Large diameter polymer monofilament take-up device

A coiling device and large-diameter technology, used in transportation and packaging, conveying filamentous materials, and thin material processing, etc., can solve the problems of low spring fatigue life, large cam wear, and poor numerical accuracy of tension adjustment. The effect of post-processing use, improving coiling quality, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

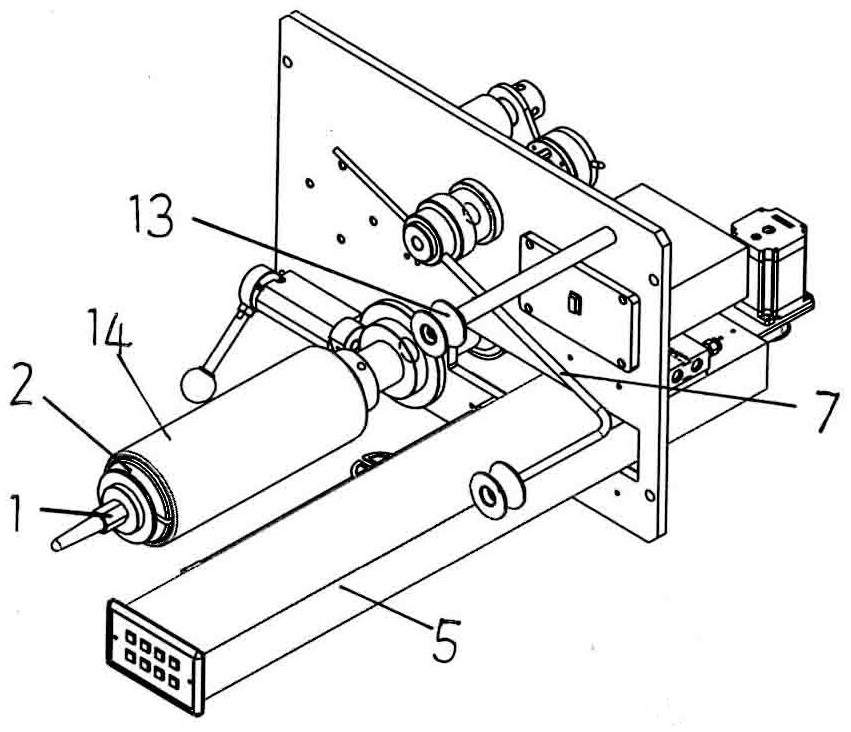

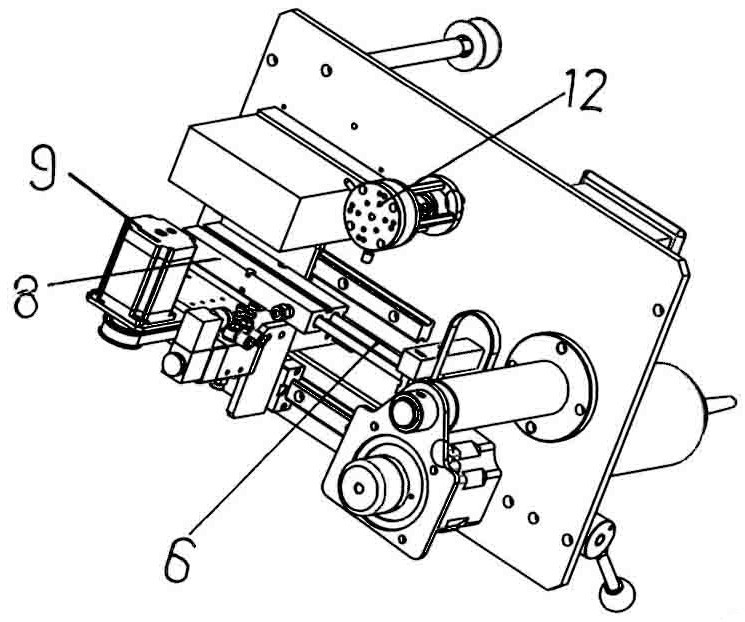

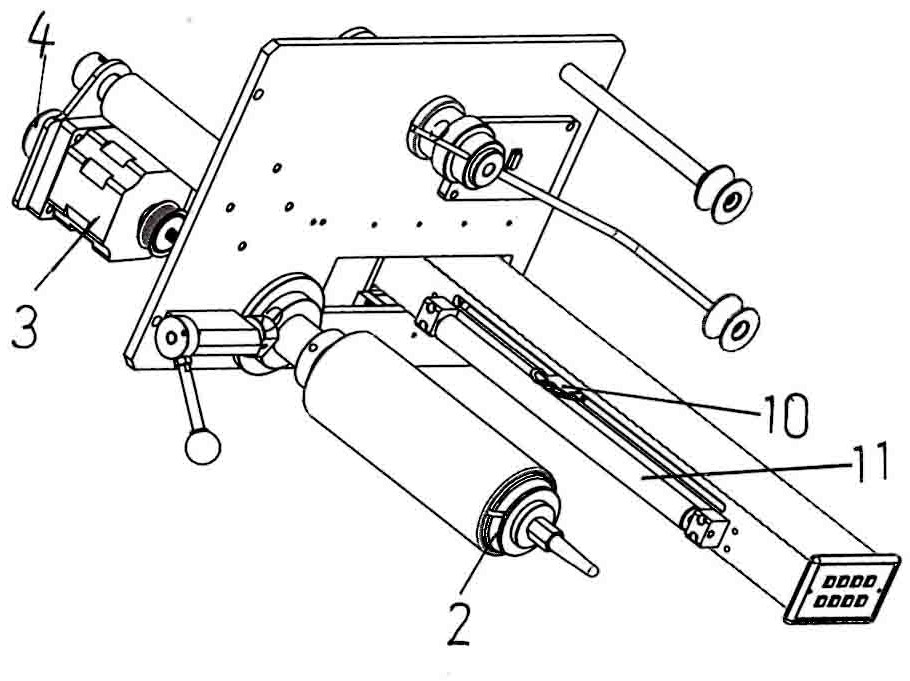

[0022] A large-diameter polymer monofilament winding device, the large-diameter polymer monofilament is a polymer monofilament with a diameter of 0.2-0.5 mm; the winding device includes a main shaft 1 driven by a main servo motor, and bobbins 14 are installed On the bobbin tensioning fixture 2 on the main shaft, the main servo motor 3 is provided with a rotary encoder 4; the reciprocating mechanism assembly 5 is installed on the linear guide rail 6 through a fixed bracket, and the linear guide rail is installed on the panel 1, and the reciprocating mechanism assembly A pressure rod 11 is installed on the side opposite to the main shaft; one side of the cylinder 8 is fixed on the panel, and the cylinder is connected with the reciprocating assembly mechanism to push the reciprocating assembly mechanism and the pressure rod to move back and forth; a reciprocating servo motor is installed on the panel, reciprocating The servo motor 9 drives the reciprocating movement of the recipro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com