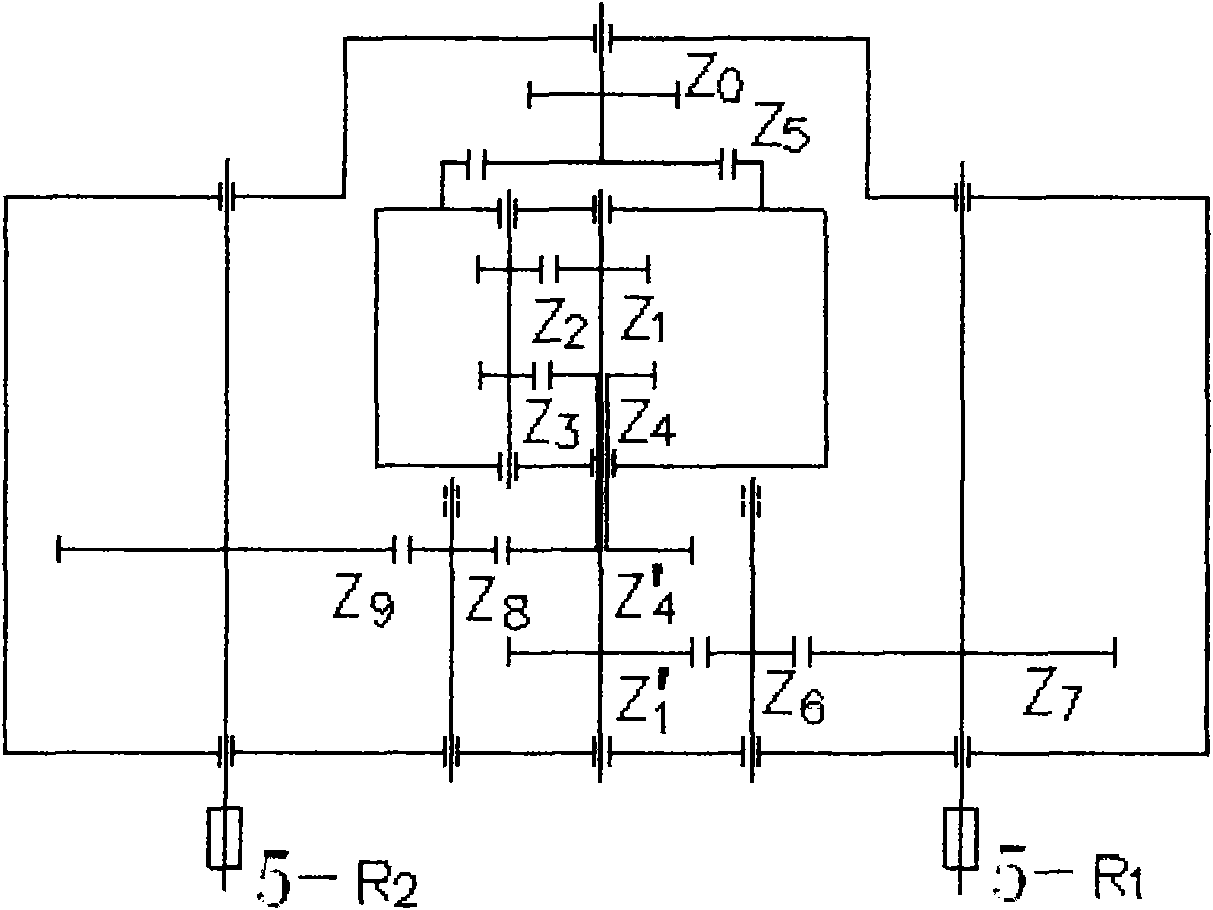

[0023] The coupling transmission package 4 is not an ordinary cylindrical gear meshing, but a planetary gear train using the principle of differential gear transmission, which is derived from the form of two-axis input and one-axis output to one-axis input and two-axis output.

[0024] Such as figure 2 As shown, the coupling transmission package 4 is a sun gear input structure, including input gear Z0, sun gear Z1, planetary gear Z2, planetary gear Z3, output gear Z4, output gear Z4′, planet carrier gear Z5, idler gear Z6, and reel gear Z7, idler gear Z8, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com