Gantry type bagged cement unmanned truck loading device

A gantry type, cement technology, applied in the directions of loading/unloading, transportation and packaging, stacking of objects, etc., can solve the problems of certain requirements for the smoothness of the road surface of the running line, shutdown of enterprises, poor popularity, etc., to enhance practicability And the effect of application scope, blanking efficiency improvement, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

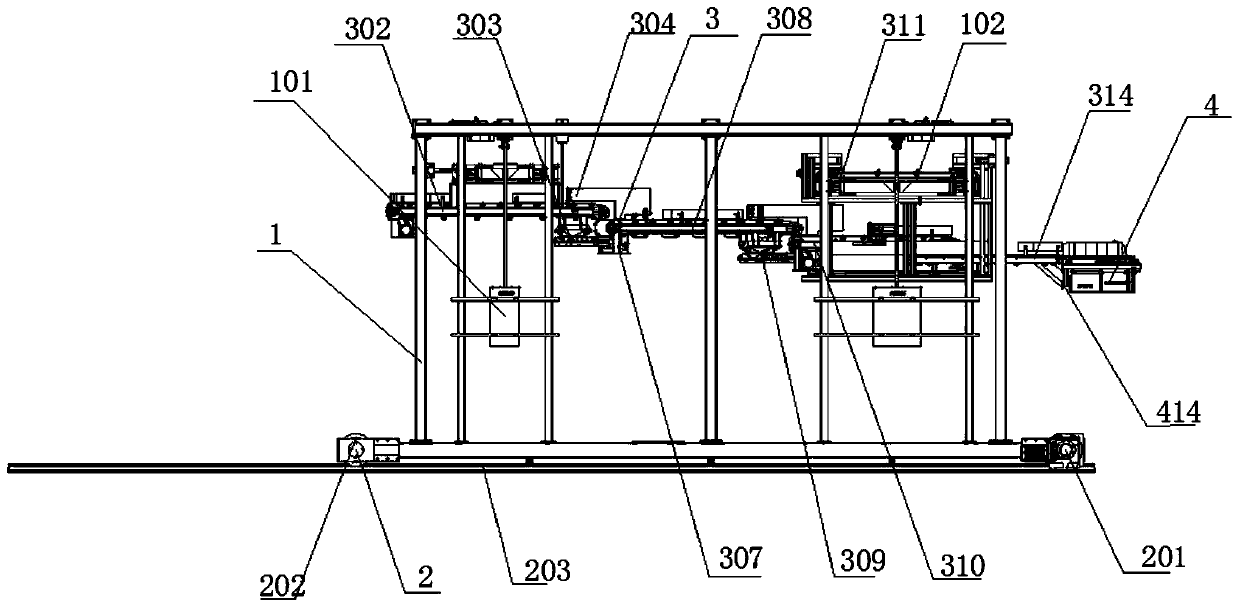

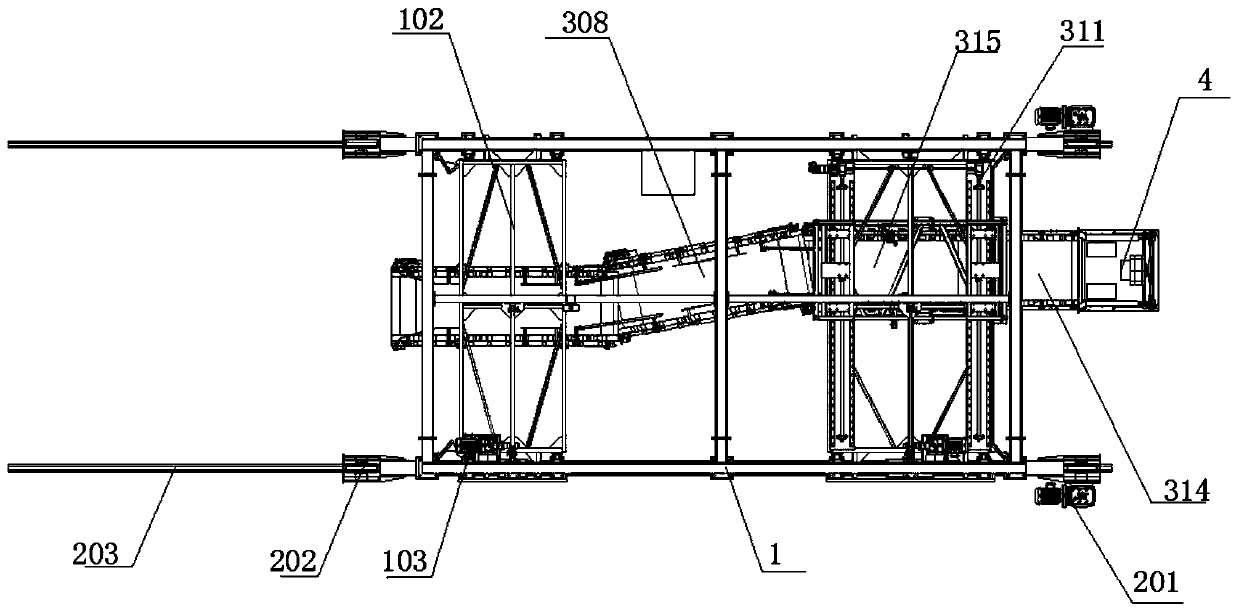

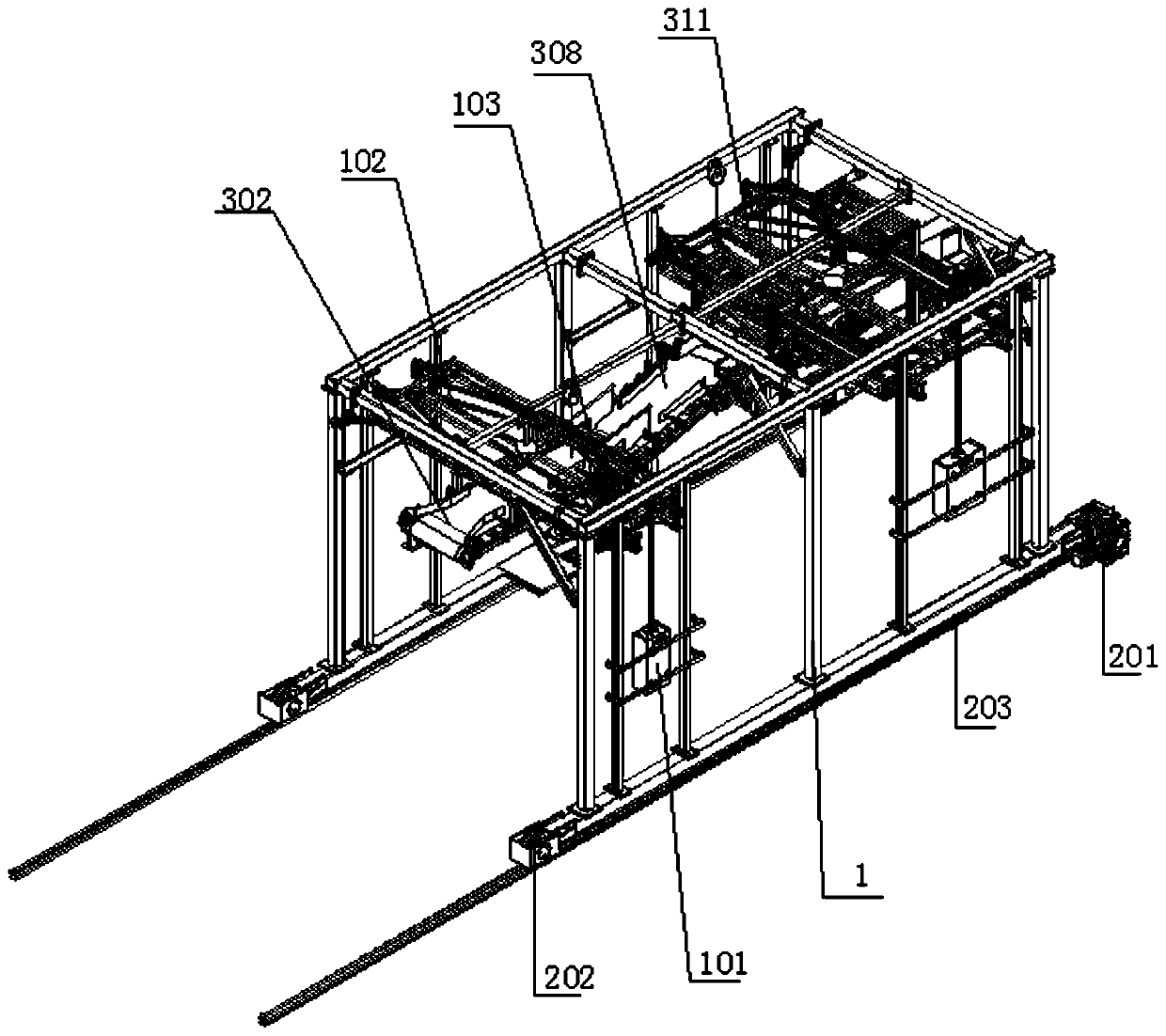

[0037] like Figure 1-Figure 7 As shown, an embodiment of the gantry-type bagged cement unmanned loading equipment provided by the present invention includes a gantry 1, a flexible transmission mechanism 3, a manipulator 4 and an electrical system.

[0038] The gantry 1 is connected with a lifting mechanism, the lifting mechanism can move up and down along the gantry 1, the lifting mechanism is fixedly connected with the flexible transmission mechanism 3, the feeding end of the flexible transmission mechanism 3 is fixedly connected with the lifting mechanism, and the flexible transmission mechanism 3 can move along the lifting mechanism. Moving in the width direction, the discharge end of the flexible transmission mechanism 3 is fixedly connected with the manipulator 4 .

[0039] In this embodiment, a powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com