Patents

Literature

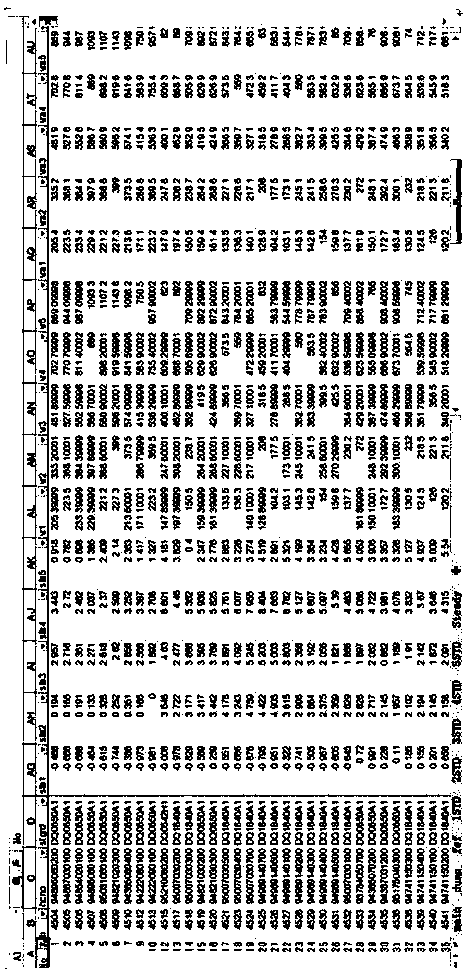

34results about How to "Avoid stacking steel accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rolling technique of lead treated steel

InactiveCN101386031AAvoid stacking steel accidentsHigh yieldTemperature control deviceWork treatment devicesFree machining steelRolling mill

The invention belongs to the field of metallurgy and relates to rolling process of lead-containing free-machining steel. A rolling mill is used for rolling, in the rough rolling process, the rolling temperature is controlled at 1030-1060 DEG C, the former three-pass material form is reduced 1-3mm based on the standard material form; in the intermediate rolling process, the roll material form is the standard material form, and the rolling temperature is controlled at 980-1030 DEG C; in the pre-finish rolling process, the roll material form is the standard material form, the rolling temperature is controlled at 1060-1030 DEG C, and the temperature of the rolled piece reaches 1005-1040 DEG C after the pre-finish rolling process; in the finish rolling process, the temperature of the rolled piece in a finishing mill is less than 980 DEG C, the roll material form is the standard material form, and the rolling temperature is controlled at 1020-1050 DEG C. The rolling process can prevent steel heaping caused by the cleavage crack of the cold, hot and frailty susceptible head of the rolled piece, prevent sliding accident caused by the high temperature of the steel, steadily increase the yield of the lead-containing free-machining steel, obviously reduce the waste, and greatly reduce the 100t steel fault time.

Owner:NANJING NANGANG IND DEV CO LTD

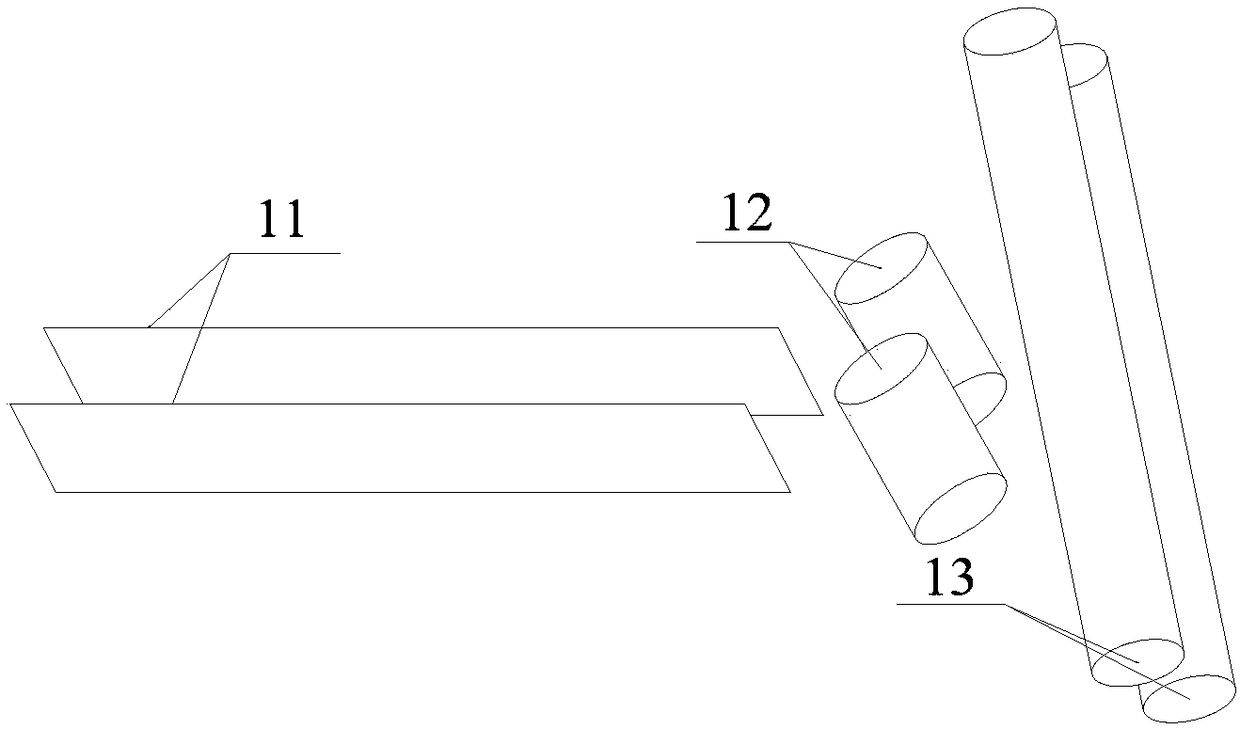

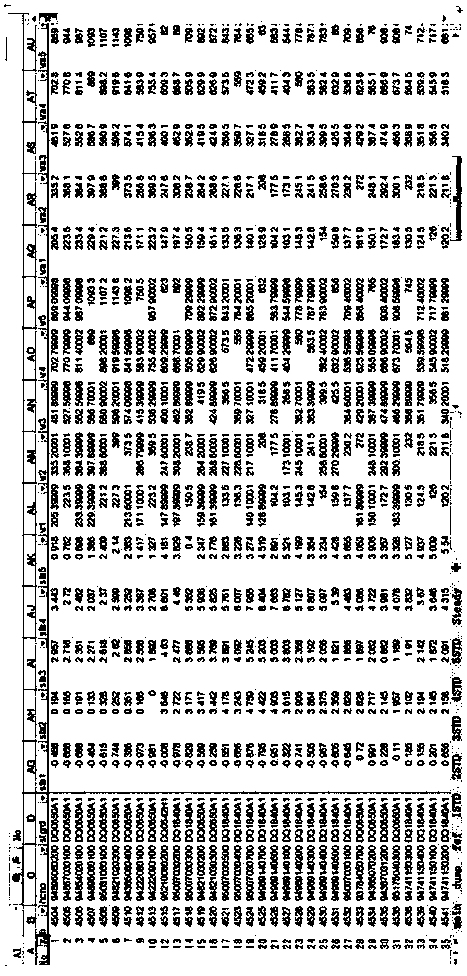

Rough rolling vertical roll shallow pass treatment method

ActiveCN108838213ASave process investmentAvoid productivity lossRoll mill control devicesMetal rolling arrangementsMachine pressEngineering

The invention discloses a rough rolling vertical roll shallow pass treatment method. The method comprises the steps that a to-be-rolled steel blank is determined from a rolling plan; whether width fixing needs to be conducted on the to-be-rolled steel blank through a width-fixed pressure machine or not is judged, and a judgment result is obtained; the width self-learning function of a rough rolling unit is closed; the first opening degree of a front guide board and the width of a first roll seam of a vertical roll are adjusted, and forward rolling is conducted; in the forward rolling process,the to-be-rolled steel blank is processed according to the judgment result and guided in through the front guide board, and the vertical roll serves as a transition roller way to conduct shallow passtreatment on the to-be-rolled steel blank; the second opening degree of the front guide board and the width of a second roll seam of the vertical roll are adjusted, and inverse rolling is conducted; and in the inverse rolling process, the vertical roll serves as a transition roller way to conduct shallow pass treatment on the to-be-rolled steel blank, and the to-be-rolled steel blank is guided outthrough the front guide board. The rough rolling vertical roll shallow pass treatment method provided by the invention can avoid capacity loss caused by halt production and ensure controllability ofthe width of finished products.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Production method for improving large dimension wire size precision and surface quality

InactiveCN101733273AHigh dimensional accuracyQuality improvementRoll mill control devicesMetal rolling arrangementsProduction lineWire rod

The invention discloses a production method for improving large dimension wire size precision and surface quality. The method is implemented by using the existing finishing mill set to modify the dummied frame in the finishing mill set used in producing large dimension wire into a regular round frame on the high speed wire production line for non-reducing sizing machine set, performing primary regular round rolling to the wires rolled by a finished product frame, thus improving large dimension wire size precision and surface quality, and simultaneously reducing head and tail cutting quantity of finished product wire and enhancing yield.

Owner:NANJING IRON & STEEL CO LTD

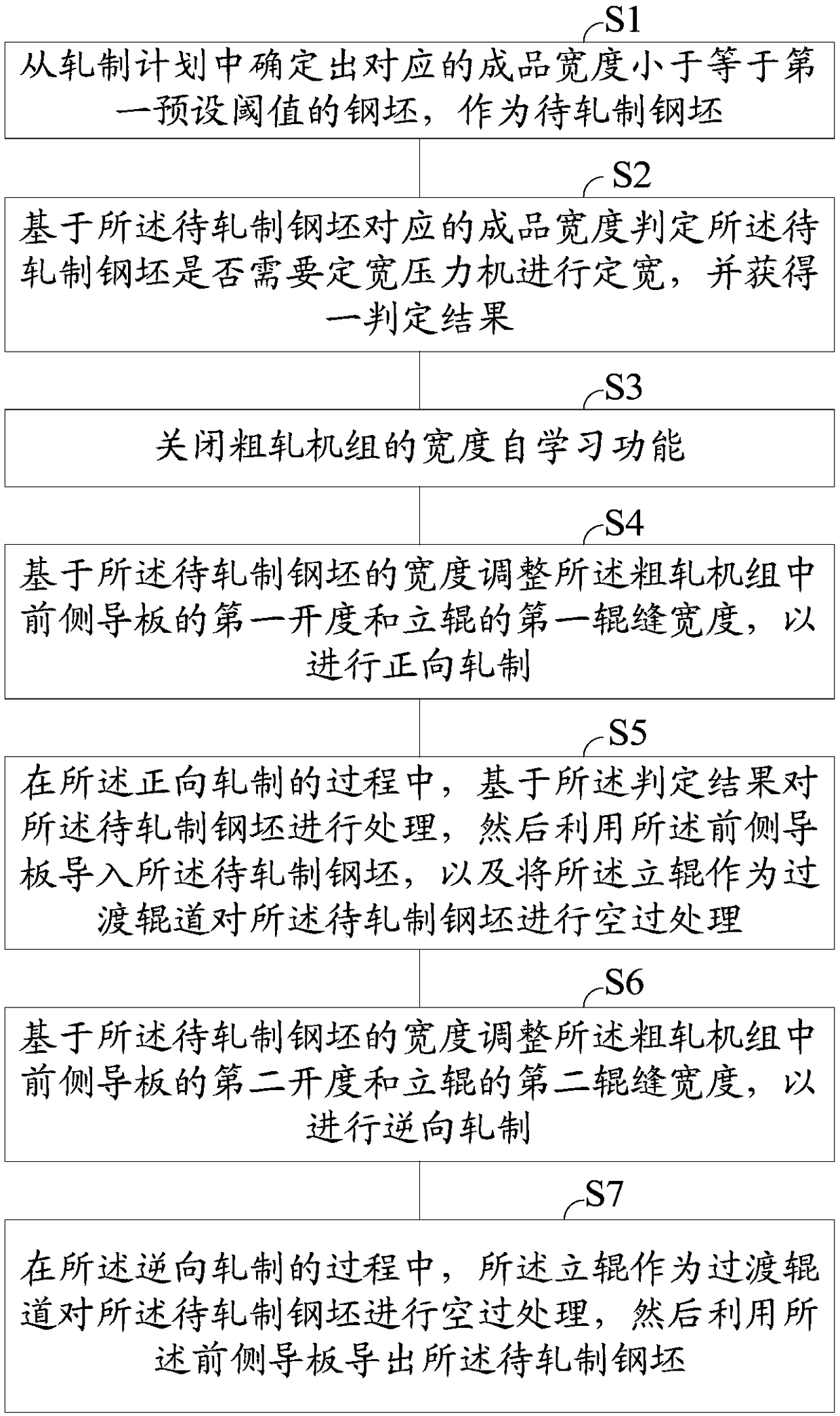

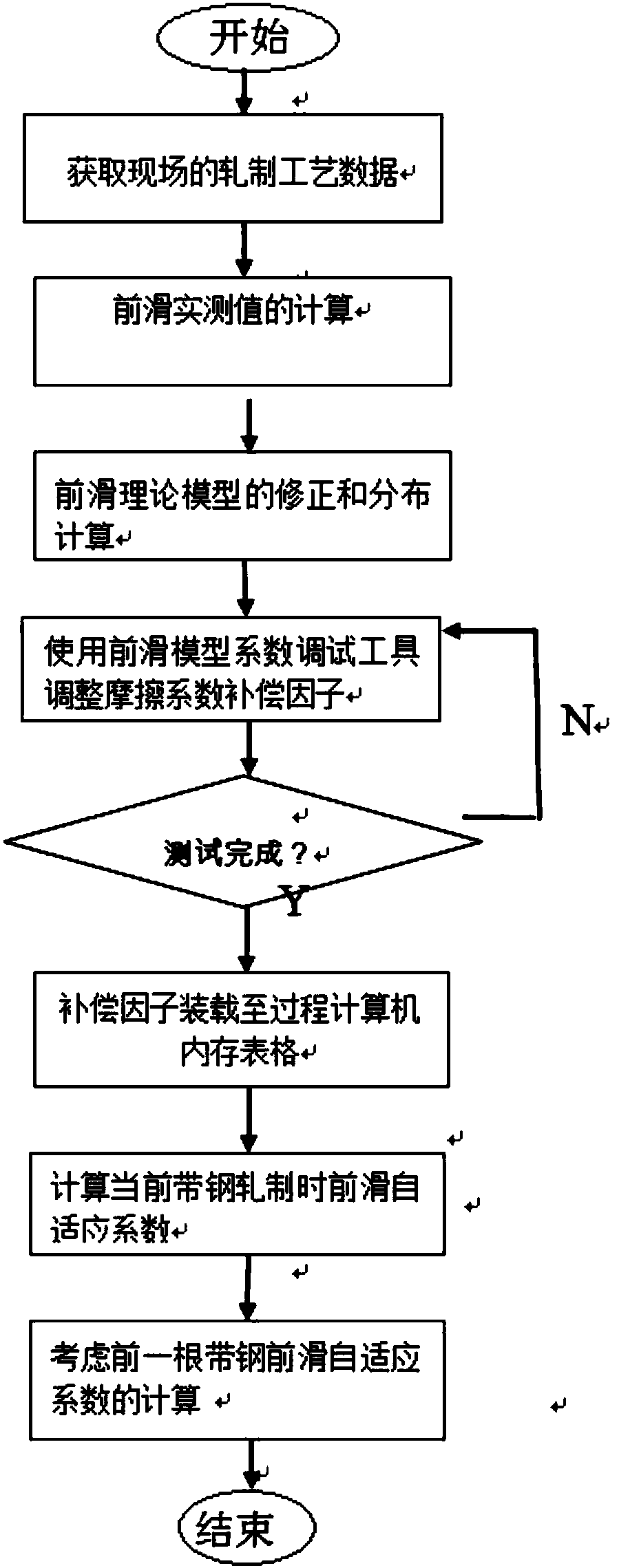

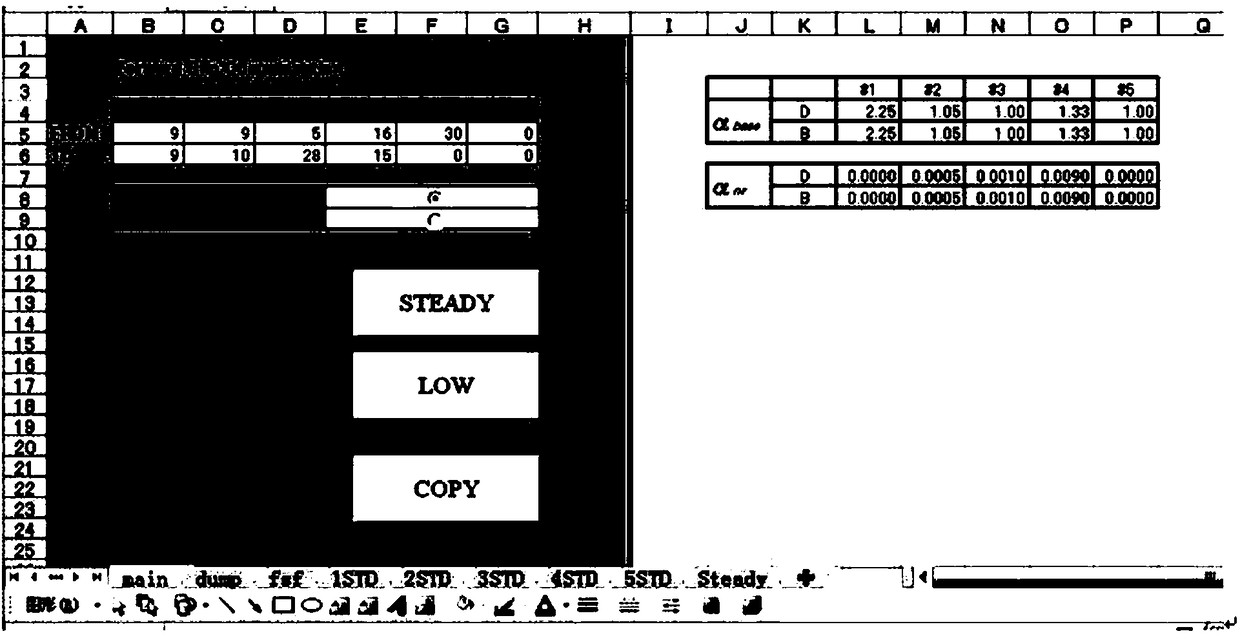

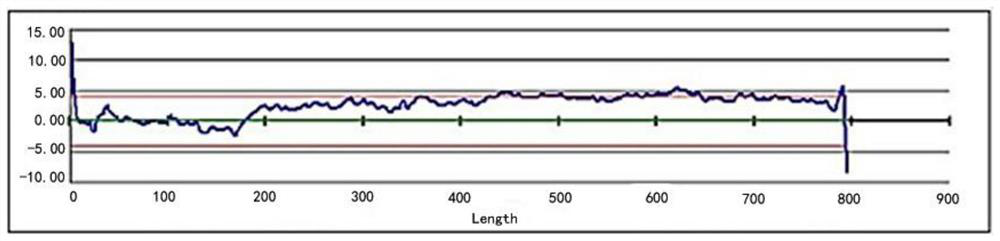

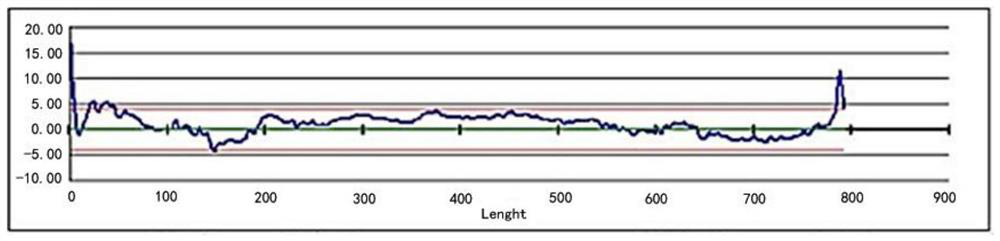

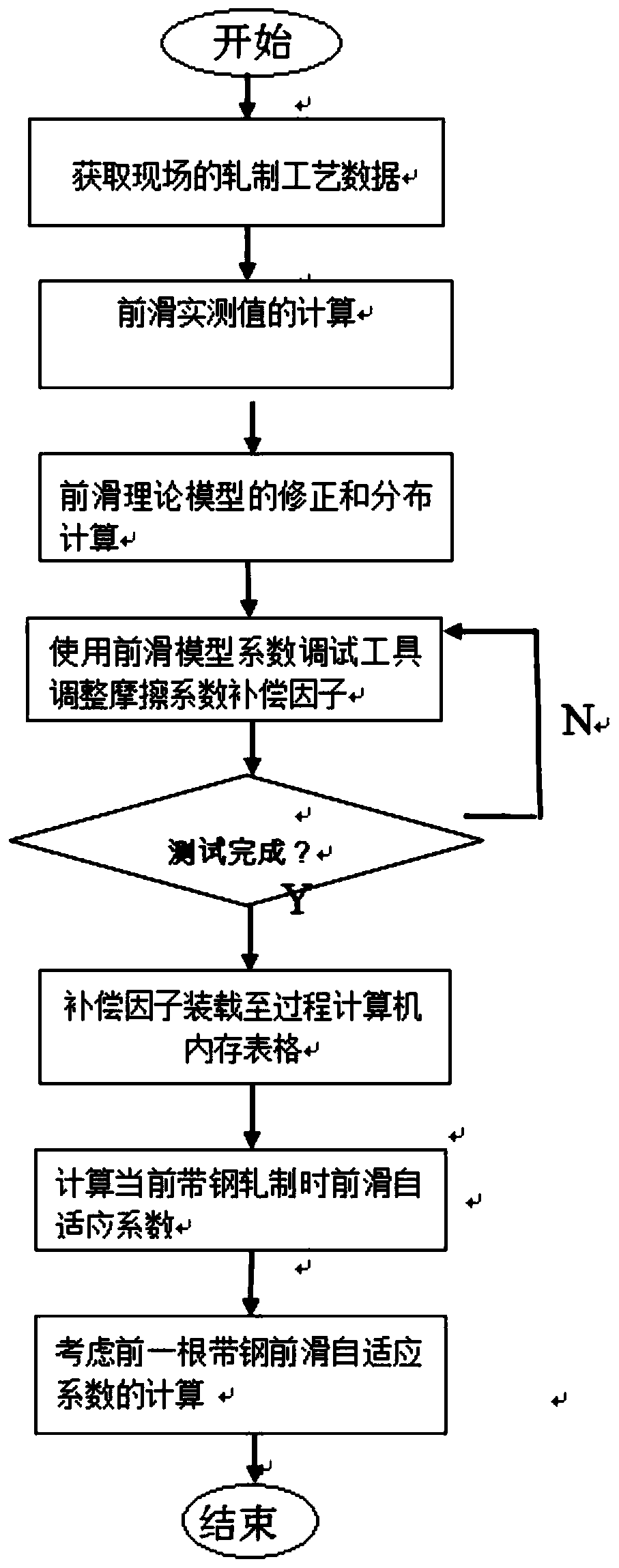

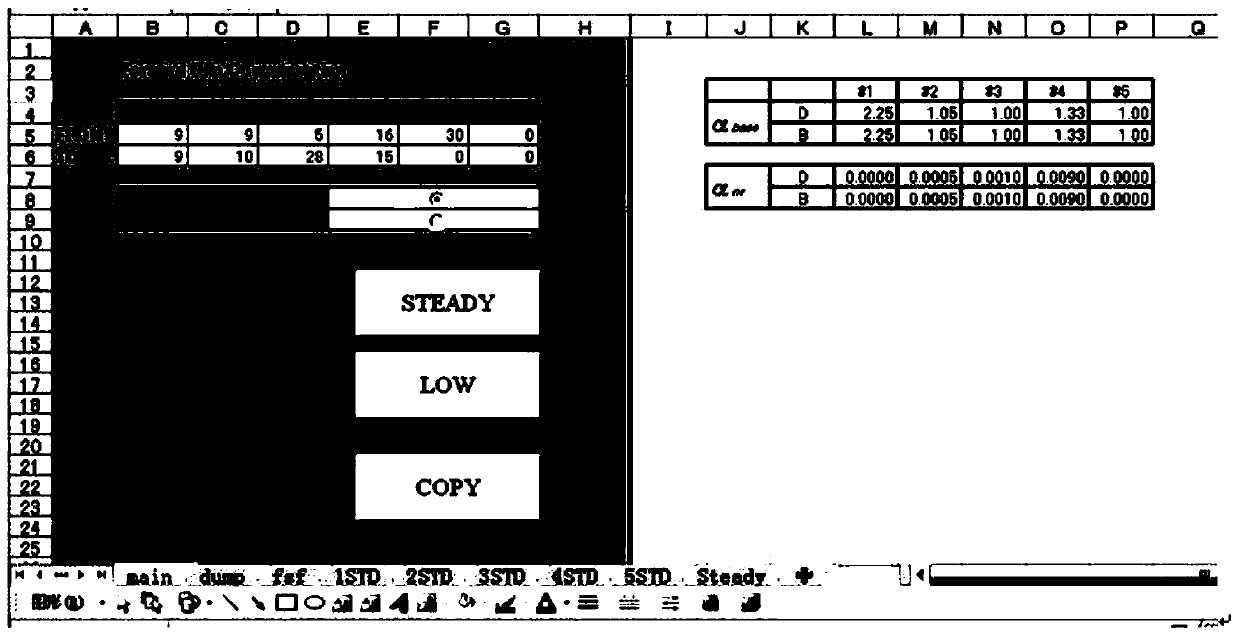

Self-adaptive calculation method of cold-rolled forward-sliding model for stable rolling

ActiveCN108655176AReasonable calculationImprove forecast accuracyGeometric CADDesign optimisation/simulationForward slidingStrip steel

The invention relates to a self-adaptive calculation method of a cold-rolled forward-sliding model for stable rolling. The self-adaptive calculation method of the cold-rolled forward-sliding model forthe stable rolling is characterized by comprising the following steps that step 1, collecting rolling technology data; step 2, calculating of a forward-sliding measured value; step 3, correcting anddistributing calculation of a forward-sliding theoretical model; step 4, adjusting a friction coefficient compensation factor by using a forward-sliding model coefficient debugging tool; step 5, and loading finally determined compensation factors into a process computer memory table; step 6, calculating a forward sliding self-adaptive coefficient when a current strip steel is rolled; and step 7, considering the calculation of the forward-sliding self-adaptive coefficient of a previous strip steel. According to the method, the forward-sliding value can be accurately calculated out, so that thesetting precision of the circumferential speed of each rack roller is guaranteed, the phenomenon that the metal mass flow is unstable is avoided, and the rolling stability is improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

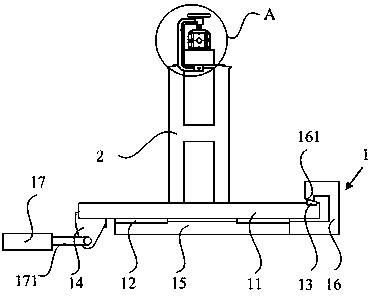

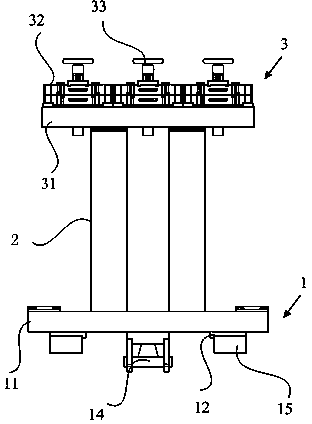

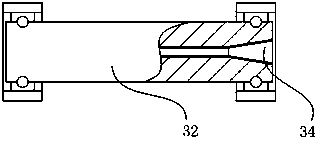

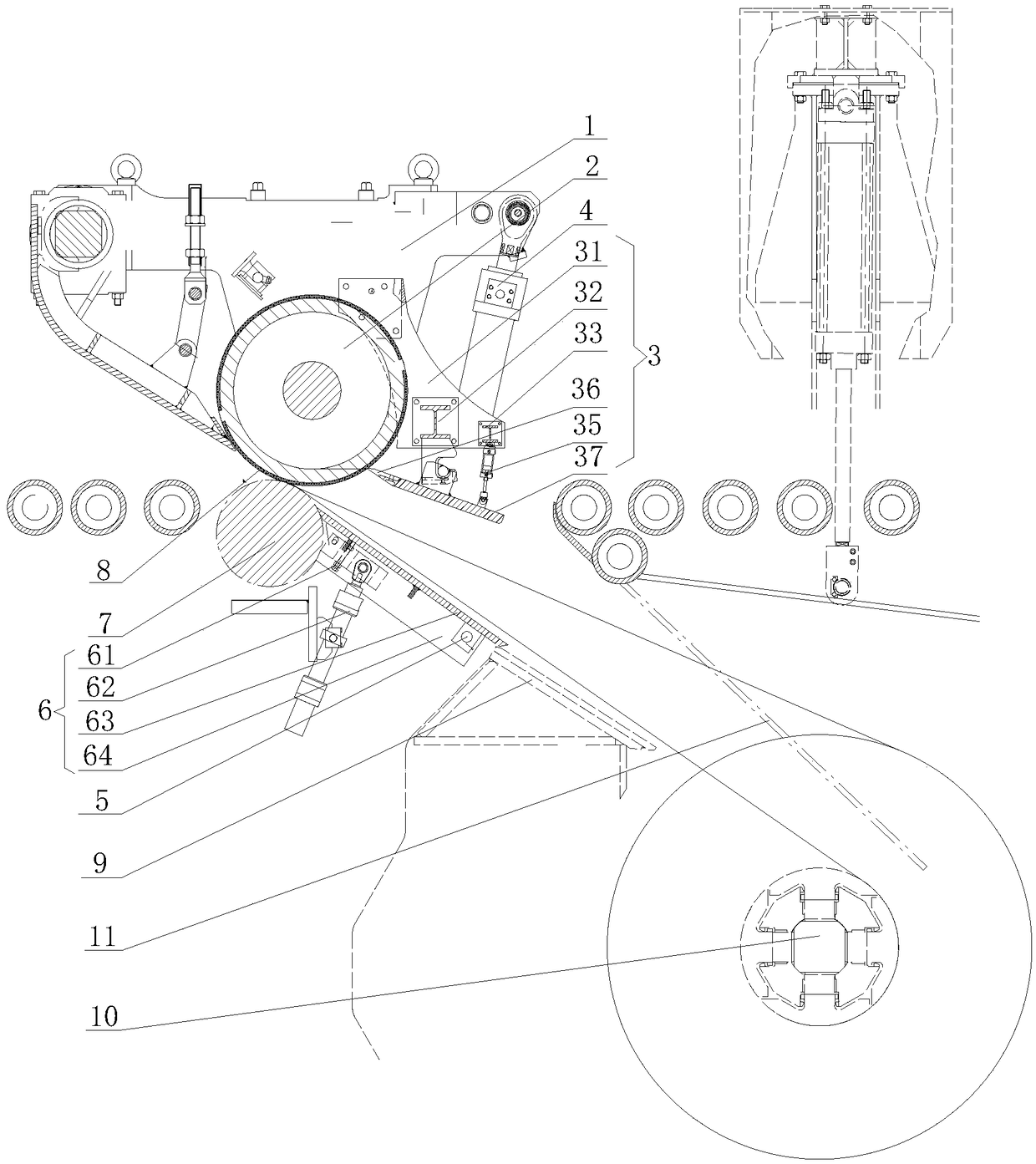

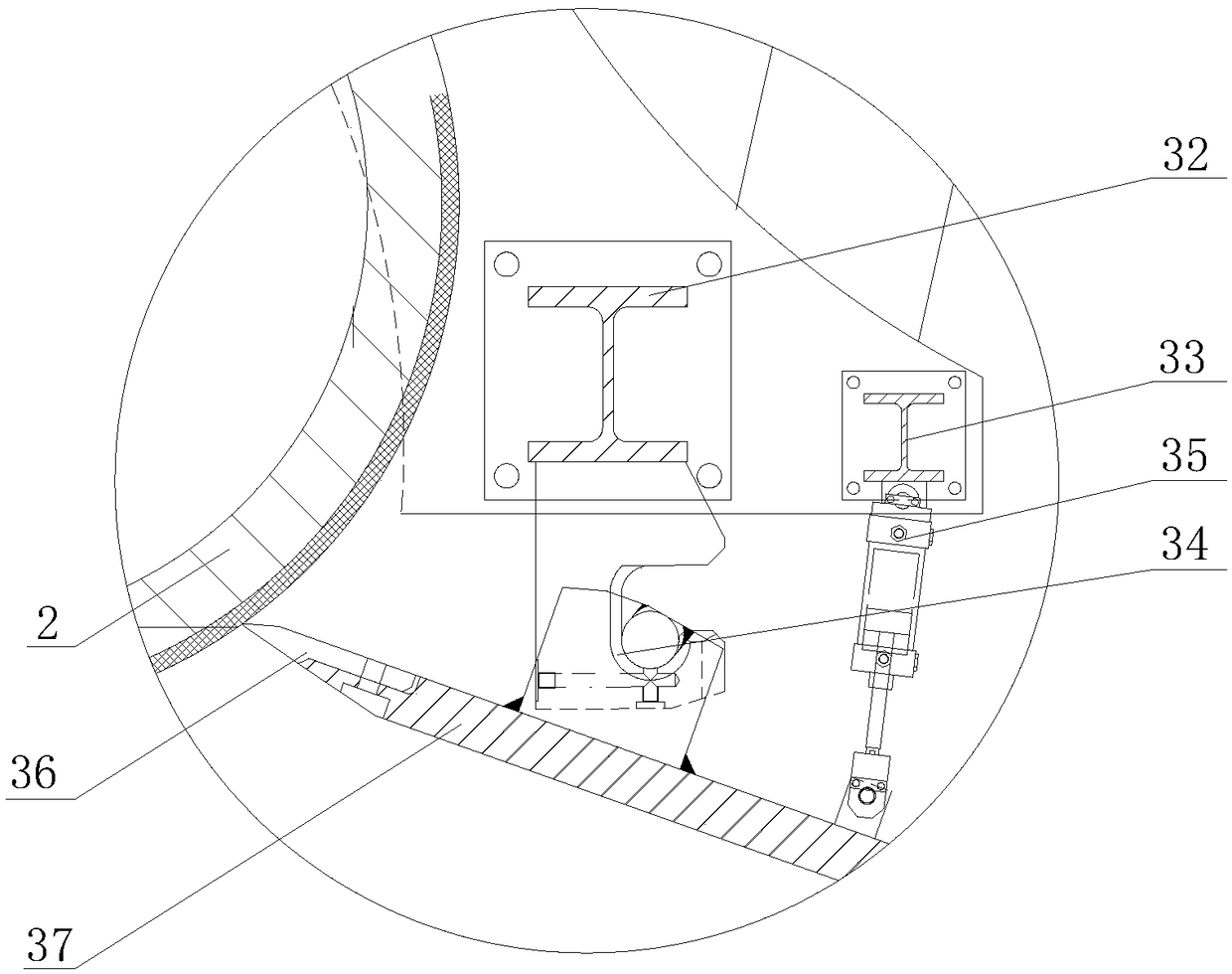

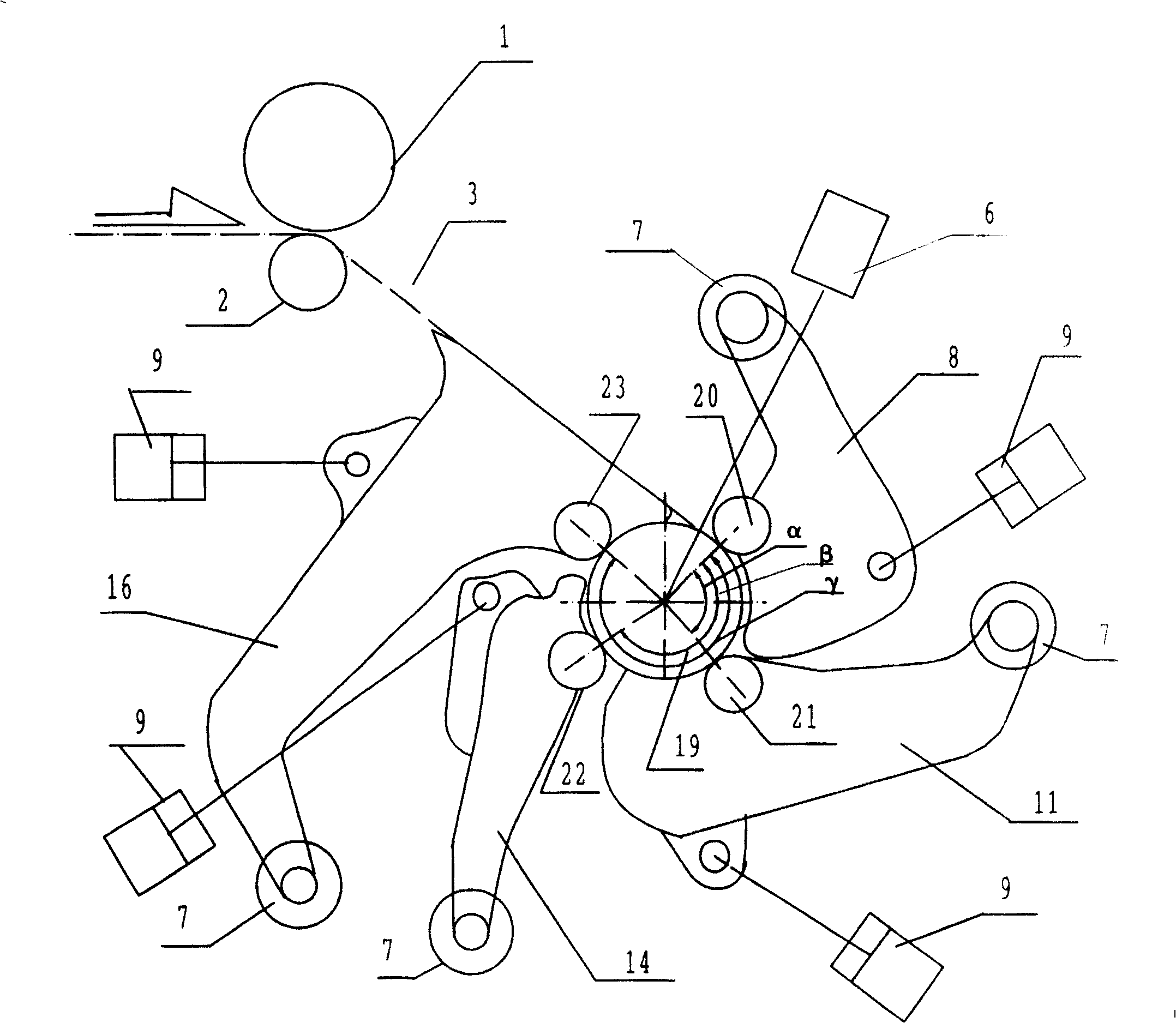

Wire rod idling device and steel rolling device

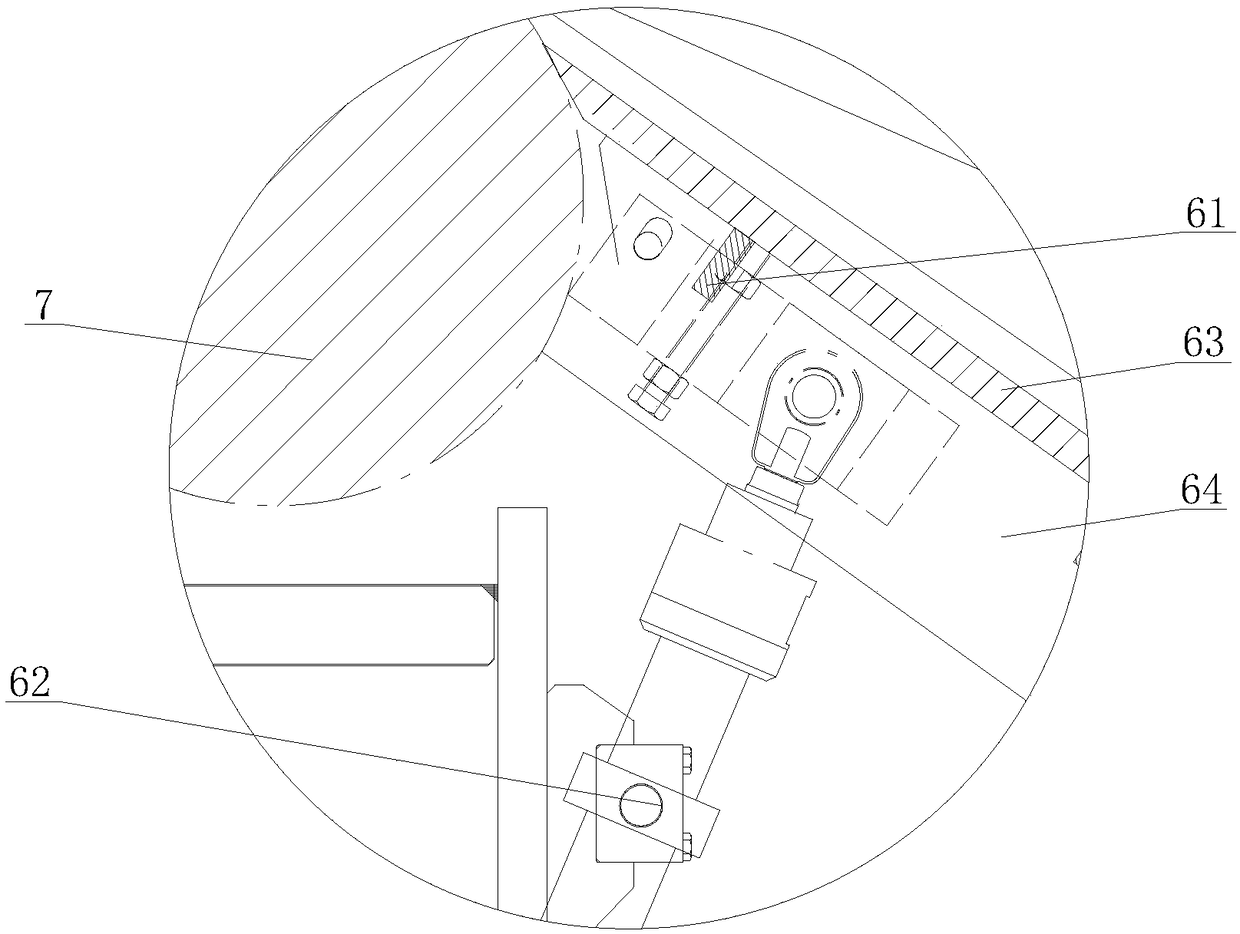

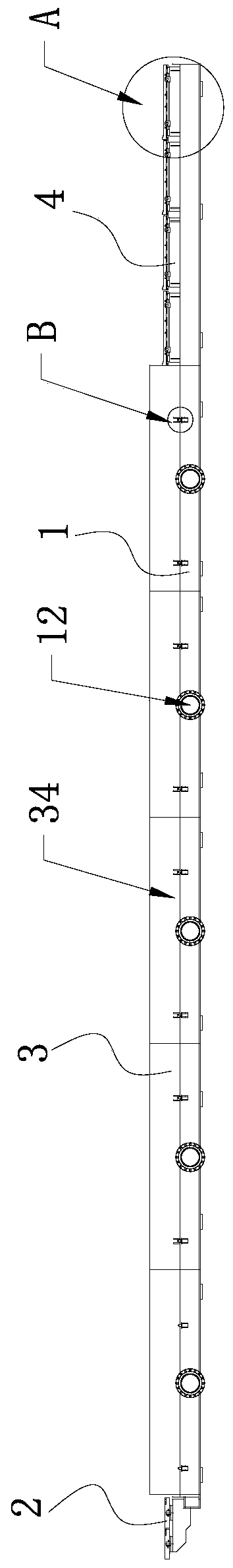

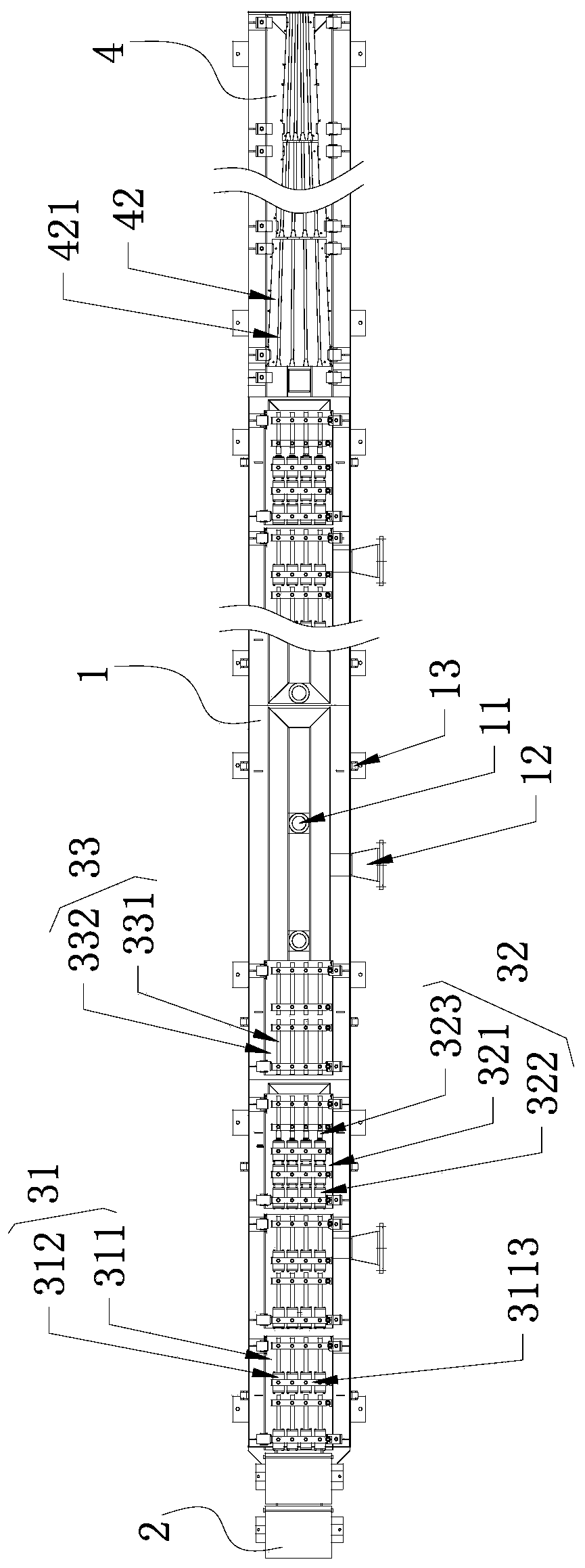

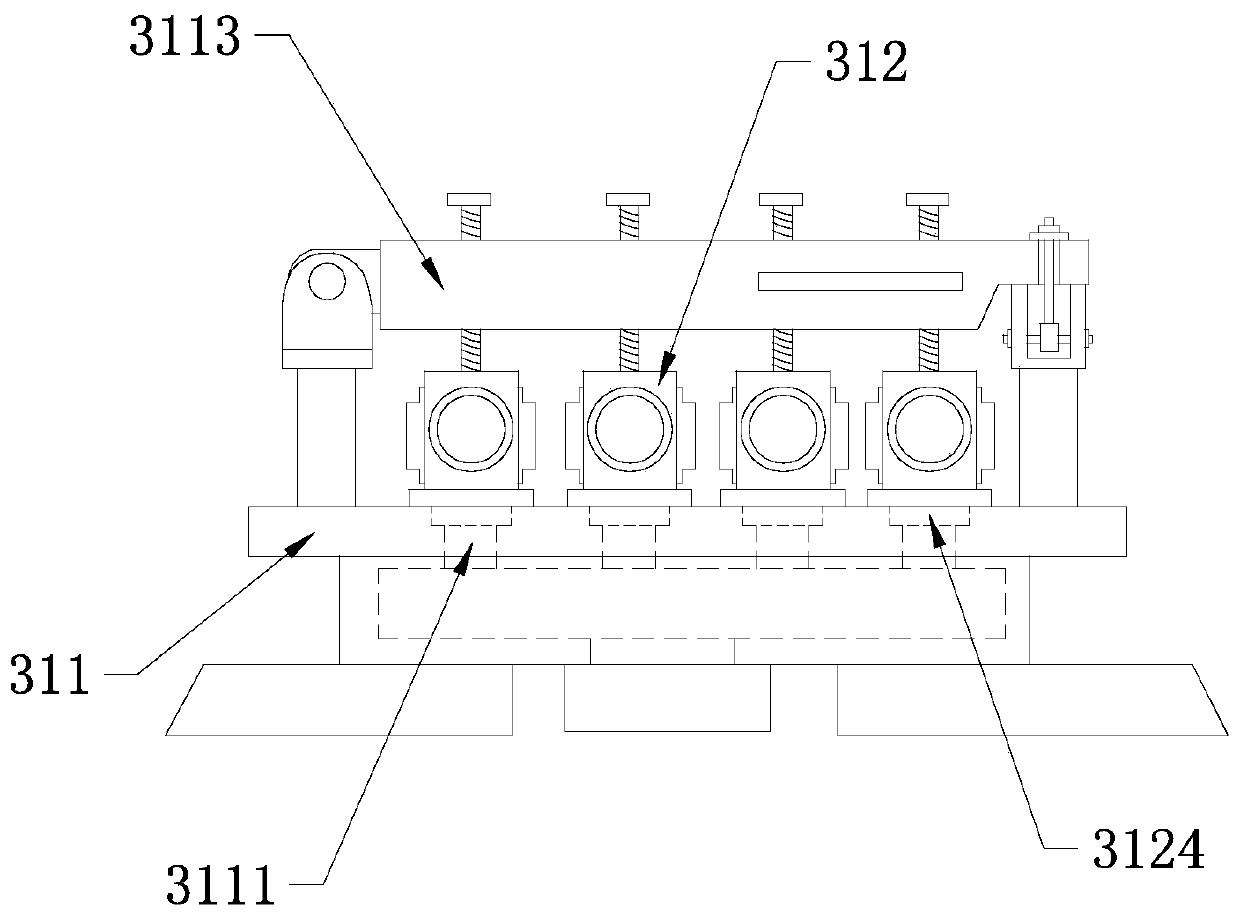

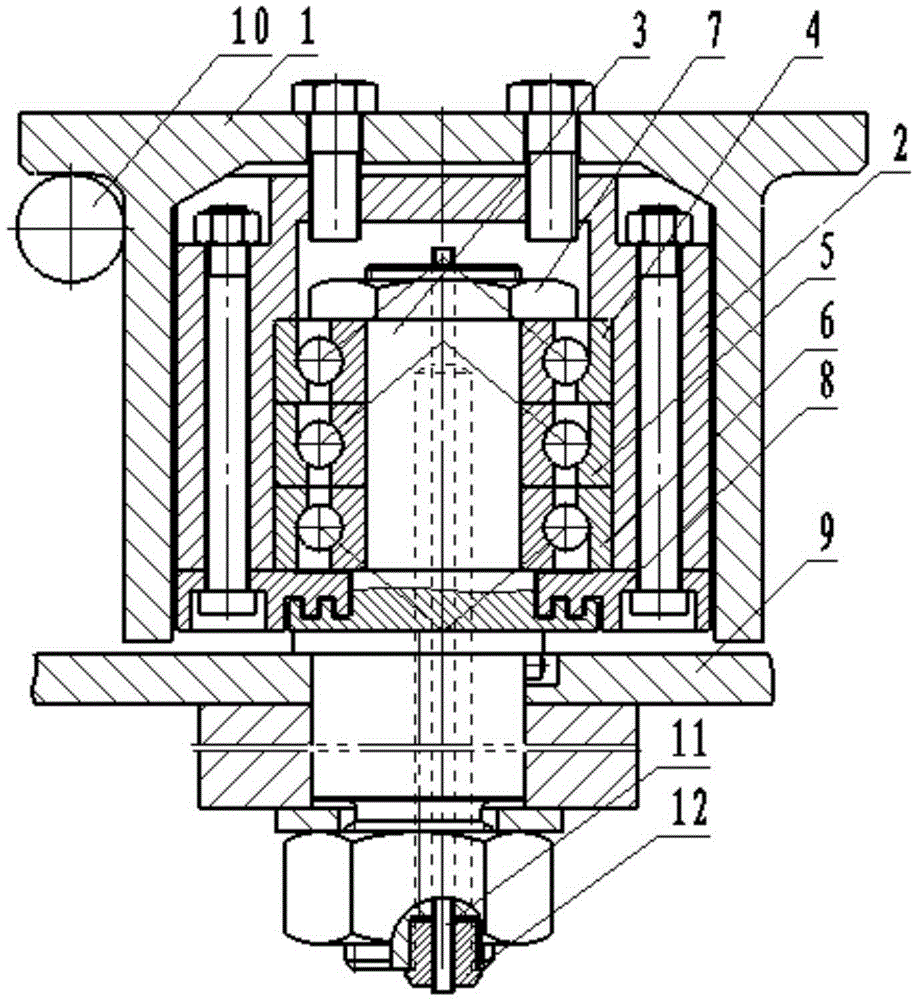

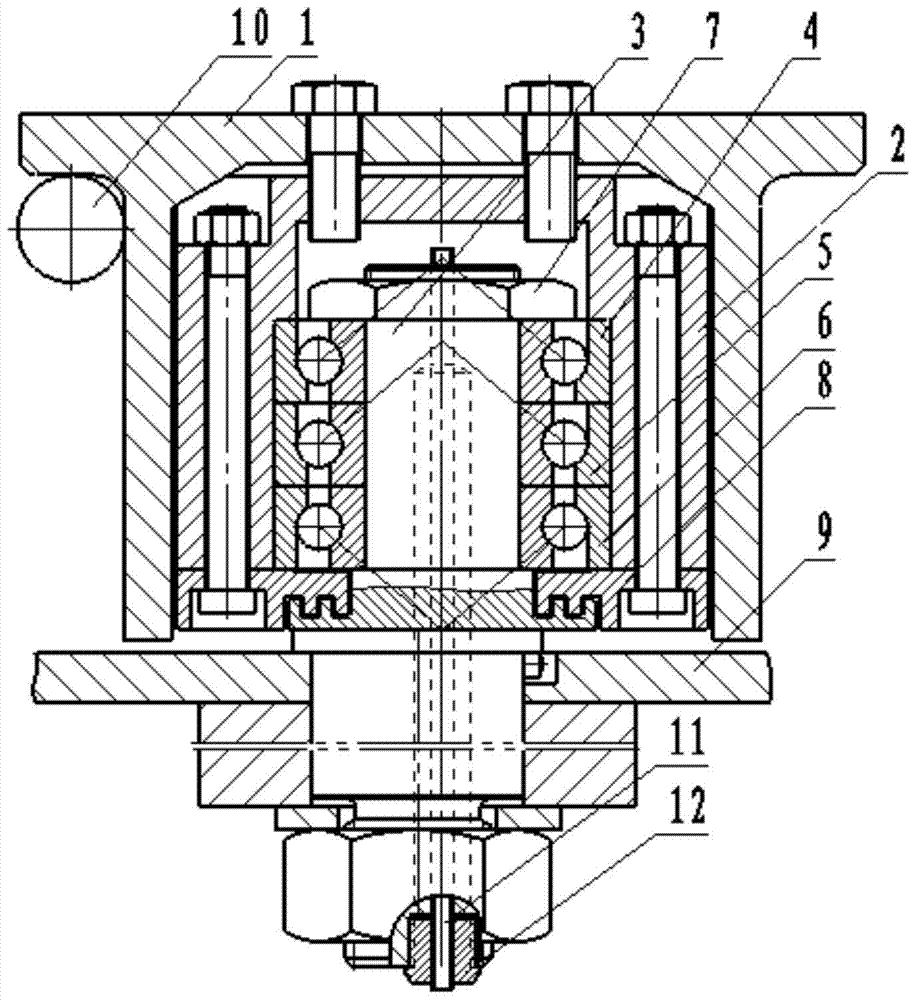

ActiveCN103706633AAvoid stacking steel accidentsImprove production efficiency and product qualityGuiding/positioning/aligning arrangementsMetal rolling arrangementsPistonPiston cylinder

The invention provides a wire rod idling device and a steel rolling device. The wire rod idling device comprises a fixed base, a supporting frame and an idling guiding groove structure. The fixed base comprises a fixed plate, sliding plates, a wedge block, a stopping block, a guiding rail, a positioning frame and a piston cylinder. The two sides of the bottom of the fixed plate are fixedly provided with the sliding plates. The wedge block is fixed to one end of the fixed plate, and the stopping block is welded to the other end of the fixed plate. A piston rod of the piston cylinder is connected with the stopping block. The fixed plate is connected to the guiding rail in a sliding mode through the sliding plates. The positioning frame is arranged on one side of the guiding rail. A positioning slope used for being matched with the wedge block is arranged on the positioning frame. The idling guiding groove structure is fixed to the fixed plate through the supporting frame. The fixed base is firmly fixed through the mutual matching of the piston rod, the guiding rail and the positioning frame, so that wire rods smoothly pass through the idling guiding groove structure, the steel stacking accident caused when the idling guiding groove structure waggles is avoided, and product quality and production efficiency are improved.

Owner:QINGDAO SPECIAL STEEL CO LTD

High-speed bar yield improvement method

InactiveCN110180890AIncrease water pressureUniform heating temperatureTemperature control deviceMetal rolling arrangementsTemperature controlHeating furnace

The invention relates to the technical field of high-speed bar yield improvement, and discloses a high-speed bar yield improvement method. The method comprises the following steps that (1) the yield is improved by controlling a heating zone with the heating temperature controlled at 1,000-1,400 DEG C to be preserved for 4-7 hours, the start heating temperature in a heating furnace is 1,100 DEG C,and the temperature in the heating furnace is controlled higher than or equal to 850 DEG C after the heating is finished; a heating system is strictly executed, and the heating efficiency is improved,so that the billet heating temperature is promoted to be uniform, black marks do not appear, the oxidation burning loss is reduced, the furnace condition is kept normal, the maintenance difficulty ofthe bottom of the heating furnace is reduced, and the production is guaranteed to be smooth. According to the method, less finished scale is generated due to good guide groove air nozzles of water tanks, good water nozzle gaps, correct maintenance and water pressure increase of the water tanks, the yield of high-speed bars is integrally improved from multiple aspects, therefore, it is convenientfor an enterprise to implement the method effectively and efficiently, the implementation efficiency and the yield of the high-speed bars are improved, and the method is convenient to apply.

Owner:成渝钒钛科技有限公司

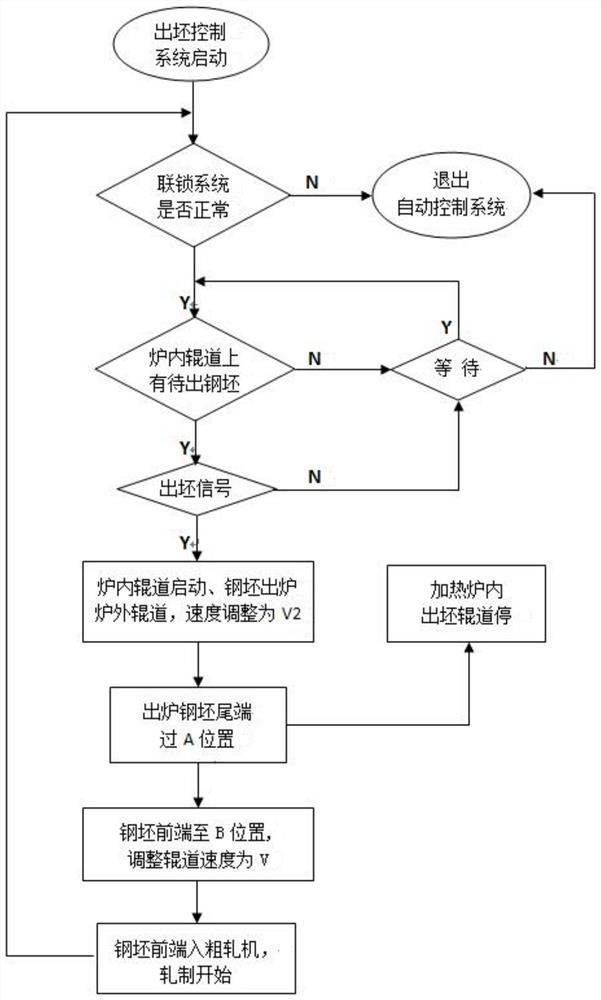

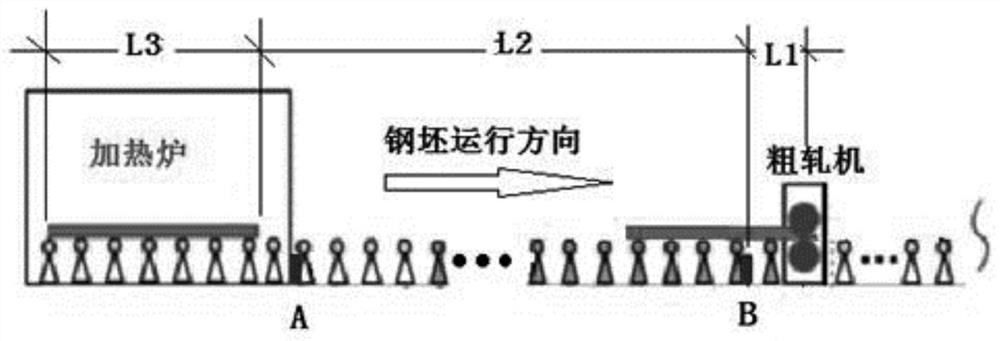

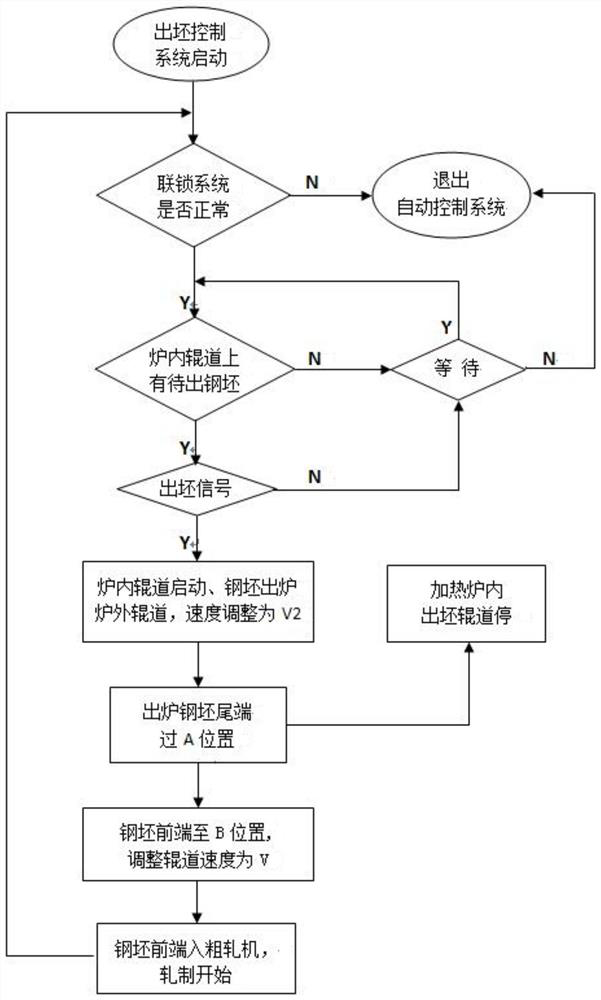

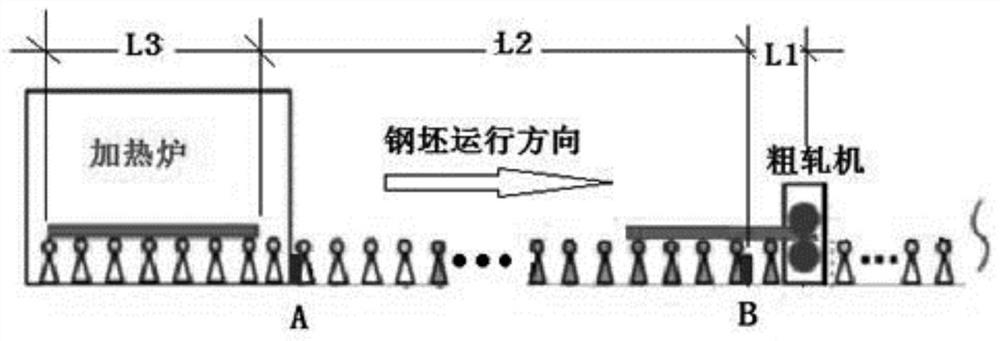

Control method for improving ejection efficiency of heating furnace

ActiveCN112934976AImprove blanking efficiencyRealize automatic controlRoll mill control devicesMetal rolling arrangementsAutomatic controlControl system

The invention relates to the technical field of steel rolling, in particular to a control method for improving the ejection efficiency of a heating furnace. After the rolling condition is met, a post person gives an instruction; a control system performs automatic control that step 1, a billet discharge roller way in the heating furnace starts to operate, a steel billet is conveyed out of the furnace, and the running speed of the steel billet is V2; step 2, when a tail end of the discharged steel billet passes through a point A, the roller way in the furnace stops running; step 3, when a front end of the steel billet runs to a point B, the running speed of the steel billet is adjusted to be V; step 4, when the front end of the steel billet enters into a roughing mill to start rolling, the roller way in the heating furnace is started to run, the steel billet is conveyed out of the furnace, and the steel billet running speed is V2; and after the steel billet is discharged, the first to fourth steps are repeated for steel billet conveying and rolling control. According to the control method, automatic control of billet discharging can be realized, steel piling accidents can be prevented, billet discharging efficiency and rolled steel yield are improved, and labor intensity of post personnel is reduced.

Owner:YANCHENG LIANXIN IRON & STEEL CO LTD

Method for improving yield rate of high speed bar

InactiveCN110180891AHigh yieldUniform heating temperatureMetal rolling arrangementsHeating furnaceHeating temperature

The invention relates to the technical field of yield rate of high speed bars, and discloses a method for improving the yield rate of a high speed bar. The method comprises the following steps that (1), the weight of a steel billet is strictly controlled, so that raw material of a heating furnace is good in quality, if the weight of the steel billet is found to have serious deviation with a setting billet, the interval range of the deviation is larger than or equal to 20, then the adjustment is required immediately through contact with a upper working procedure, the yield rate is determined tothe maximum extent after the steel billet is rolled, the waste rate is reduced, and the waste rate is less than or equal to 5%; (2), a heating system is strictly executed, the heating efficiency andthe heating speed are improved, the heating temperature of the steel billet is promoted to be uniform, and the condition that the temperature is too high or too low is avoided. The method for improving the yield of the high speed bar has the advantage that measurements of setting a heating area and a rolling area are used for improving the yield rate, and the cold shearing loss is controlled by acooling bed finishing zone, the yield rate of the high speed bar is improved, the yield speed of the high speed bar is improved, so that the expenditure of cost is reduced and the waste of enterpriseresources is reduced; the method for improving the high yield rate of the high speed bar is convenient for users to carry out and operate.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

Rolling technique of lead treated steel

InactiveCN101386031BAvoid stacking steel accidentsHigh yieldTemperature control deviceWork treatment devicesFree machining steelRolling mill

The invention belongs to the field of metallurgy and relates to rolling process of lead-containing free-machining steel. A rolling mill is used for rolling, in the rough rolling process, the rolling temperature is controlled at 1030-1060 DEG C, the former three-pass material form is reduced 1-3mm based on the standard material form; in the intermediate rolling process, the roll material form is the standard material form, and the rolling temperature is controlled at 980-1030 DEG C; in the pre-finish rolling process, the roll material form is the standard material form, the rolling temperatureis controlled at 1060-1030 DEG C, and the temperature of the rolled piece reaches 1005-1040 DEG C after the pre-finish rolling process; in the finish rolling process, the temperature of the rolled piece in a finishing mill is less than 980 DEG C, the roll material form is the standard material form, and the rolling temperature is controlled at 1020-1050 DEG C. The rolling process can prevent steel heaping caused by the cleavage crack of the cold, hot and frailty susceptible head of the rolled piece, prevent sliding accident caused by the high temperature of the steel, steadily increase the yield of the lead-containing free-machining steel, obviously reduce the waste, and greatly reduce the 100t steel fault time.

Owner:NANJING NANGANG IND DEV CO LTD

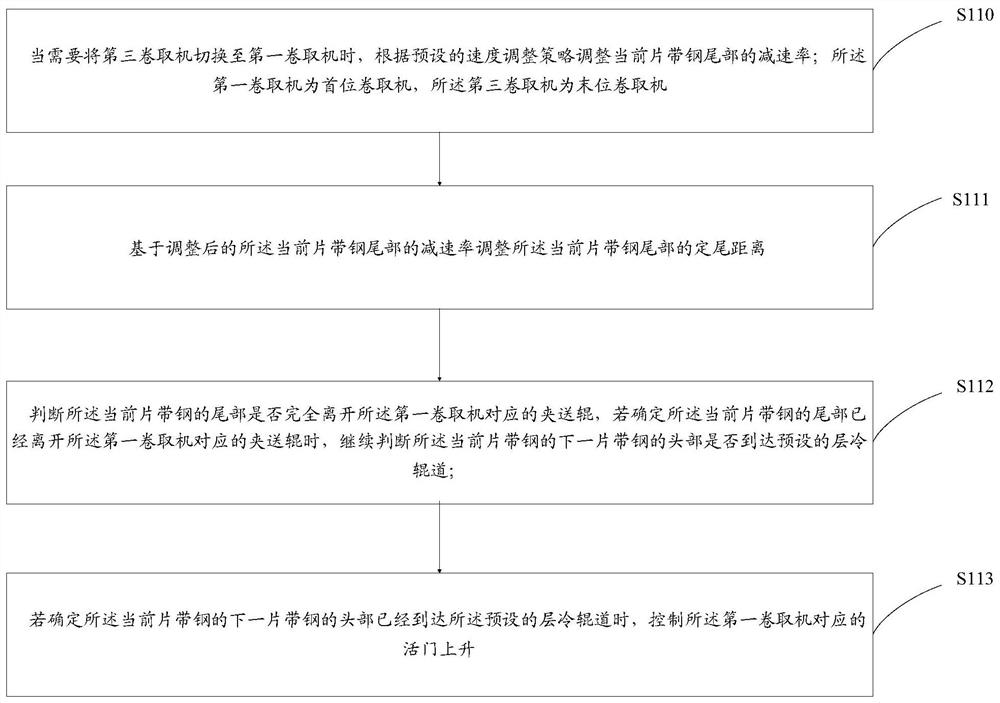

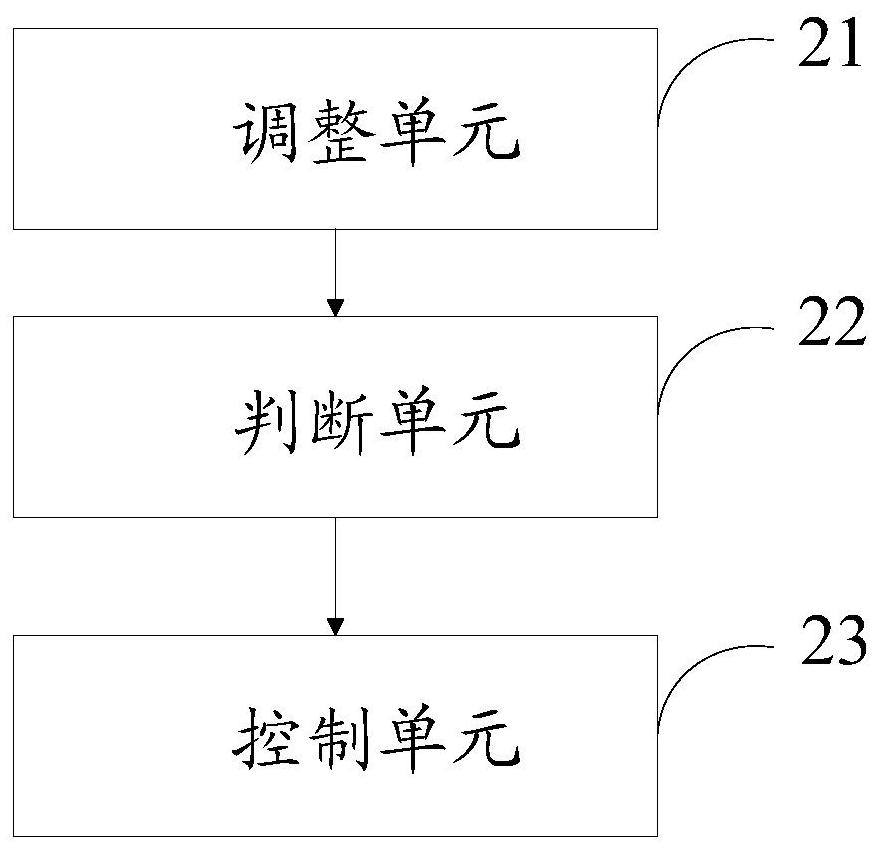

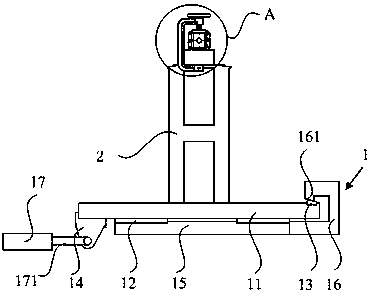

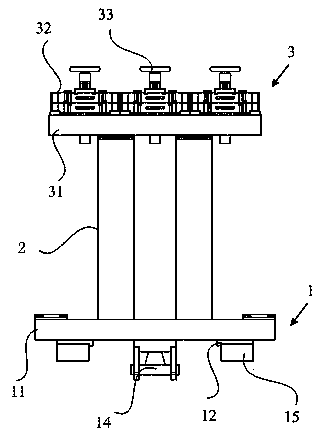

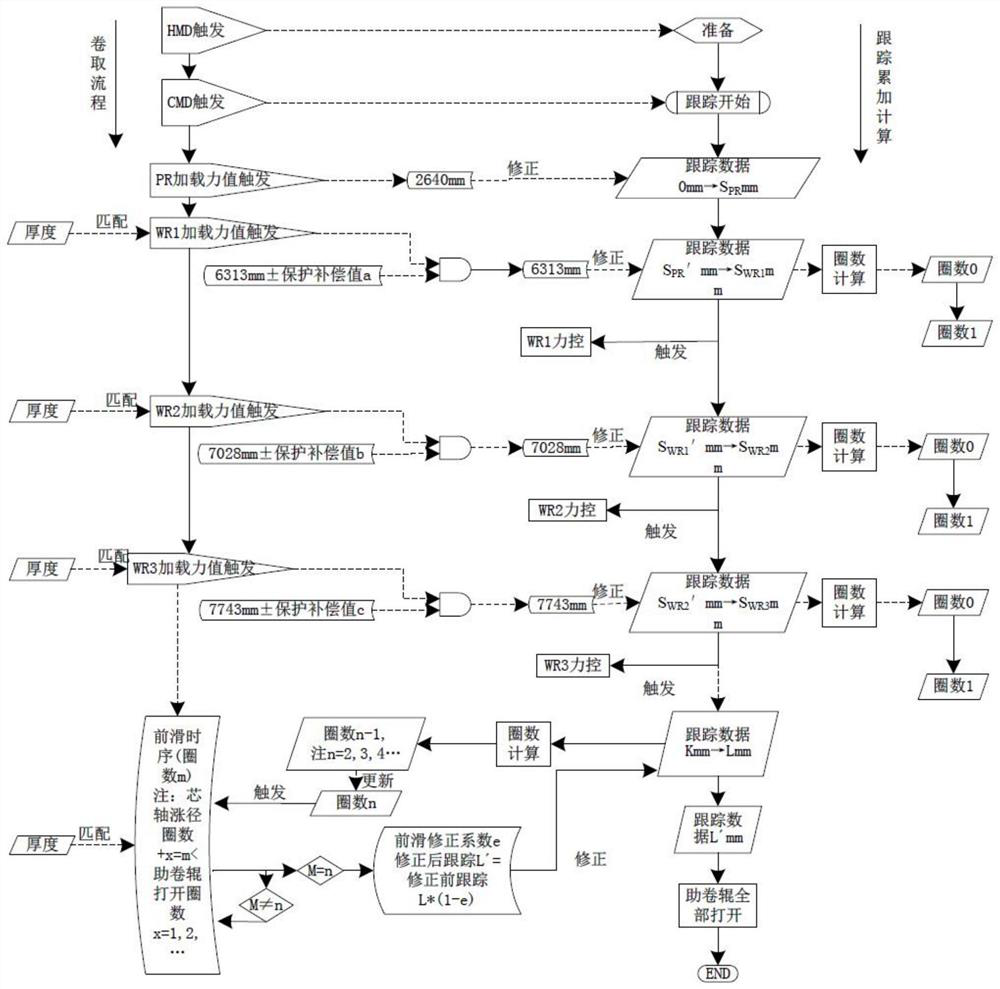

Coiling control method and device

ActiveCN112453065AFast switching speedIncreased handover preparation timeRoll mill control devicesMetal rolling arrangementsStrip steelMachine

The invention provides a coiling control method and device. The method comprises the steps that the deceleration rate of the tail part of a current piece of strip steel is adjusted according to a preset speed adjustment strategy when a third coiling machine needs to be switched to a first coiling machine; the tail fixing distance of the tail part of the current piece of strip steel is adjusted based on the adjusted deceleration rate of the tail part of the current piece of strip steel; whether the tail part of the current piece of strip steel completely leaves a pinch roll corresponding to thefirst coiling machine or not is judged, and if the tail part of the current piece of strip steel leaves the pinch roll, whether the head part of a next piece of strip steel of the current piece of strip steel reaches a preset layer cooling roller way or not is judged; and if the tail part of the current piece of strip steel reaches the pinch roll, a valve corresponding to the first coiling machine is controlled to ascend; According to the coiling control method and device, by adjusting the deceleration rate and the tail fixing distance of the tail part of the current piece of strip steel, thetail part of the current piece of strip steel can complete the coiling process at the fastest speed; and meanwhile, in order to increase the switching speed of the coiling machines, the switching preparation time of the first coiling machine is prolonged, so that the next piece of strip steel of the current piece of strip steel can smoothly enter the first coiling machine, the steel heaping accident is avoided, and the production efficiency is ensured.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

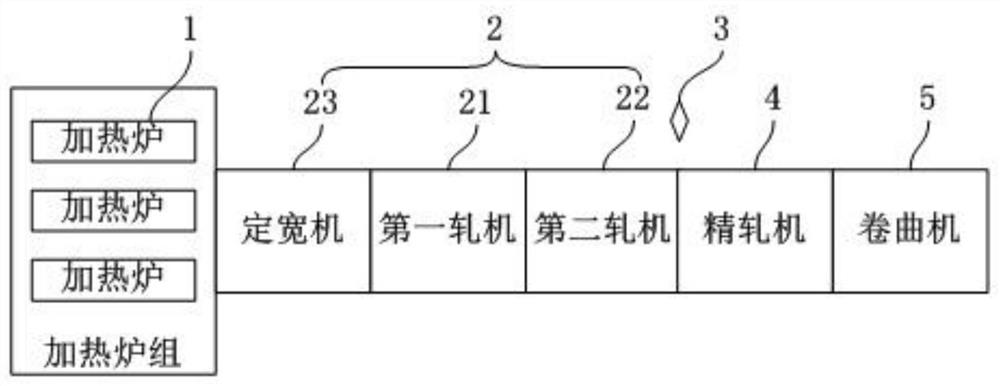

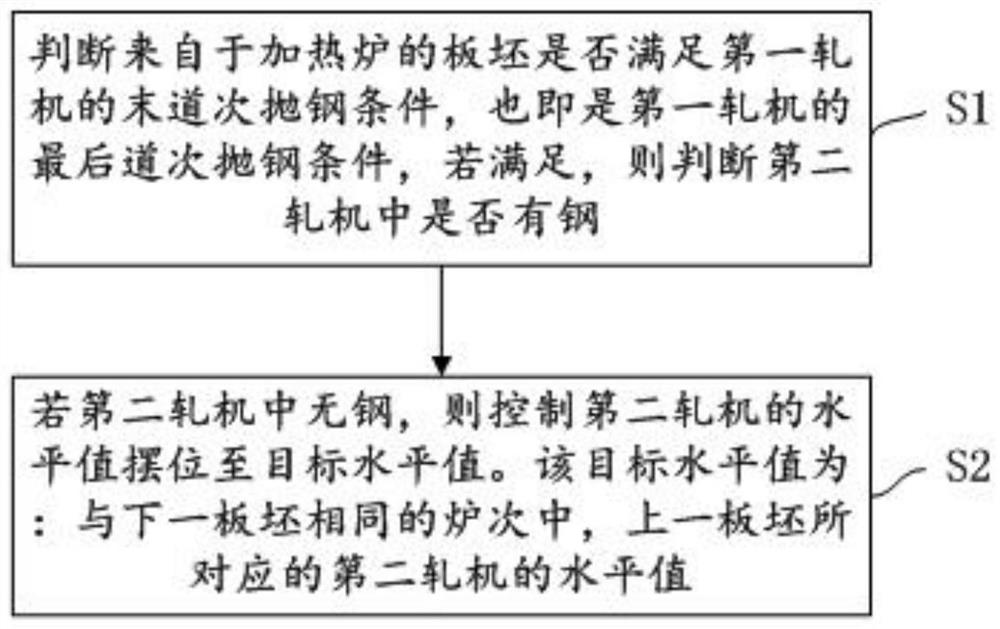

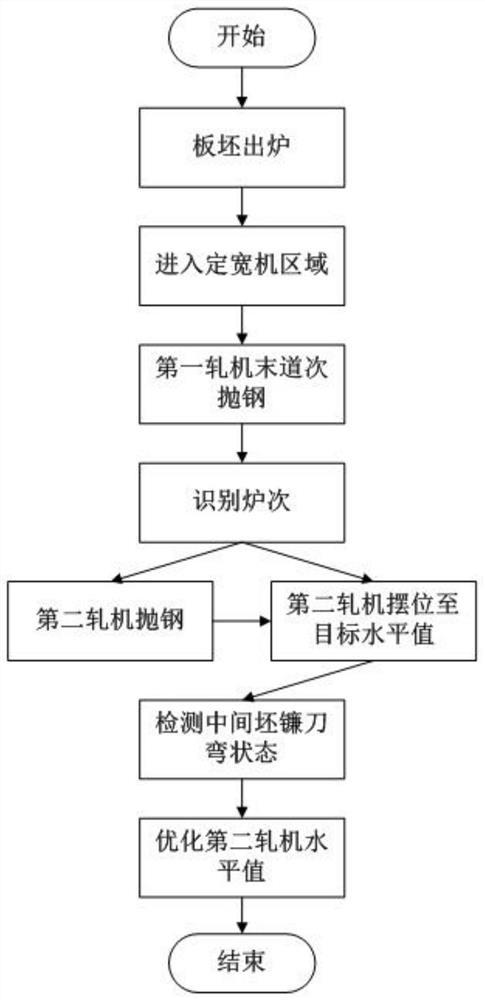

Roughing mill level value giving method, device and system

ActiveCN113042542AEliminate differencesAvoid pushover accidentsRoll force/gap control deviceHeating furnaceIndustrial engineering

The invention discloses a roughing mill level value giving method, which comprises the following steps of: judging whether a plate blank from a heating furnace meets the last-pass steel throwing condition of a first rolling mill or not, and if so, judging whether steel exists in a second rolling mill or not; if no steel exists in the second rolling mill, controlling the horizontal value of the second rolling mill to be set to a target horizontal value; and the target horizontal value is a horizontal value, corresponding to the previous plate blank, of the second rolling mill in the same heat as the next plate blank. The method can solve the problems of intermediate plate blank waste pushing accidents and steel piling accidents caused by plate blank head deviation in a hot-rolled strip steel rolling process in the metallurgical industry.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Hot-rolled strip steel laminar cooling device and control method thereof

PendingCN112404148AAvoid problems with poor coolingGuaranteed performance consistencyTemperature control deviceWork cooling devicesLaminar coolingStructural engineering

The invention provides a hot-rolled strip steel laminar cooling device and a control method thereof. The hot-rolled strip steel laminar cooling device and the control method thereof are used for solving the problem of water accumulation of a steel strip in the prior art. The hot-rolled strip steel laminar cooling device is located between a finishing mill group and a coiling machine and comprisesa middle cooling section and a tail end side water spraying group, the middle cooling section is used for cooling the steel strip, and the tail end side water spraying group is also used for cooling the steel strip. The tail end side water spraying group comprises at least one water spraying nozzle arranged on the side face in the steel strip conveying direction, the purging angles of the water spraying nozzles are larger than or equal to the width of the steel strip, the water spraying directions of the water spraying nozzles deviate to the steel strip conveying direction or the direction opposite to the steel strip conveying direction, and an acute angle is formed between the water spraying directions of the water spraying nozzles and the left-right direction. Accumulated water of the steel strip can be swept away.

Owner:CHONGQING IRON & STEEL CO LTD

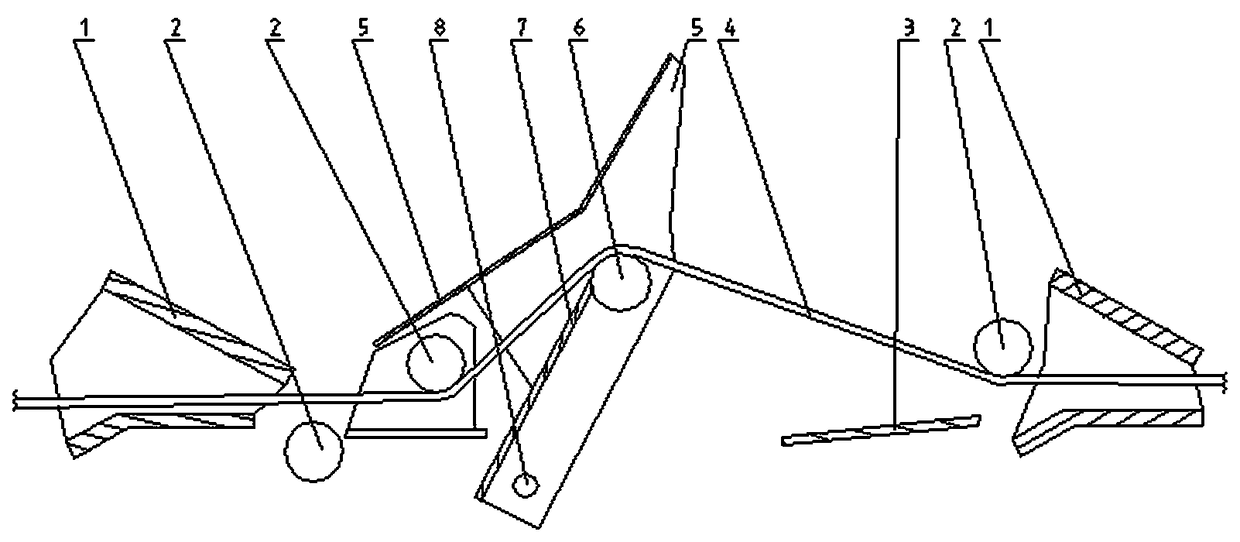

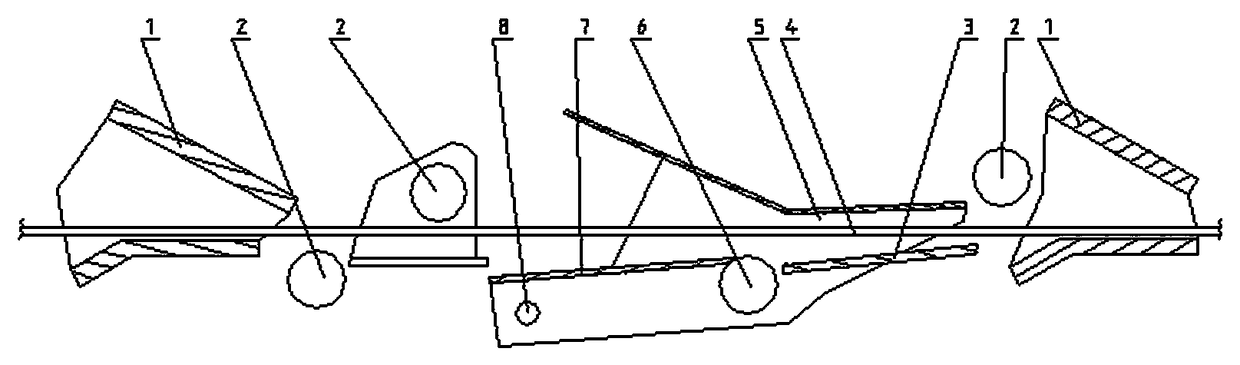

Guide switching device capable of automatically adjusting clearance

PendingCN108787752AReduce upturnAvoid the problem of entanglement on the upper pinch rollMetal rolling arrangementsHydraulic cylinderMechanical equipment

The invention relates to the technical field of strip sheet mill production line mechanical equipment, and discloses a guide switching device capable of automatically adjusting the clearance. The guide switching device comprises an upper pinch roll swing arm assembly, an upper guide switching device and a lower guide switching device. The upper guide switching device is composed of a supporting connecting arm, a first connecting cross beam, a second connecting cross beam, a hook, air cylinders, a water scraping wear-resisting plate and an upper guide plate. The lower guide switching device iscomposed of adjusting screws, a lower switching guide hydraulic cylinder, a lower chute plate and a lower switching guide frame. One end of the lower chute plate is connected to the lower switching guide frame through a connecting pin shaft, and the other end of the lower chute plate is connected to the lower switching guide frame through the two sets of adjusting screws. According to the guide switching device, the problem that the head of thin strip steel is thin and is upwarped to be wound into an upper pinch roll is avoided, meanwhile, the situation that the thick head is buckled downwardsto be drilled into the clearance of the lower chute plate and the steel stacking accident between the lower pinch roll and a coiler mandrel are avoided, and production stability is guaranteed.

Owner:MAANSHAN IRON & STEEL CO LTD

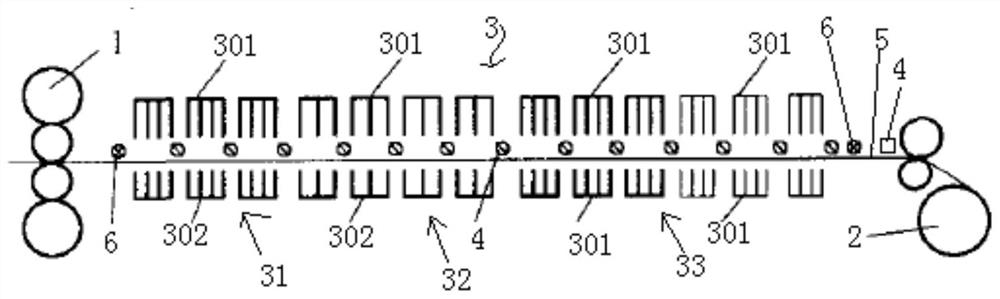

Multi-wire slitting and rolling controlled cooling device for bar

PendingCN110586669AReduce the risk of stacking steelQuick positioning installationWork cooling devicesMetal rolling arrangementsTemperature differenceMiddle line

The invention relates to a multi-wire slitting and rolling controlled cooling device for a bar . The multi-wire slitting and rolling controlled cooling device for the bar comprises a plurality of single-wire cooling devices which are arranged in parallel; the multiple single-wire cooling devices are arranged on a same fixed water beam; the accuracy of alignment of a running middle line of the baris remarkably improved; the steel stacking risk of the bar is reduced; each single-wire cooling device comprises a transition guide groove, a cooling structure and a collection guide groove which aresequentially arranged in the production direction of the bar; cooling structures comprise water cooling units, and water counterattacking units and empty passing units. According to the structure arrangement of the water cooling units and the empty passing units, the quick positioning installation of cooling nozzles and empty passing pipes can be realized, first assembling seats of the cooling nozzles and second assembling seats of the empty passing pipes are arranged to be of the same structure, the different distribution of the cooling nozzles and the empty passing pipes on the fixed water beam can be realized by adopting the same installation mode, and accordingly, the production process and the production error can be quickly adjusted, such as from continuous cooling to intermittent cooling process and temperature difference between wires.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

A control method for improving the billet discharge efficiency of the heating furnace

ActiveCN112934976BImprove blanking efficiencyRealize automatic controlRoll mill control devicesMetal rolling arrangementsDischarge efficiencyAutomatic control

The present invention relates to the technical field of steel rolling, in particular to a control method for improving the billet discharge efficiency of a heating furnace. Running, conveying the billet out of the furnace, the running speed of the billet is V2; the second step, when the tail end of the discharged billet passes point A, the roller table in the furnace stops running; the third step, when the front end of the billet runs to point B, the billet running speed is adjusted to V ; In the fourth step, when the front end of the billet enters the roughing mill to start rolling, the roller table in the heating furnace starts to run, and the billet is conveyed out of the furnace at a speed of V2; after the billet is released from the furnace, repeat the first step to the fourth step to carry out the billet conveying and rolling control. The control method provided by the invention can realize the automatic control of billets out of the furnace, can prevent stacking accidents, improve the efficiency of billets out of the furnace and the steel rolling output, and reduce the labor intensity of the post personnel.

Owner:YANCHENG LIANXIN IRON & STEEL CO LTD

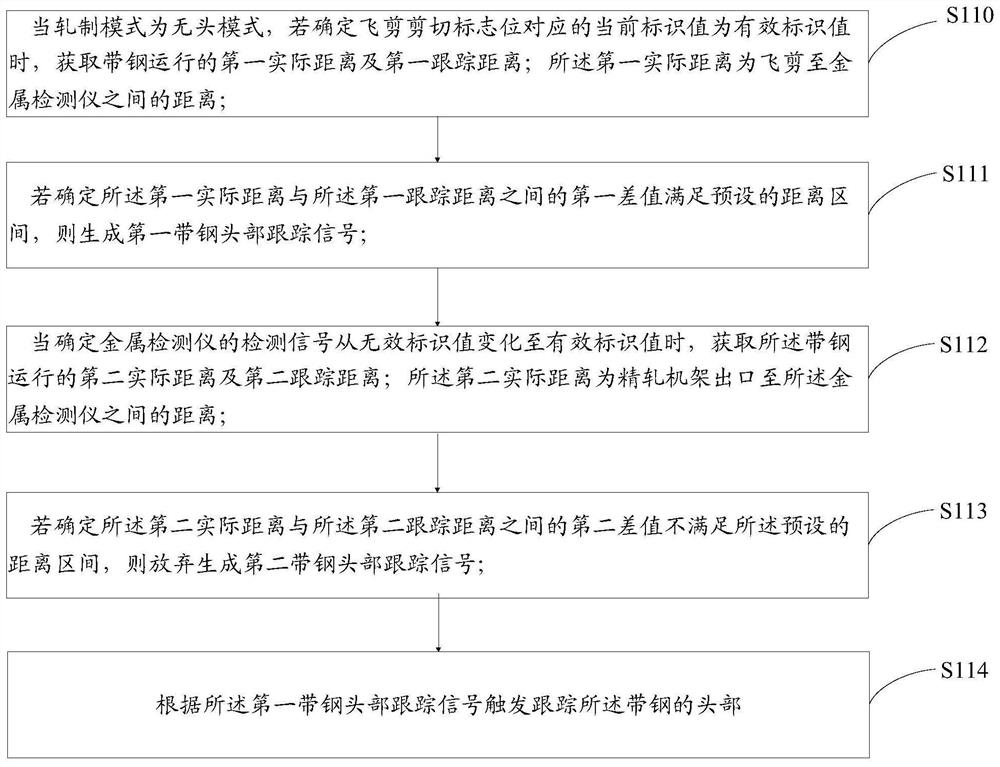

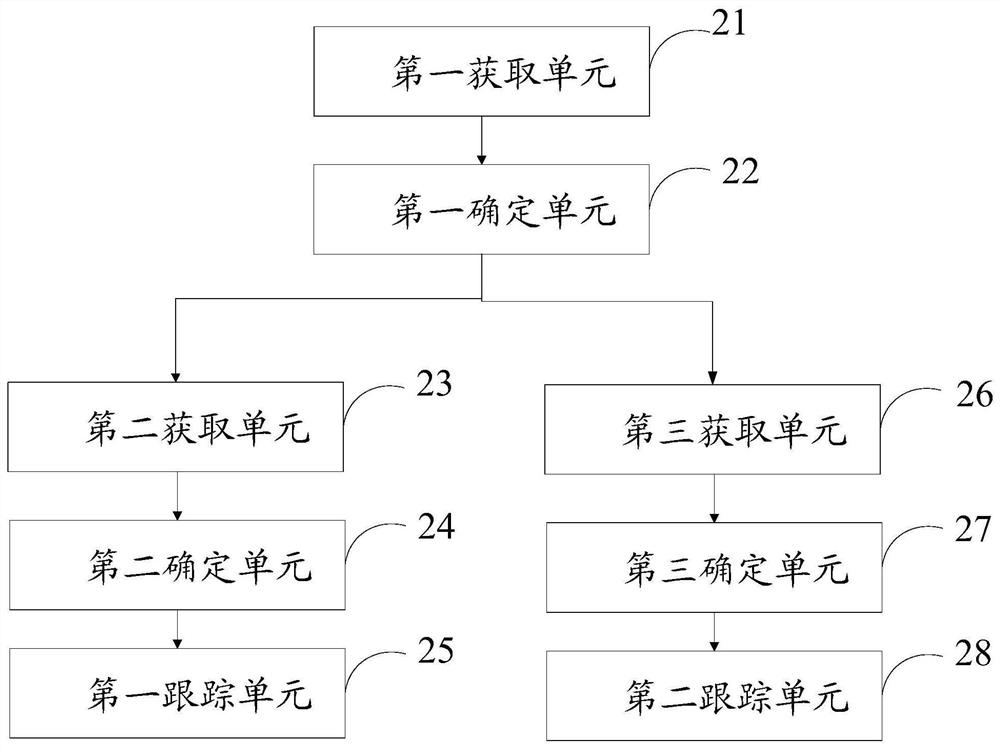

Method and device for tracking head part of strip steel

ActiveCN113042546AAvoid Tracking FailuresAvoid stacking steel accidentsRare end control deviceMeasuring devicesEngineeringStructural engineering

The invention provides a method and device for tracking the head part of strip steel. The method comprises the steps: if it is determined that a current identity value corresponding to a shearing mark position of a flying shear is a valid identity value, acquiring first actual distance and first tracking distance of operation of the strip steel; if it is determined that a first difference value between the first actual distance and the first tracking distance meets a preset distance interval, generating a first strip steel head part tracking signal; when it is determined that a detection signal of a metal detector changes from an invalid identity value to the valid identity value, acquiring second actual distance and second tracking distance of the operation of the strip steel; if it is determined that a second difference value between the second actual distance and the second tracking distance does not meet the preset distance interval, giving up generation of a second strip steel head part tracking signal; and tracking the head part of the strip steel according to the first strip steel head part tracking signal. In such a manner, even if the head part of the strip steel cannot be tracked through the detection signal, the head part of the strip steel is triggered and tracked according to the second strip steel head part tracking signal, and the head part of the strip steel is accurately identified, so that a steel-heaping accident is avoided, and the production efficiency is guaranteed.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Horizontal loop guide roller device

ActiveCN105363807AInnovative designEasy to implementFlexible work arrangmentsMetal rolling arrangementsEngineeringAxial load

The invention discloses a horizontal loop guide roller device which comprises a loop table, a guide roller with a table and a lining arranged in the guide roller with the table. The guide roller device further comprises an eccentric shaft, a bearing set and locking devices used for locking the two ends of the bearing set. The eccentric shaft comprises a first shaft part and a second shaft part arranged in the lining. The guide roller with the table is connected with the loop table through the first shaft part. The bearing set is arranged between the second shaft part and the lining and bears axial loads in the axial directions of the two ends of the bearing set by means of the series-connection arrangement and back-to-back arrangement between bearings. According to the guide roller device, the loop bearings and clamping springs can be prevented from being damaged, the situation that because the guide roller plays, a rolled piece is scratched by an outlet guide groove is avoided, the steel piling accidents caused by falling-off of the guide roller are eradicated, abrasion to the loop outlet guide groove and an inlet guide of a rolling mill is reduced, the product quality is improved, and rolling cost is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

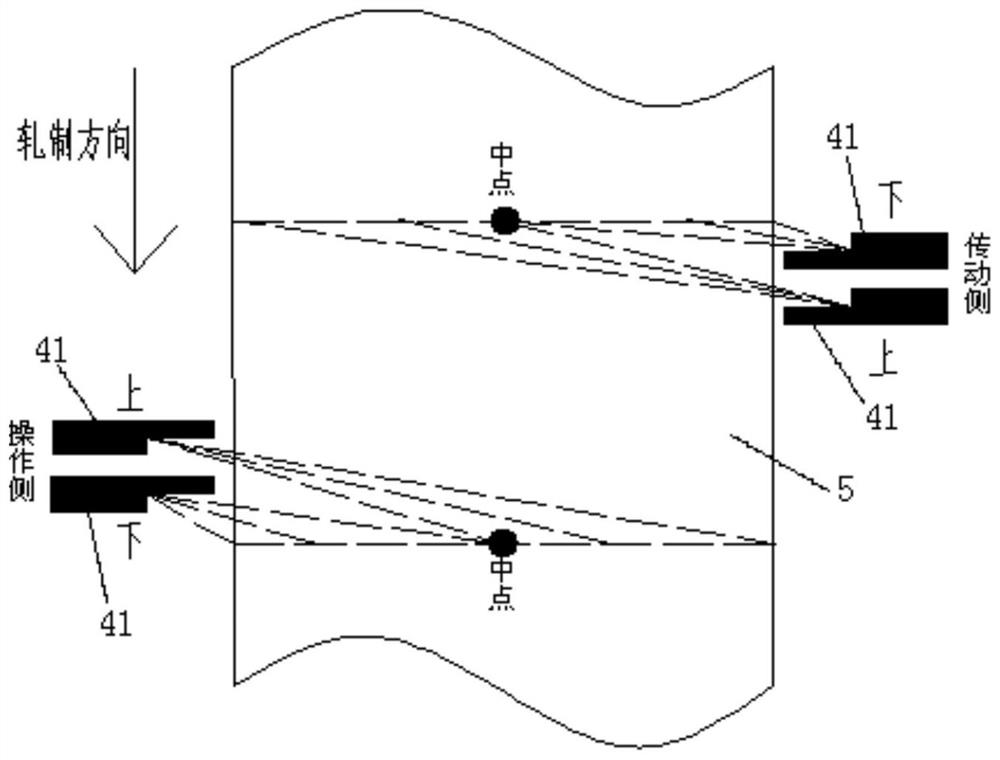

Hot rolling process of non-oriented silicon steel

PendingCN114682630AReduce the amount of width reductionReduce trimmingMetal rolling stand detailsRoll mill control devicesMetallurgy

The invention discloses a hot rolling process of non-oriented silicon steel. Aiming at the phenomenon that the width of the head of a plate strip within 100m in the finish rolling process is easily narrowed in the finish rolling process due to small deformation resistance in the hot rolling process of non-oriented silicon steel, an intermediate billet width compensation amount model is established according to main factors such as chemical components, rolling temperature and rack tension, and the intermediate billet width compensation amount is calculated according to the model. And meanwhile, a short-stroke control method of the vertical roller is combined, so that the purpose of reducing the width difference of the through roll is achieved. And the width difference of the whole roll is reduced from 30mm to below 15mm, and the edge cutting amount and the head and tail loss are reduced.

Owner:ANYANG IRON & STEEL +1

Wire Rod Air Passing Device and Steel Rolling Device

ActiveCN103706633BAvoid stacking steel accidentsImprove quality and efficiencyGuiding/positioning/aligning arrangementsMetal rolling arrangementsEngineeringSlide plate

The invention provides a wire rod idling device and a steel rolling device. The wire rod idling device comprises a fixed base, a supporting frame and an idling guiding groove structure. The fixed base comprises a fixed plate, sliding plates, a wedge block, a stopping block, a guiding rail, a positioning frame and a piston cylinder. The two sides of the bottom of the fixed plate are fixedly provided with the sliding plates. The wedge block is fixed to one end of the fixed plate, and the stopping block is welded to the other end of the fixed plate. A piston rod of the piston cylinder is connected with the stopping block. The fixed plate is connected to the guiding rail in a sliding mode through the sliding plates. The positioning frame is arranged on one side of the guiding rail. A positioning slope used for being matched with the wedge block is arranged on the positioning frame. The idling guiding groove structure is fixed to the fixed plate through the supporting frame. The fixed base is firmly fixed through the mutual matching of the piston rod, the guiding rail and the positioning frame, so that wire rods smoothly pass through the idling guiding groove structure, the steel stacking accident caused when the idling guiding groove structure waggles is avoided, and product quality and production efficiency are improved.

Owner:QINGDAO SPECIAL STEEL CO LTD

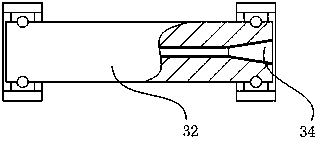

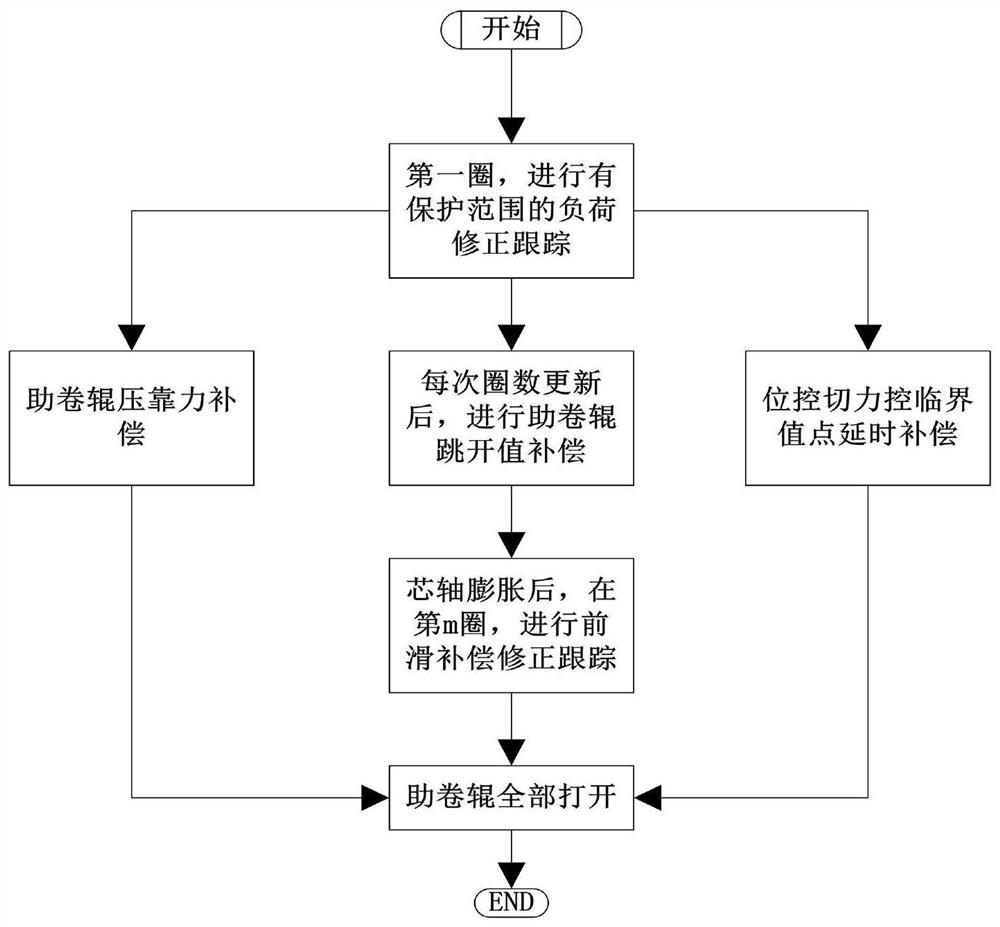

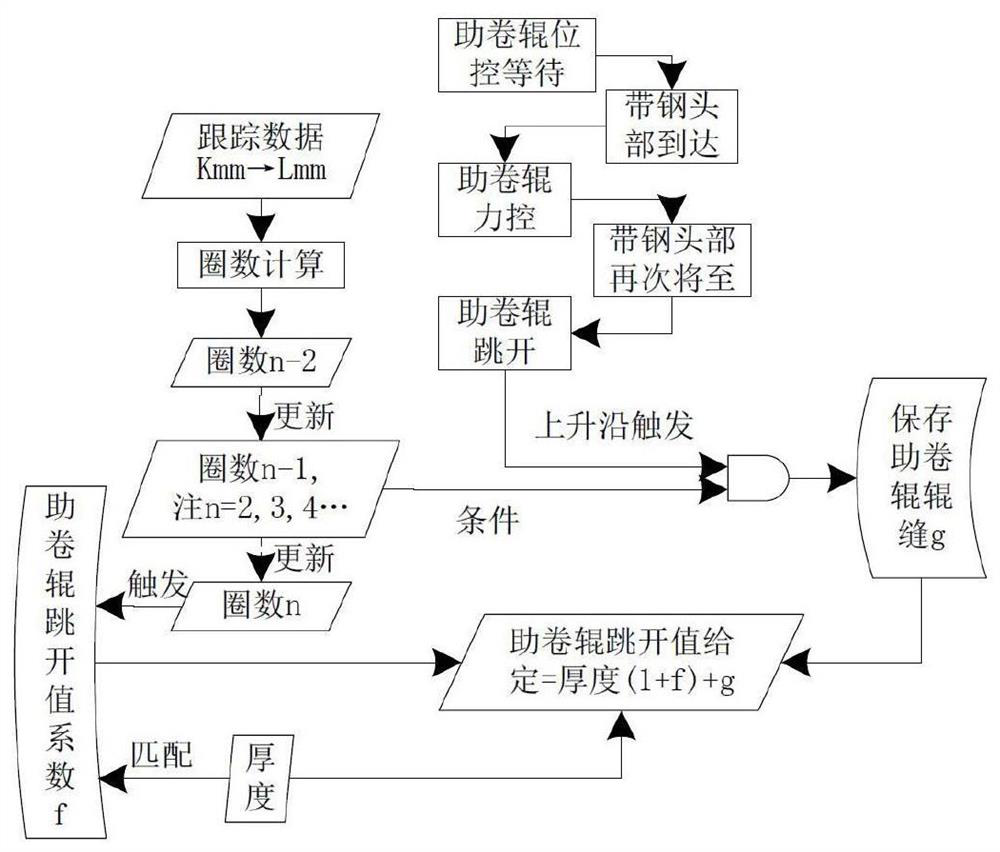

Effective method for solving problem of hot rolling coiling indentations

ActiveCN112404141AEliminate indentation defectsPrevent bugfixesRare end control deviceRoll force/gap control deviceStructural engineeringStrip steel

The invention discloses an effective method for solving the problem of hot rolling coiling indentations, and relates to a method special for a control technology of a metallurgical hot rolling strip steel coiling machine. The control precision of the head of strip steel is improved from the four aspects of correction tracking calculation, wrapper roller pressing force compensation, wrapper rollerbounce-off value compensation and position control-force control switch critical point delay compensation, and correction tracking comprises load correction and forward slip compensation correction within a protection range, so that the pressure control time sequence deviation borne by the head of the strip steel is greatly reduced, the pressure impact is obviously reduced, steel stacking accidents are effectively avoided, and the problem that head indentations cannot be thoroughly eliminated in an existing control scheme is solved.

Owner:BAOTOU IRON & STEEL GRP

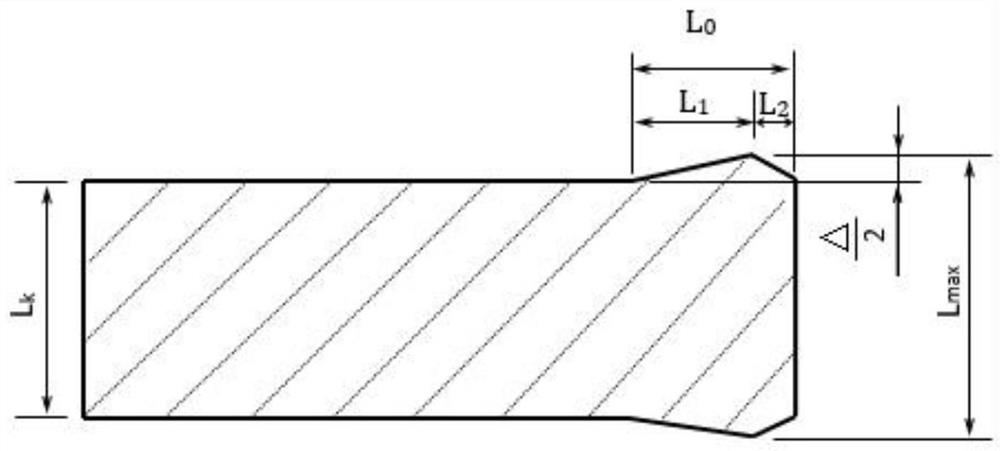

Fast centering method of water-cooled line workpieces in high-speed wire rod production line

InactiveCN101879524BPerform alignment checksReduce breakdown delaysRolling equipment maintainenceMetal rolling arrangementsProduction lineWire rod

Owner:NANJING IRON & STEEL CO LTD

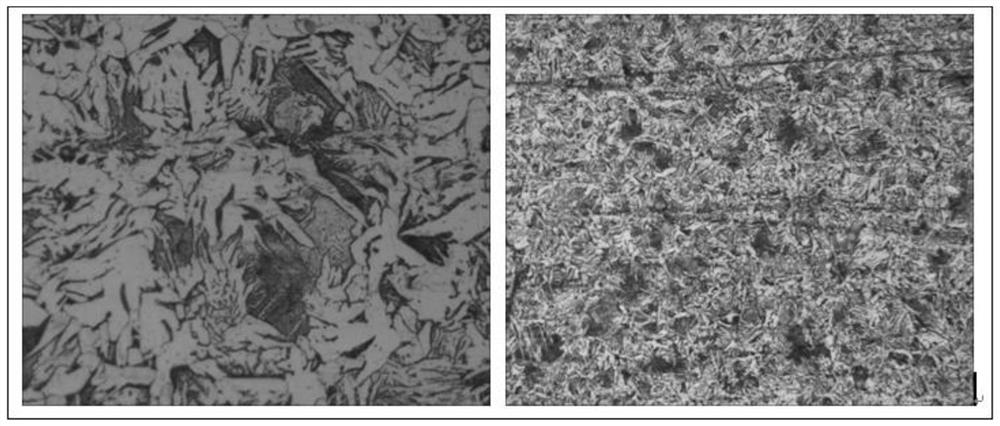

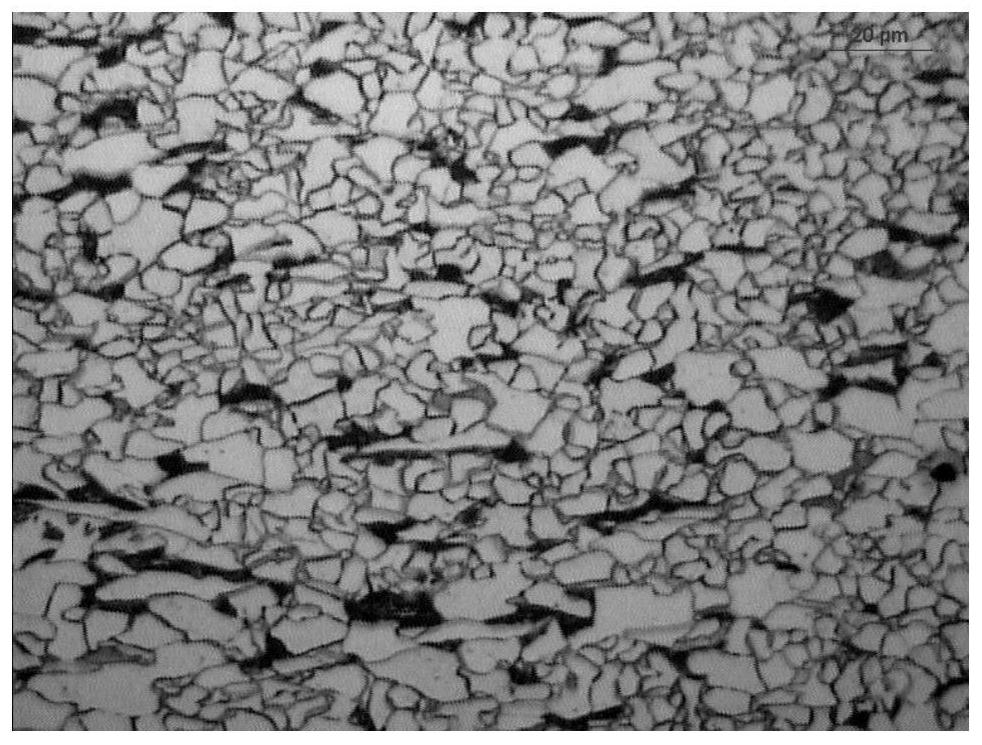

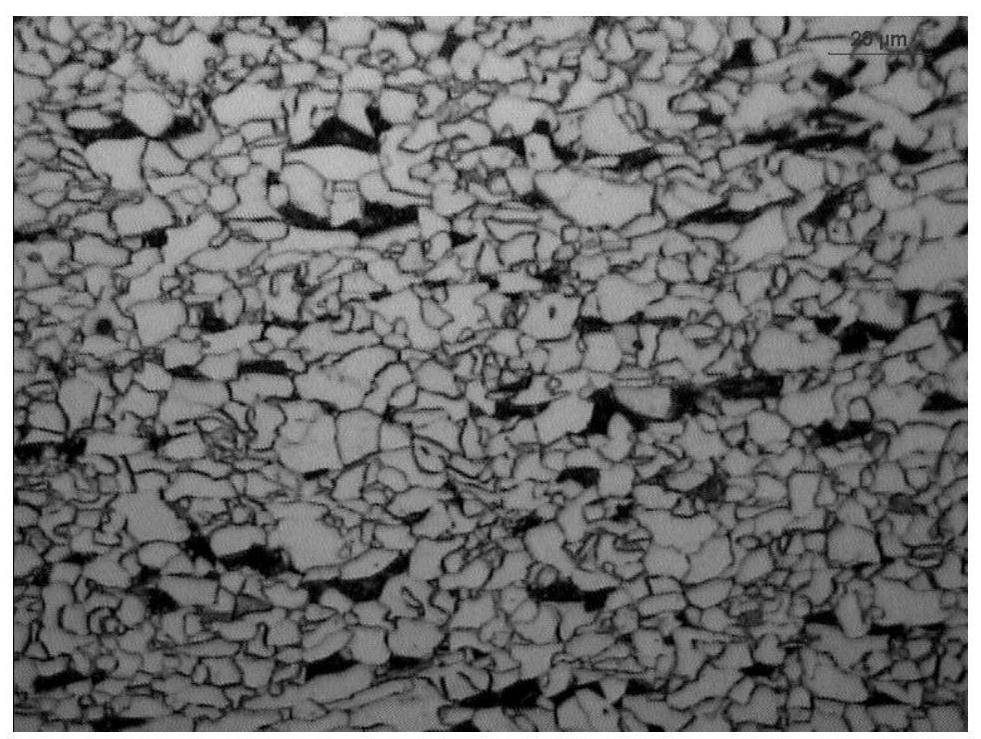

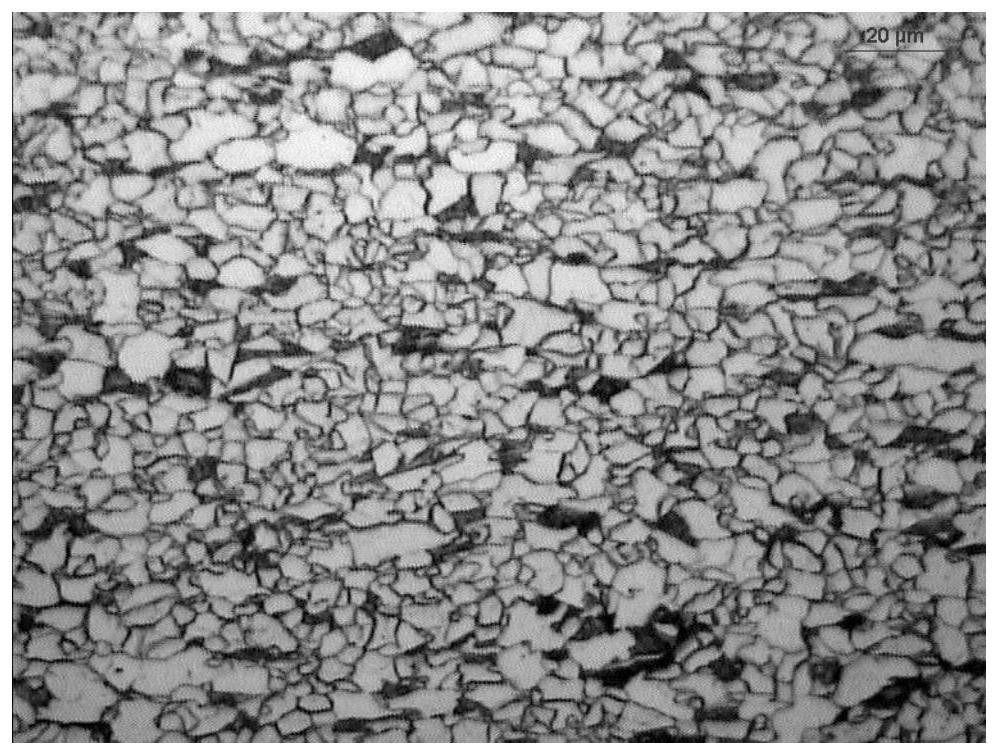

A kind of lightweight fatigue-resistant hot-rolled dual-phase wheel steel and production method thereof

The invention discloses lightweight fatigue-resistant hot-rolled two-phase wheel steel and a production method thereof. The hot-rolled two-phase wheel steel is prepared from chemical components in percentage by mass as follows: 0.05%-0.09% of C, 0.5%-0.8% of Si, 1.0%-1.6% of Mn, 0.4%-0.7% of Cr, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S, 0.015%-0.045% of Als, 0.01%-0.03% of Nb and the balance of Fe and inevitable impurities. The production method comprises smelting, continuous casting, heating, rolling, cooling and rolling procedures. On the basis of existing 2250 mm hot continuous rolling production and cooling equipment, the hot-rolled two-phase wheel steel with the thickness specification of 10-14 mm, the uniform grain size in the thickness direction, low yield ratio, high elongation and significant weight reduction and lightweight effects is developed, and various performance requirements of wheel production are completely met.

Owner:HANDAN IRON & STEEL GROUP +1

Anti-slip coating as well as preparation method and application thereof

InactiveCN107384059AStrong adhesionAvoid steel punching accidentsCellulose coatingsAnti-corrosive paintsWear resistantCalcium carbonate

The invention belongs to the field of anti-slip coating, and particularly relates to anti-slip coating as well as a preparation method and application thereof. The coating is prepared from the following raw materials in parts by weight: 20 to 100 weight parts of wear-resistant agents and 5 to 30 weight parts of attaching agents; preferably, the wear-resistant agents are any one kind of materials or a mixture of two kinds of materials or more from calcium carbonate, tricalcium silicate and silicon dioxide; more preferably, the wear-resistant agents are prepared from 20 to 50 weight parts of calcium carbonate, 5 to 30 weight parts of tricalcium silicate and 1 to 10 weight parts of silicon dioxide. The raw materials of the anti-slip coating comprise the wear-resistant agents and the attaching agents; the anti-slip effects are good; the rolling trial run pile steel punching accidents can be avoided; the production and the use are convenient.

Owner:DAYE SPECIAL STEEL CO LTD

Adaptive Calculation Method of Cold Rolling Forward Slip Model for Stable Rolling

ActiveCN108655176BReasonable calculationImprove forecast accuracyGeometric CADDesign optimisation/simulationForward slidingEngineering

The invention relates to a self-adaptive calculation method of a cold-rolled forward-sliding model for stable rolling. The self-adaptive calculation method of the cold-rolled forward-sliding model forthe stable rolling is characterized by comprising the following steps that step 1, collecting rolling technology data; step 2, calculating of a forward-sliding measured value; step 3, correcting anddistributing calculation of a forward-sliding theoretical model; step 4, adjusting a friction coefficient compensation factor by using a forward-sliding model coefficient debugging tool; step 5, and loading finally determined compensation factors into a process computer memory table; step 6, calculating a forward sliding self-adaptive coefficient when a current strip steel is rolled; and step 7, considering the calculation of the forward-sliding self-adaptive coefficient of a previous strip steel. According to the method, the forward-sliding value can be accurately calculated out, so that thesetting precision of the circumferential speed of each rack roller is guaranteed, the phenomenon that the metal mass flow is unstable is avoided, and the rolling stability is improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Rolling machine for hot-rolled sheets with excellent rolling assisting property

A hot-rolled sheet coiling machine with better coil-helping performance has a reel, coil-helping rollers, swinging arms for supporting said coil-helping rollers, and hydraulic cylinders for driving said swinging arms. It features that 1-3 coil-helping roller are additionally used for increasing the points to where the pressure is applied, so improving its coil-helping performance.

Owner:HEBEI IRON AND STEEL

A horizontal loop guide roller device

ActiveCN105363807BInnovative designSimple designFlexible work arrangmentsMetal rolling arrangementsAxial loadRolling mill

The invention discloses a horizontal loop guide roller device which comprises a loop table, a guide roller with a table and a lining arranged in the guide roller with the table. The guide roller device further comprises an eccentric shaft, a bearing set and locking devices used for locking the two ends of the bearing set. The eccentric shaft comprises a first shaft part and a second shaft part arranged in the lining. The guide roller with the table is connected with the loop table through the first shaft part. The bearing set is arranged between the second shaft part and the lining and bears axial loads in the axial directions of the two ends of the bearing set by means of the series-connection arrangement and back-to-back arrangement between bearings. According to the guide roller device, the loop bearings and clamping springs can be prevented from being damaged, the situation that because the guide roller plays, a rolled piece is scratched by an outlet guide groove is avoided, the steel piling accidents caused by falling-off of the guide roller are eradicated, abrasion to the loop outlet guide groove and an inlet guide of a rolling mill is reduced, the product quality is improved, and rolling cost is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

Production method for improving large dimension wire size precision and surface quality

InactiveCN101733273BHigh dimensional accuracyQuality improvementRoll mill control devicesMetal rolling arrangementsProduction lineWire rod

The invention discloses a production method for improving large dimension wire size precision and surface quality. The method is implemented by using the existing finishing mill set to modify the dummied frame in the finishing mill set used in producing large dimension wire into a regular round frame on the high speed wire production line for non-reducing sizing machine set, performing primary regular round rolling to the wires rolled by a finished product frame, thus improving large dimension wire size precision and surface quality, and simultaneously reducing head and tail cutting quantity of finished product wire and enhancing yield.

Owner:NANJING IRON & STEEL CO LTD

Efficient production method of phi 12mm wire

PendingCN113714278ASmall amount of depressionAvoid stacking steel accidentsMetal rolling arrangementsWire rodPolishing

The invention relates to the technical field of wire production, and discloses an efficient production method of a phi 12mm wire. The method comprises the following steps that rough refining is carried out; refining is carried out; continuous casting is carried out; heating is carried out; and rolling, polishing and grinding are carried out, wherein a wire solid steel blank obtained after heating sequentially enters a rough mill unit, a finish mill unit and a flying shear unit to obtain a wire steel rolling piece blank, the obtained wire steel rolling piece blank sequentially enters a rough polishing and grinding unit and a finish polishing and grinding unit to be polished and ground, and a wire steel rolling piece is obtained after grinding. According to the efficient production method for the phi 12mm wire, the rolling passes of a pre-finish mill and a finish mill are changed, the rough mill unit is two passes, the finish mill unit is six passes, the finish mill unit is totally provided with two pass patterns, the pass pattern of two of the passes are phi 18, the pass pattern of the other four passes is phi 12, so that the rolling reduction of pre-finish rolling is reduced, the remaining rolling reduction is distributed to the finish mill, and therefore steel heaping accidents caused by speed increase due to large rolling reduction are eradicated, the yield is improved, and speed increase of the finish mill and the pre-finish mill is achieved.

Owner:金鼎重工有限公司

Tail pressing looper

PendingCN108772427AAvoid stacking steel accidentsFlexible work arrangmentsMetal rolling arrangementsMechanical engineering

The invention discloses a tail pressing looper in the technical field of steel rolling. A looper roll and a looper guide plate are installed on a looper guide box also as a looper arm, fixing guide rollers and guide boxes are installed on the front and rear ends of a looper shaft; the looper guide box whose opening faces downward is in a groove structure, and can rotate up and down with the looperroll; and the looper guide box and the looper roll can descend to the lowest position to cover a rolling tail in the smallest space when the rolling tail passes through the looper. Therefore, steel-heaping accidents caused by whipping and splitting of the rolling tails can be effectively prevented.

Owner:XINJIANG BAYI IRON & STEEL

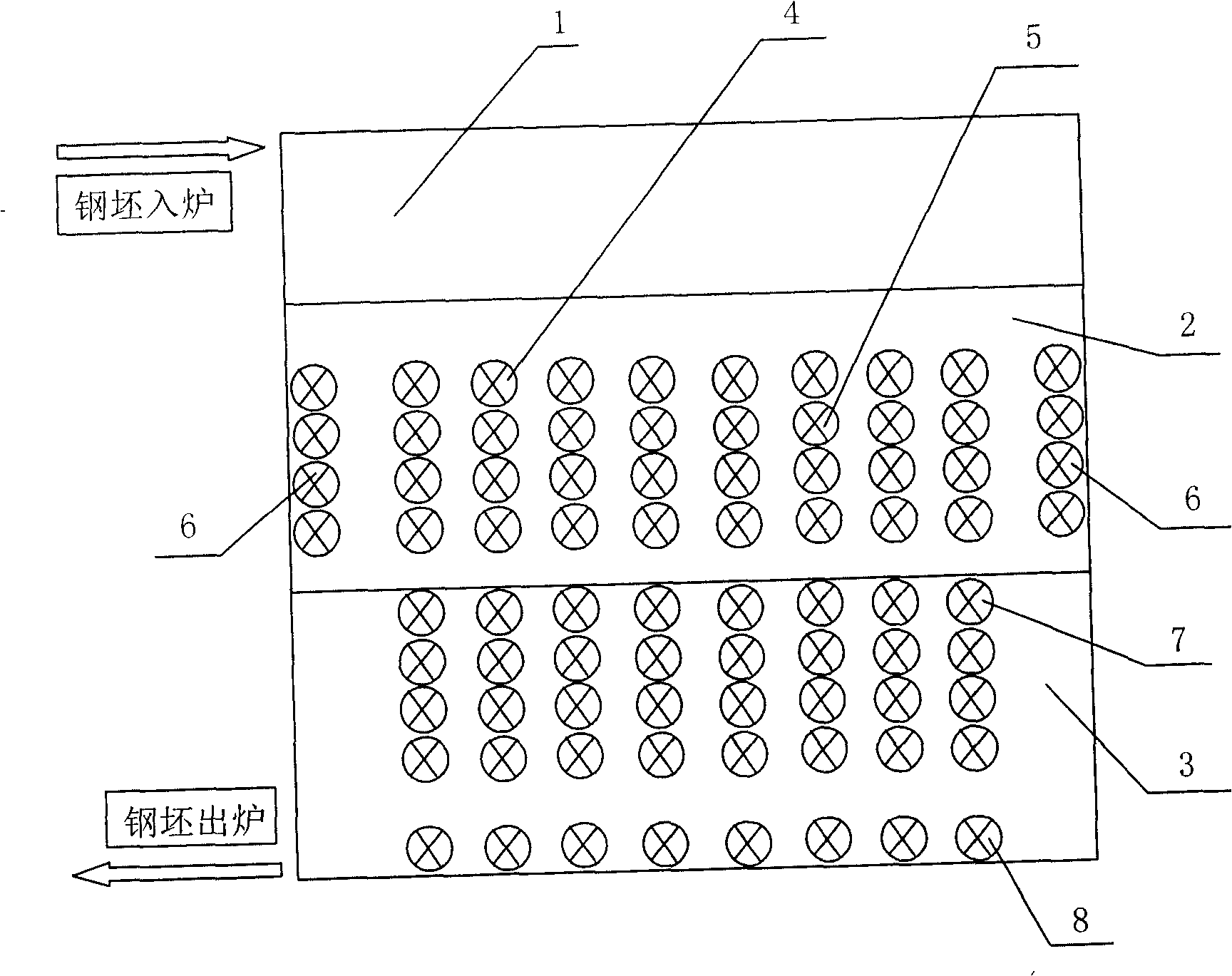

Process of heating lead-containing free-cutting steel

InactiveCN100457927CHigh yieldCleave Chance ReducedTemperature control deviceFurnace typesHeating furnace

The present invention relates to heating process in metallurgy, and is especially process of heating lead-containing free cutting steel. The heating process in a heating furnace includes a pre-heating step, a heating step, and a heat soaking step. The steel blank is first pre-heated to 700-800 deg.c in the pre-heating step with the afterheat of the heating step and the heat soaking step; then heated to 1150-1230 deg.c in the heating step with the heating burner in the heating furnace; and final heat soaked to 1150-1250 deg.c in the heat soaking step while ensuring the output temperature of 1140-1190 deg.c. Thus heated lead-containing free cutting steel has less sliding and cracking in the rolling process.

Owner:NANJING NANGANG IND DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com