All-in-one machine for producing elastomer modified asphalt waterproof coiled material

A technology of asphalt waterproofing membrane and body modification, which is applied in the direction of layered products, lamination auxiliary operation, lamination system, etc. Large, small footprint, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

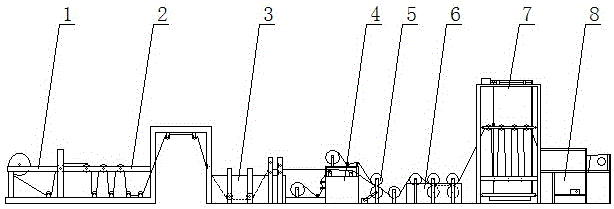

[0018] The all-in-one machine for producing elastomer-modified asphalt waterproof coils includes a support for placing base material 1, a stretching device 2, an elastomer-modified asphalt coating device 3, a film-coating device 4, extrusion rollers 5, cooling cutting cutting device 6, storage device 7 and coiling device 8; stretching device 2 transitions between support 1 and elastomer modified asphalt coating device 3; one side of elastomer modified asphalt coating device 3 is sequentially provided with extrusion The pressing roller 5 and the cooling and cutting device 6; one side of the cooling and cutting device 6 is provided with a storage device 7 and a coiling device 8 in sequence.

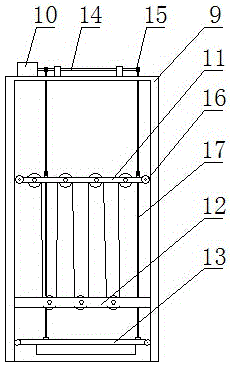

[0019] The storage device 7 is composed of a frame 9, a lifting motor 10, a movable frame 11, a fixed frame 12 and a counterweight 13. The top of the frame 9 is fixedly equipped with a lifting motor 10, and one side of the lifting motor 10 is equipped with a transmission shaft 14 through a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com