Coiling method of oriented silicon steel MgO coated steel coil

A technology for oriented silicon steel and steel coils, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., which can solve problems such as wrinkles, water cannot be effectively discharged, and waste judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

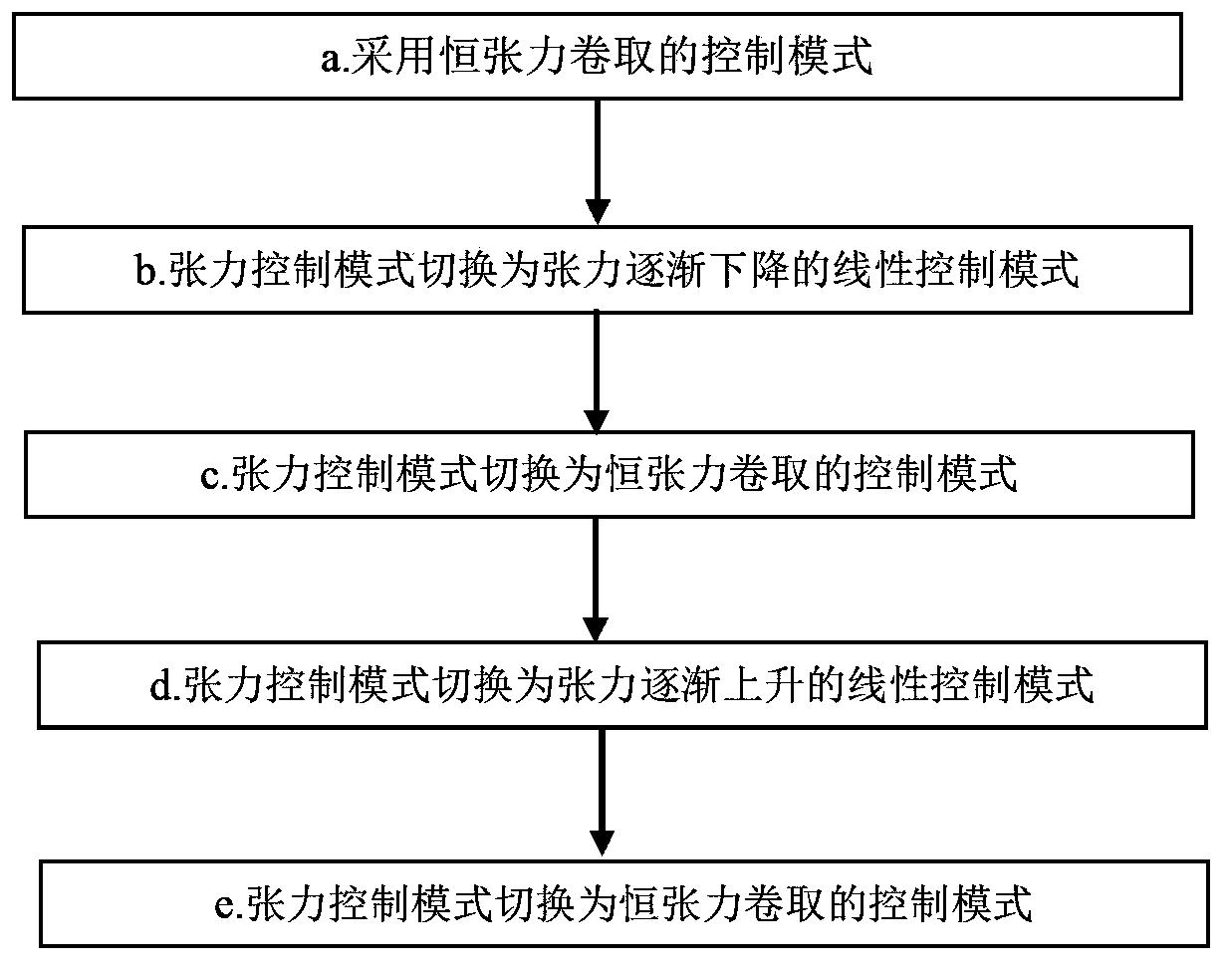

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. as attached figure 2 Shown is the flow chart of the coiling method of the oriented silicon steel MgO coated steel coil of the present invention.

[0043] Set the second constant tension value Y2 of the steel coil as the main tension, the initial outer diameter X1 of the inner core of the steel coil, set the second outer diameter value X2, the third outer diameter value X3, the fourth outer diameter value X4 and the fifth The outer diameter value X5, and the outer diameter of the steel coil is monitored in real time, the ratio K1 of the first constant tension value Y1 of the inner layer of the steel coil to the second constant tension value Y2 and the ratio K1 of the outer layer of the steel coil are set. The ratio of the third constant tension value Y3 to the second constant tension value Y2 is the value of the tension taper coefficient K2. The setting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com