Hook head of steel hooking machine

A technology of hook steel machine and hook head, which is applied in the field of hook head of steel hook machine, can solve the problems that are not conducive to increasing the casting speed of casting slabs, prolonging the time of billet discharge, etc., so as to reduce the number of start and stop times and acceleration and deceleration time, and improve the production efficiency. The effect of billet efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

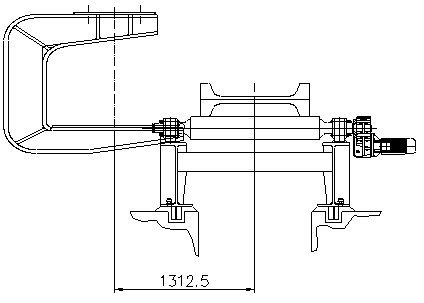

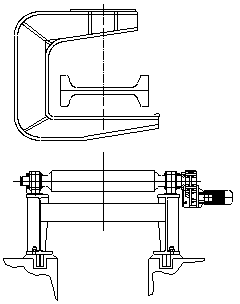

[0023] Marks in the attached drawings: 1—lifting frame; 2—blank support; 3—shaft; 4—cylindrical helical torsion spring; 5—positioning device.

[0024] The present invention will be further described below in conjunction with the accompanying drawings and implementation.

[0025] The original C-shaped hook is changed to a movable hook head that can be rotated by 90°. The hook head of the hook steel machine includes a lifting frame 1, a supporting blank plate 2, a shaft 3 and a cylindrical helical torsion spring 4. The supporting blank plate 2 and the lifting frame 1 adopt The shaft 3 is hinged, and the cylindrical helical torsion spring 4 is installed on the movable shaft 3. When the cylindrical helical torsion spring 4 is in normal state, the support blank plate 2 and the lifting frame 1 are in a vertical state (90 degrees), and the back of the support blank plate encounters resistance. The slab moves closer to the lifting frame.

[0026] During the normal state, that is, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com