Coiling control method and device

A control method and coiler technology, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as stacking accidents, failure to switch coilers at the end position, and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a coiling control method, which is applied in a hot rolling production line. In order to understand the technical solution of the present invention more clearly, the hot rolling production line is firstly introduced here. Taking the running direction of the strip as a reference, the hot rolling production line includes: finishing stand, layer cooling roller table, valve, pinch roller, first coiler, second coiler and third coiler; A heat detector is installed before the coiler, and each coiler has a corresponding valve and pinch roller; the valve and pinch roller can guide the strip steel so that the strip steel enters the corresponding coiler for coiling; The layer cold roller table includes nine groups.

[0042] Here, the first coiler can be understood as the first coiler, and the third coiler can be understood as the last coiler, and each coiler coils the strip in turn.

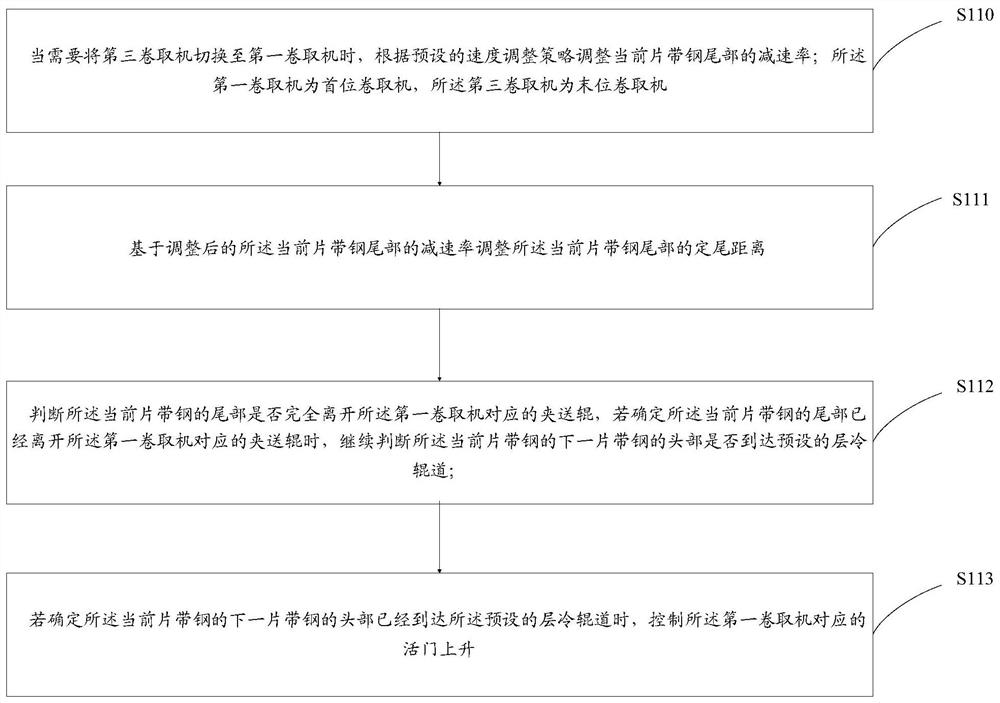

[0043] Specifically, such as figure 1 As shown, the methods include: ...

Embodiment 2

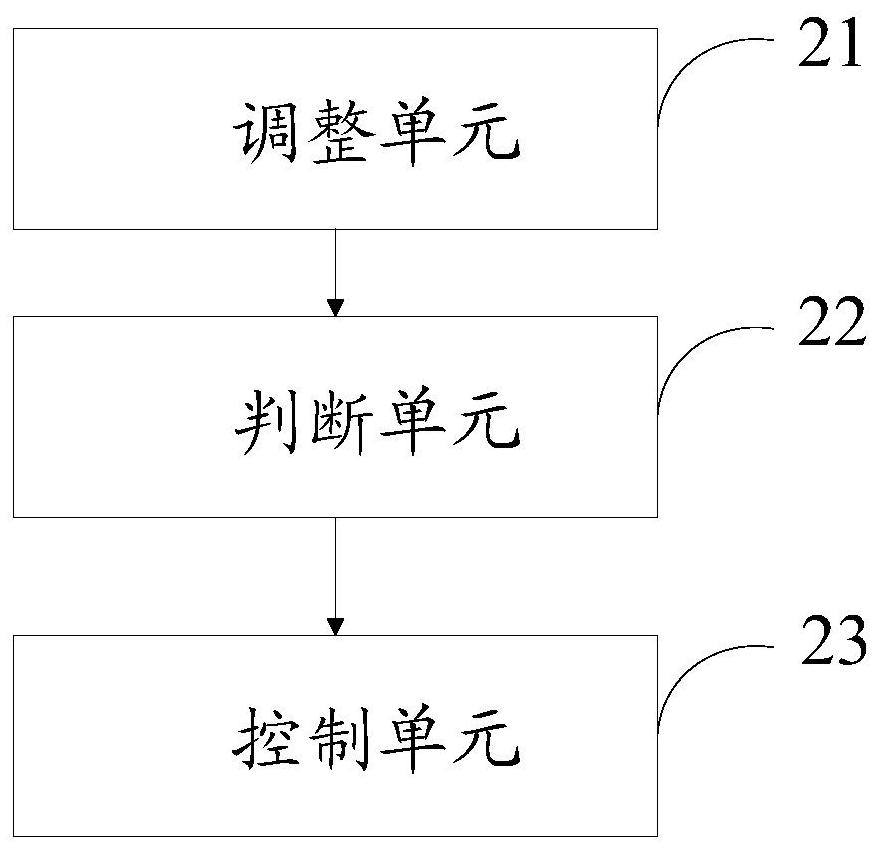

[0072] This embodiment provides a coiling control device, such as figure 2 As shown, the device includes: an adjustment unit 21, a judgment unit 22 and a control unit 23; wherein,

[0073] The adjustment unit 21 is used to adjust the deceleration rate of the tail of the current strip according to the preset speed adjustment strategy when the third coiler needs to be switched to the first coiler; the first coiler is the first coiler A take-up machine, the third coiler is a final coiler; adjust the fixed tail distance of the current strip tail based on the adjusted deceleration rate of the tail of the current strip;

[0074] Judging unit 22, configured to judge whether the tail of the current strip has completely left the pinch roller corresponding to the first coiler, if it is determined that the tail of the current strip has left the first coiler When corresponding to the pinch roller, continue to judge whether the head of the next strip of the current strip reaches the pres...

Embodiment 3

[0103] In actual application, when using the coiling control method provided in Embodiment 1 and the coiling control device provided in Embodiment 2 to coil the strip steel on a hot rolling production line, the specific implementation is as follows:

[0104] When it is necessary to switch the third coiler to the first coiler, adjust the deceleration rate of the tail of the current strip steel according to the preset speed adjustment strategy; adjust the deceleration rate based on the adjusted deceleration rate of the tail of the current strip steel Describe the fixed tail distance of the front strip steel tail; When making the front strip steel tail arrive before the heat detector installed before the third coiler, the current running speed of the front strip steel tail is consistent with the fixed tail speed.

[0105] Increase the valve rising sequence corresponding to the first coiler, and judge whether the tail of the current strip has completely left the pinch roller corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com