Constant tension winding device for nylon zipper drawn yarn

A winding device and constant tension technology, applied in transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problem that the winding speed and wire output speed are difficult to automatically match, and achieve more reasonable equipment automation Sexuality, eliminating sinking due to gravity, and improving the effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

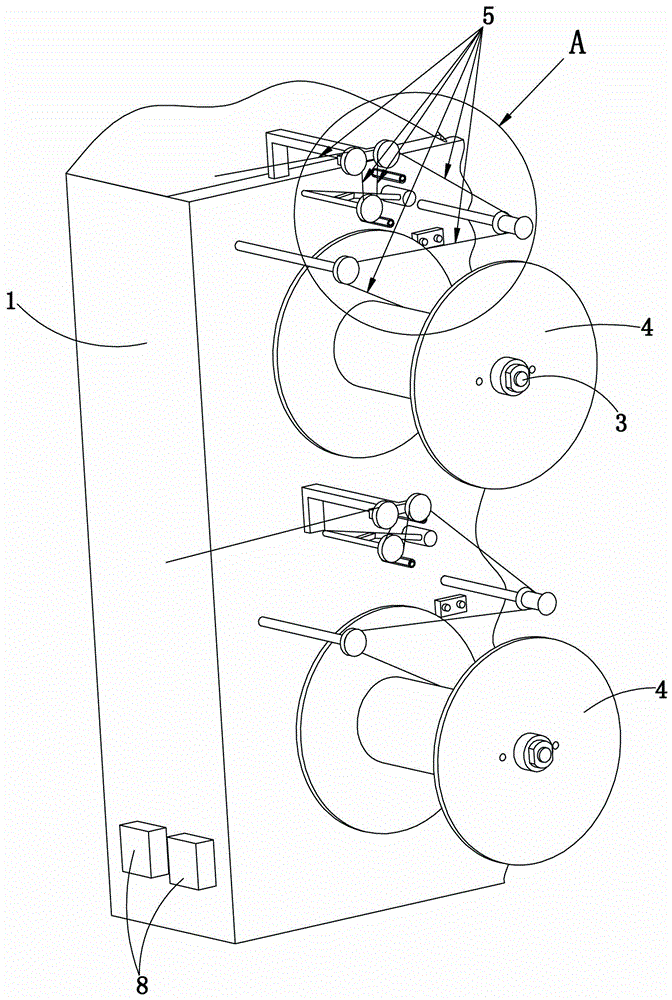

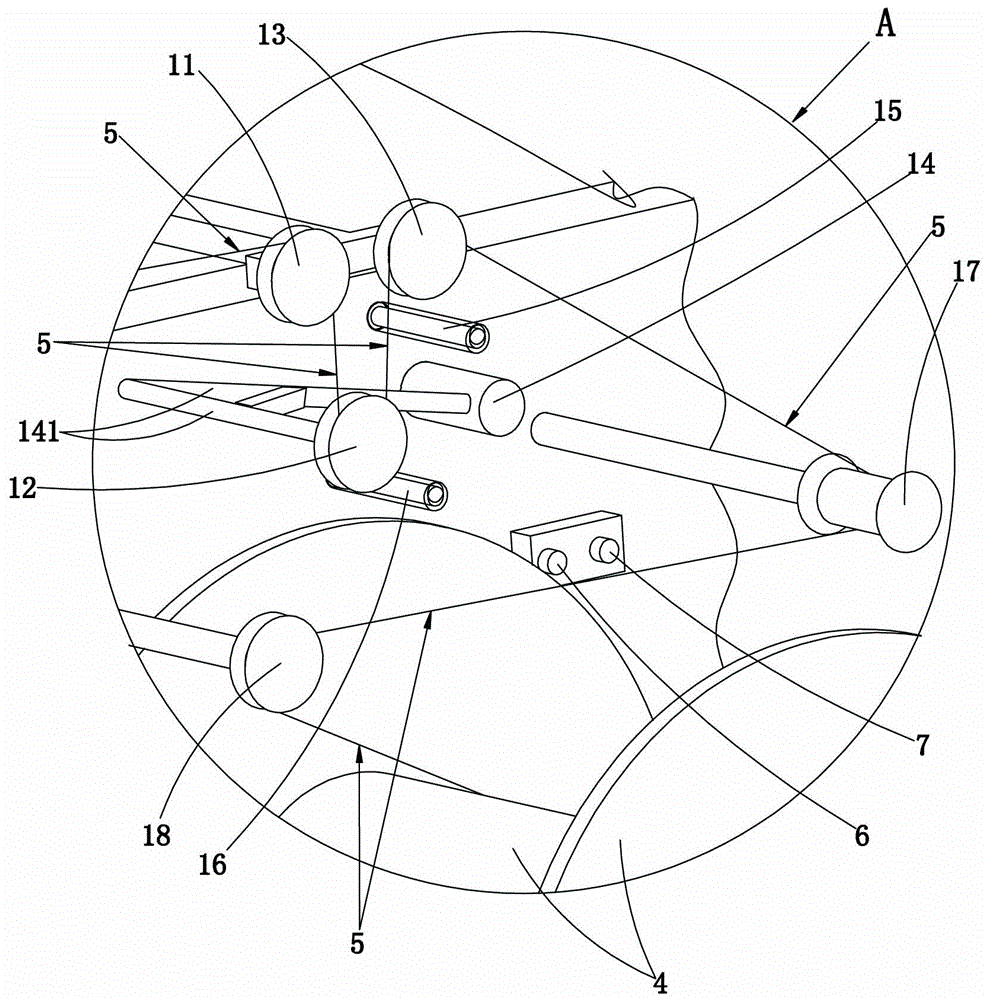

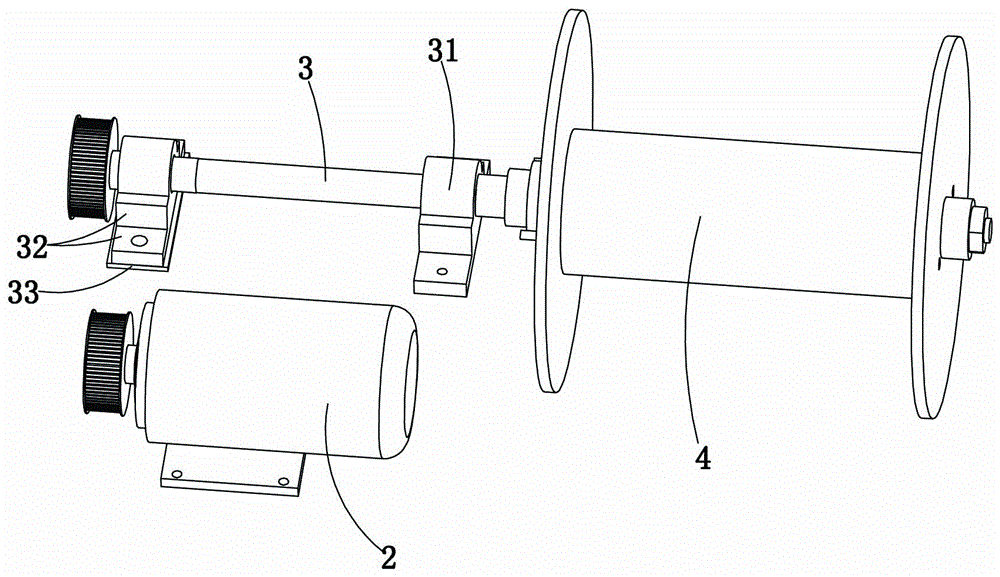

[0030] refer to figure 1 , figure 2 , a constant tension winding device for nylon filaments of nylon zippers, including a frame 1 (or a chassis) and a motor 2 and a main shaft 3 assembled on the frame 1, and the motor 2 drives the main shaft 3 to rotate and then drives the I-shaped cylinder on the main shaft 3 4 rotations; This frame 1 is also fixedly equipped with left fixed wheel 11, right fixed wheel 13, tension resistor 14, upper limit post 15, lower limit post 16, steering wheel 17 and cable system running wheel 18. refer to figure 1 , The frame 1 is provided with upper and lower sets of constant tension rewinding devices, and multiple sets of constant tension rewinding devices work independently.

[0031] refer to figure 1 , figure 2 , the tension resistor 14 is fixedly equipped with a swing rod 141, the swing rod 141 is equipped with a swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com