Patents

Literature

69results about How to "Improve blanking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

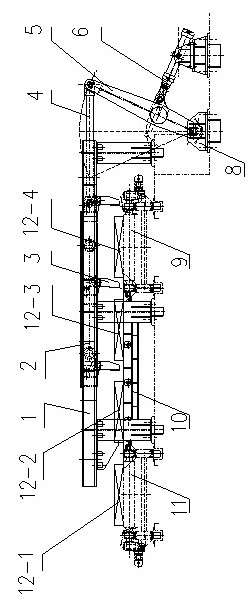

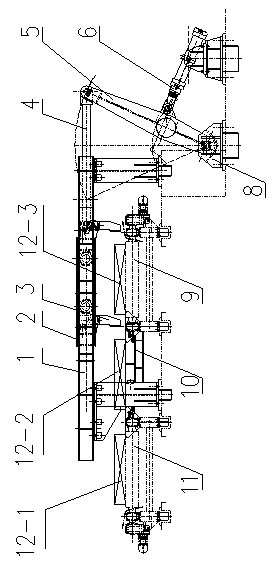

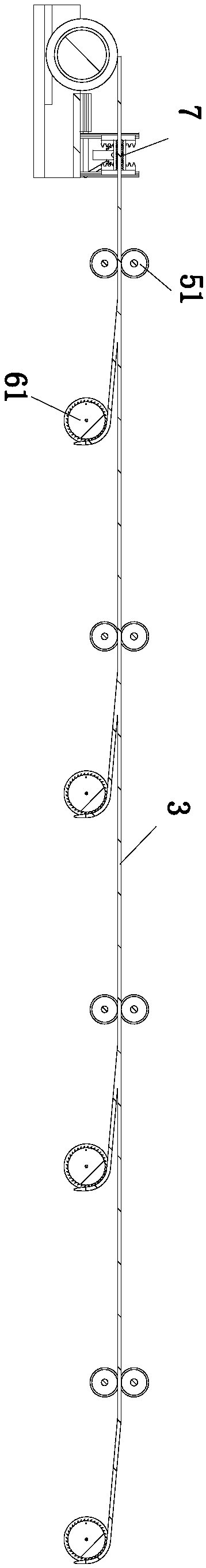

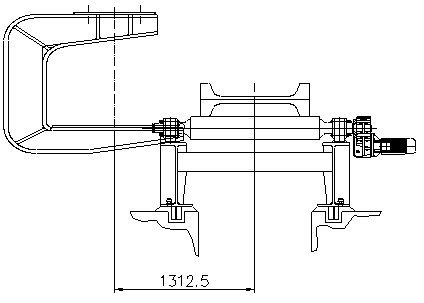

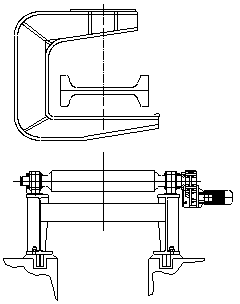

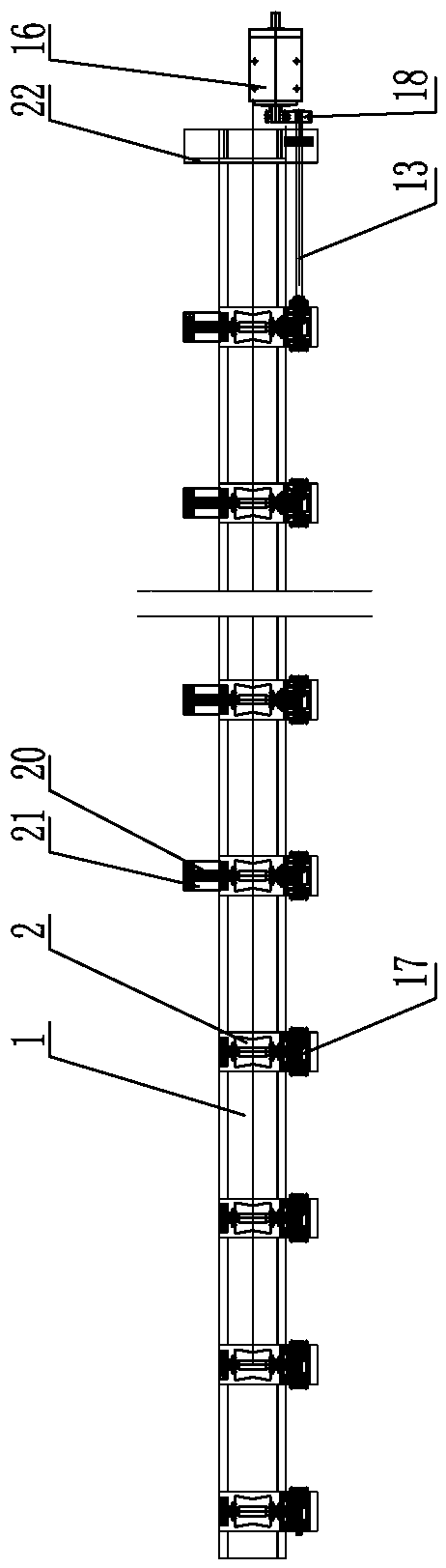

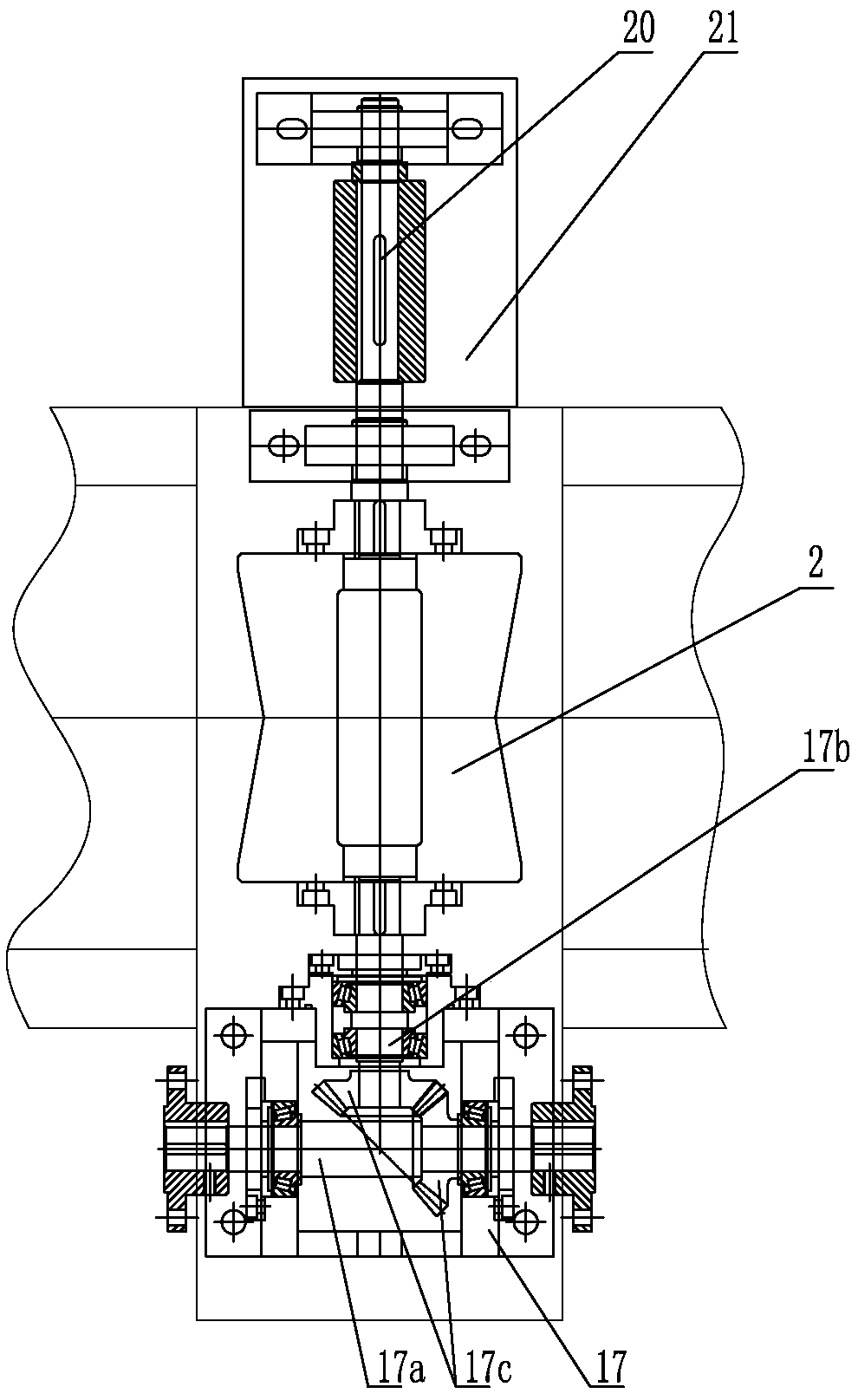

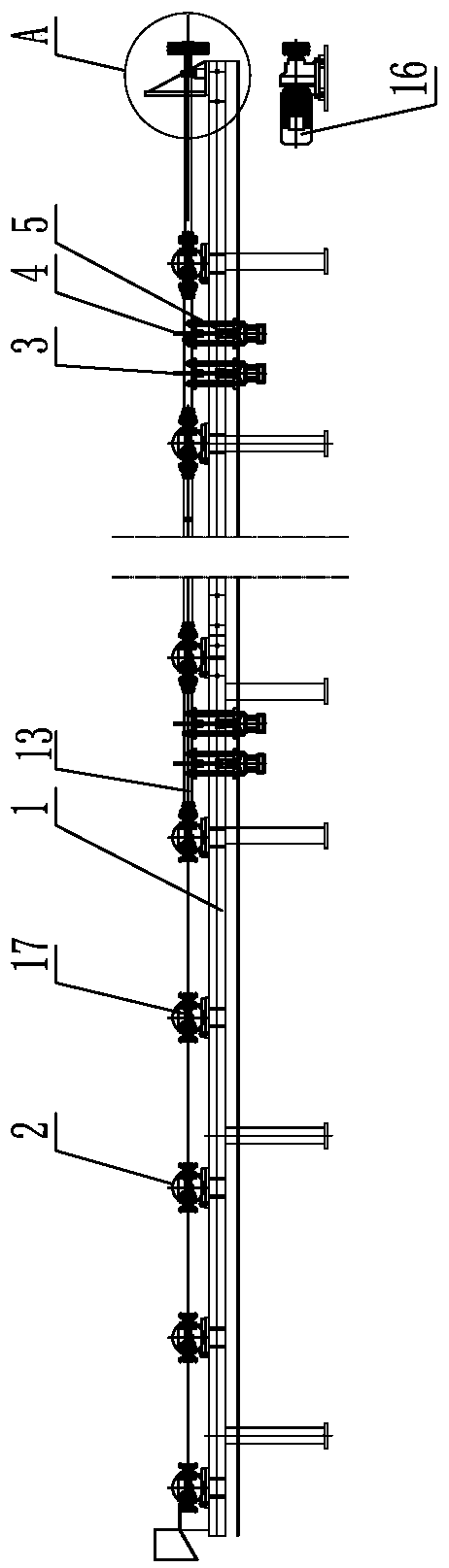

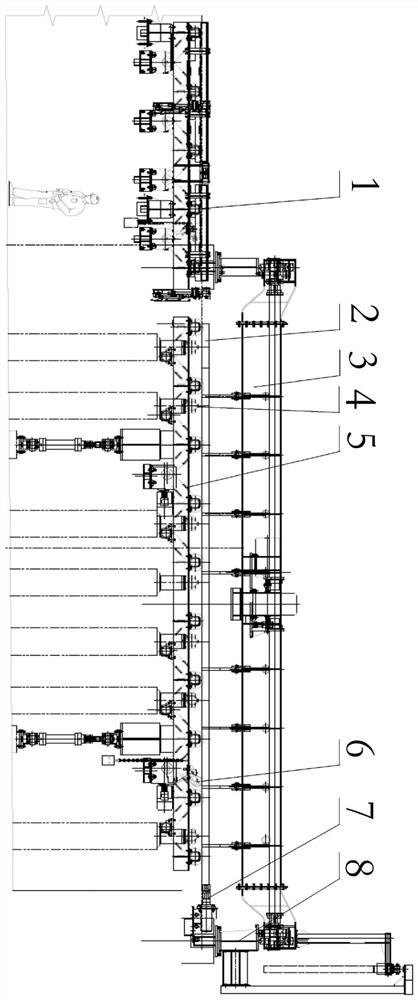

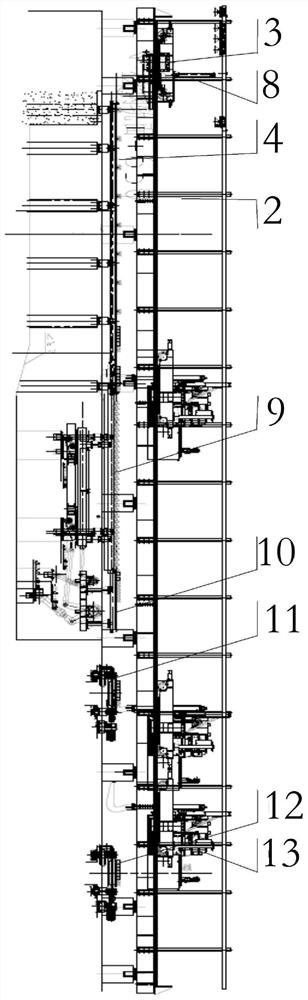

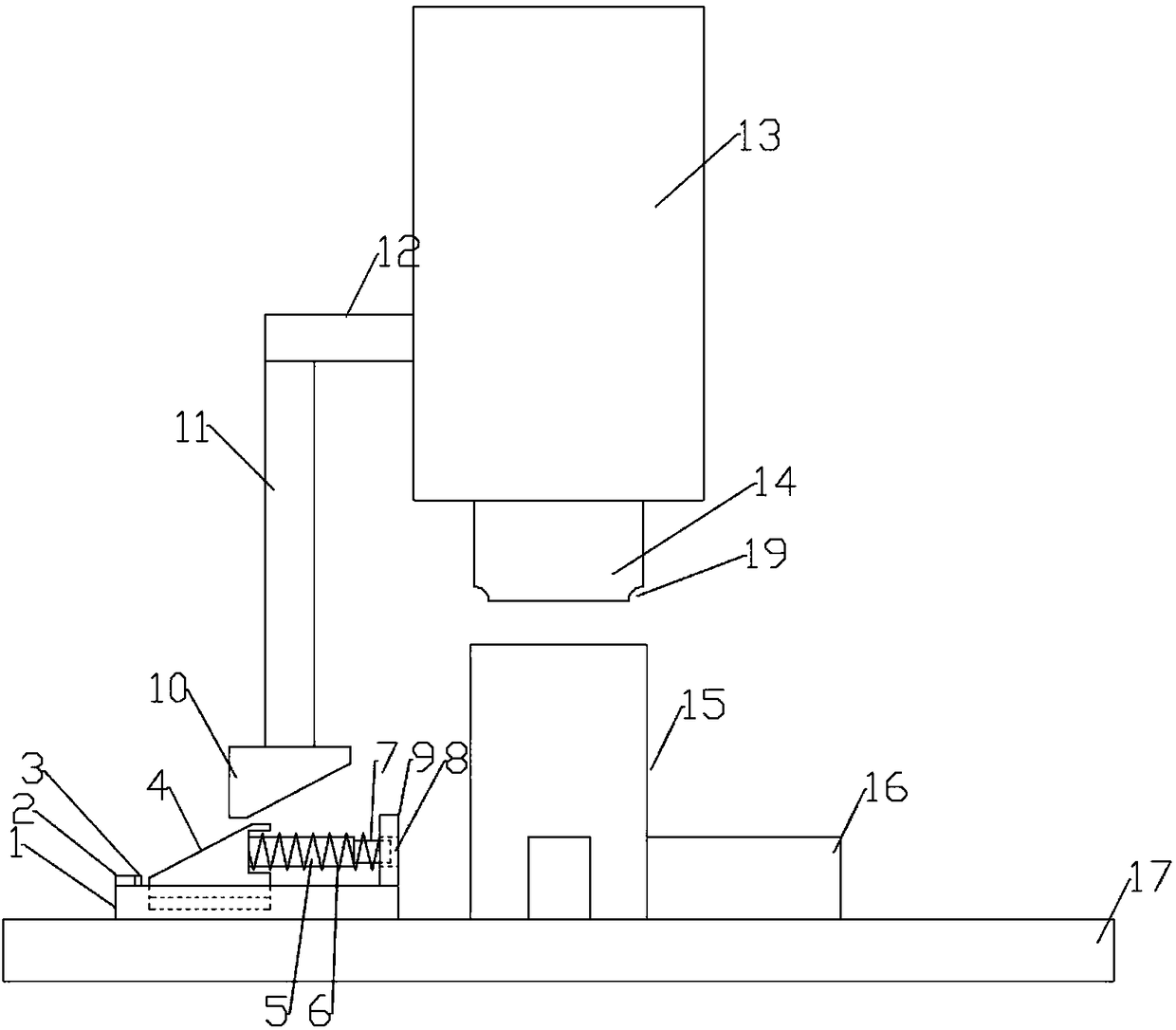

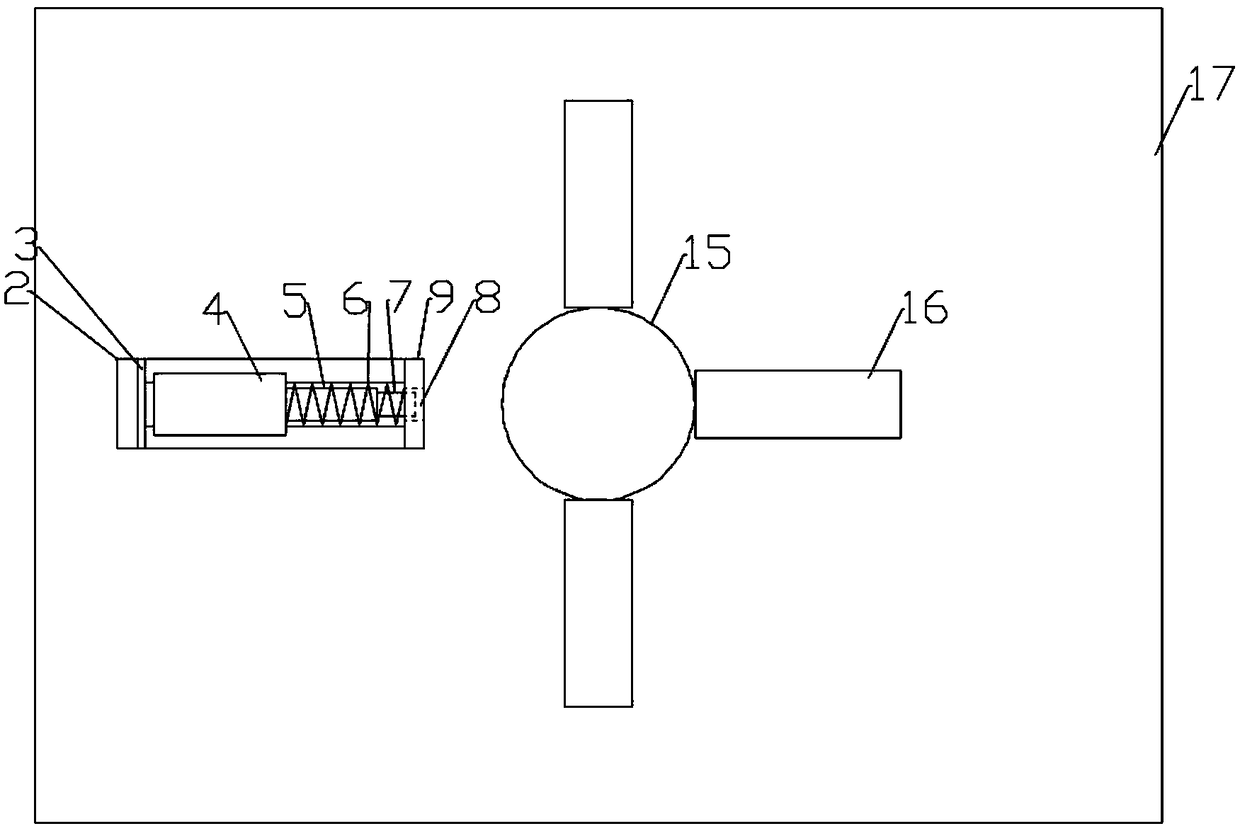

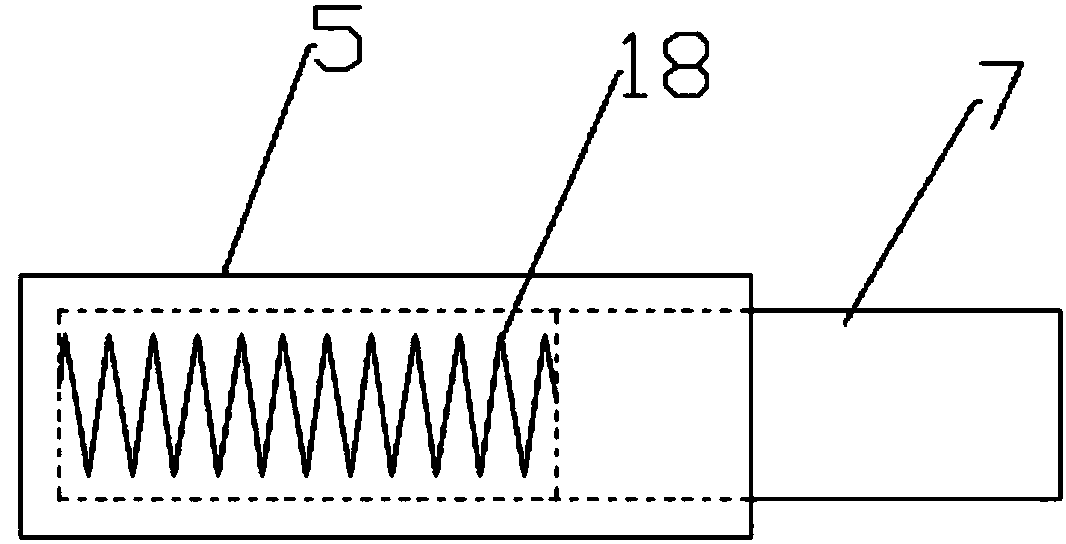

Casting blank transverse moving mechanism

The invention discloses a casting blank transverse moving mechanism, which comprises a transverse moving trolley and a drive device which are connected. The casting blank transverse moving mechanism is characterized by also comprising a sliding rail arranged between roller ways and a guide rail arranged above the sliding rail, wherein the transverse moving trolley is positioned on the guide rail and can move along the guide rail; and at least two push heads are arranged on the transverse moving trolley and a casting blank is moved from one roller way to the other roller way by the push heads in a relay way. In the invention, the transverse moving trolley with the push heads travels back and forth on the guide rail to push the casting blank on the sliding rail and the casting blank is moved from a primary roller way to a secondary roller way by a plurality of push heads in a relay way. The casting blank transverse moving mechanism has a simple and compact structure, occupies a small space, has a high speed, a short period and high efficiency, is flexible, moveable and suitable for moving the casting blanks of various thickness specifications and specified lengths, particularly ultra-short cut-length casting blanks, and can greatly improve blank production efficiency.

Owner:CISDI ENG CO LTD

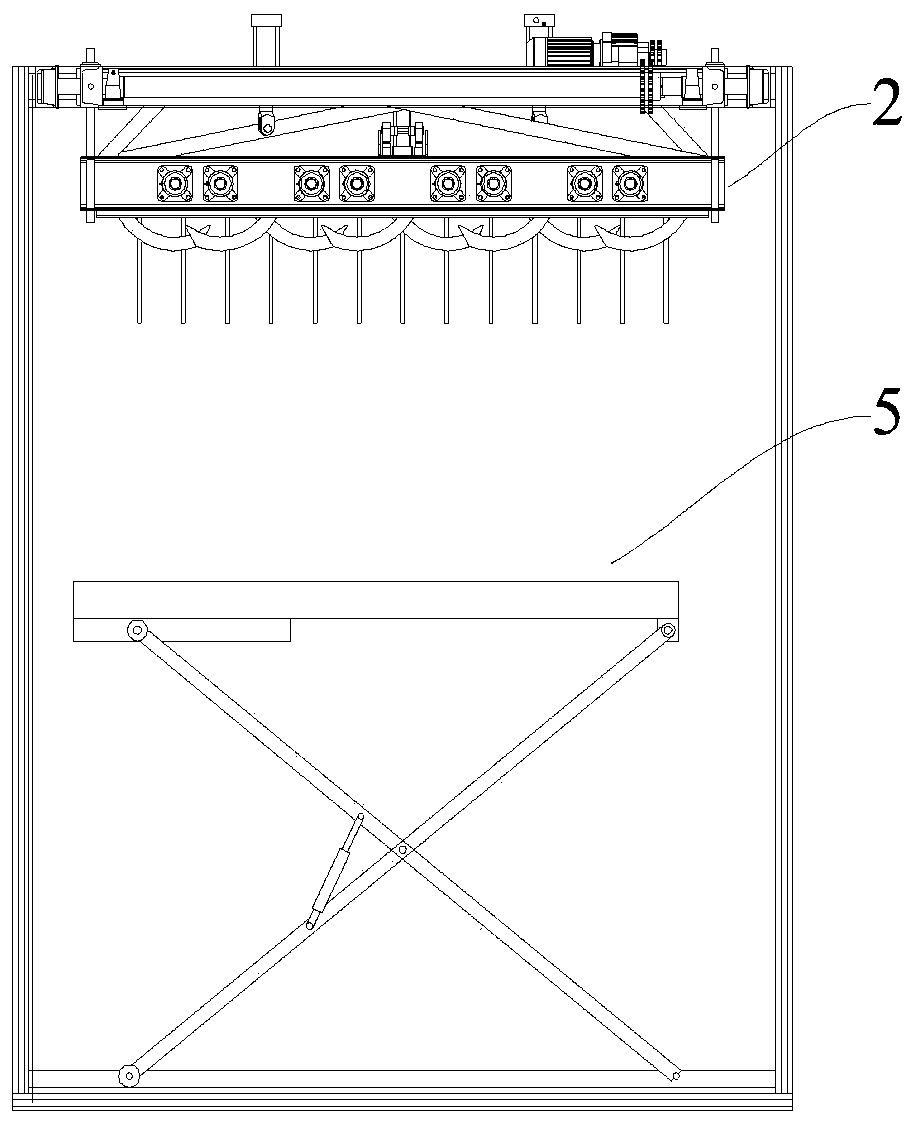

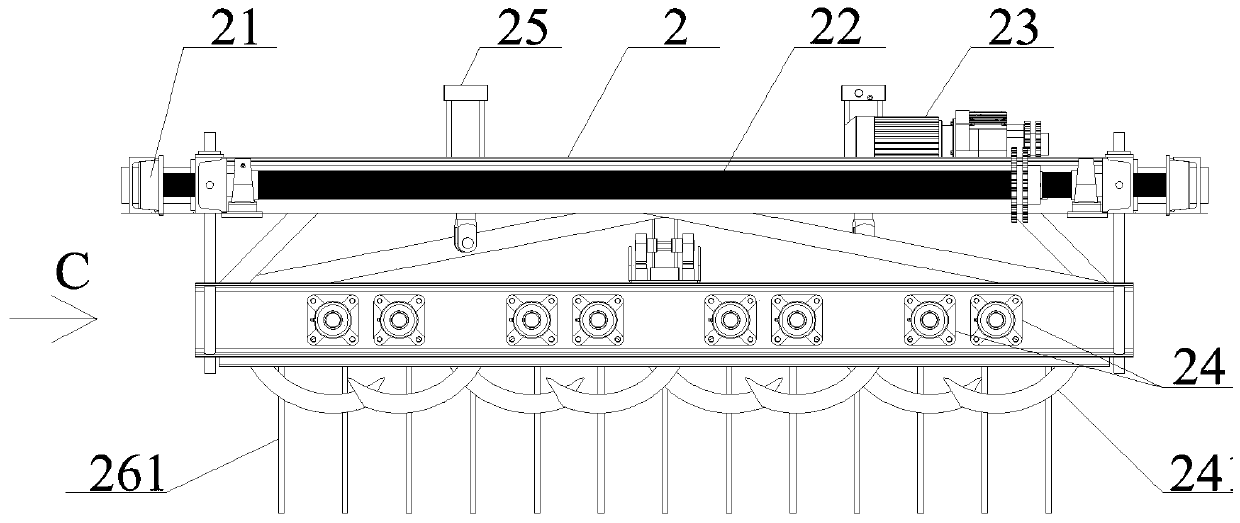

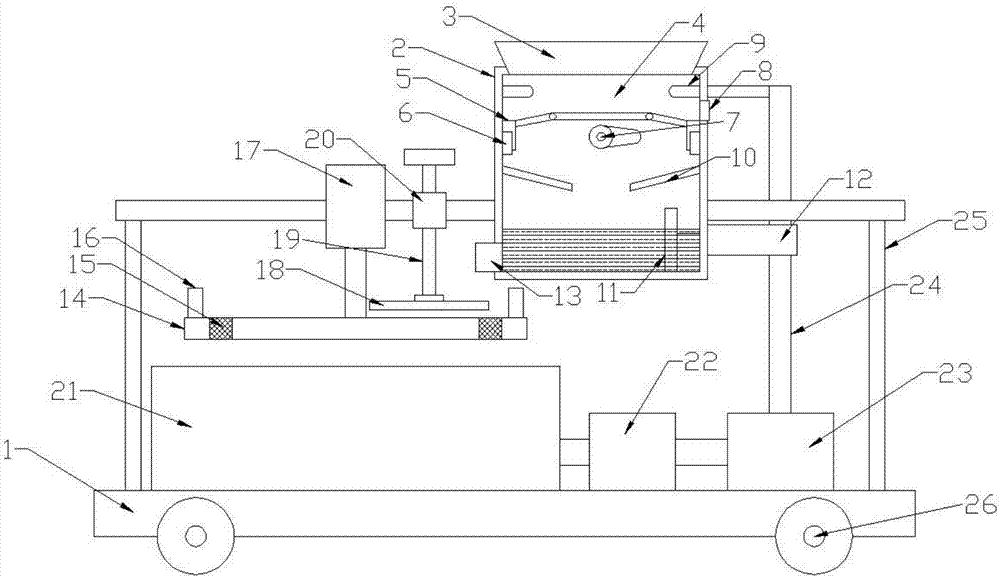

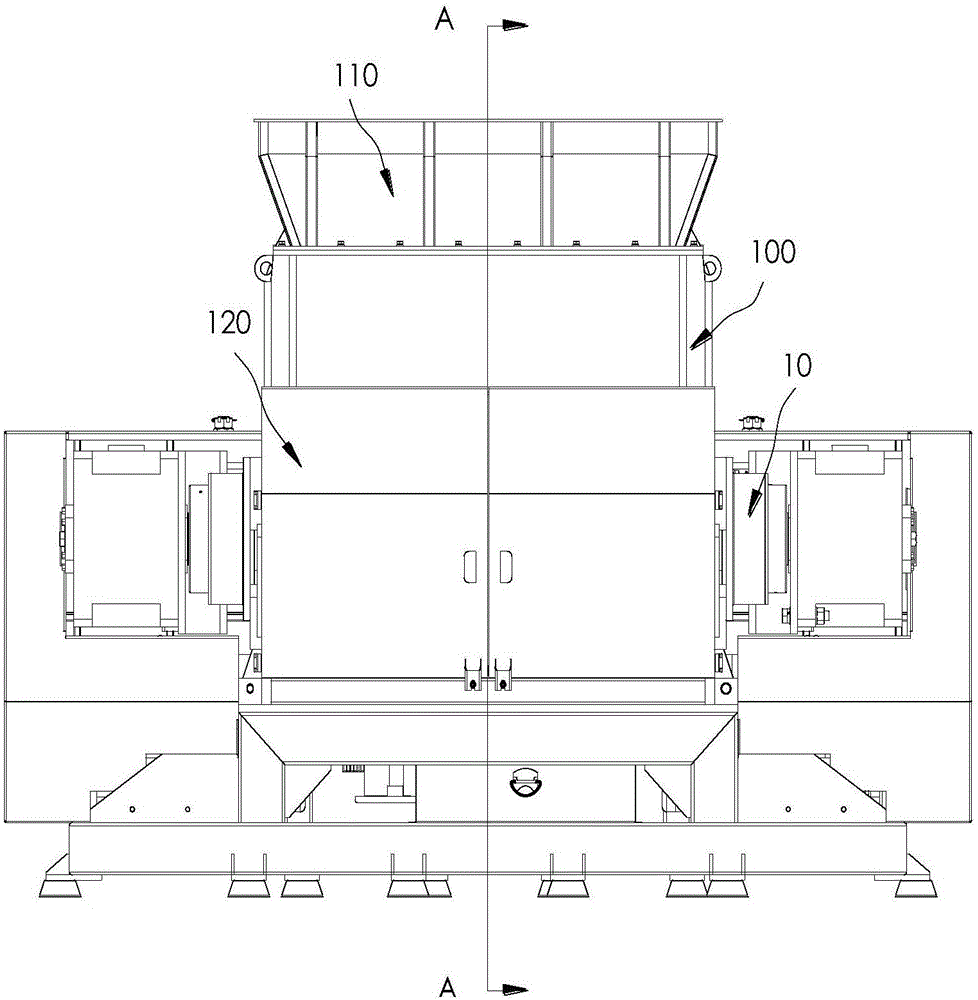

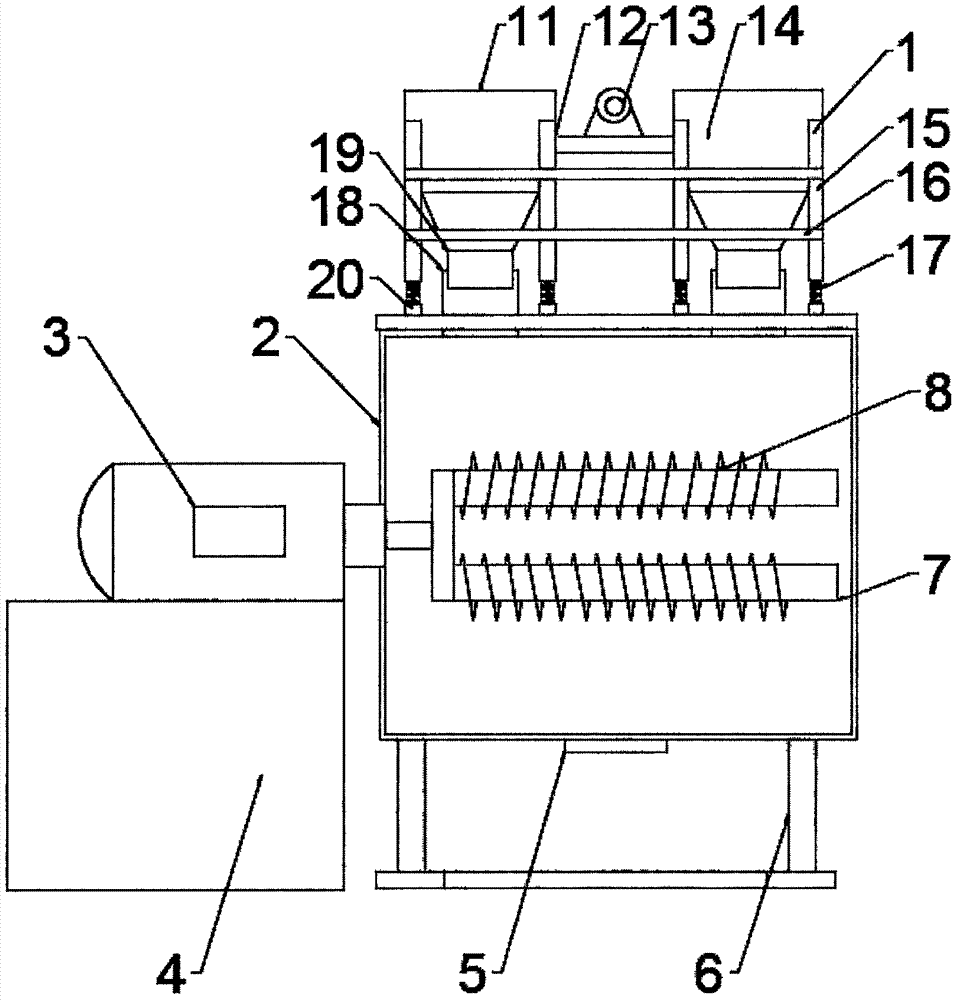

Automatic bag opening machine

The invention relates to the technical field of bag opening equipment, and provides an automatic bag opening machine. The automatic bag opening machine comprises a machine frame body, a moving frame,a lifting mechanism, a cutting knife assembly and a material receiving hopper, wherein the moving frame, the lifting mechanism, the cutting knife assembly and the material receiving hopper are arranged on the machine frame body; a bag grabbing assembly is arranged on the moving frame and comprises at least one group of rotary shaft group, each rotary shaft group comprises two bag grabbing rotary shafts with opposite rotation directions, and a plurality of grabbing hooks are symmetrically arranged on the two bag grabbing rotary shafts. According to the automatic bag opening machine, the liftingmechanism, the moving frame, the cutting knife assembly and the material receiving hopper are arranged on the machine frame body, and the bag grabbing assembly is arranged on the moving frame; afterpackaging bags are lifted, the bag grabbing assembly tightly catches the packaging bags and sends the packaging bags to the upper part of the material receiving hopper by the moving frame; and in theprocess, the cutting knife assembly continuously cuts the lower parts of the packaging bags to form a plurality of cutting openings, and materials flow into the material receiving hopper from the cutting openings. In the whole process, material lifting and material dropping are separated, and the structure of equipment is optimized. The packaging bags are cut from the bottoms in the feeding process, and the material dropping efficiency is improved.

Owner:山东伟豪思智能仓储装备有限公司

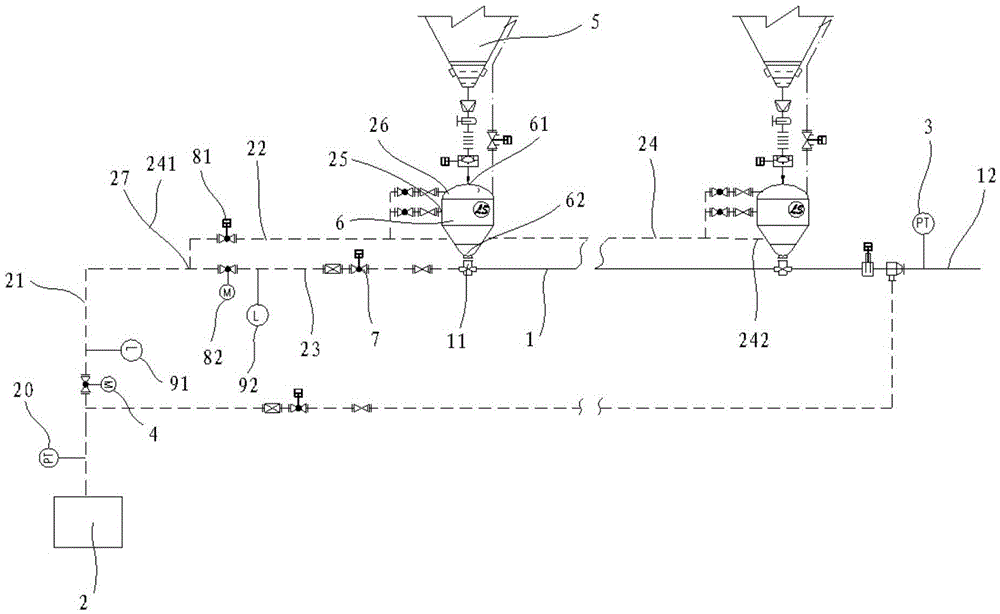

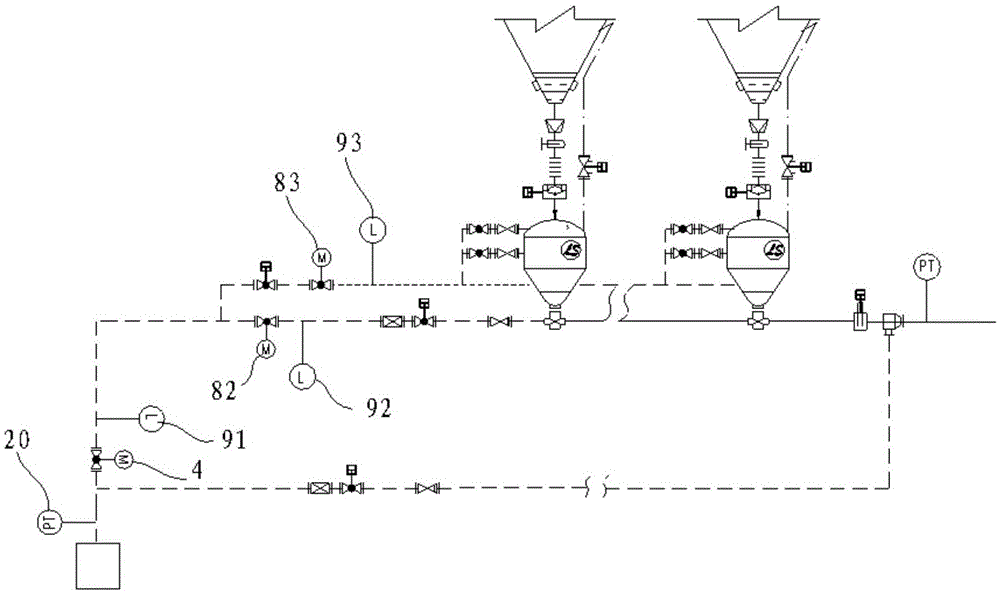

Pneumatic conveying device and auxiliary pipeline control system of pneumatic conveying device

The invention discloses a pneumatic conveying device which comprises a conveying pipeline, an air feeding device, a material way pressure detecting device, a main flow adjusting device and an intelligent control system, wherein the conveying pipeline is provided with a material falling inlet, the air feeding device is used for introducing compressed air into the conveying pipeline so that materials can fall into the conveying pipeline, the material way pressure detecting device is arranged on the portion, close to the downstream portion of a material falling inlet of the air feeding device, of the conveying pipeline, and the intelligent control system is used for controlling adjustment of the main flow adjusting device according to the material way pressure detected by the material way pressure detecting device. An auxiliary pipeline control system of the pneumatic conveying device comprises a flow detecting device, a flow adjusting device and a controller, wherein the flow detecting device is used for detecting real-time air flow of the auxiliary pipeline, the flow adjusting device is used for adjusting the air flow of the auxiliary pipeline, and the controller comprises a receiving unit, a comparing unit and a processing unit. By the adoption of the pneumatic conveying device and the auxiliary pipeline control system of the pneumatic conveying device, the pressure of a material way mixed with the materials can be directly detected, measuring results and flow adjustment are more accurate, and the utilization rate of a fluidization nozzle and a pressurization nozzle is increased.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

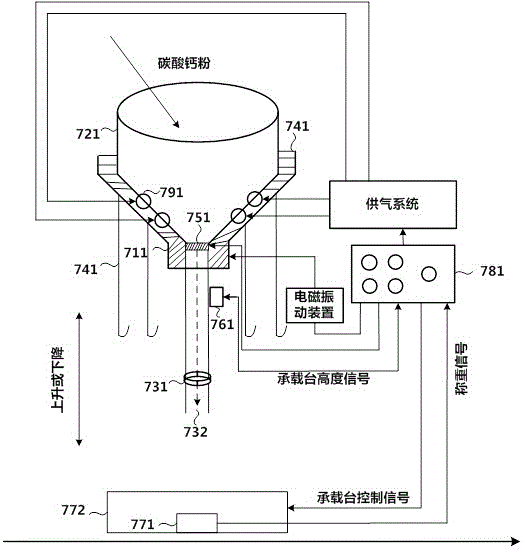

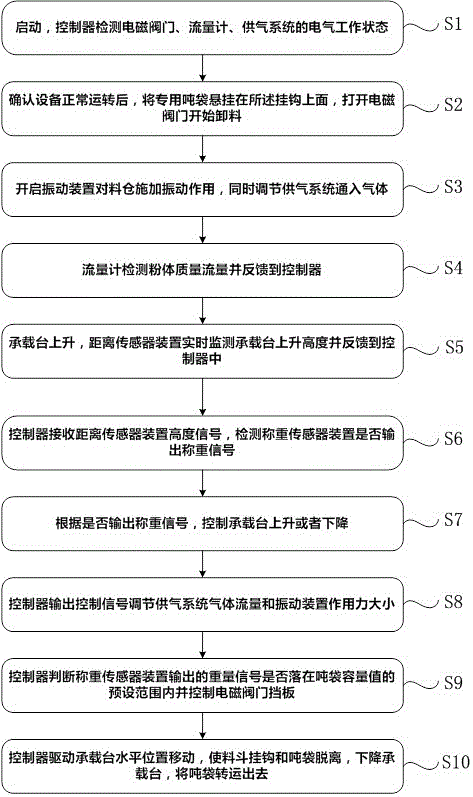

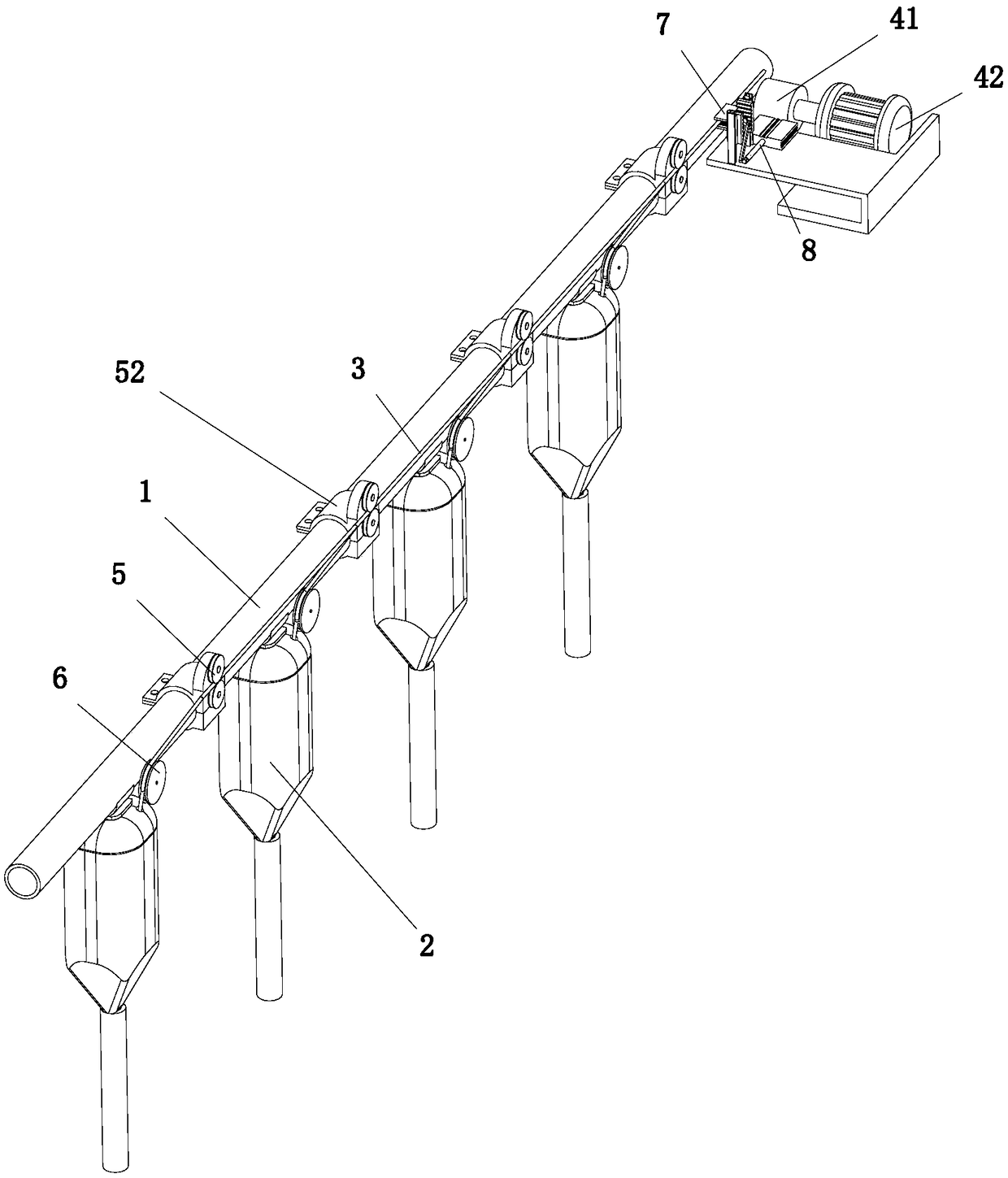

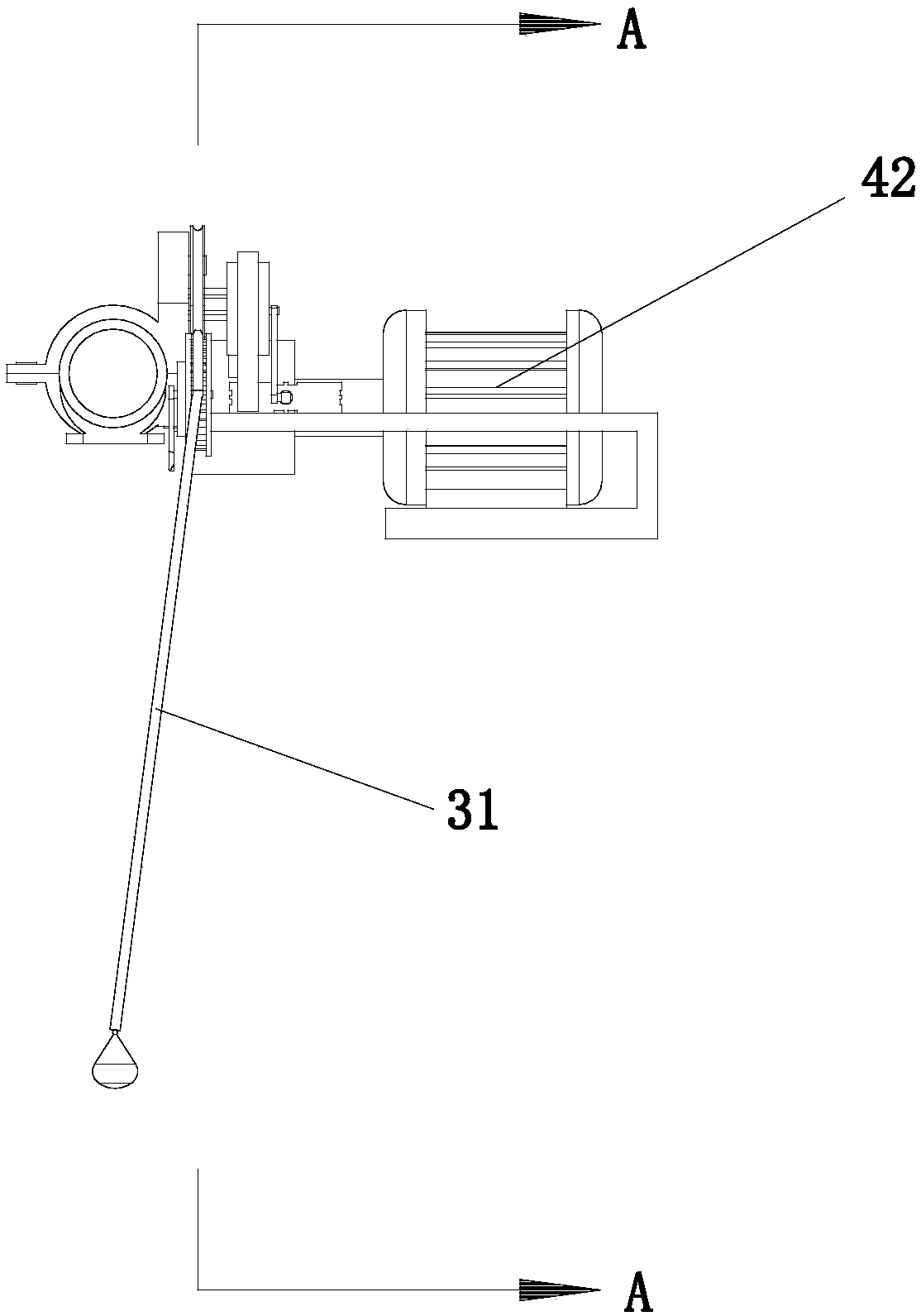

Calcium carbonate powder ton bag packaging system and packaging method

ActiveCN106742124AFast blankingSolve the problem of stagnation and slow blankingSolid materialSolenoid valveProduct gas

The invention discloses a calcium carbonate powder ton bag packaging system and packaging method. The packaging system includes a controller, a loading hopper, a vibrating device, an unloading pipeline, a solenoid valve baffle plate, a distance sensor device, a weighing sensor device, a bearing platform motion control motor, a pressure air supplying sub system and elastic members; the vibrating device is arranged on the bottom of the loading hopper; calcium carbonate powder in the loading hopper shakes under the action of the vibrating device, and is loaded to a ton bag through the unloading pipeline; air holes and a seal cover plate are arranged on the loading hopper; the pressure air supplying sub system is connected to the air holes through air pipelines, and can supply air to the loading hopper; and the seal cover plate can prevent powder in the loading hopper from flying. The method can control the electrical system by testing the weight and the flow of the calcium carbonate powder, and can achieve automatic operation of calcium carbonate powder ton bag packaging. The calcium carbonate powder ton bag packaging system is smooth in material unloading, is accurate in weighing, and is high in packaging efficiency.

Owner:SICHUAN YIXIN NEW MATERIAL CO LTD

Distribution system capable of automatically controlling discharge of dispensers

InactiveCN108849587AAvoid entanglementImprove blanking efficiencyAnimal feeding devicesAutomatic controlDistribution system

The invention relates to the technical field of agricultural product breeding, in particular to a distribution system capable of automatically controlling discharge of dispensers, which comprises a feed conveying pipeline, a plurality of dispensers, a switching device and a control device, the discharge ports of all dispensers are provided with a conical block for sealing the discharge opening, the switching device comprises a traction mechanism, a positioning mechanism and a plurality of guide mechanisms, wherein the control device comprises a controller and a manual control component, wherein the traction mechanism comprises a traction rope and a winding component, the positioning mechanism comprises a clamping assembly and a driving assembly, wherein the guide mechanism comprises a guide assembly and a reset assembly. The distribution system capable of automatically controlling discharge of dispensers achieves automatic control of the dispenser discharging, improves feed dischargingefficiency, and avoids waste of more labor costs. By means of the traction rope, feed can be simultaneously discharged by all the dispensers, so that the situation where too many ropes get intertwined can be avoided, and the amount of feed discharge can be ensured to be substantially equal.

Owner:安徽斯高德农业科技有限公司

Wet type sand screening machine for building

The invention discloses a wet sand screening machine for construction, which comprises a base, a screening box, a feeding hopper and a bracket; a screening device is arranged in the screening box, and the sand screening device includes an outer installation frame and a screen in the horizontal direction And the sloping plates located at both ends of the screen, cams are installed under the screen; several water spray pipes are installed on the side wall of the screening box above the sand screening device; a horizontal drain pan is installed below the discharge port , a sink is fixed on the base below the drain pan. The present invention sprays water on the sand through the water spray pipe provided, so that the fine sand follows the water flow through the screen, improves the passing speed of the fine sand, adheres to the screen, improves the efficiency of blanking, and can adapt to dry sand and sand Wet sand is not affected by the external environment, ensuring the use of sand, internal water recycling, and the water in the fine sand is also convenient for the subsequent use of sand.

Owner:张峰

Automatic crushing and grinding processing system for calcium carbonate preparation

ActiveCN113441254AAvoid jammingImprove processing efficiencySievingScreeningPhysical chemistryProcess engineering

The invention relates to an automatic crushing and grinding processing system for calcium carbonate preparation. The automatic crushing and grinding processing system comprises a bottom plate, a grinding pipe, crushing devices and a grinding device, the grinding pipe is installed at the upper end of the bottom plate through a supporting column, a plurality of square through holes are evenly formed in the side wall of the grinding pipe in the circumferential direction, the crushing devices are slidably connected into the square through holes, and the grinding device is installed in the middle of the grinding pipe. According to the automatic crushing and grinding processing system for calcium carbonate preparation, the following problems that when an existing system is used for crushing and grinding blocky calcium carbonate, the situation that the calcium carbonate is blocked in the system during crushing and grinding due to the fact that the size of the calcium carbonate is too large is likely to occur, then the grinding efficiency is reduced, and meanwhile, the existing system cannot be correspondingly adjusted according to the size of calcium carbonate needing to be crushed and ground, so that the flexibility of the system in the using process is reduced.

Owner:徐州紫聚石化设备有限公司

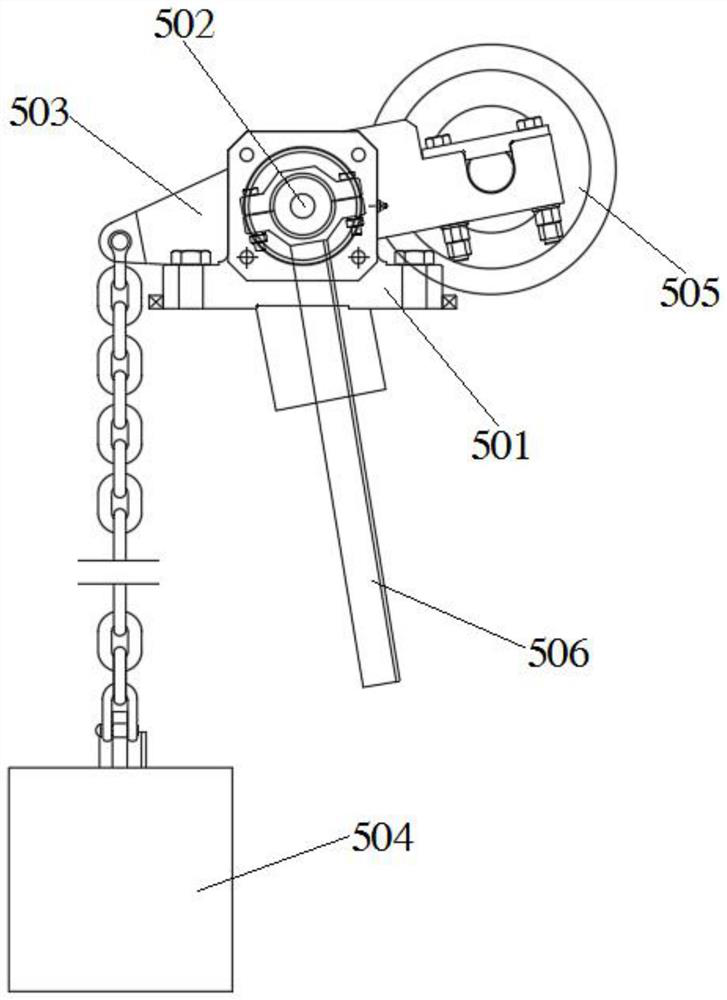

Hook head of steel hooking machine

The invention relates to a hook head of a steel hooking machine, in particular to a movable hook head capable of being rotated by 90 degrees. According to the hook head, a blank supporting board is perpendicular to a raising frame in the normal state and the blank supporting process through the action of a cylindrical spiral torsion spring; when a raising mechanism descends, the blank supporting plate can be close to the raising rack till closed; and with the adoption of the arrangement, the process that after a hook is lowered down, the steel hooking machine is required to travel a short distance and then the hook is lifted is eliminated, so that the knockout efficiency is improved.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

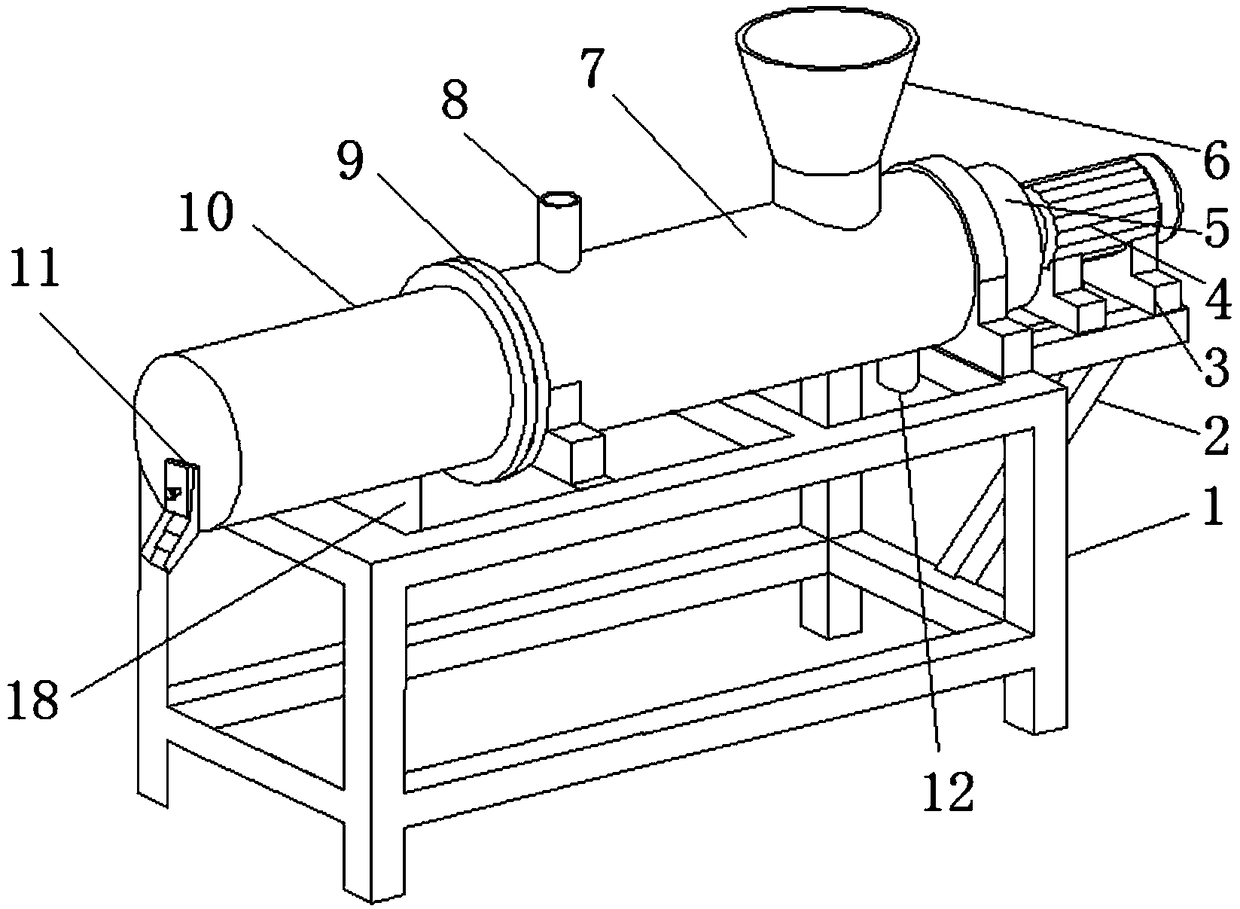

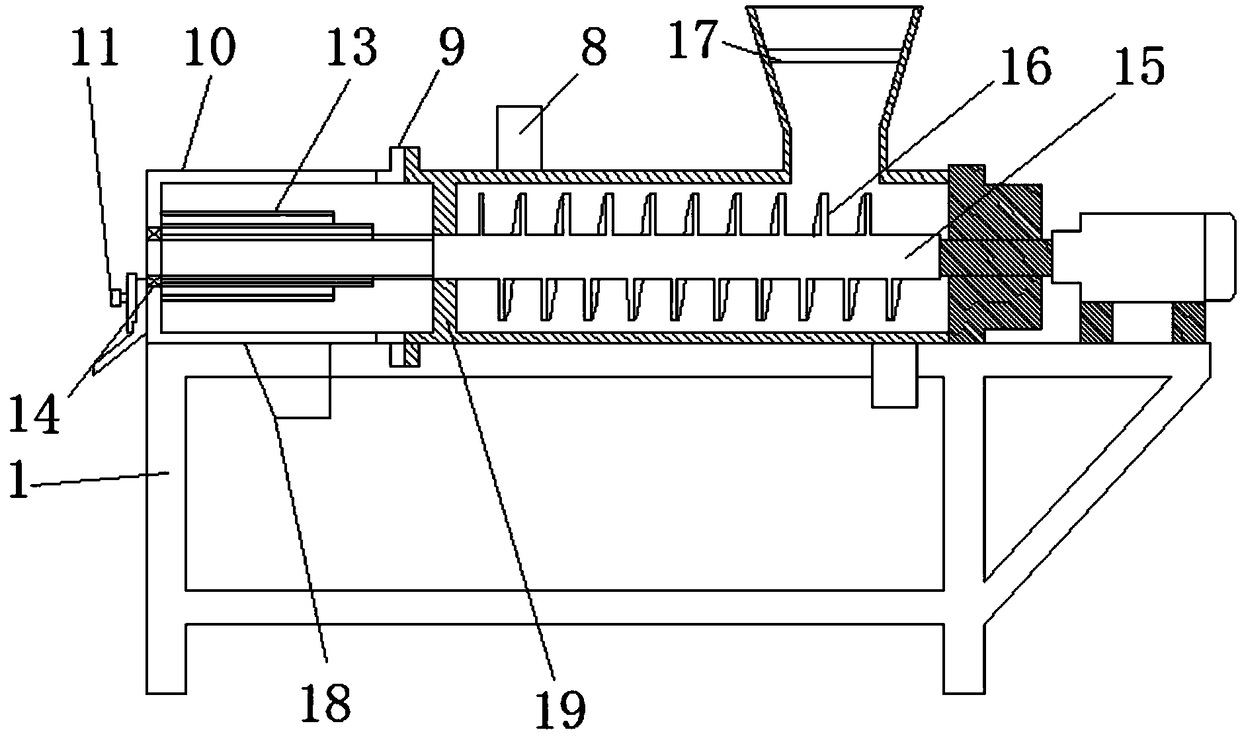

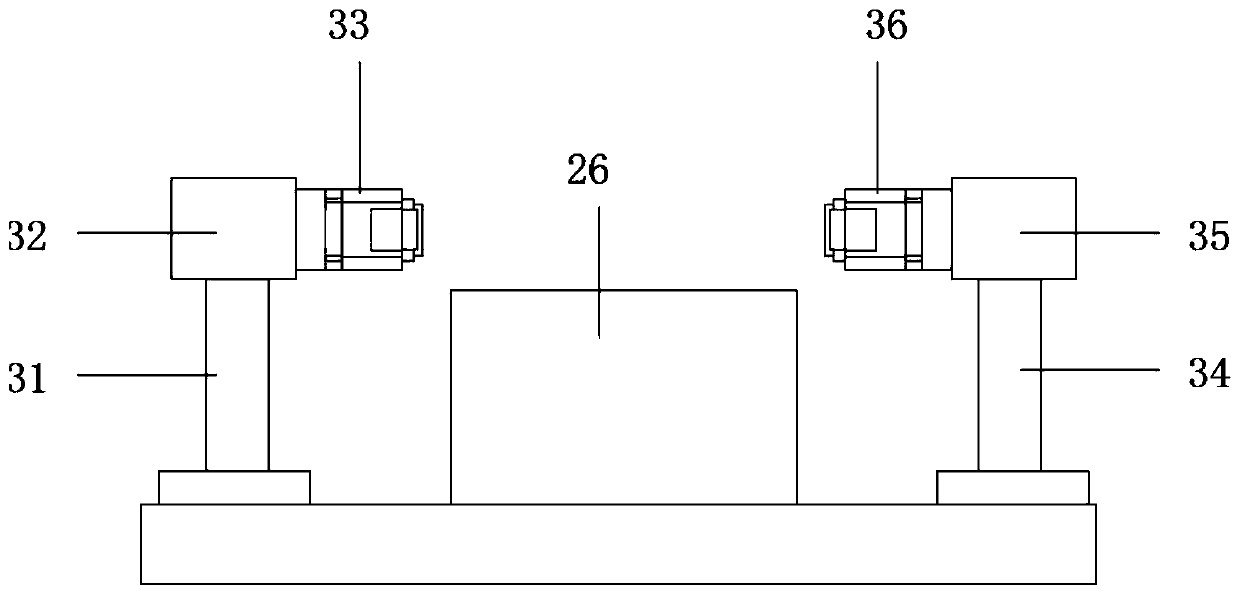

Full-automatic tea coarse filtering and extracting equipment for deep processing of tea

InactiveCN108850318AImprove blanking efficiencyRealize fully automatic coarse filtration and refiningTea extractionElectric machineryHigh pressure water

The invention discloses full-automatic tea coarse filtering and extracting equipment for deep processing of tea. The full-automatic tea coarse filtering and extracting equipment comprises a machine frame, wherein an inclined frame is fixedly welded at one end of the machine frame; two groups of support seats are symmetrically and fixedly arranged at the top part of the inclined frame; a servo motor is welded at the top part of each of the support seats; an output shaft of one end, near the machine frame, of each servo motor is in drive connection with an input shaft of the interior of a decelerator. The full-automatic tea coarse filtering and extracting equipment has the advantages that the tea is conveyed into a filter net cylinder structure by a spiral conveying device; the spiral conveying device is of a roller structure, the hot water is conveyed to a water drain pipe of a soaking tank from a water intake pipe of the soaking tank by a high-pressure water pump, the tea is fully soaked in the soaking tank, and then the full-automatic tea coarse filtering and extracting of the tea are completed; a tea residue juice recycling tank is also connected with filtering equipment, and theresidua tea juice is filtered and purified to form a final tea beverage, so that the extracting rate of tea juice is improved, and the tea is discharged out of the tea discharge device.

Owner:HUIZHOU WULING KANGTAI HEALTH TECH CO LTD

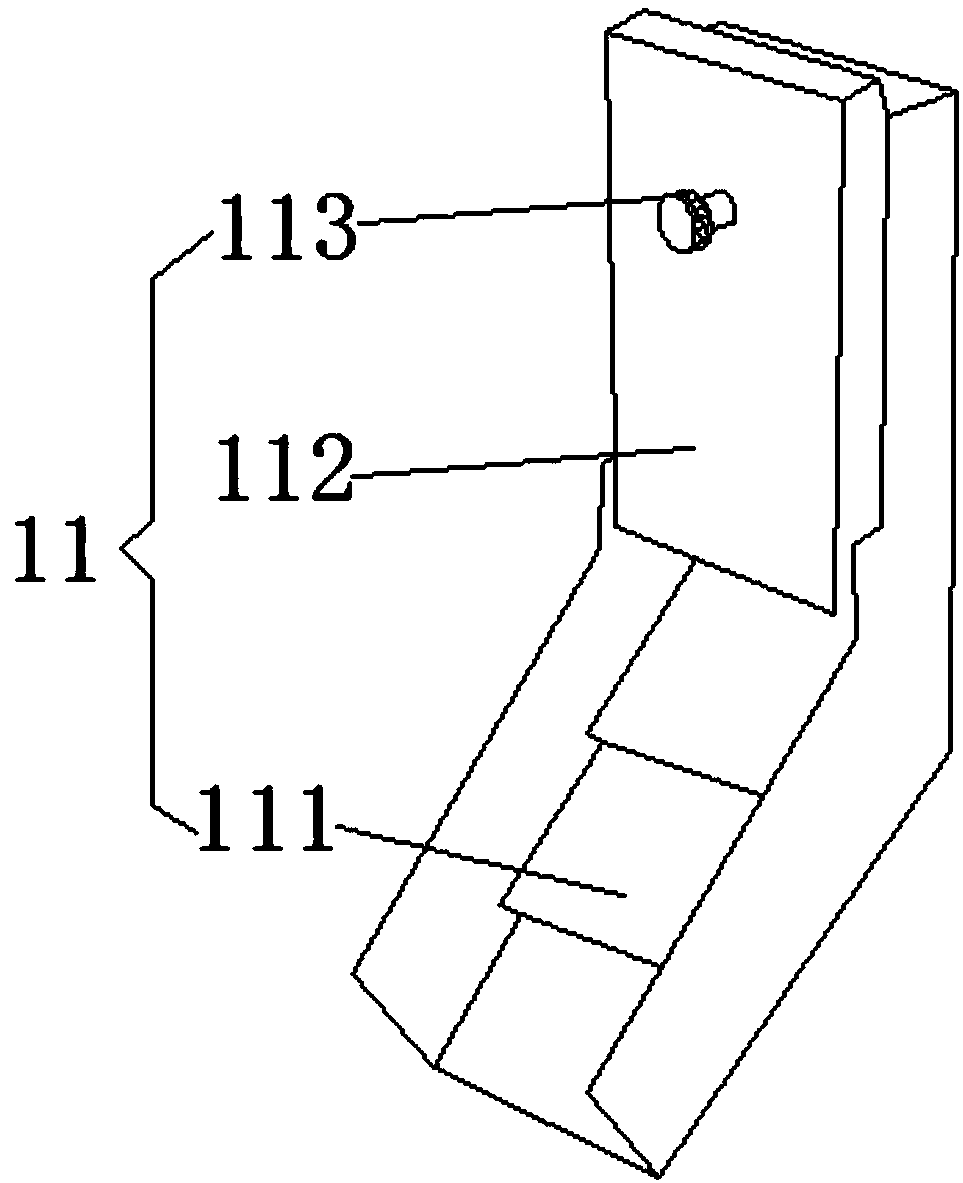

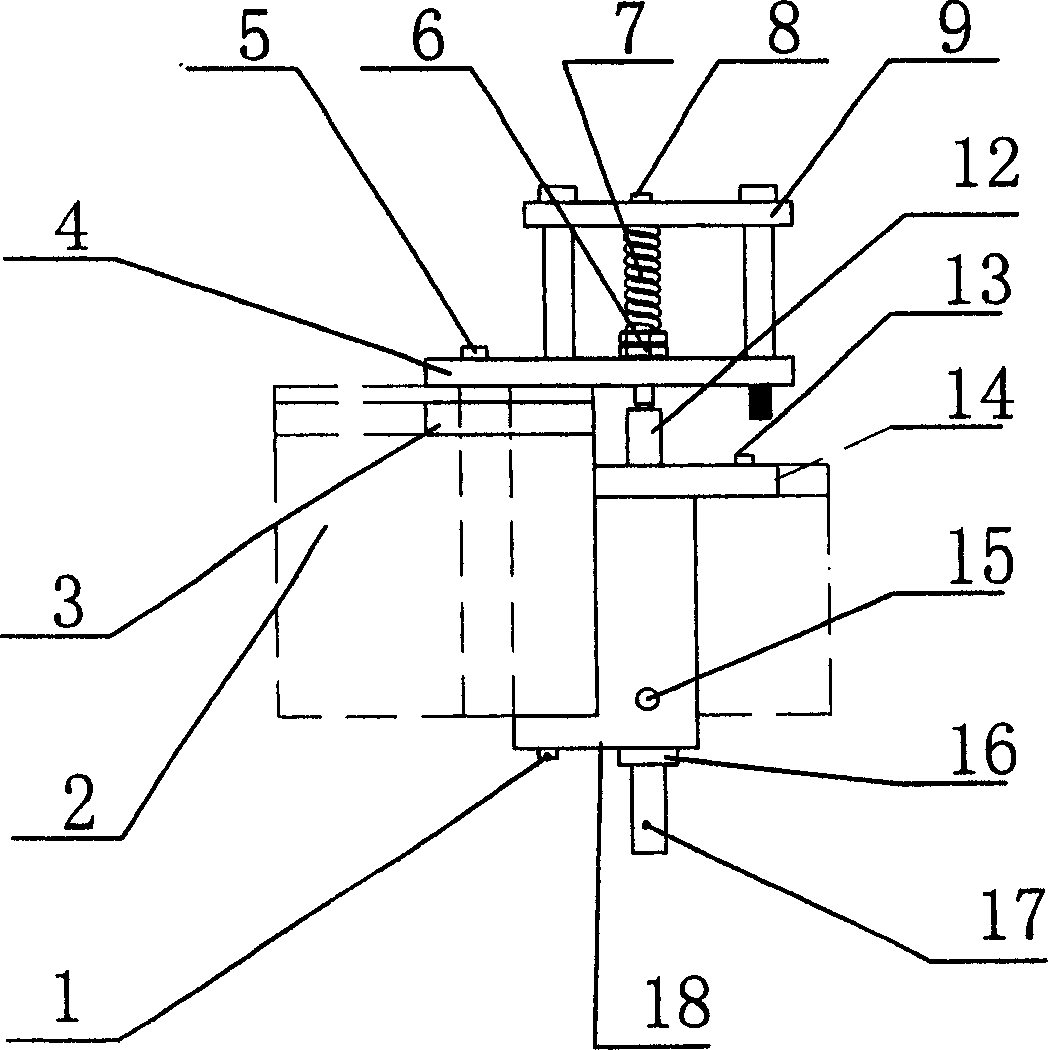

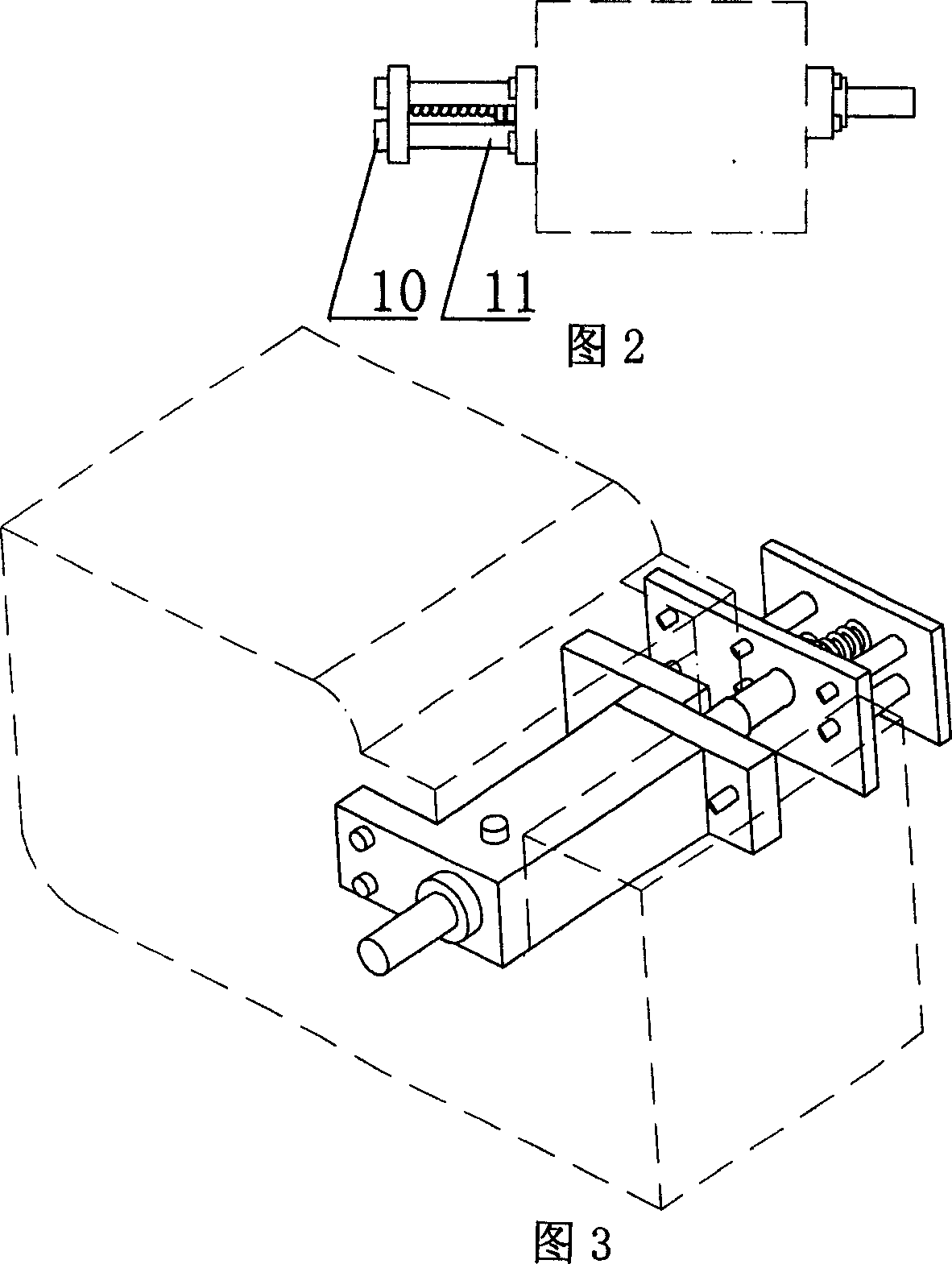

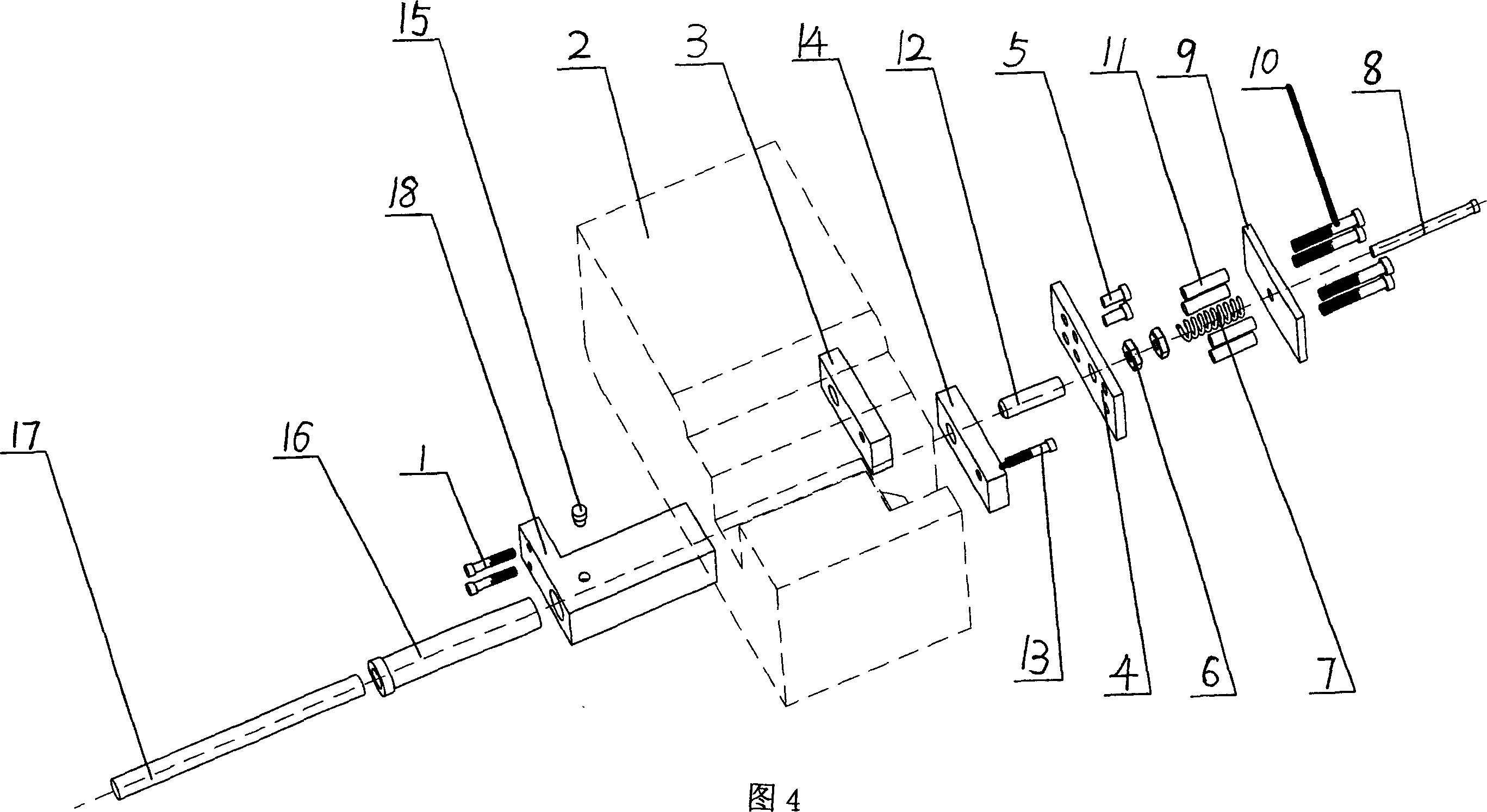

Round rod feeding device on steel bar cutter

InactiveCN1785564ANovel structureSimple structureShearing machinesShearing machine accessoriesBlade plateEngineering

A circular rod blanking unit of reinforcing bar cutting-off machine is composed of machine base, movable plate cutter, fixed plate cutter, length fixating mechanism, guide seat on machine base, and guide sleeve matched with a circular hole in said guide seat. Its advantages are high cutting-off quality and high blanking efficiency.

Owner:SHANGHAI UNIV OF ENG SCI

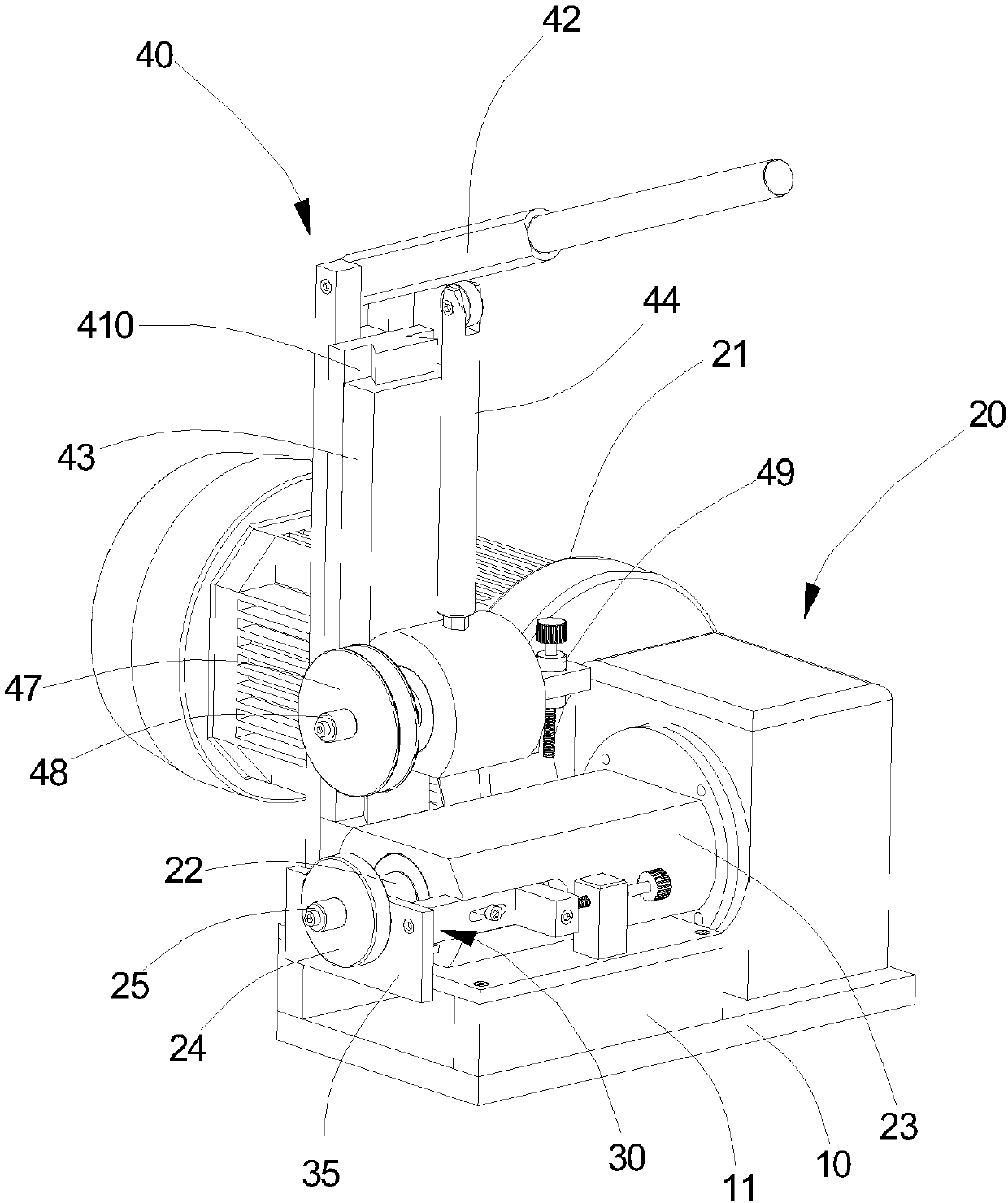

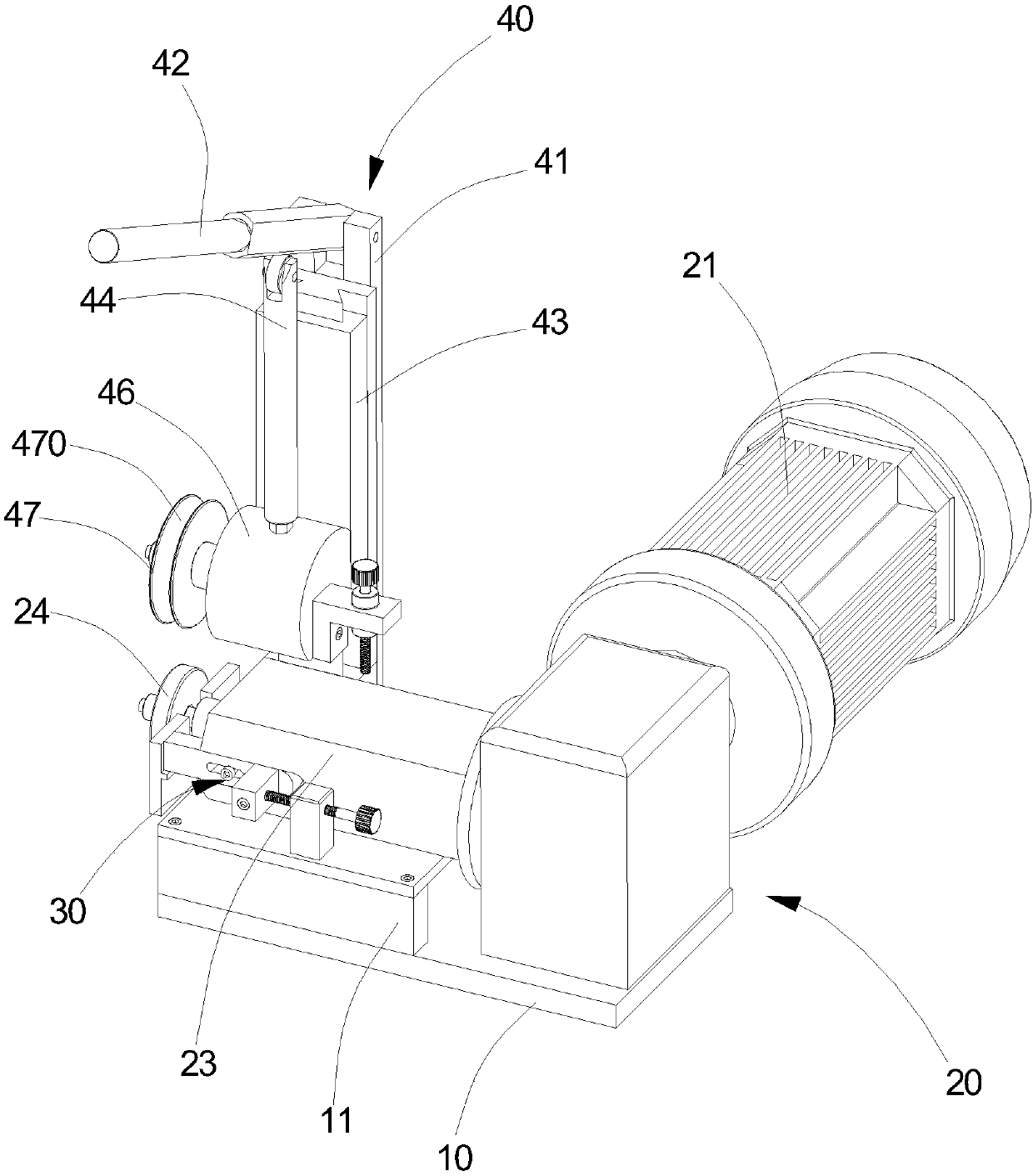

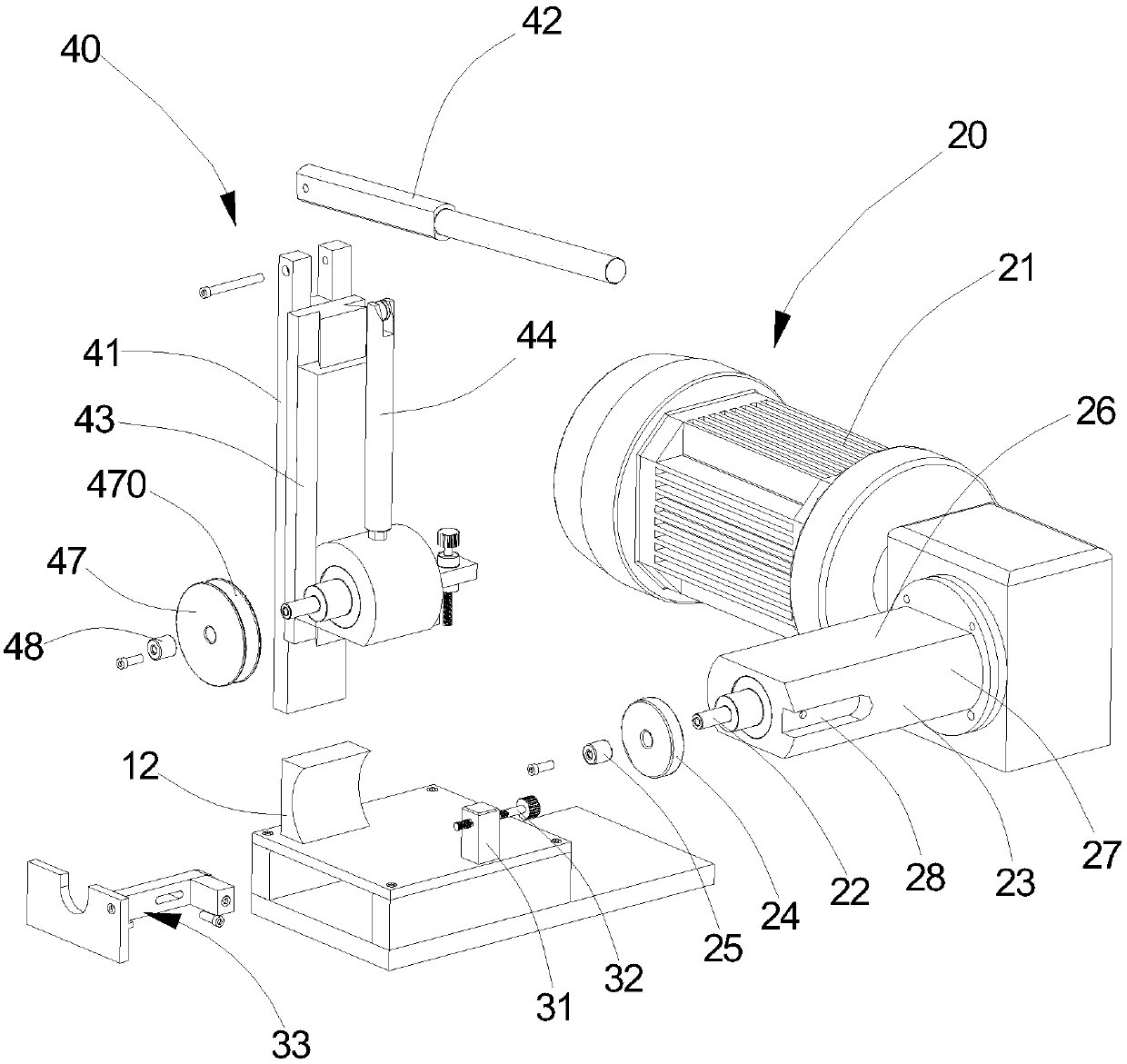

Bracelet edge pressing machine

InactiveCN107716810ARealize the function of pressing edgeReduce wearWristbandsEngineeringMechanical engineering

The invention relates to a bracelet edge pressing machine. The bracelet edge pressing machine comprises a base, a driving device, an adjustment assembly and a locating device, wherein the driving device is mounted on the base, and the locating device is mounted on the base. The driving device comprises a motor, a rotating shaft and a tubular body, wherein the rotating shaft is connected with the motor, and the tubular body is arranged on the rotating shaft in a sleeving manner. The rotating shaft is provided with a bracelet chuck in a sleeved manner. The bracelet chuck is arranged to be in a disc shape. The adjustment assembly is located at one side of the tubular body. One end of the adjustment assembly is located at the inner side of the bracelet chuck. The locating device comprises a guiding plate, a sliding component and a locating shaft, wherein the sliding component is arranged on the guiding plate in a sliding manner, and the locating shaft is mounted on the sliding component. The guiding plate is located at one side of the tubular body. The locating shaft is provided with a edge pressing tool in a sleeved manner. The edge pressing tool corresponds to the bracelet chuck. Anannular groove is formed in the circumferential wall of the edge pressing tool. The bracelet edge pressing machine is simple in structure, convenient to operate and high in edge pressing efficiency; edgings obtained by bending bracelets are high in elegance degree, and the appearance is guaranteed; in addition, wear of the bracelets can be reduced; and quality of the bracelets can be improved conveniently.

Owner:DONGGUAN JINLONG JEWELRY CO LTD

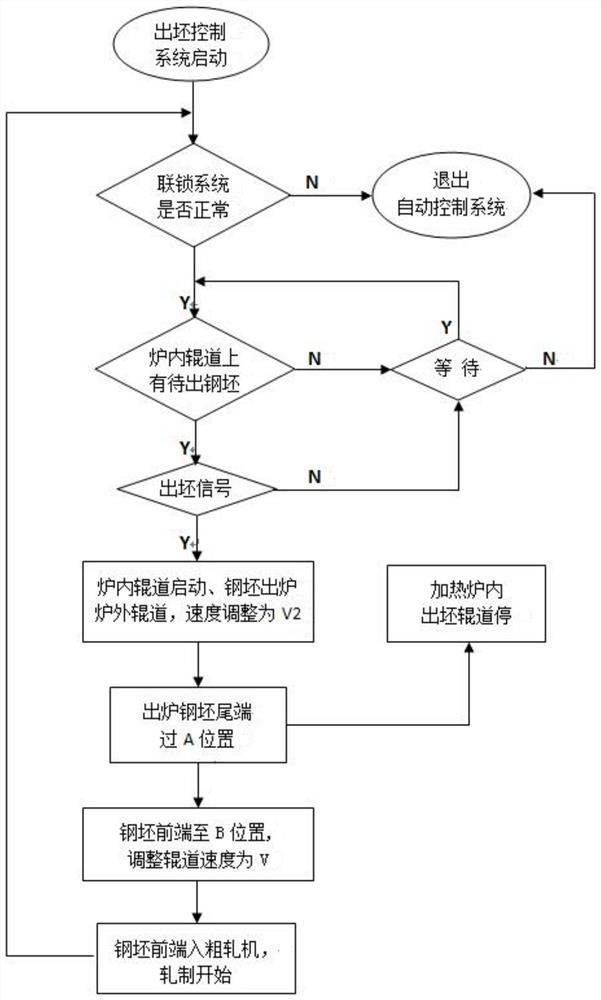

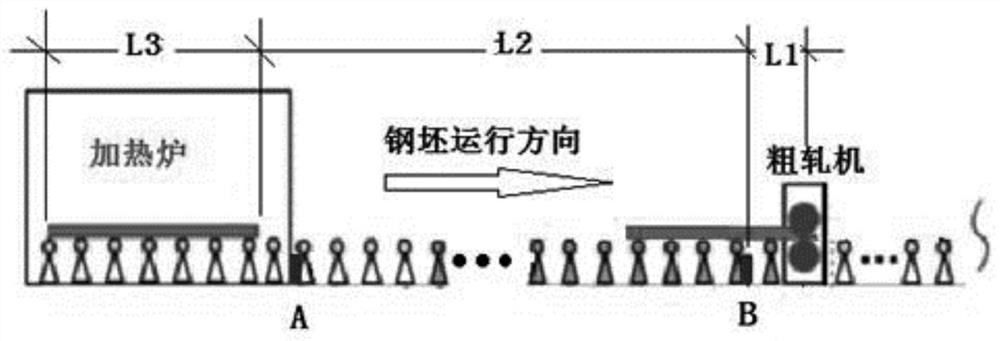

Control method for improving ejection efficiency of heating furnace

ActiveCN112934976AImprove blanking efficiencyRealize automatic controlRoll mill control devicesMetal rolling arrangementsAutomatic controlControl system

The invention relates to the technical field of steel rolling, in particular to a control method for improving the ejection efficiency of a heating furnace. After the rolling condition is met, a post person gives an instruction; a control system performs automatic control that step 1, a billet discharge roller way in the heating furnace starts to operate, a steel billet is conveyed out of the furnace, and the running speed of the steel billet is V2; step 2, when a tail end of the discharged steel billet passes through a point A, the roller way in the furnace stops running; step 3, when a front end of the steel billet runs to a point B, the running speed of the steel billet is adjusted to be V; step 4, when the front end of the steel billet enters into a roughing mill to start rolling, the roller way in the heating furnace is started to run, the steel billet is conveyed out of the furnace, and the steel billet running speed is V2; and after the steel billet is discharged, the first to fourth steps are repeated for steel billet conveying and rolling control. According to the control method, automatic control of billet discharging can be realized, steel piling accidents can be prevented, billet discharging efficiency and rolled steel yield are improved, and labor intensity of post personnel is reduced.

Owner:YANCHENG LIANXIN IRON & STEEL CO LTD

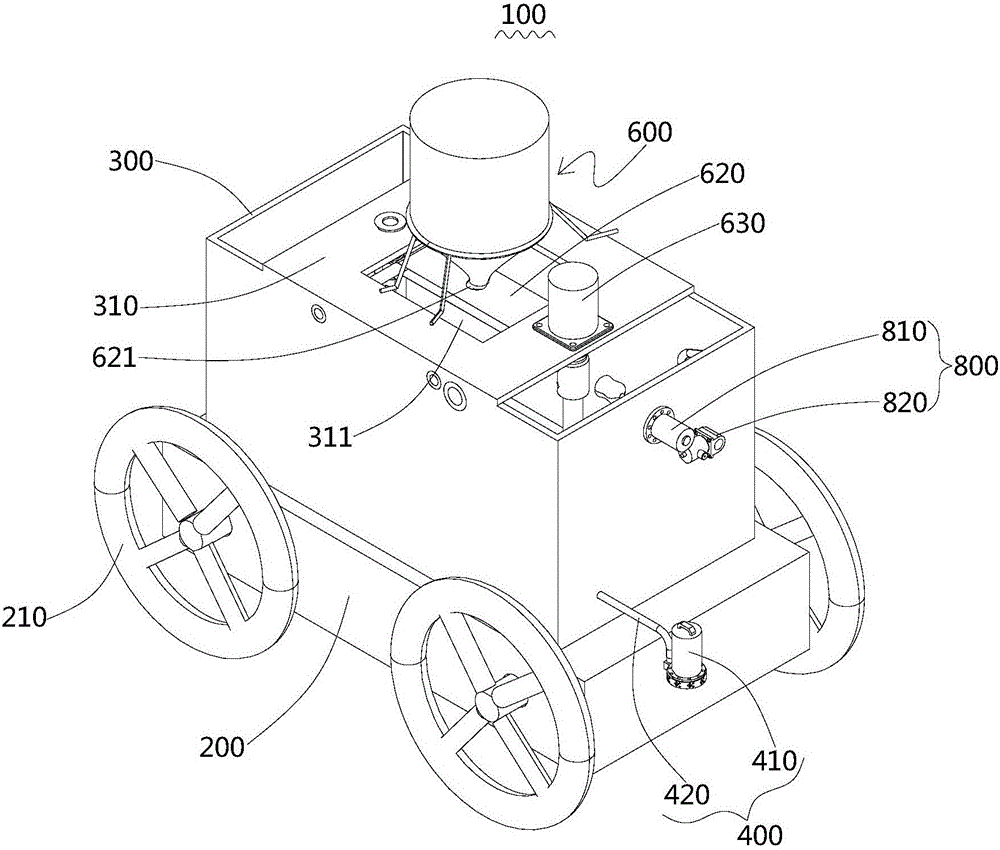

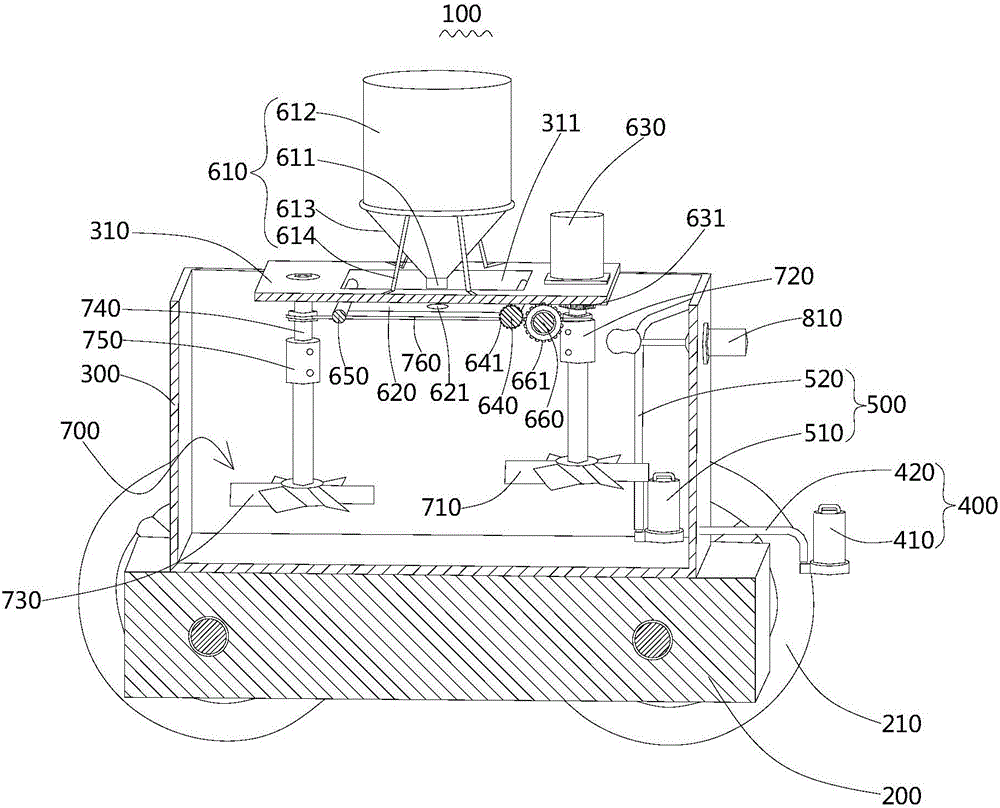

Intelligent nereis breeding and feeding system

InactiveCN106069960AImprove work efficiencyRealize automatic feedingPisciculture and aquariaEngineeringAutomation

The invention provides an intelligent nereis breeding and feeding system which comprises a vehicle, a box, a water incoming device, a discharging device, a blanking device and a stirring device. The box is mounted on the vehicle, multiple traveling wheels are arranged on the vehicle, the blanking device is mounted at the top of the box, the water incoming device is arranged on the box, the stirring device is arranged in the box, and the discharging device is arranged in the box. The blanking device comprises a blanking box, a blanking port is arranged at the bottom of the blanking box, a conveying belt and a motor are arranged at the top of the box and are in transmission connection, an opening is formed in the conveying belt, and the discharging port selectively faces the opening directly. The intelligent nereis breeding and feeding system is simple in structure, high in practicability, capable of improving feeding efficiency and high in automation level, thereby reducing manpower resources.

Owner:YANCHENG INST OF TECH

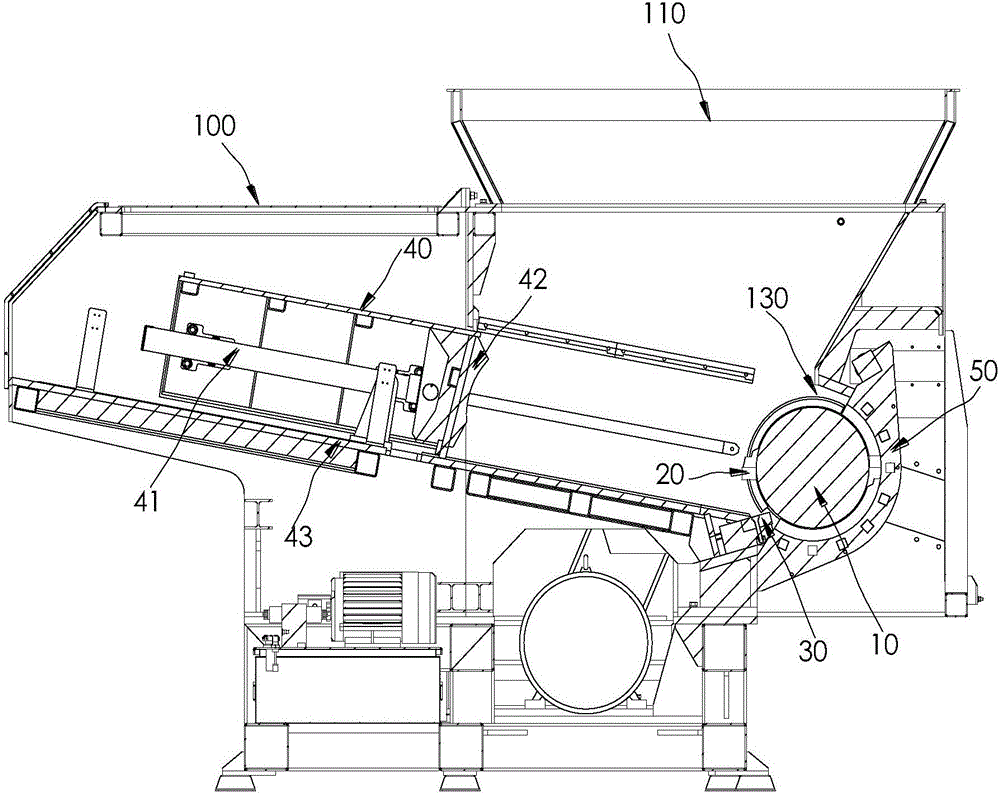

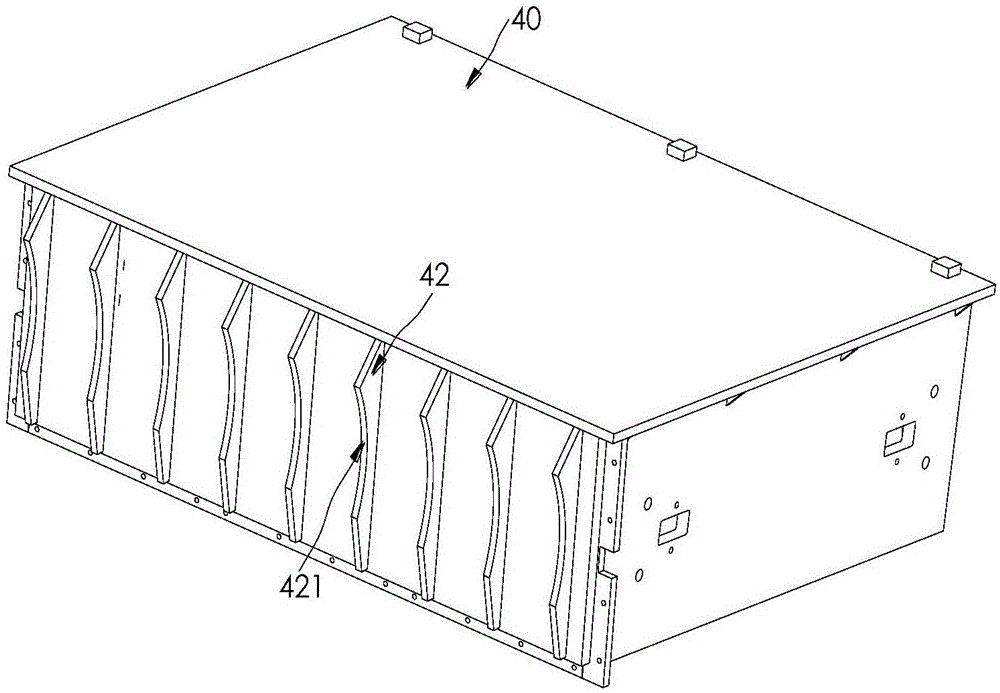

Single-shaft shredder

InactiveCN106824435AImprove crushing efficiencyReduce gapGrain treatmentsEngineeringMechanical engineering

The invention discloses a single-shaft shredder which comprises a box body, a tool assembly and a material pushing mechanism. A crushing cavity is formed in one end of the box body. The tool assembly comprises a fixed tool, a plurality of movable tools and a tool shaft, and the tool shaft is pivoted to the interior of the crushing cavity. The multiple movable tools are installed on the outer surface of the tool shaft. The fixed tool is fixedly arranged on one side of the crushing cavity. The fixed tool and the outer surface of the tool shaft are arranged in a spaced mode, and a cutting gap is formed. The material pushing mechanism comprises a material pushing box and a first driving device, and the first driving device is used for driving the material pushing box to move towards the crushing cavity. The end, close to the crushing cavity, of the material pushing box is fixedly provided with a plurality of material pushing strips, and the end faces, close to the crushing cavity, of the material pushing strips are provided with arc-shaped grooves matched with the outer circumference of the tool shaft. By the adoption of the single-shaft shredder, the blanking efficiency is improved, and the crushing efficiency of materials is improved.

Owner:GENOX RECYCLING TECH

Edge pressing device used when pasting tape on side of glass

PendingCN109185296AEasy to operateHigh control precisionMaterial gluingEngineeringMechanical engineering

The invention discloses an edge pressing device used when pasting a tape on a side of a glass, comprising a working table, a rotary frame, a glass clamp, a roller pressing assembly and a locating frame; the roller pressing assembly comprises an installation base as well as an extrusion roller and a first elastic piece which are installed on the installation base; the rotary frame or the roller pressing assembly is slidingly installed on the working table along a Y-shaft direction and moved to an edge pressing position and a rotary position along the Y-shaft direction; the rotary frame or the roller pressing assembly is slidingly installed on the working table along a X-shaft direction and moved to an initial position and a terminal position along the X-shaft direction; the locating frame comprises a locating corner frame corresponding to a glass corner, and one side of the locating corner frame corresponds to the edge pressing position and lifts to a place as high as the glass along anupright direction; in the initial position and the terminal position, the extrusion roller is respectively located at the two relative sides of the glass clamp along the X shaft; and in the edge pressing position, the roller pressing assembly closes to the glass clamp so that the extrusion roller can extrude the side of the glass under the effect of an first elastic piece. The edge pressing device provided by the invention has convenient operation, high edge pressing efficiency and uniform edge pressing force.

Owner:DONGGUAN WORLD PRECISION MACHINERY

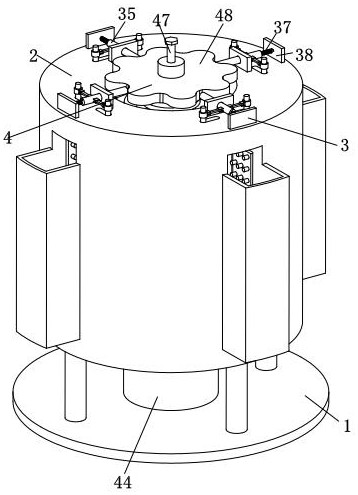

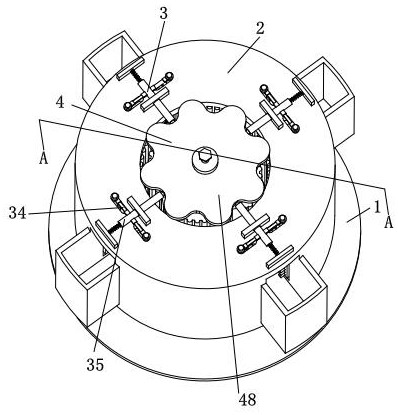

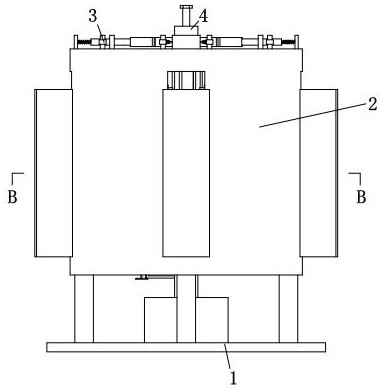

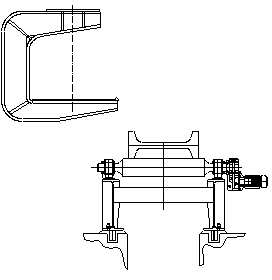

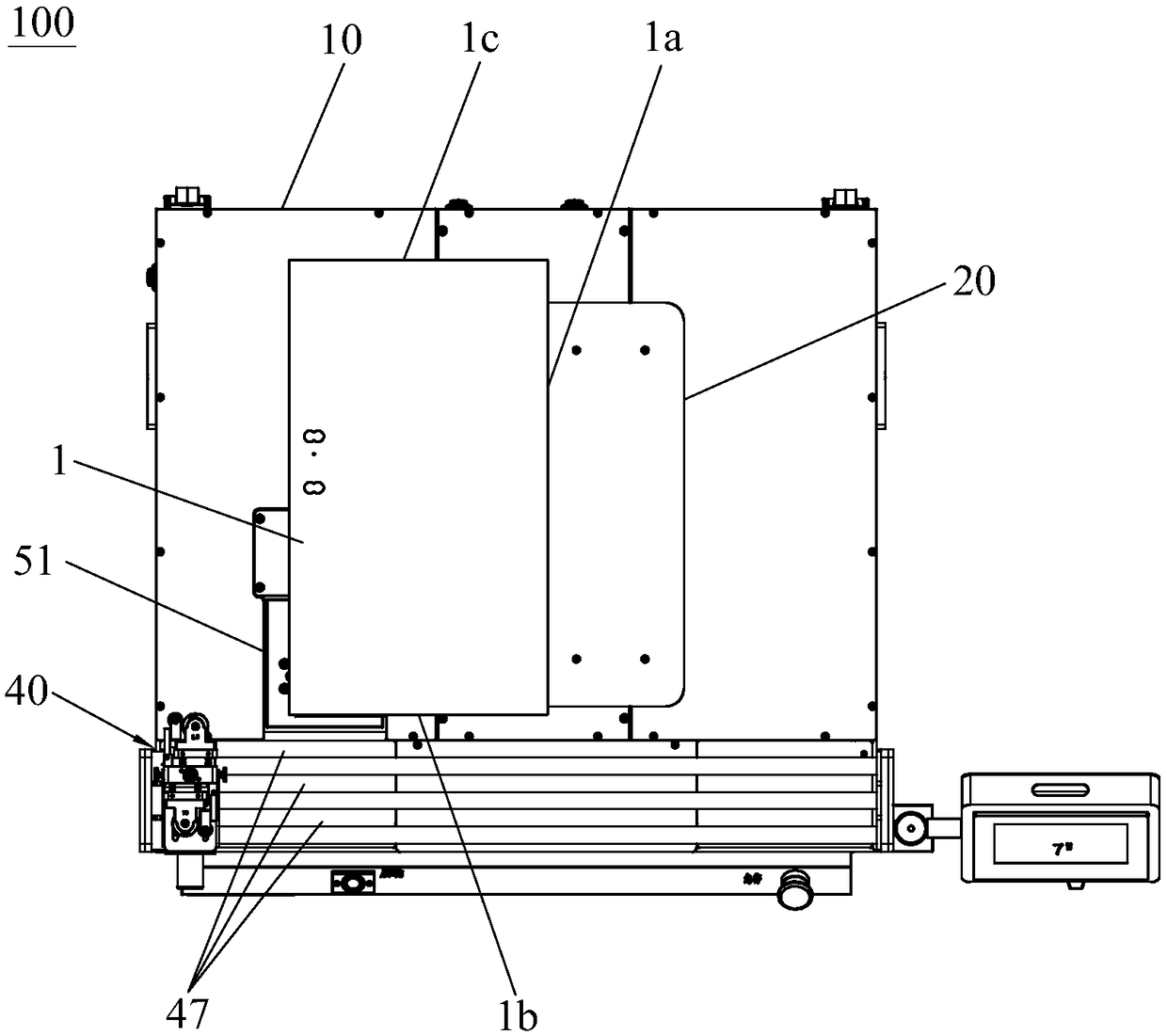

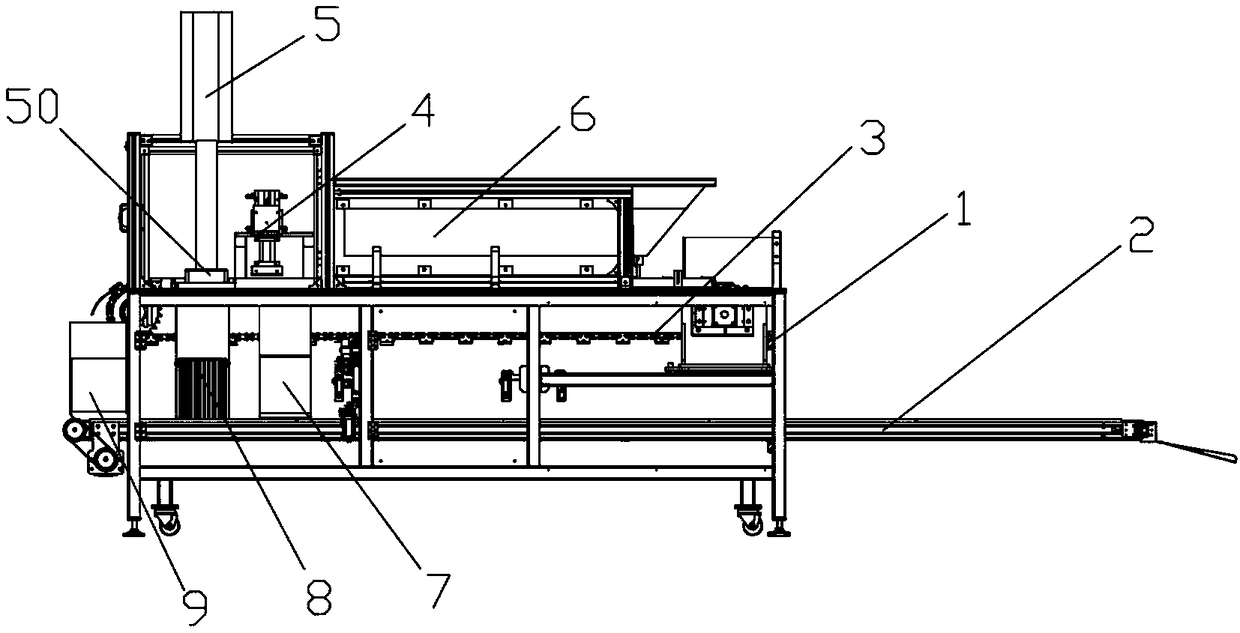

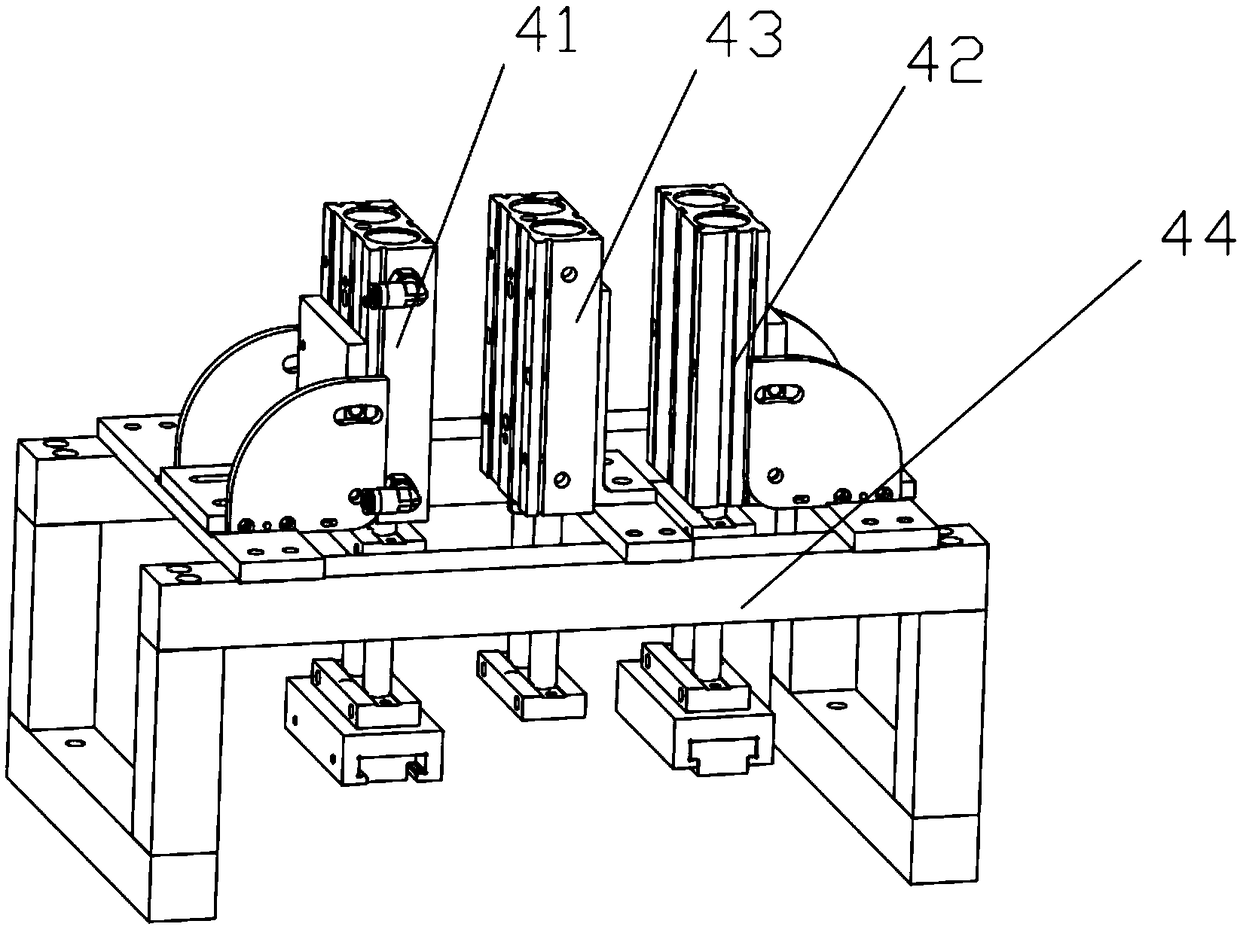

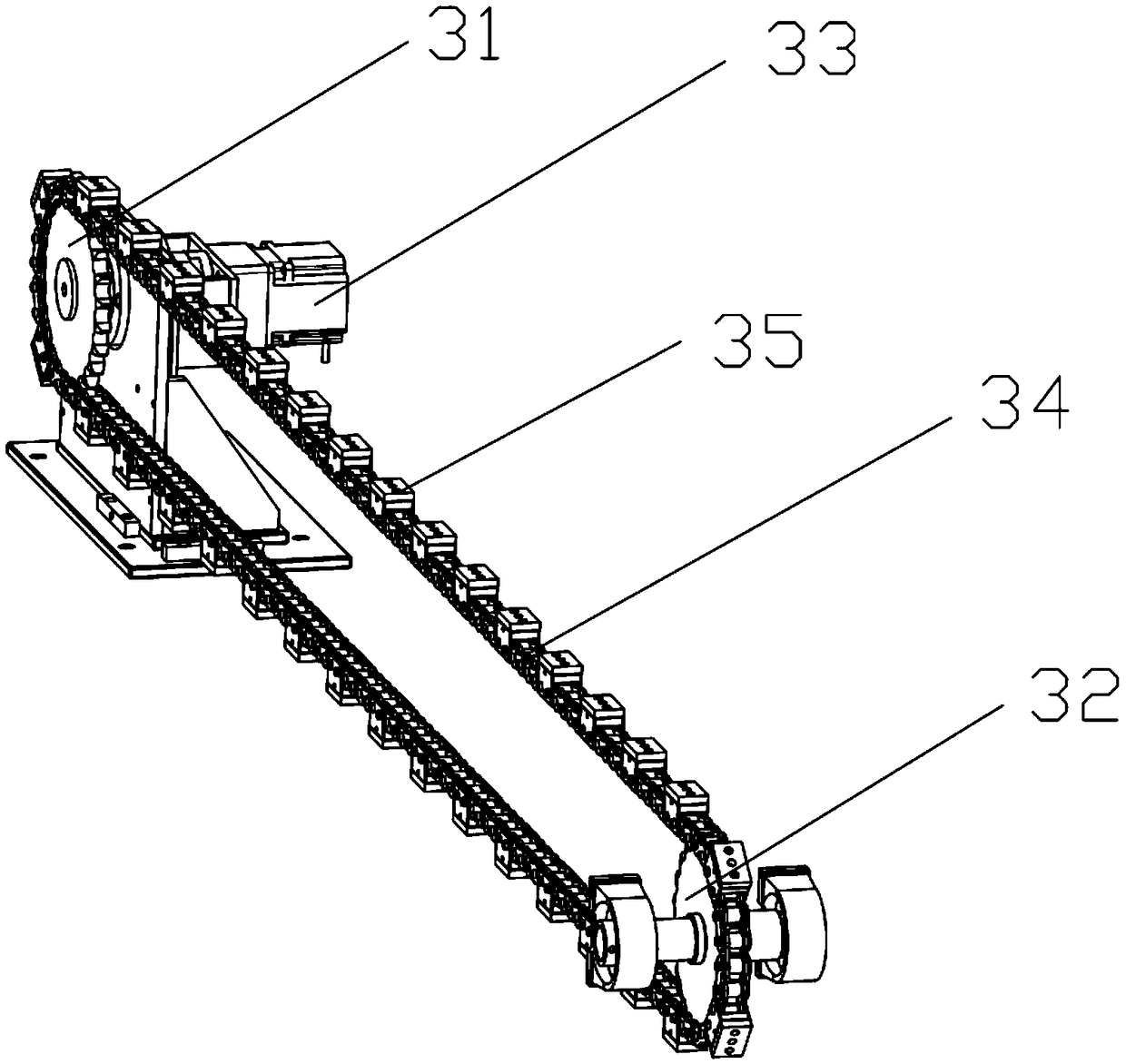

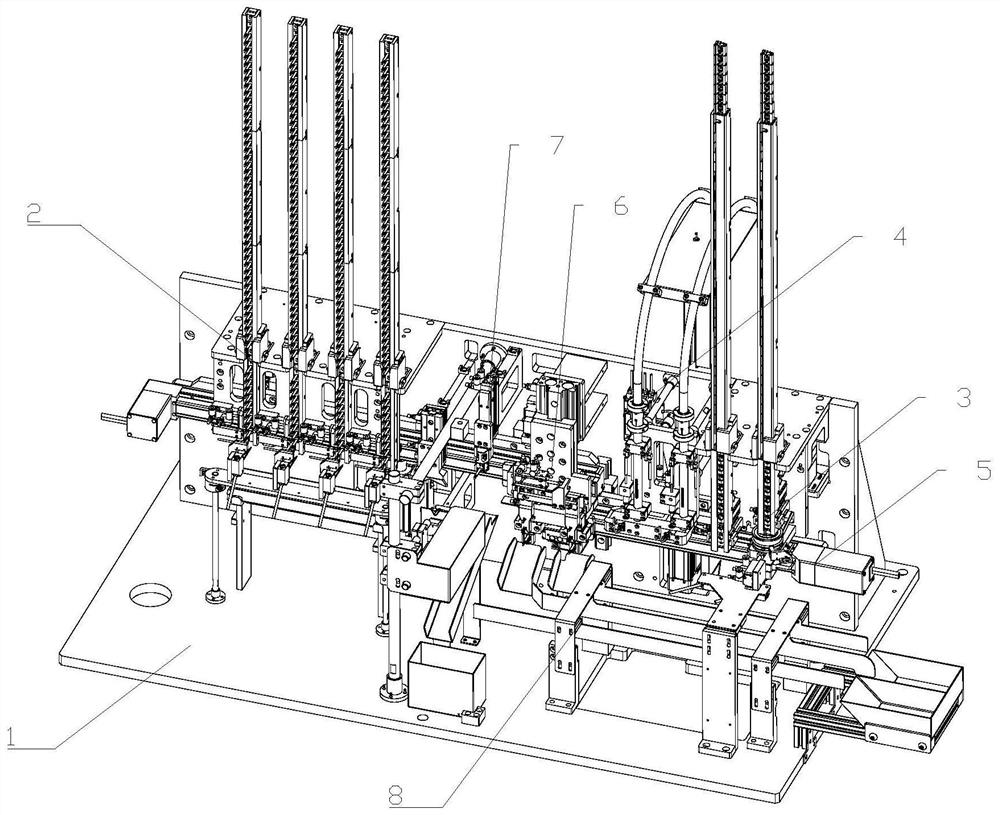

Discharging machine for zinc alloy castings

PendingCN108907159ASimple structureImprove blanking efficiencyDischarge efficiencyUltrasonic vibration

The invention discloses a discharging machine for zinc alloy castings and relates to the field of casting equipment. The discharging machine for the zinc alloy castings comprises an equipment framework, a transmission belt assembly penetrating through the equipment framework, a hinge assembly, a discharging assembly, an ultrasonic vibration platform, a cooling system, a material bag channel, a finished product channel and a material handle channel, wherein the hinge assembly is fixed to the equipment framework and used for conveying the zinc alloy castings, the discharging assembly is fixed tothe equipment framework and located at the front end of the hinge assembly, the ultrasonic vibration platform is fixed to the equipment framework and located on the outer side of the discharging assembly, the cooling system is fixed to the equipment framework and located above the hinge assembly, the material bag channel is fixed to the equipment framework and located below the discharging assembly, the finished production channel is fixed to the equipment framework and located below the ultrasonic vibration platform, and the material handle channel is fixed to the front end of the equipmentframework. According to the discharging machine for the zinc alloy castings, by means of design of the ultrasonic vibration, thus the discharging machine is simple in structure and higher in discharging efficiency; and by means of design of a replaceable die, application of the discharging machine is wider, and the discharging machine can be applicable to the different zinc alloy castings.

Owner:浙江华铸铸业科技有限公司

Square billet weighing, mark spraying and billet discharging system and method thereof

ActiveCN113600769ASolve phosphorus removalSolve the billet orientation problemCasting parameters measurement/indication devicesMetallurgyEngineering

The invention provides a square billet weighing, mark spraying and billet discharging system. The system comprises a conveying roller way, a mark spraying machine, a billet discharging roller way and a steel fishing machine; the conveying roller way is used for conveying casting blanks, and a weight fixing device is arranged above the conveying roller way; the mark spraying machine is arranged at the tail end of the conveying roller way, a weighing position detection device is arranged in front of the mark spraying machine, and a lifting baffle is arranged behind the weighing position detection device; the billet discharging roller way is arranged behind the mark spraying machine; and the steel fishing machine is arranged above the billet discharging roller way. The invention further provides a square billet weighing, mark spraying and billet discharging method which is implemented by adopting the square billet weighing, mark spraying and billet discharging system.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Production and processing device for building ceramsite sand

InactiveCN107335354ASteady declineAvoid safety hazardsRotary stirring mixersTransportation and packagingDrive shaftBiochemical engineering

The invention discloses a production and processing device for building ceramsite sand. The device comprises a tank body, a twin-screw stirring device and driving devices, wherein the tank body adopts a horizontal structure convenient to rotate, a support for supporting the tank body to rotate is arranged at the bottom of the tank body, a first driving device driving the tank body to rotate is arranged in the middle of the end surface of one end of the tank body, fixed outside the tank body and fixed on a mounting seat, and an outer end surface of a driving shaft of the first driving device is fixedly connected with the center of the corresponding end surface of the tank body; a vibrating type loading device is mounted at the top end of the tank body; the twin-screw stirring device which comprises a transverse rod and two screw rods is arranged in the middle in the tank body, the transverse rod corresponds to one side in the tank body, the middle of one side of the transverse rod is connected with a second driving device outside the tank body through a connecting shaft, and a bearing part is arranged in the matched position of the connecting shaft and the tank body; one screw rod is arranged at each of two ends of the other side of the transverse rod, and the two screw rods are parallel correspondingly.

Owner:金柯楠

Double-sided material falling device

The invention discloses a double-sided material falling device in the field of material falling devices. The double-sided material falling device comprises a machine base; a plurality of rotatable transmission rollers are sequentially arranged on the machine base from left to right; the transmission rollers are horizontally arranged; each transmission roller is in transmission connection with a rotary driving mechanism; pipe fittings are horizontally supported on the transmission rollers; pushing mechanisms capable of pushing the pipe fittings to a front material falling area and a rear material falling area correspondingly are arranged on the machine base; and the pushing mechanisms and the transmission rollers are arranged in a mutually staggered manner. Cut and formed steel pipes can correspondingly fall into the front material falling area and the rear material falling area, the qualified pipe fittings and defective pipe fittings can be sorted out, and the material falling efficiency is higher.

Owner:江苏省南扬机械制造有限公司

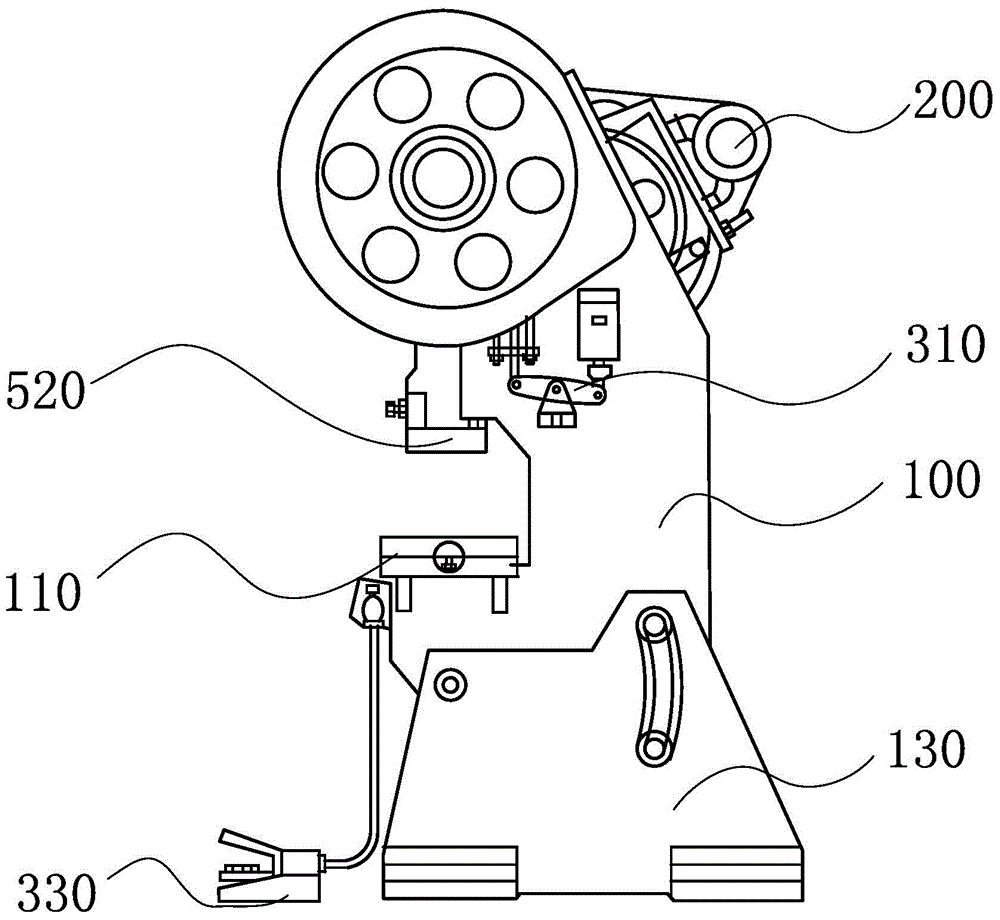

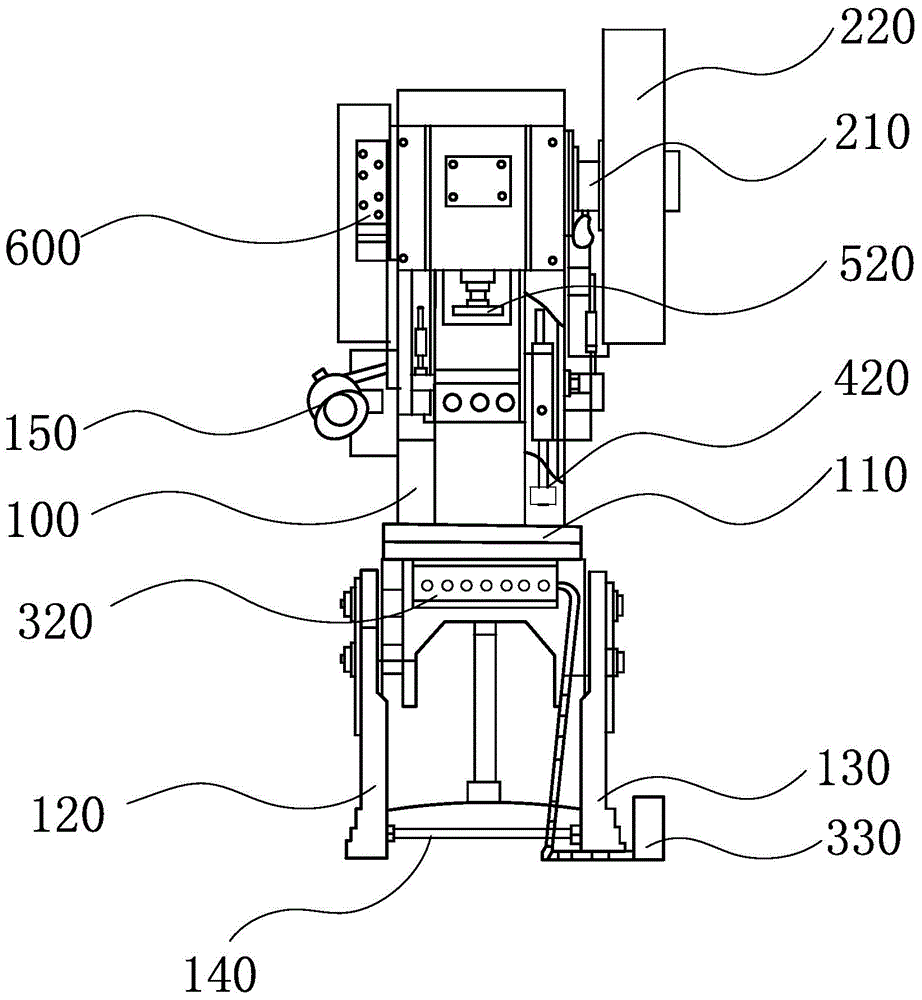

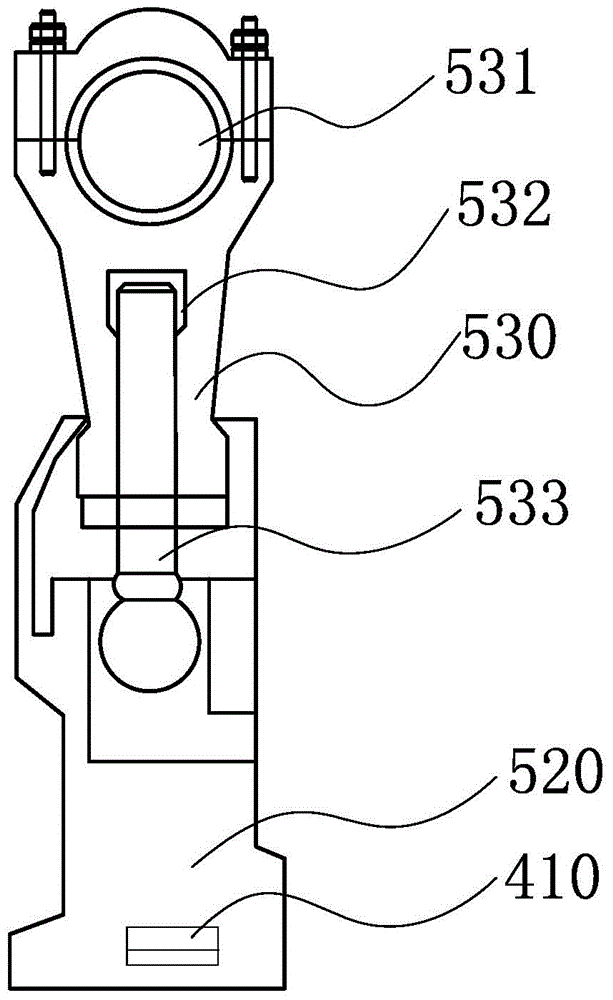

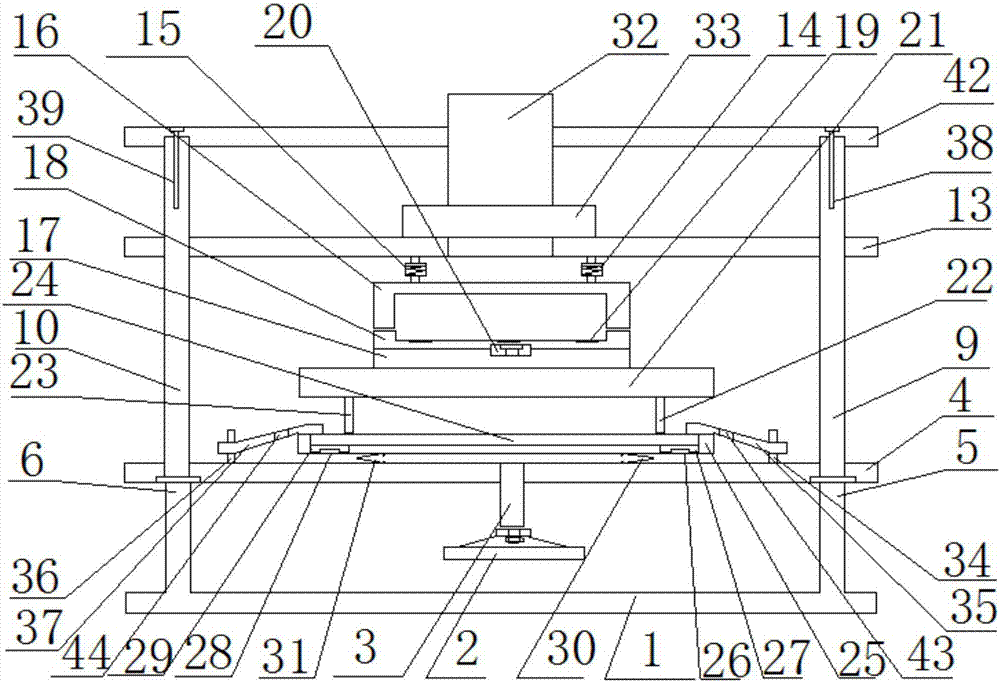

Tiltable press

ActiveCN104875422AAvoid falling off and not falling off smoothlyImprove blanking efficiencyPressesReciprocating motionEngineering

The invention provides a tiltable press, belongs to the technical field of press equipment, and solves the problem of instability in blanking of the existing press. The tiltable press comprises a tiltable body, a power component, a control component connected with the power component and a pushing mechanism used for pushing workpieces are arranged on the body, a workbench used for mounting the workpieces and a slide block mechanism located over the workbench are arranged on the body, the slide block mechanism is connected with the power component which can drive the slide block mechanism to reciprocate, and the pushing mechanism is enabled to push the machined workpieces to leave the workbench. The tiltable press has the advantages of stable falling of the workpieces and high working efficiency.

Owner:NINGBO LONGTIME MACHINE

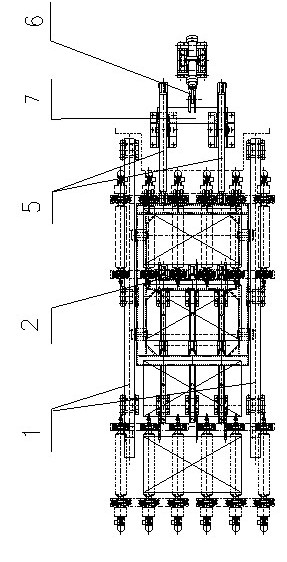

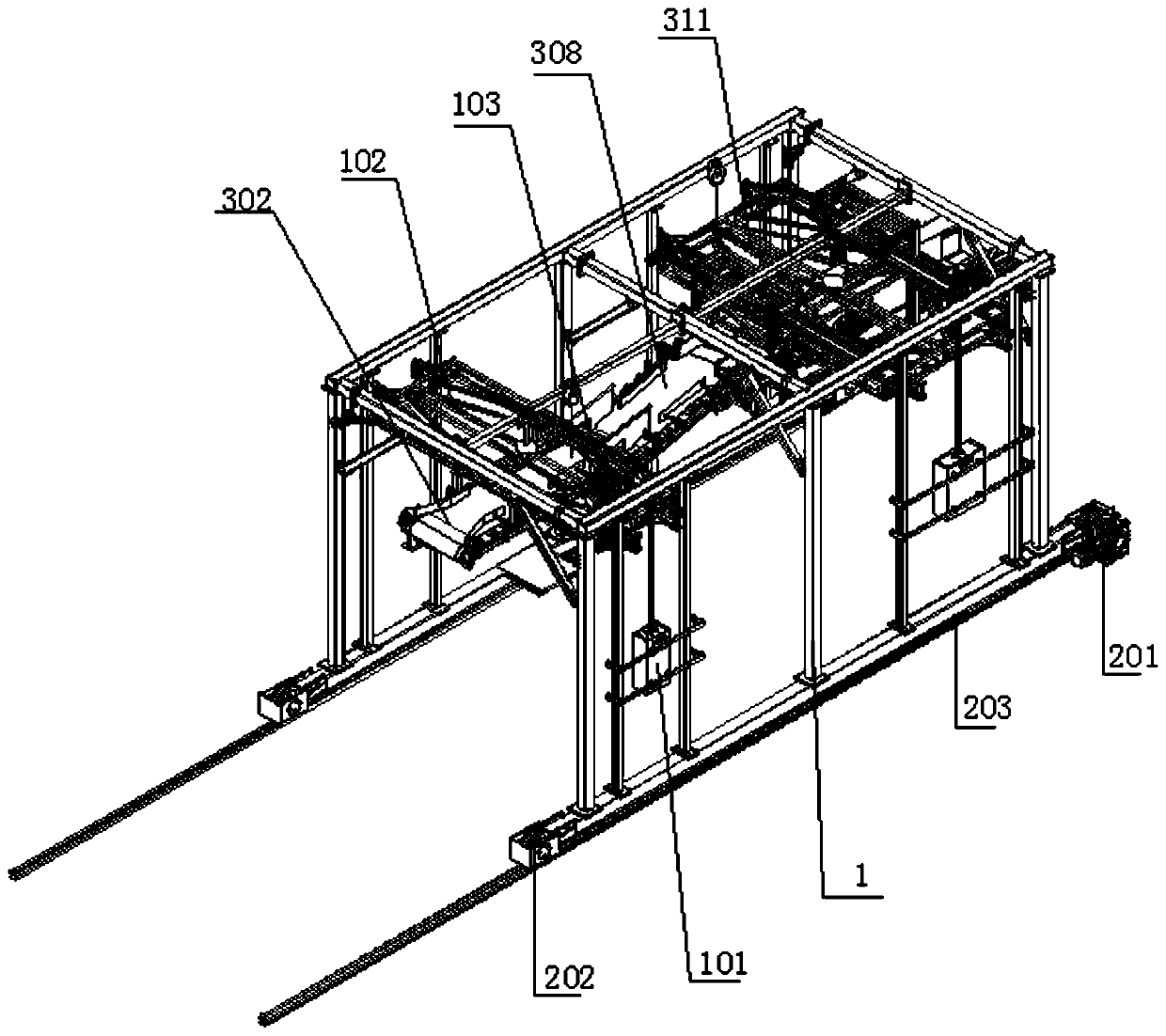

Gantry type bagged cement unmanned truck loading device

ActiveCN110790042AContinuous movementAvoid the problem of not being easy to stop at any timeStacking articlesDe-stacking articlesRobot handControl theory

The invention relates to a gantry type bagged cement unmanned truck loading device which comprises a portal frame, a flexible conveying mechanism, a mechanical hand and an electrical system. A liftingmechanism is connected with the portal frame. A guide rail device is slidingly connected with the lower side of the portal frame. The portal frame can move along the guide rail device. The feeding end of the flexible conveying mechanism is fixedly connected with the lifting mechanism. The discharging end of the flexible conveying mechanism is fixedly connected with the mechanical hand. One end ofthe flexible conveying mechanism is fixedly connected with the portal frame through the lifting mechanism. The other end of the flexible conveying mechanism is fixedly connected with the mechanical hand, and the mechanical hand can be driven to do telescopic movements. According to the gantry type bagged cement unmanned truck loading device, through the longitudinal movements of the portal frame,the transverse movements of a beam, the reverse compensating movements of a follow-up telescopic device and the bag grabbing and bag releasing of the mechanical hand, intelligent truck loading is realized. The gantry type bagged cement unmanned truck loading device has the advantages of being high in stability, neat and orderly in stacking, high in efficiency and high in automation degree.

Owner:XINGTAI POLYTECHNIC COLLEGE

Horn edge pressing device for electronic accessory machining

InactiveCN109772974AImprove blanking efficiencyImprove work efficiencyMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention discloses a horn edge pressing device for electronic accessory machining. A load bearing bottom plate is included. Landing legs are connected to the periphery of the bottom of the load bearing bottom plate. A containing table is fixedly connected to the middle of the upper end of the load bearing bottom plate. The upper end of one side of the containing table is connected with a second fixing support rod, and the side, close to the containing table, of the upper end of the second fixing support rod is connected with a second camera. A pressing plate capable of moving horizontallyand up and down is arranged above the containing table, the containing table is arranged below the pressing plate, a first push rod and a second push rod are arranged on the two sides of the containing table, and when one edge of a horn is pressed, the push rod on the opposite side is used for pushing, the other edge of the horn is pushed to the position below the pressing plate and pressed, andaccordingly, manual edge pressing is avoided; and meanwhile, the position of the edge, needing to be pressed, of the horn can be adjusted, and the horn edge pressing efficiency is improved.

Owner:李子衡

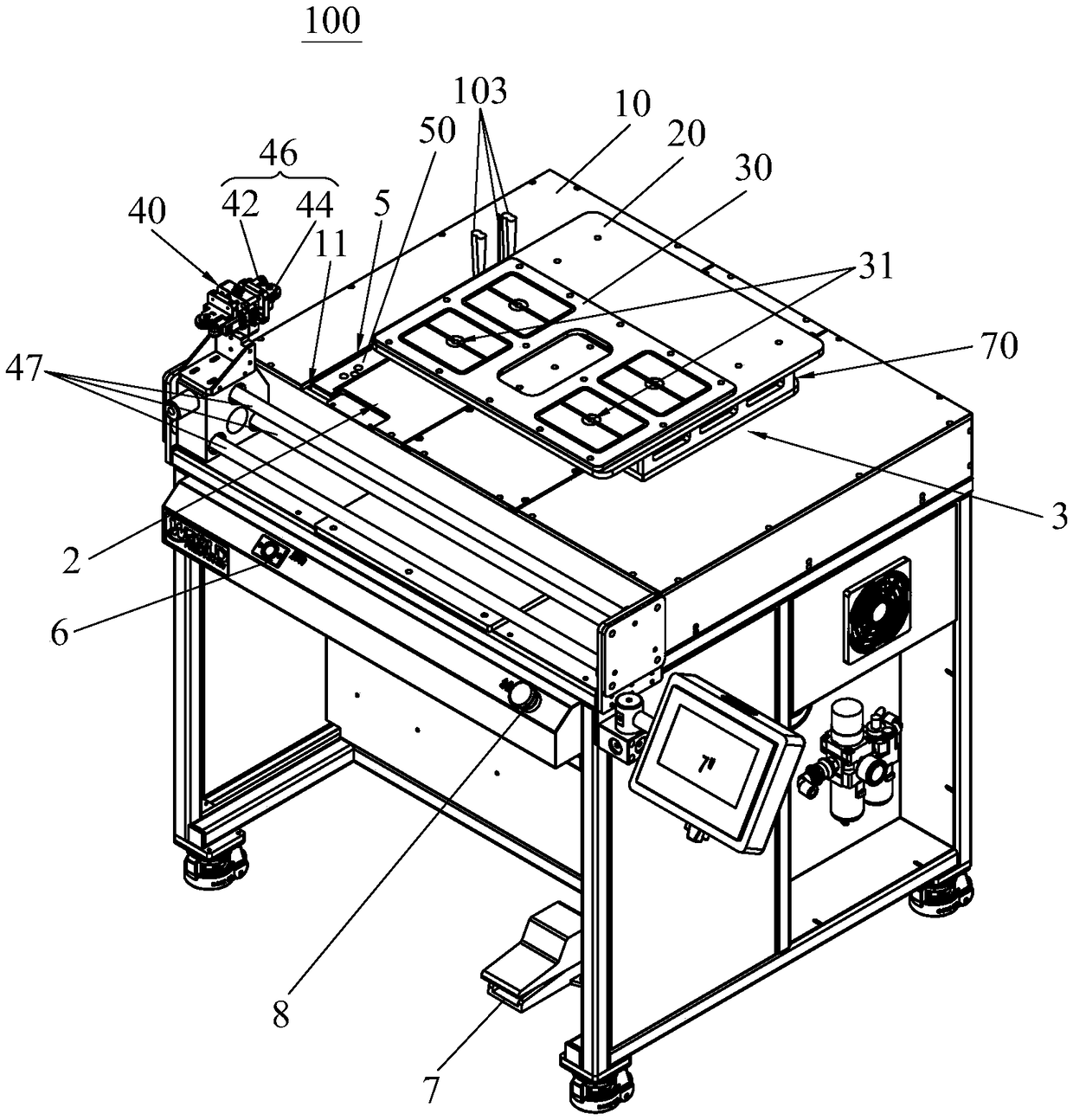

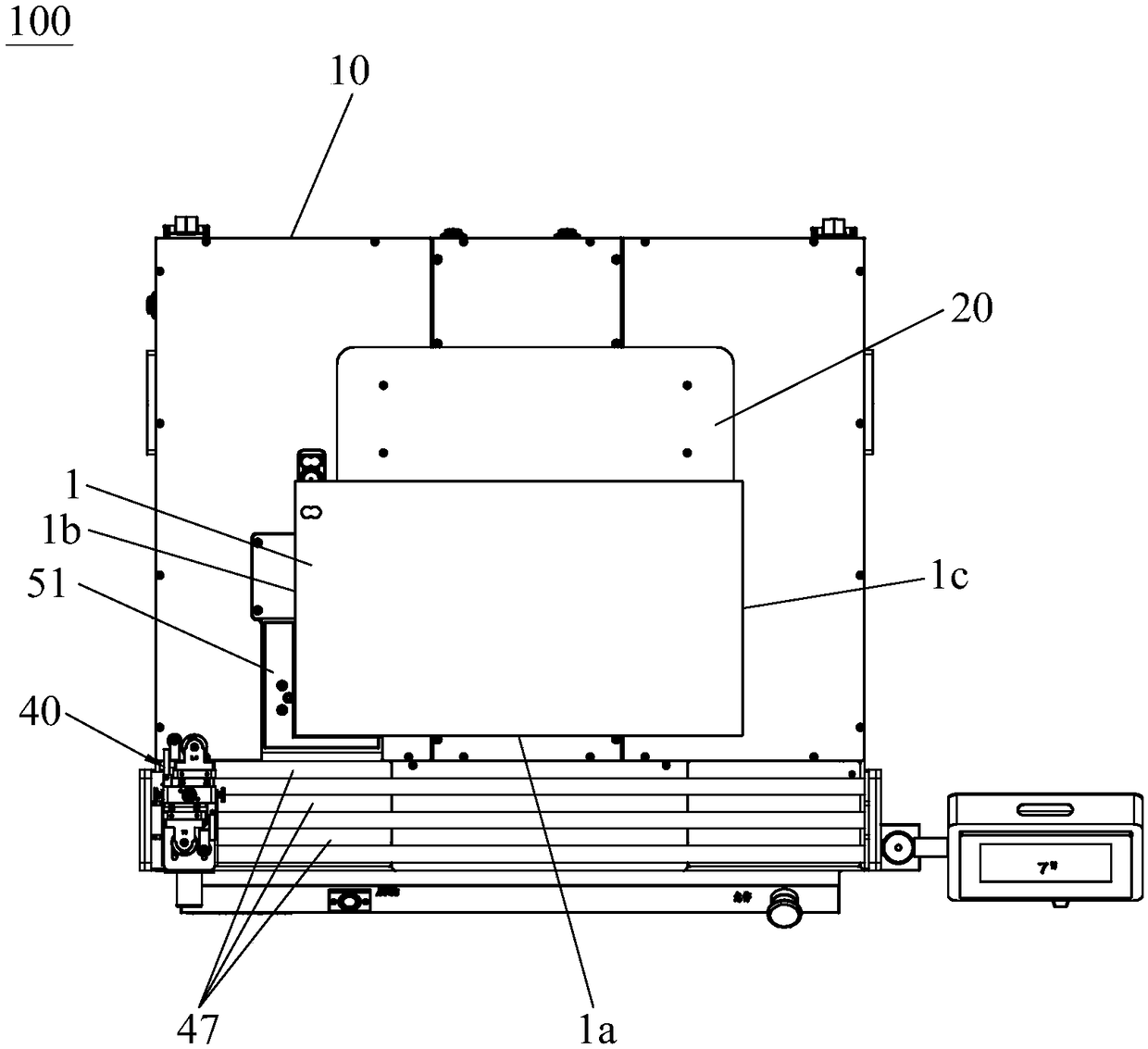

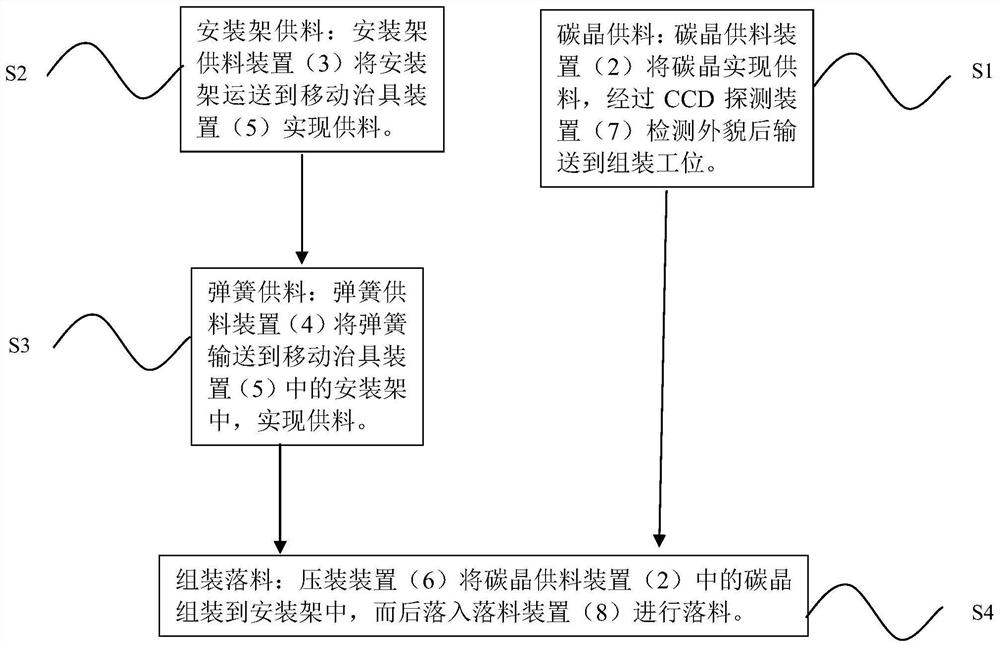

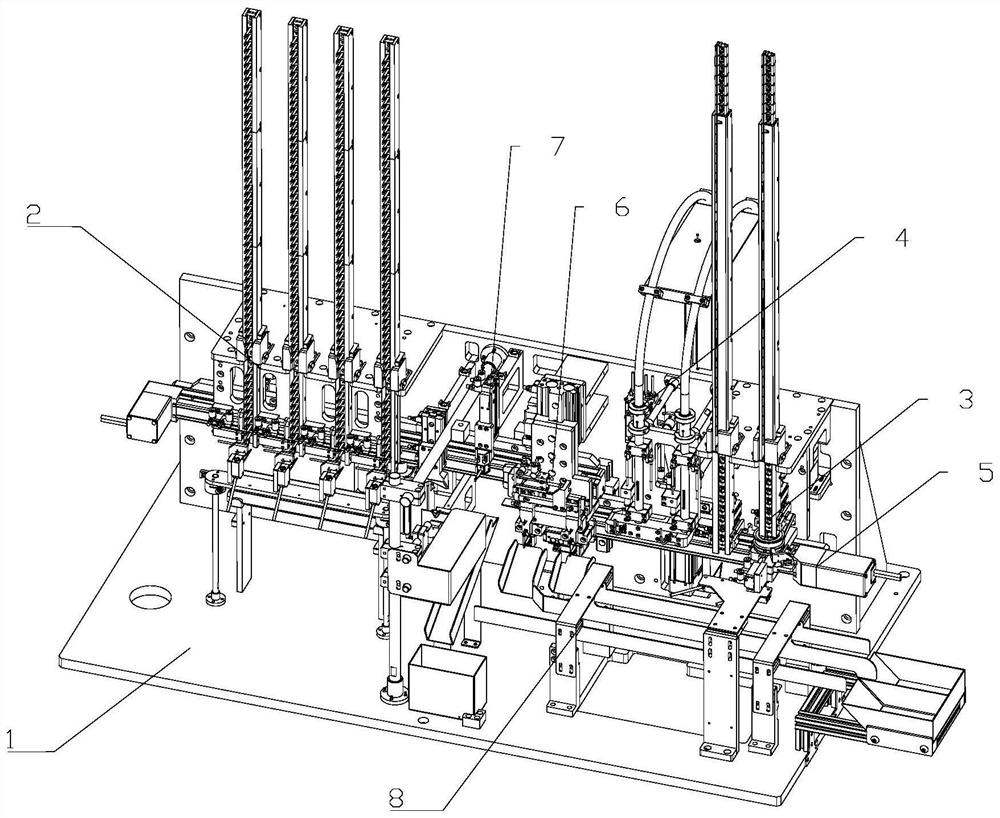

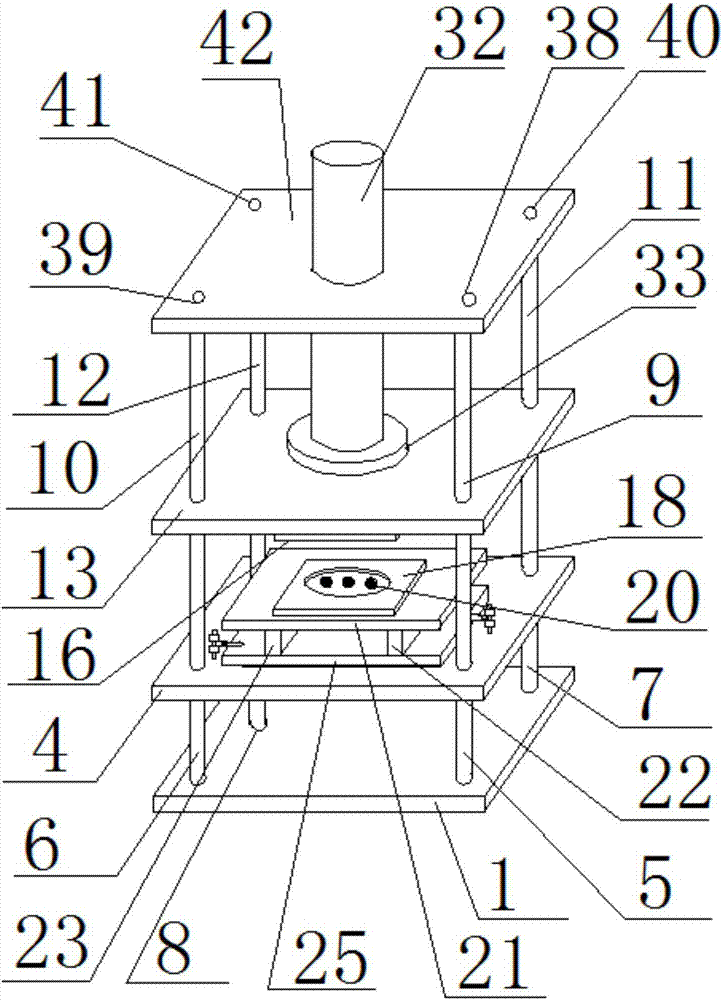

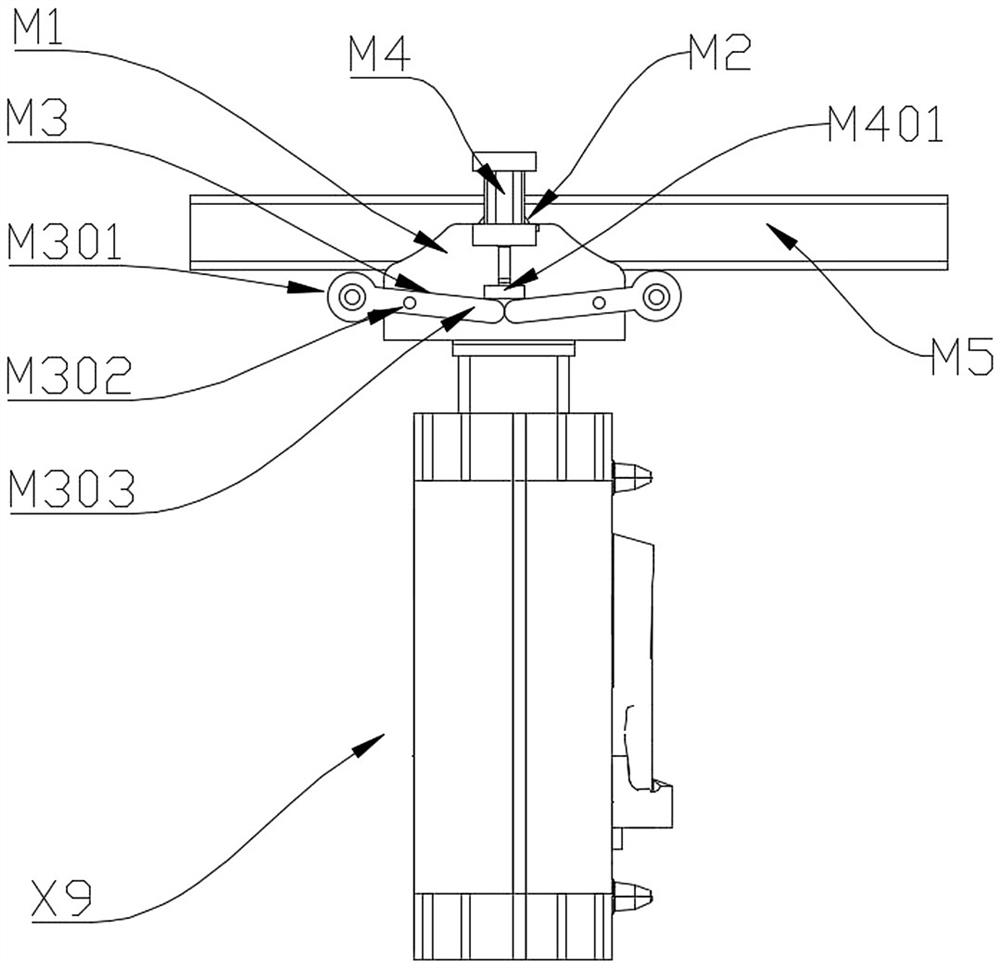

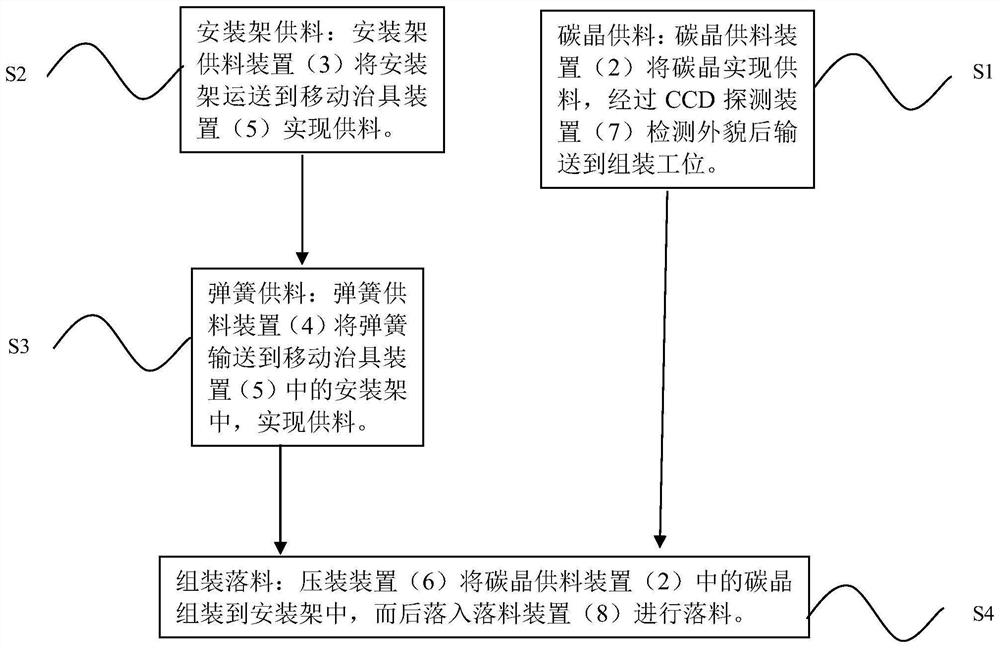

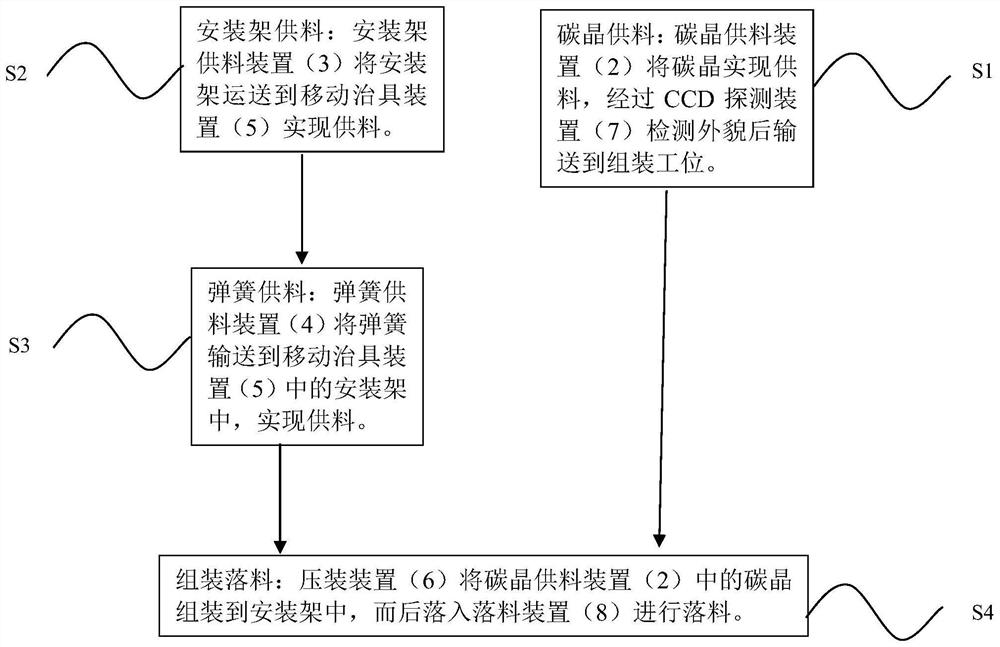

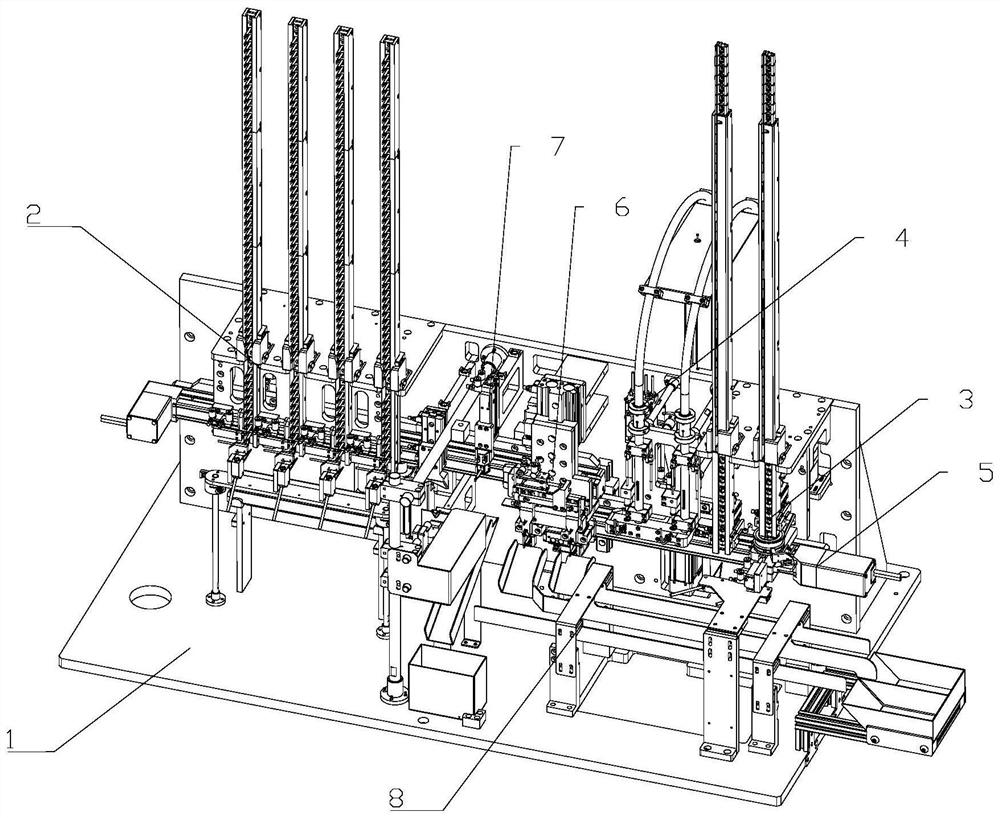

Motor carbon brush moving press-fitting device, buckling method and carbon brush assembling equipment

InactiveCN113328584AImprove efficiencyReduce waiting timeManufacturing dynamo-electric machinesMetal working apparatusElectric machineryEngineering

The invention relates to the field of motor production, and concretely relates to a motor carbon brush moving press-fitting device, a buckling method and carbon brush assembling equipment. The carbon brush moving press-fitting device comprises a moving jig device and a press-fitting device, the press-fitting device corresponds to the upper end of the moving jig device, the moving jig device comprises a two-degree-of-freedom moving mechanism, a moving frame, an opening and closing air cylinder, an opening and closing plate and two jig blocks, the moving frame is installed at the moving end of the two-degree-of-freedom moving mechanism, the jig blocks are installed on the moving frame, a limiting through groove is formed in each jig block, and the sizes of the limiting through grooves are matched with the size of a mounting frame; and the opening and closing plate is installed at the telescopic end of the opening and closing air cylinder, the opening and closing air cylinder is arranged on the moving frame, the upper end of the opening and closing plate is a plane, and the plane makes contact with the lower end face of the jig block in an attached mode. The press-fitting device has the advantages of being convenient to move, convenient to discharge and stable and reliable in press-fitting.

Owner:陈荣乾

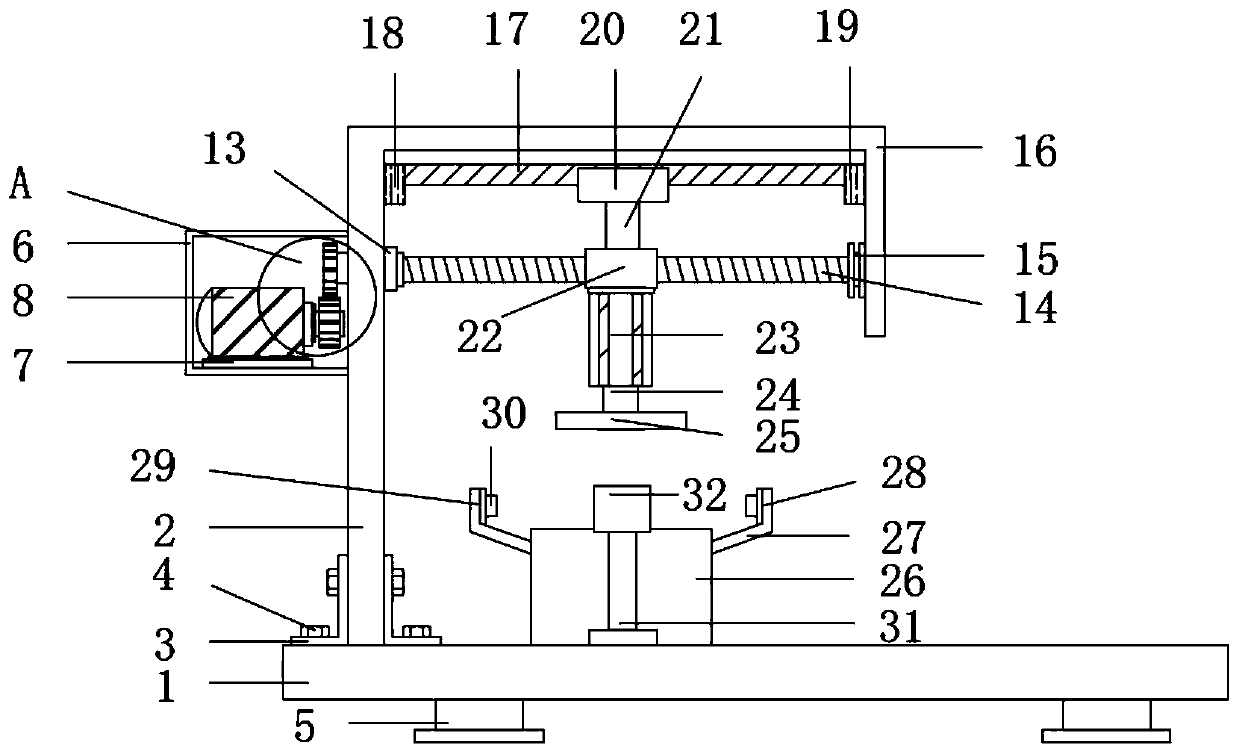

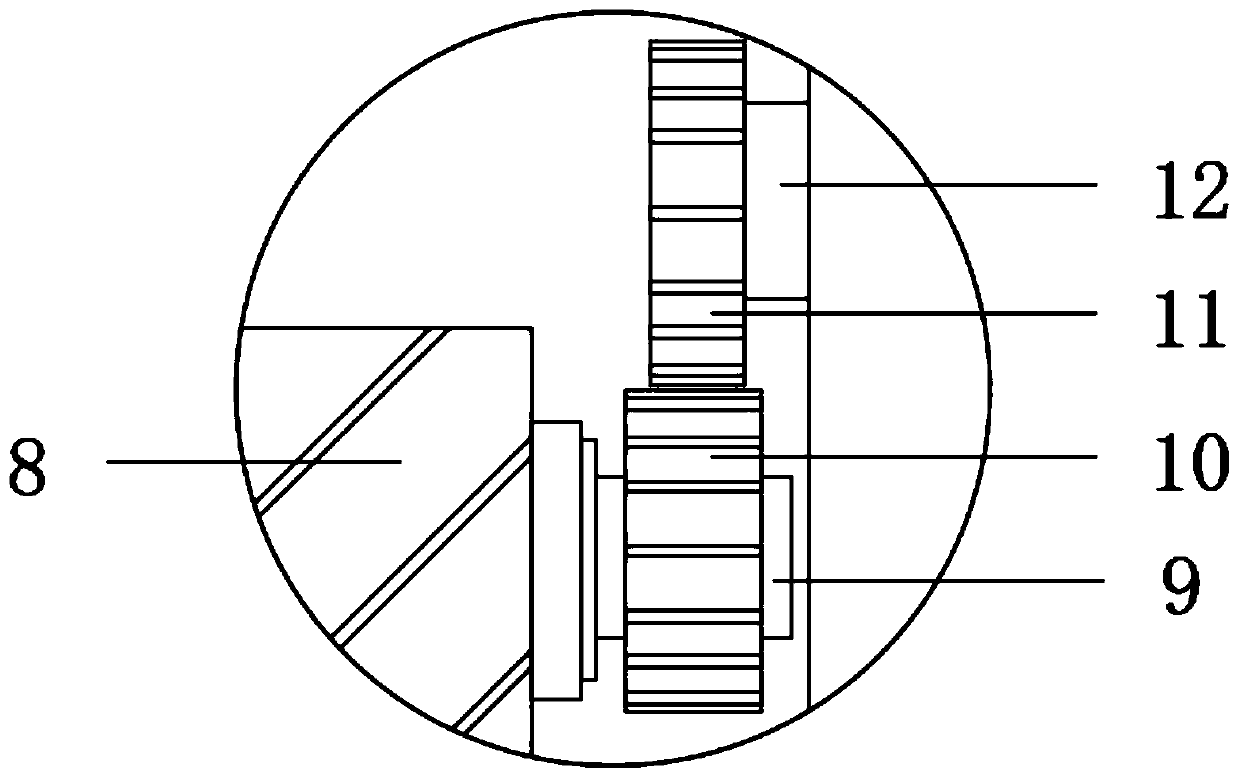

Edge pressing machine

The invention discloses an edge pressing machine. The machine comprises an upper pressing plate (16) and a lower pressing plate (18) matched with the upper pressing plate (16); a workpiece is placed on the lower pressing plate (18); an upper pressing plate supporting plate (13) is driven by a power driving assembly (32); and the upper pressing plate (16) moves towards the lower pressing plate (18)by the aid of the upper pressing plate supporting plate (13) under the combined guide effect of a first guide rod (9), a second guide rod (10), a third guide rod (11) and a fourth guide rod (12). Thus, burrs and the like on the upper edge of the workpiece are removed through extrusion between the upper pressing plate (16) and the lower pressing plate (18). Besides, a lot of fine grinding chips and metal chips are prevented from flying out during grinding machining. Damage to eyes and lungs of operators is avoided, manual grinding is replaced, and the edge pressing efficiency is improved.

Owner:HUNAN HANXING MACHINERY MFG CO LTD

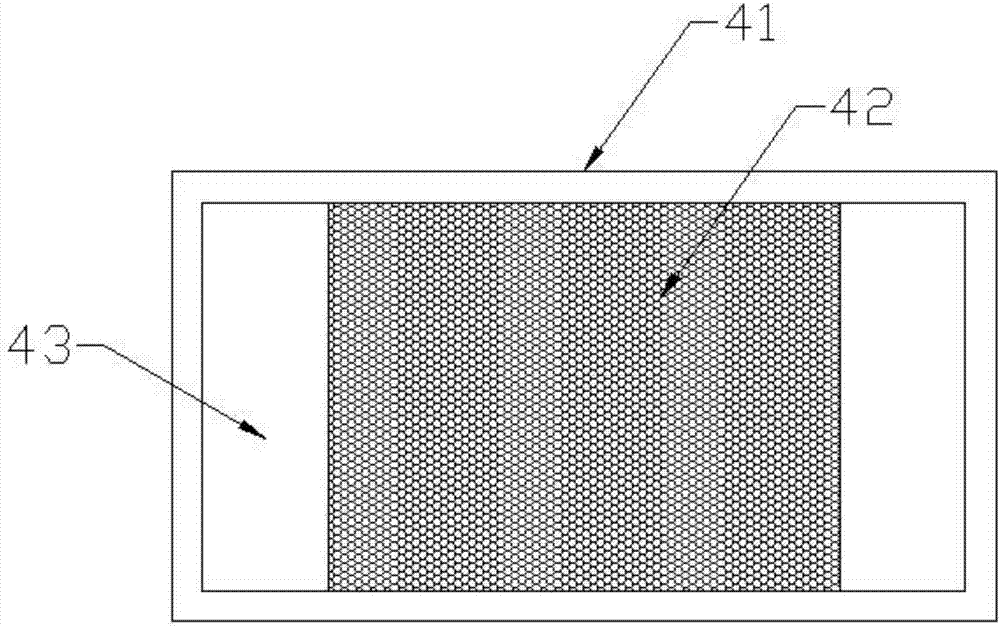

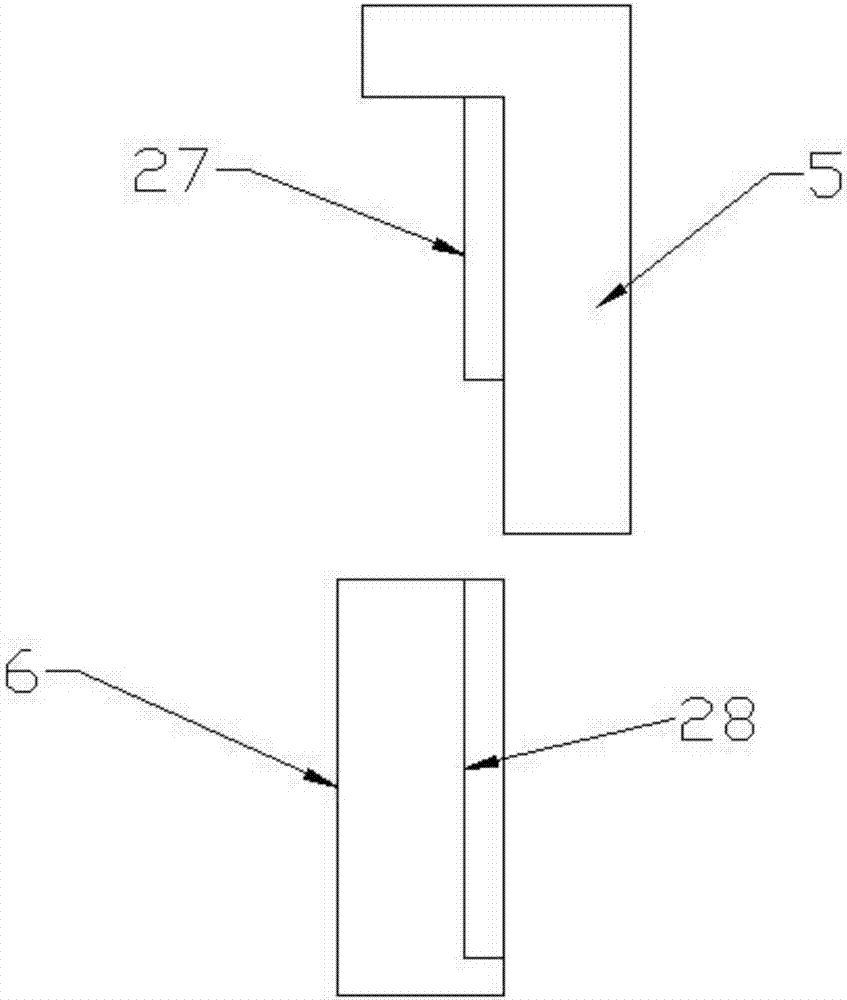

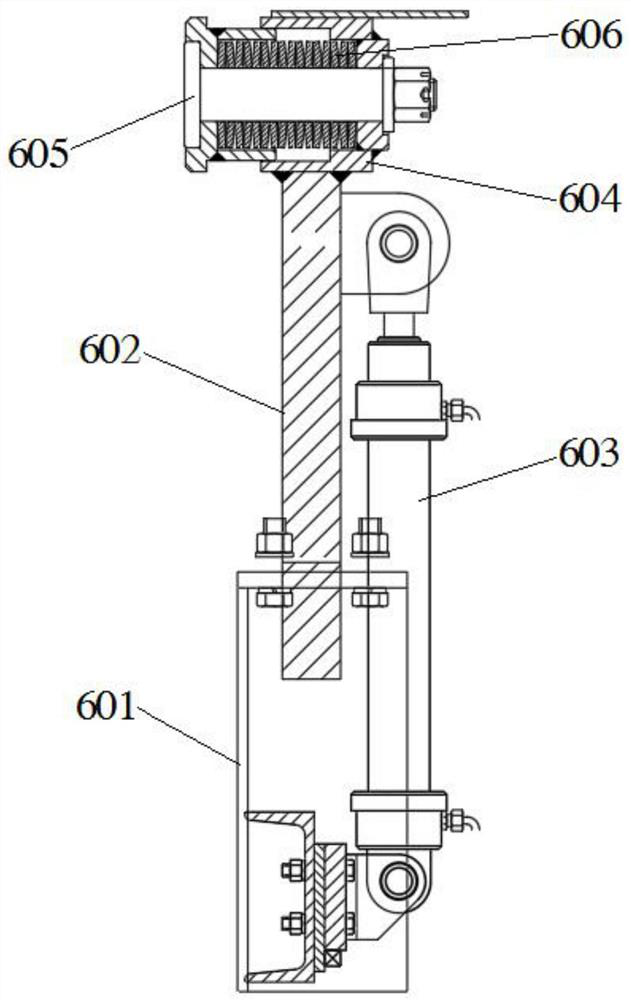

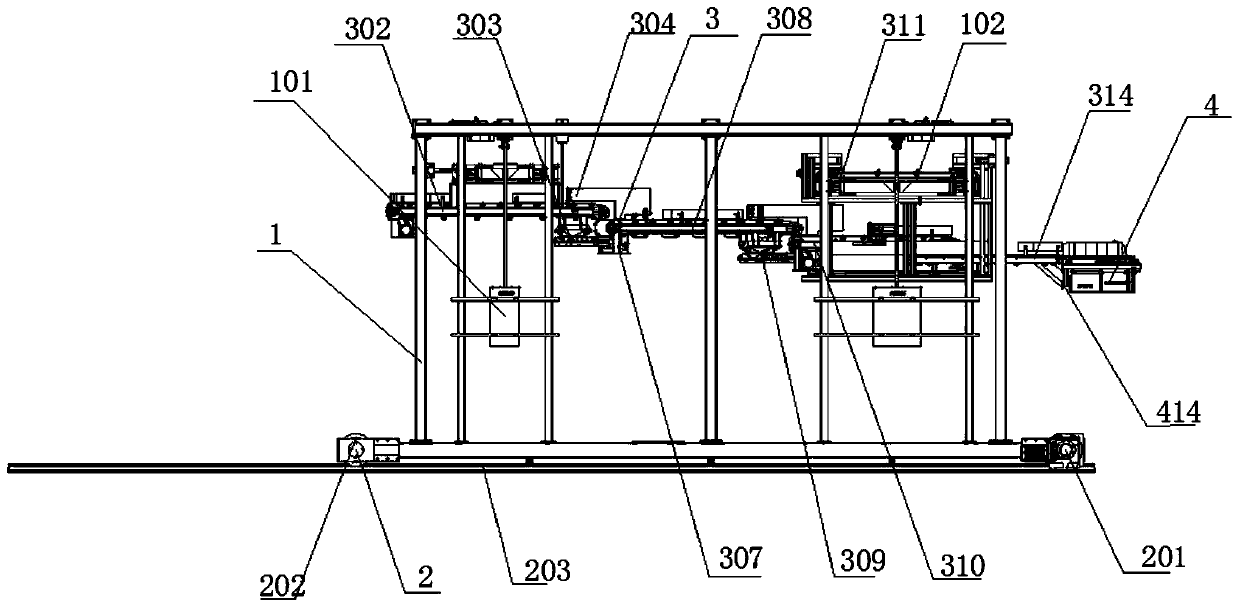

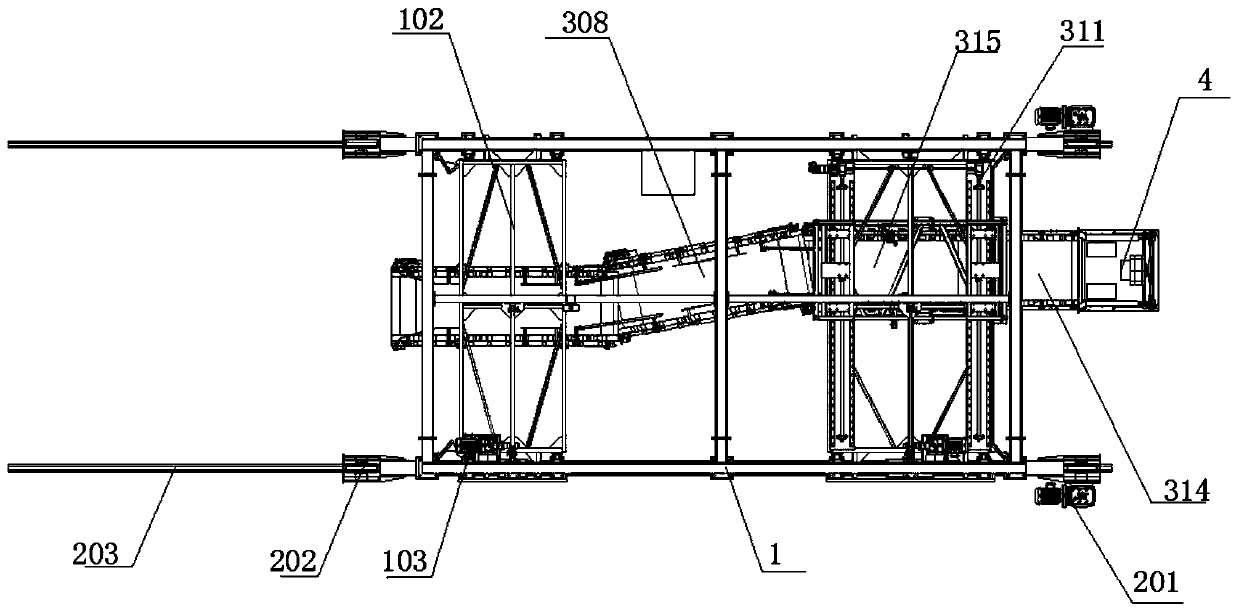

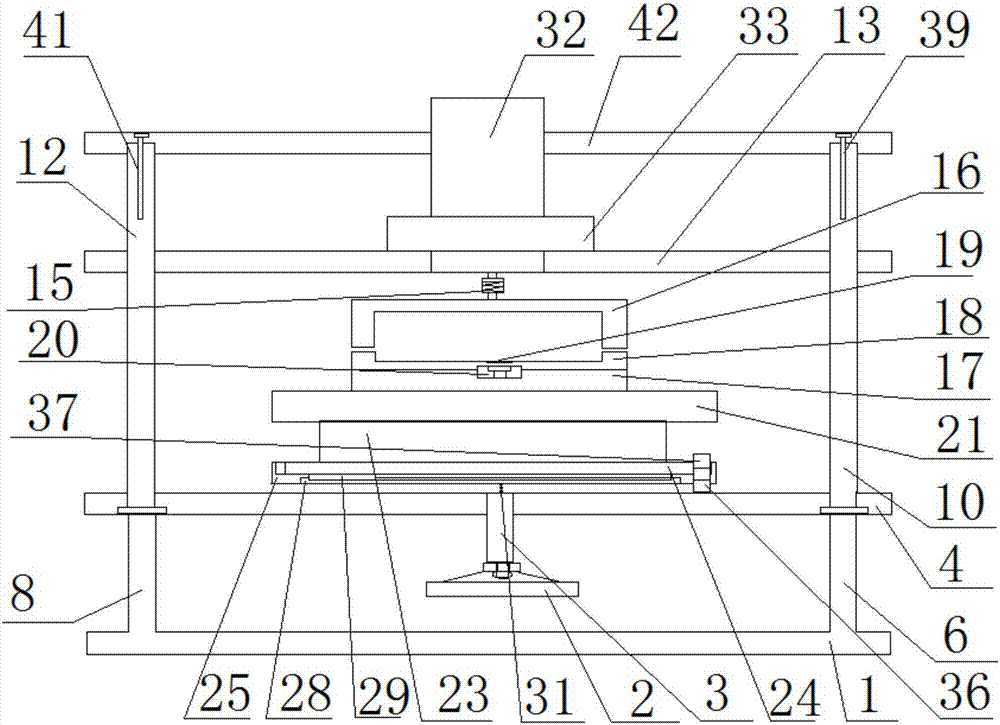

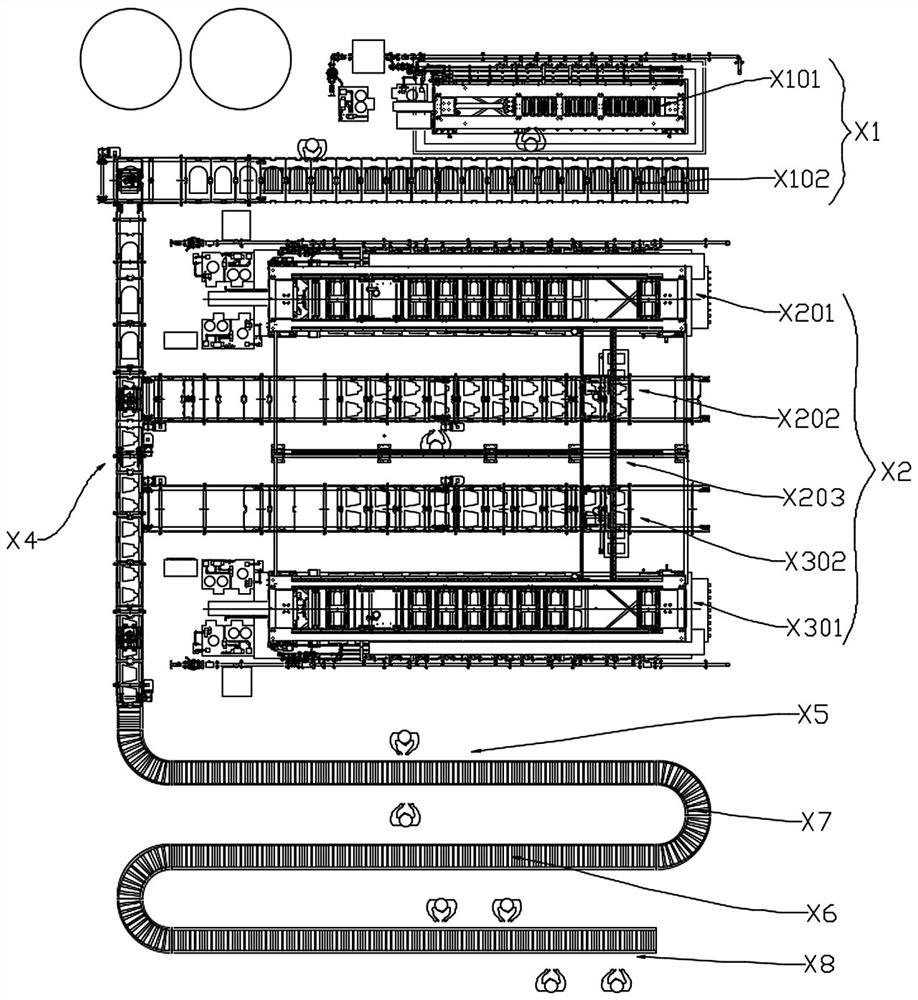

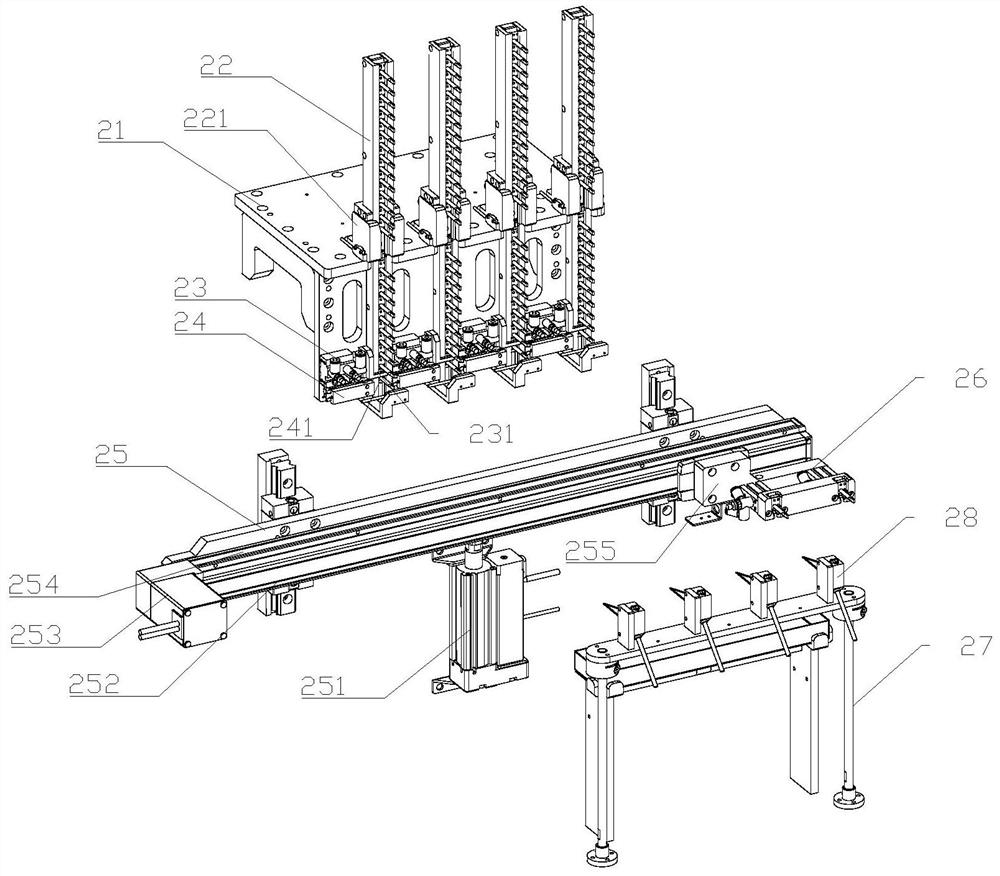

Sanitary ceramic slip casting line

ActiveCN111716512AImprove blanking efficiencyDecomposition operation difficultyDischarging arrangementCeramic shaping plantsAssembly lineSlurry

The invention relates to the technical field of blank manufacturing of sanitary ceramic products, in particular to a sanitary ceramic slip casting line. A toilet bowl blank is divided into three partsto be formed and corresponds to a seat slip casting production line and an inner container and outer sleeve slip casting production line in the ceramic slip casting line, and assembly line work is overall formed through a conveying line, a blank conveying line slurry hanging line, a bonding line and a blank repair line; a high-pressure slip casting machine is arranged in the slip casting production line, the forming time of the toilet bowl blank is saved, and the problems that in common slip casting production lines, occupied sites are large, much dust is generated, efficiency is low, and therequirement for the physical power of workers is high are solved; and meanwhile, automatic blank vehicle taking and blank sleeve taking are set in the assembly line, a work mold in a slip casting machine is arranged to be a turnover work mold, and the problems that the blank discharging efficiency is low, and the labor intensity of operation workers is large are further solved.

Owner:ZHONGTAO SANITARY WARO MFG CO LTD OF TANGSHAN

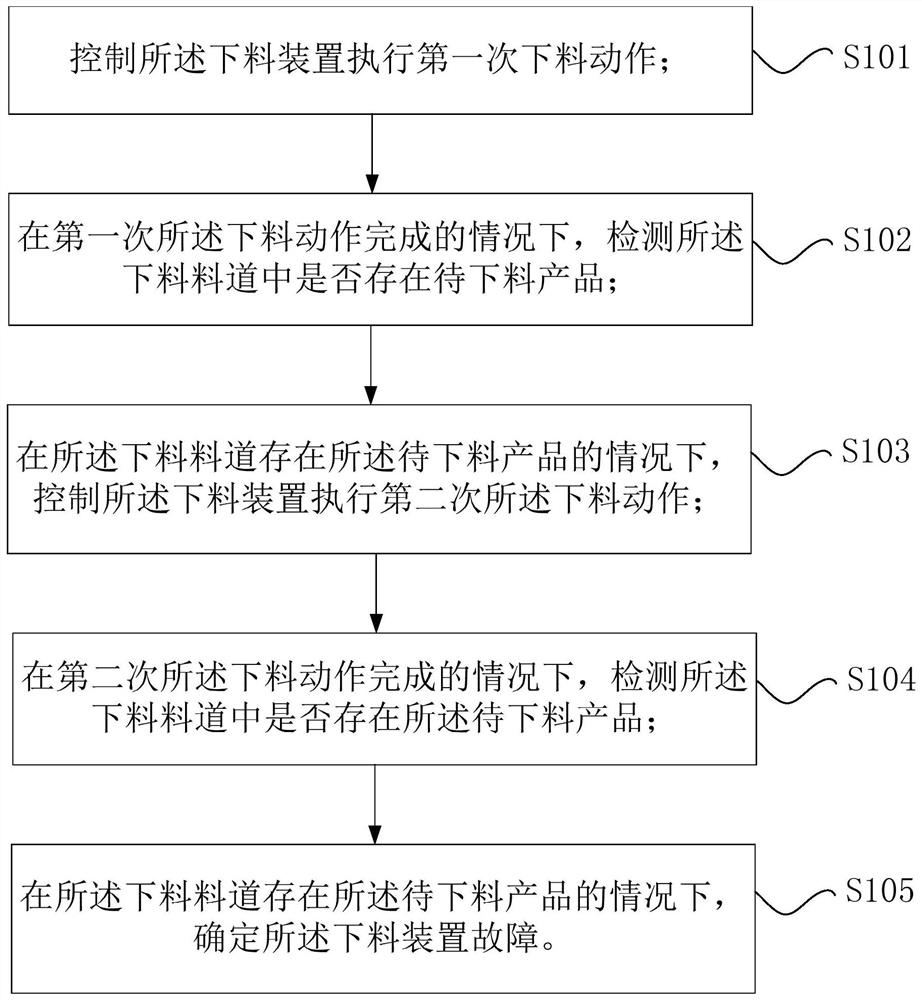

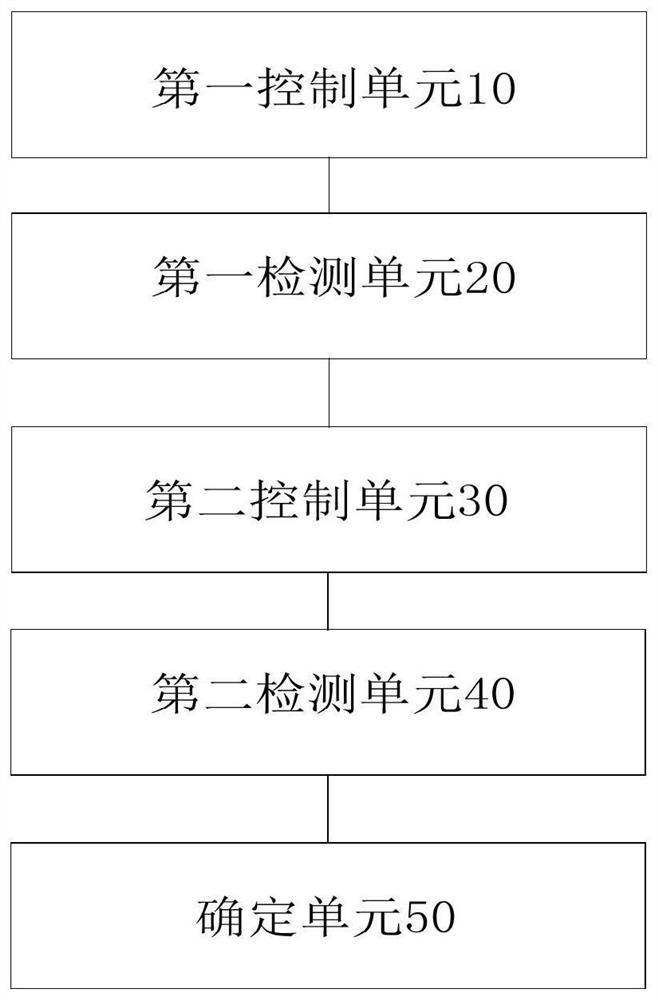

Fault determination method and device for discharging device and discharging system

PendingCN113942823AImprove blanking efficiencyReduce the frequency of manual troubleshootingConveyorsControl devices for conveyorsControl engineeringProcess engineering

The invention provides a fault determination method and device for a discharging device and a discharging system. The discharging device comprises a discharging channel, and the method comprises the steps that the discharging device is controlled to execute a first discharging action; under the condition that the first discharging action is completed, whether a to-be-discharged product exists in the discharging channel or not is detected; under the condition that the to-be-discharged product exists in the discharging channel, the discharging device is controlled to execute the second discharging action; under the condition that the second discharging action is completed, whether the to-be-discharged product exists in the discharging channel or not is detected; and under the condition that the to-be-discharged product exists in the discharging channel, it is determined that the discharging device breaks down. The method solves the problem of low discharging efficiency caused by frequent alarm of a discharging machine in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

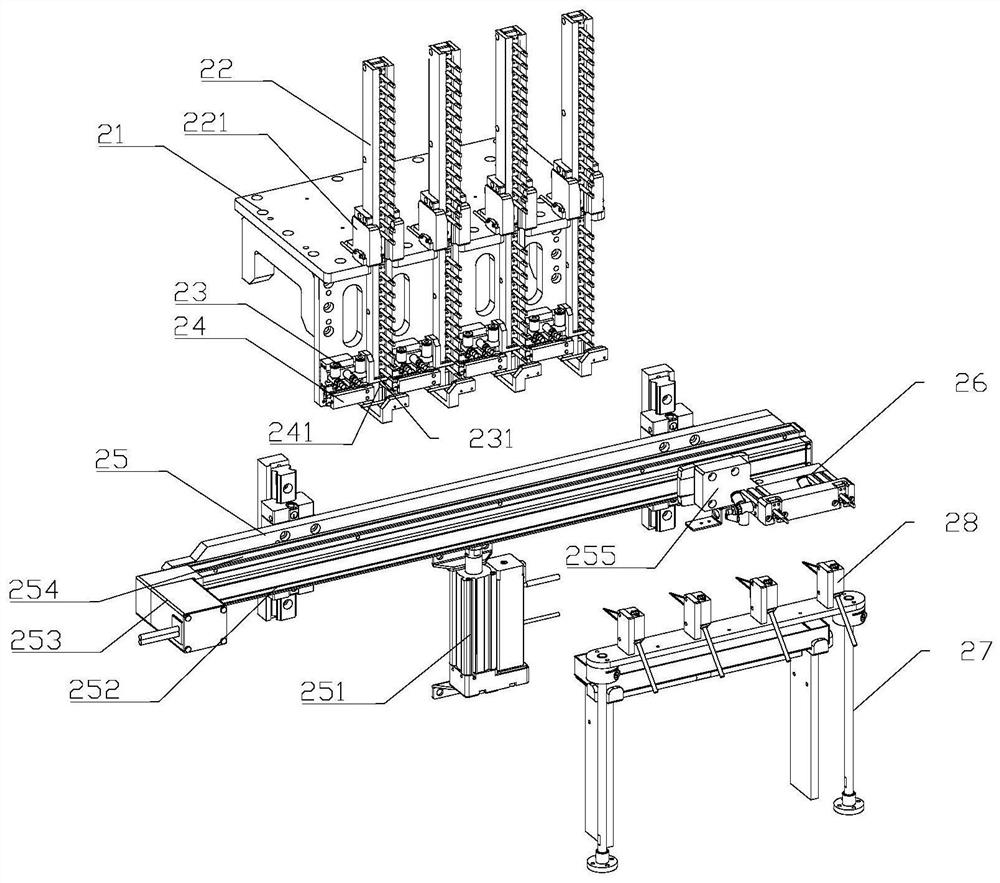

Carbon crystal feeding device and feeding method for motor carbon brush and motor carbon brush assembling equipment

InactiveCN113334065AImprove transfer efficiencyEnsuring Fall StabilityConveyorsAssembly machinesElectric machineEngineering

The invention relates to the field of motor production, and particularly relates to a carbon crystal feeding device and feeding method for a motor carbon brush and motor carbon brush assembling equipment. The carbon crystal feeding device for the motor carbon brush comprises a mounting table, carbon crystal falling rails, a first blocking air cylinder, a second blocking air cylinder, a moving assembly, a receiving assembly, a side support and a photoelectric sensor; the carbon crystal falling rails are formed on the mounting table, and carbon crystals are arranged in the carbon crystal falling rails; the first blocking air cylinder and the second blocking air cylinder are arranged on the mounting table; the first blocking air cylinder and the second blocking air cylinder correspond to the sides of the carbon crystal falling rails; a zigzag rod is arranged at the telescopic end of the first blocking air cylinder; a blocking column is arranged at the telescopic end of the second blocking air cylinder; the zigzag rod corresponds to the lower end of carbon crystal cylinder sections outside the carbon crystal falling rails; the blocking column corresponds to the lower end of the carbon crystal square column sections; the moving assembly is fixedly arranged on a rack; the receiving assembly is mounted at the telescopic end of the moving assembly; the photoelectric sensor is mounted on the side support and corresponds to the moving assembly; and the receiving assembly comprises a connecting plate, a micro air cylinder, an accepting seat and a stop pin. The carbon crystal feeding device has the advantages of multiple falling rails, high feeding efficiency and stable and reliable feeding.

Owner:陈荣乾

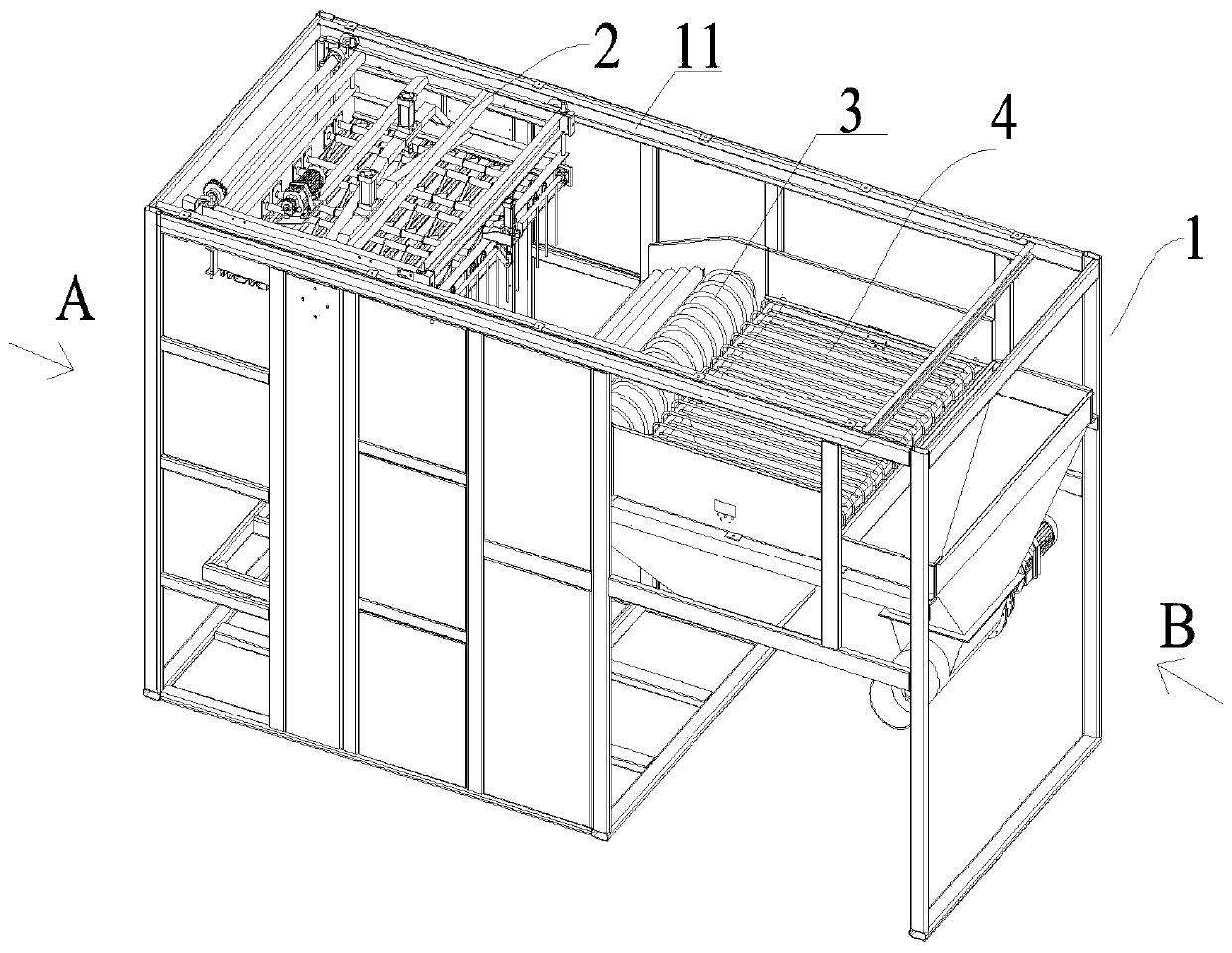

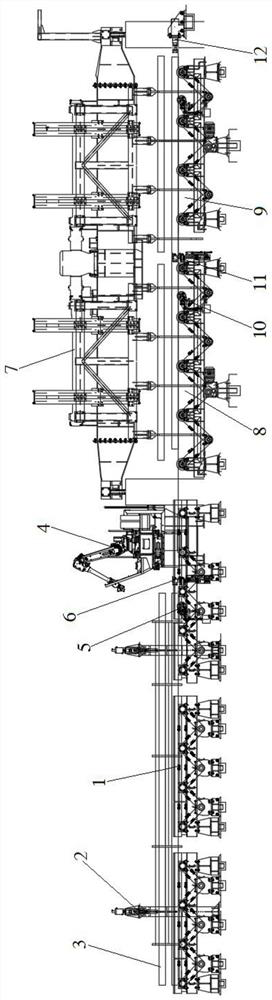

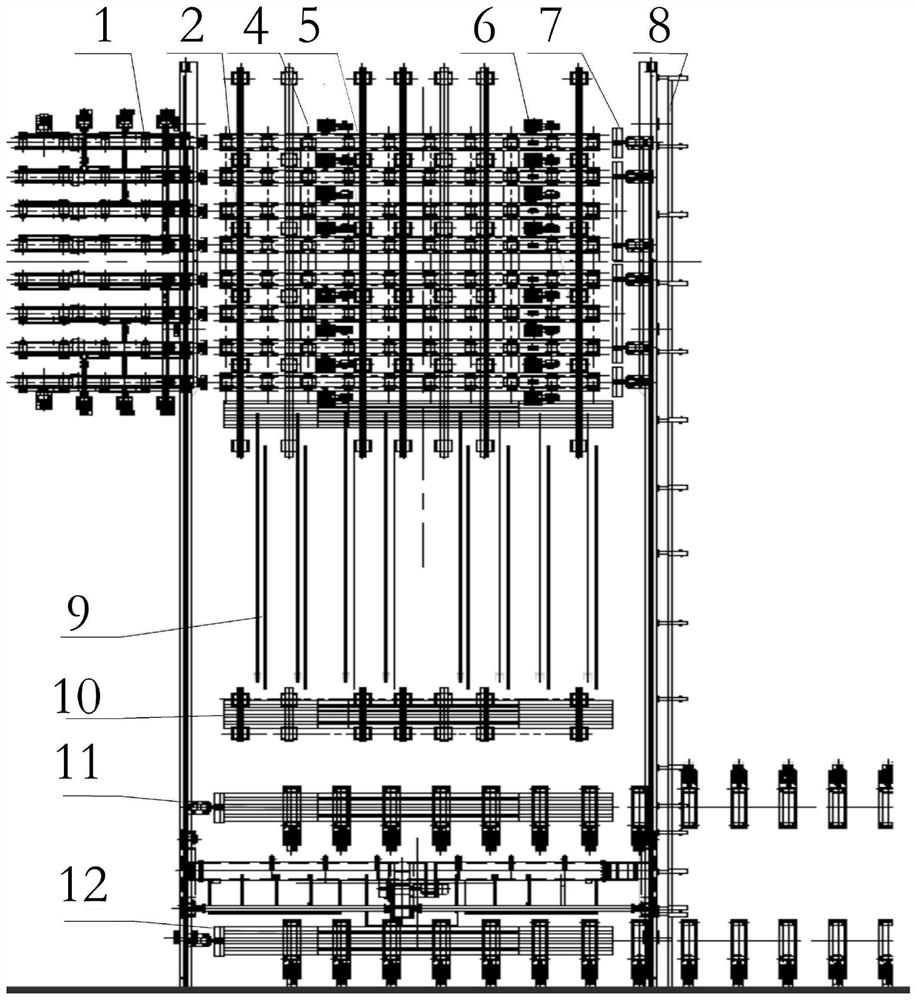

Billet ejection system and method of billet continuous casting machine

The invention belongs to the technical field of continuous casting in the metallurgical industry, and particularly provides a billet ejection system and method of a billet continuous casting machine. The billet ejection system comprises a conveying roller way, a steel moving machine, a steel moving track, a billet ejection roller way, a detection device, a trolley track, a steel fishing machine, a cold conveying roller way, a hot conveying roller way and a temporary storage device. The conveying roller way and the billet ejection roller way are sequentially arranged transversely from left to right, the steel moving track is longitudinally connected to the billet ejection roller way, the right end of the billet ejection roller way is longitudinally connected with the trolley track, the detection device is connected with the billet ejection roller way, the steel moving machine and the steel fishing machine are sequentially connected to the trolley track from back to front, and the temporary storage device, the cold conveying roller way and the hot conveying roller way are sequentially arranged in front of the steel moving rail from back to front. The problem that in the prior art, the billet ejection requirements of high pulling speed, short sizing and fast pace cannot be met is solved, billet ejection is flexible according to requirements, the billet ejection efficiency is improved, and the cold conveying rate and the hot conveying rate of casting billets are increased.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Blank holder device of tank body

The invention discloses a blank holder device of a tank body. The blank holder device comprises a working table, and a pressing device is arranged above the working table; the lower end of the pressing device is provided with a pressure head, and the side of the pressing device is provided with a cross bar connected to a supporting rod; the lower end of the supporting rod is provided with an upperwedge, and a baseplate is arranged below the upper wedge; the baseplate is provided with a sliding chute which is internally provided with a lower wedge, and the side of the wedge is provided with acircular groove which is internally provided with a casing pipe; the casing pipe is internally provided with a slidable ejector rod of which the tail part is provided with a spring II, and the springII is connected to the bottom of the casing pipe; the exterior of the casing pipe is connected to a spring I in a sleeved manner, and the spring I is fixed to the side of the lower wedge; and one endof the baseplate is provided with a stop plate which is provided with a circular hole, and the working table is further provided with three locating blocks distributed along the circumference of the pressure head. According to the blank holder device, the outer wall of the tank body is clamped through the ejector rod and the three locating blocks, and the tank body needs to be placed at the position of the locating blocks only; the operation is simple, and people can operate the blank holder device without training; the blank holder efficiency is high, and the blank holder device is applicablefor quick blank holder operation of the tank body.

Owner:ANHUI YILIANG TANK IDUSTRY TECH CO LTD

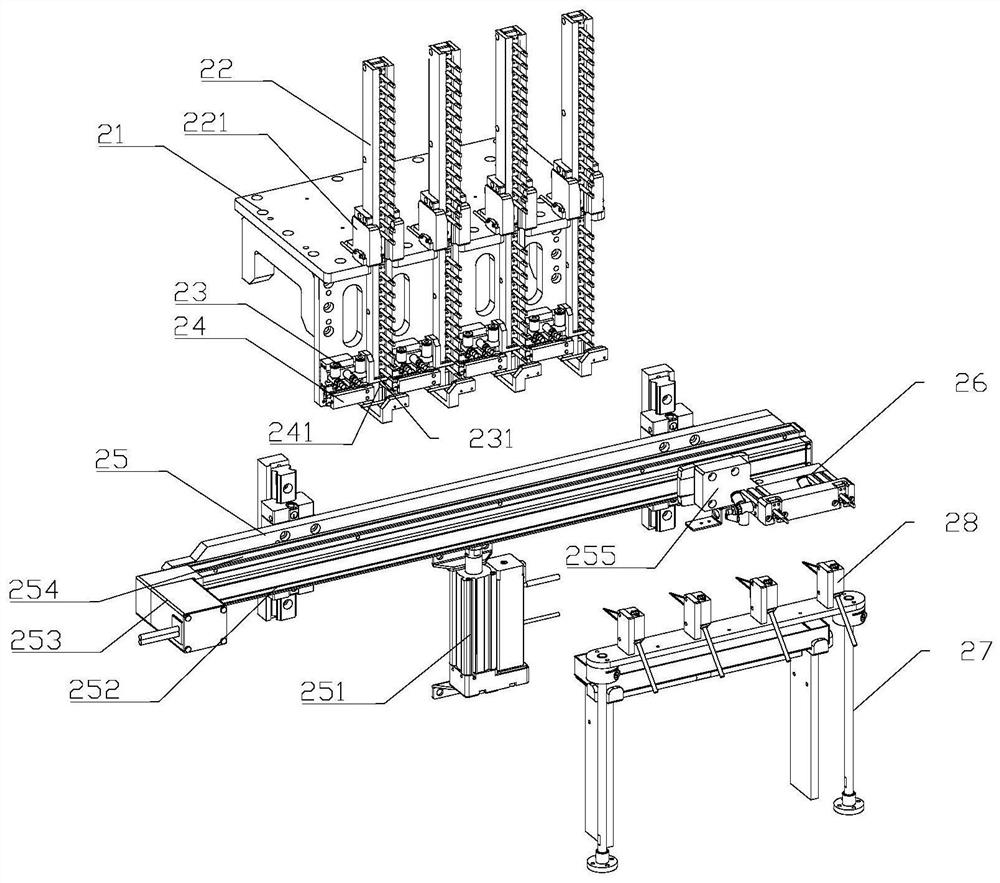

Carbon brush mounting rack feeding device and method and motor carbon brush assembling equipment

ActiveCN113319573AImprove efficiencyReduce waiting timeAssembly machinesManufacturing dynamo-electric machinesElectric machineryEngineering

The invention relates to the field of motor production, in particular to a carbon brush mounting rack feeding device and method and motor carbon brush assembling equipment. The symmetrical type carbon brush mounting rack feeding device comprises a support, a first mounting rack falling rail, a second mounting rack falling rail, upper limiting air cylinders, lower limiting air cylinders, a rotating plate, a gear motor, a rotating seat, a baffle and a telescopic air cylinder. The support is fixed to a machine frame, and the first mounting rack falling rail and the second mounting rack falling rail are both mounted on the support. The upper limiting air cylinders and the lower limiting air cylinders are arranged at the lower ends of the mounting rack falling rails. The telescopic ends of the upper limiting air cylinders and the lower limiting air cylinders are located in through grooves of the mounting rack falling rails. The rotating plate is arranged on the support, the gear motor is installed on the back side of the support, and the rotating seat is connected into the rotating plate through a bearing. A synchronizing wheel is arranged on the periphery of the rotating seat, and a synchronizing wheel is also mounted on an output shaft of the gear motor. The telescopic air cylinder is installed on the rotating plate, and the baffle is installed at the telescopic end of the telescopic air cylinder and corresponds to the lower side of a vertical channel. The carbon brush mounting rack feeding device has the advantages that feeding is efficient, overturning is convenient and fast, and a pair of carbon brushes can be produced conveniently.

Owner:WUXI KANGXIN CARBON PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com