Patents

Literature

66 results about "Compensating movements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

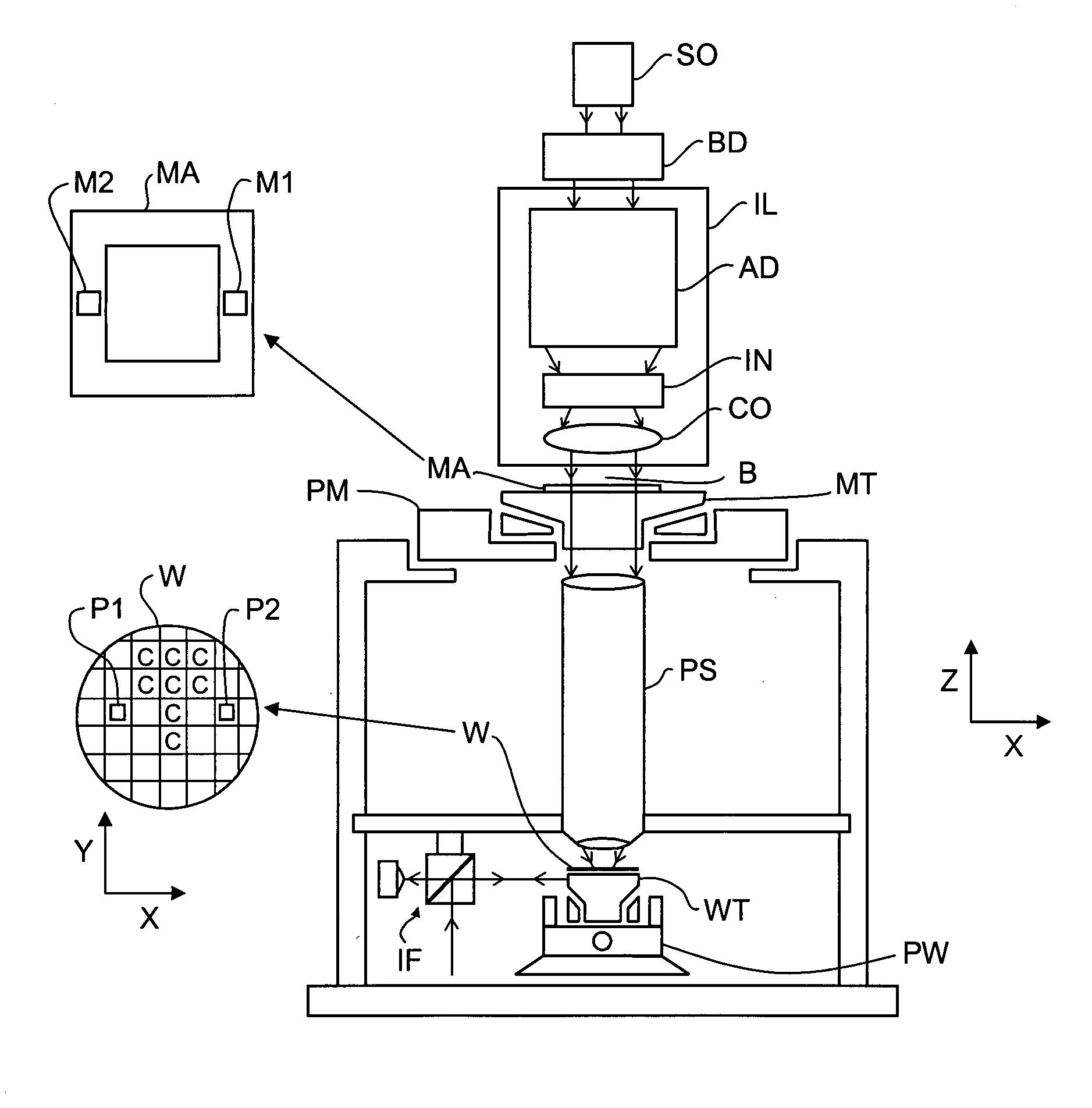

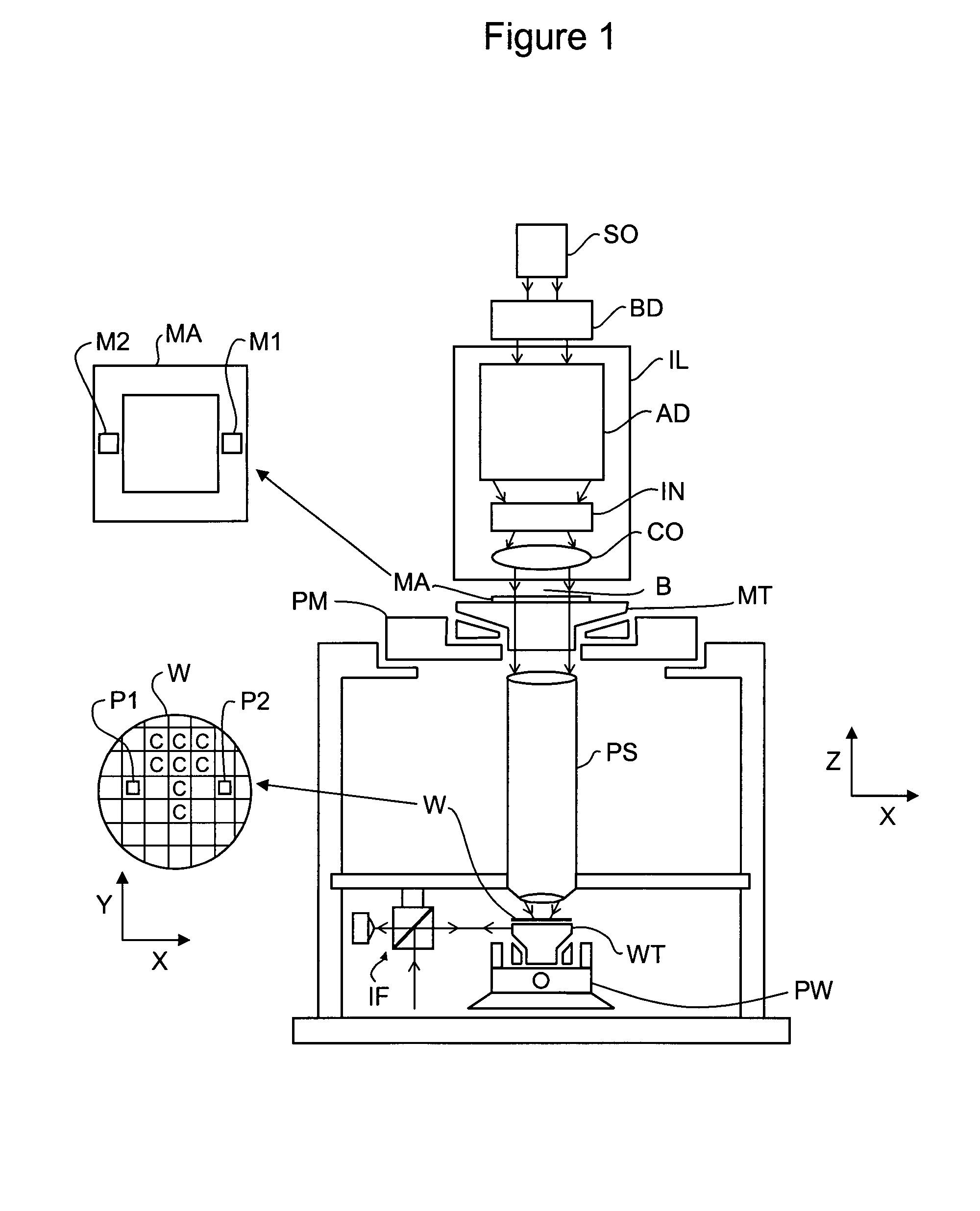

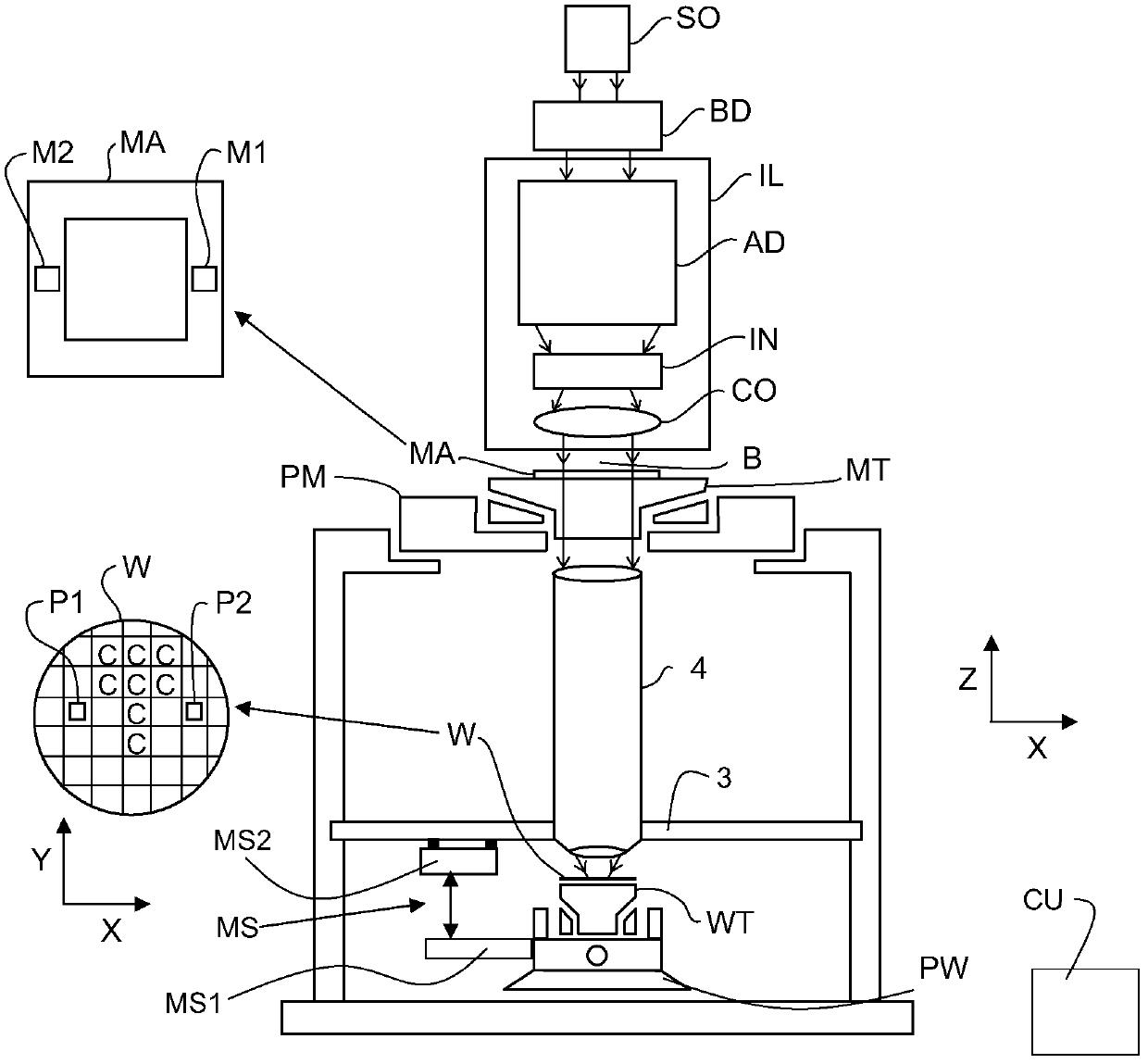

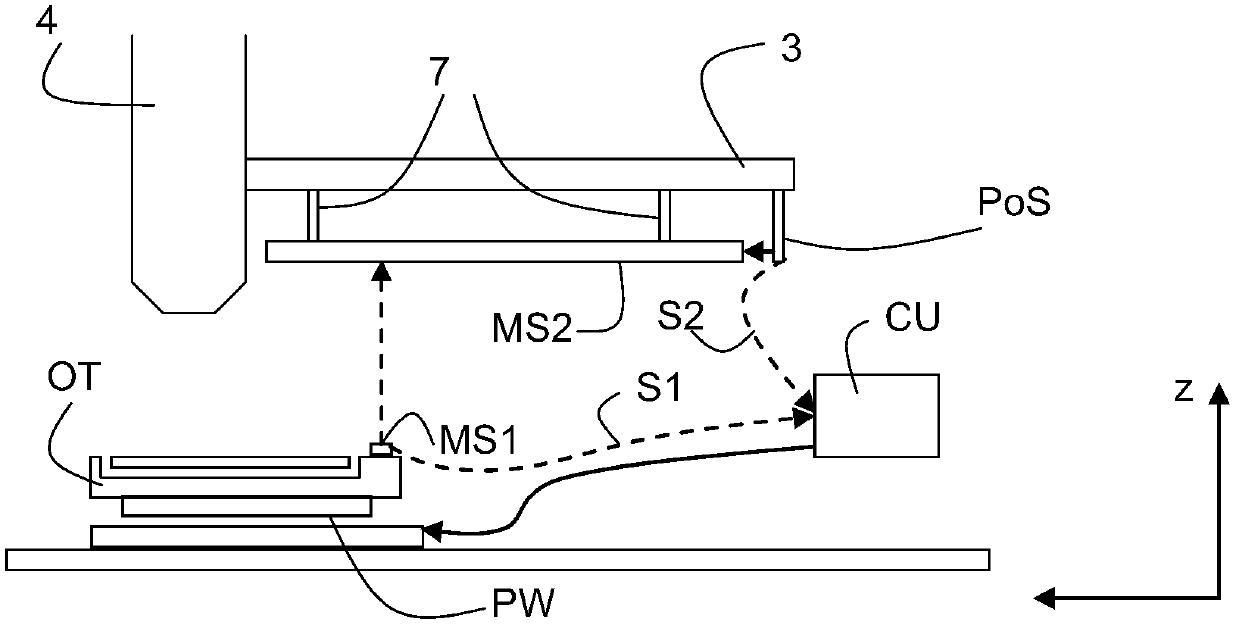

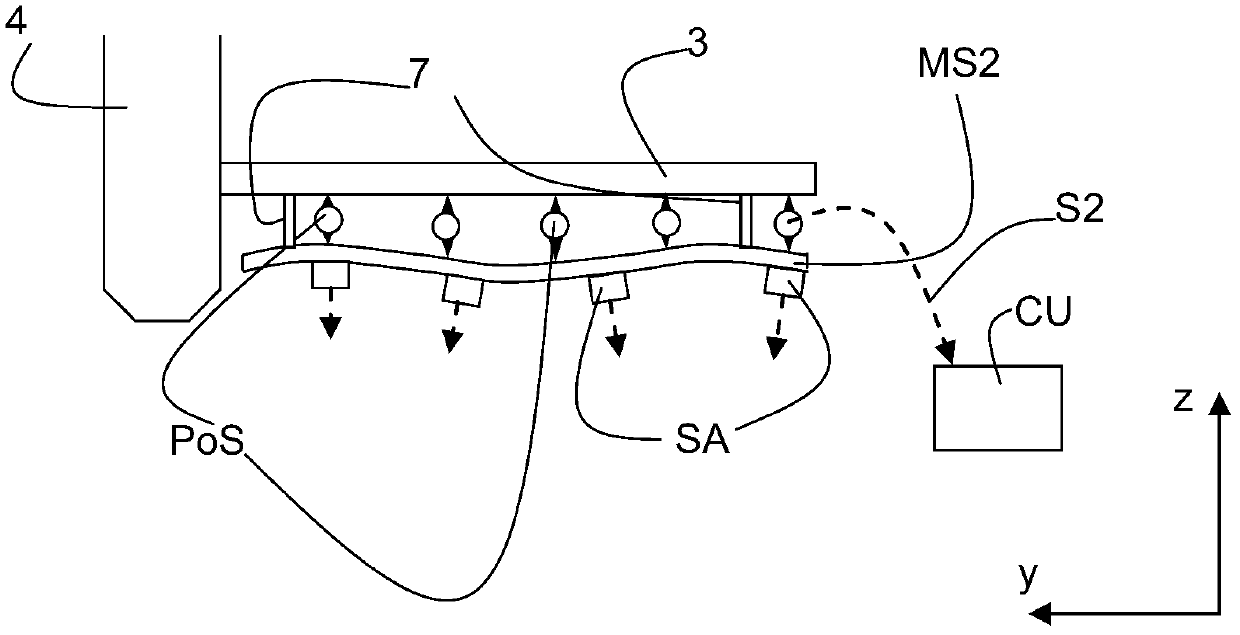

Measurement system, lithographic apparatus and method for measuring a position dependent signal of a movable object

ActiveUS20080240501A1Improve accuracyLow accuracySemiconductor/solid-state device testing/measurementPhotomechanical apparatusPosition dependentCompensating movements

An encoder-type measurement system is configured to measure a position dependent signal of a movable object, the measurement system including at least one sensor mountable on the movable object a sensor target object mountable on a substantially stationary frame, and a mounting device configured to mount the sensor target object on the substantially stationary frame. The measurement system further includes a compensation device configured to compensate movements and / or deformations of the sensor target object with respect to the substantially stationary frame. The compensation device may include a passive or an active damping device and / or a feedback position control system. In an alternative embodiment, the compensation device includes a gripping device which fixes the position of the sensor target object during a high accuracy movement of the movable object.

Owner:ASML NETHERLANDS BV

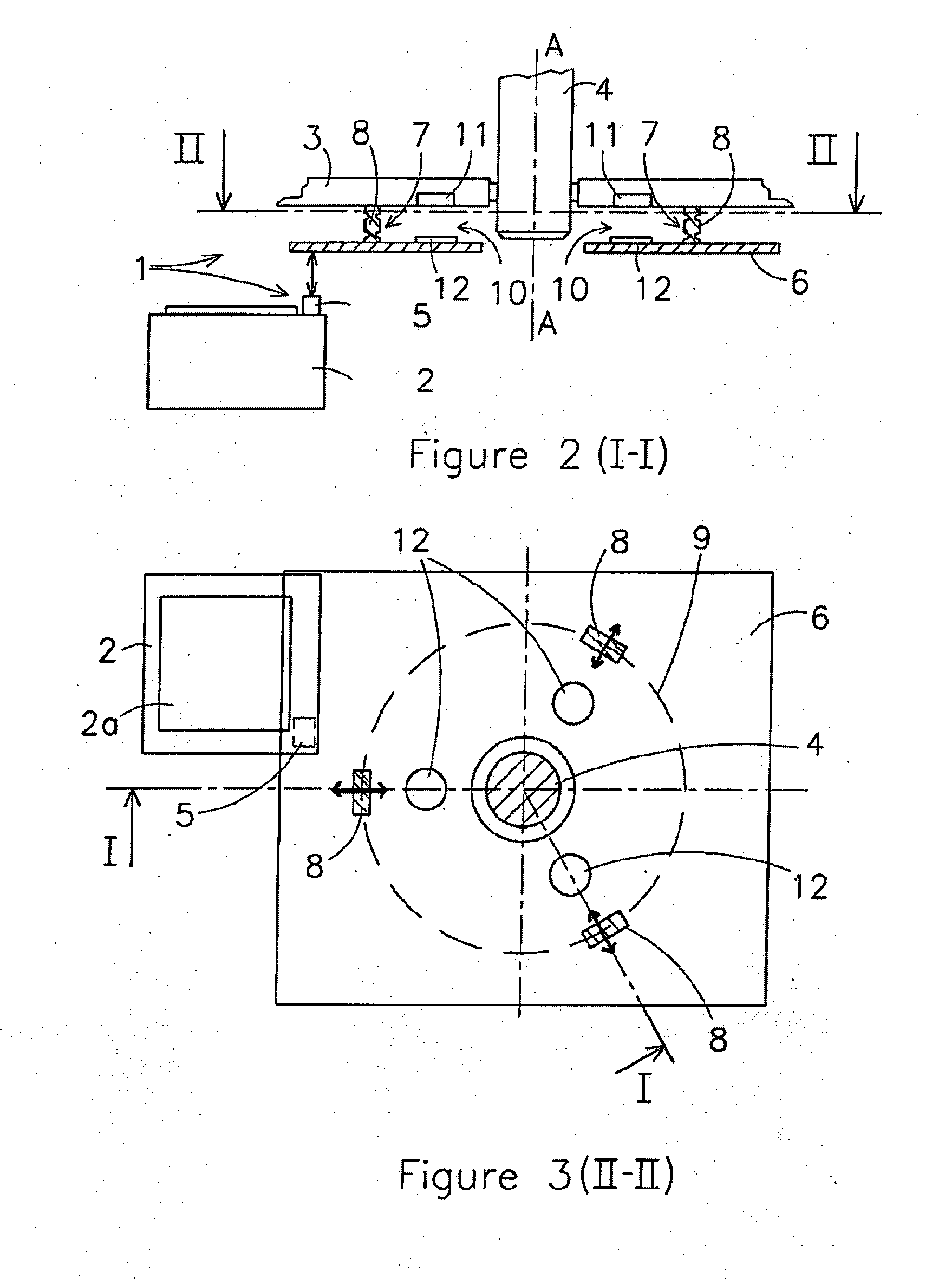

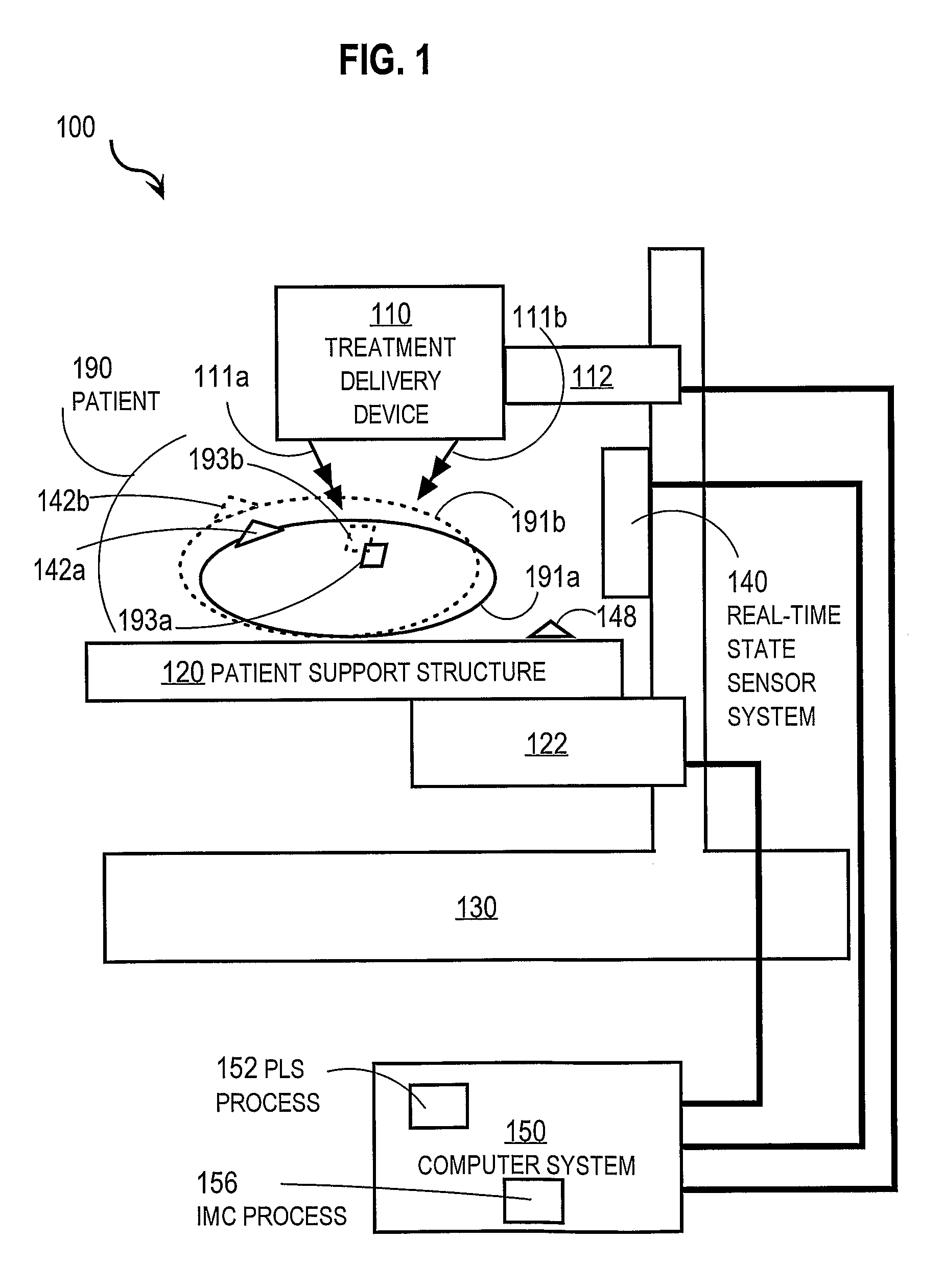

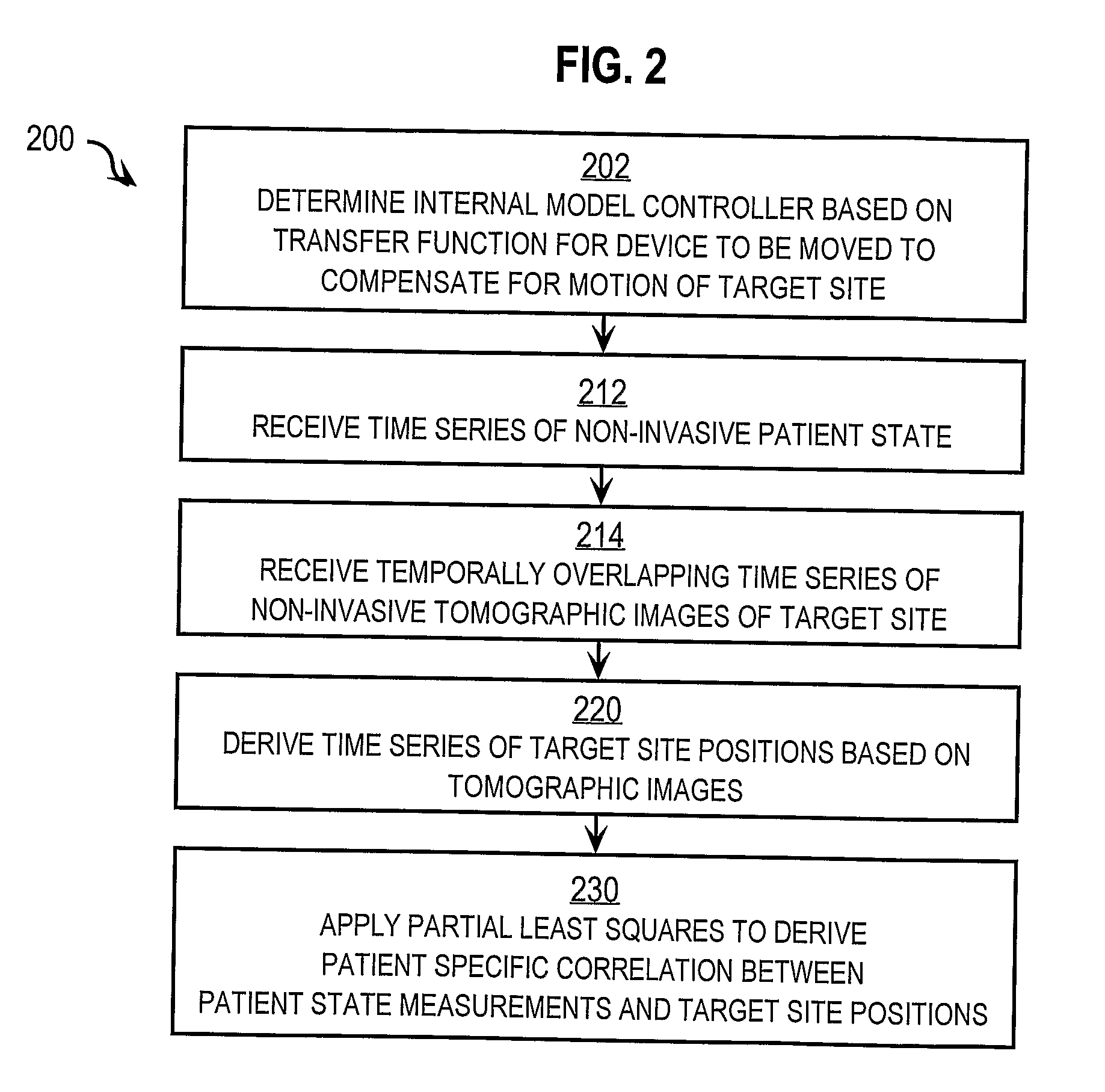

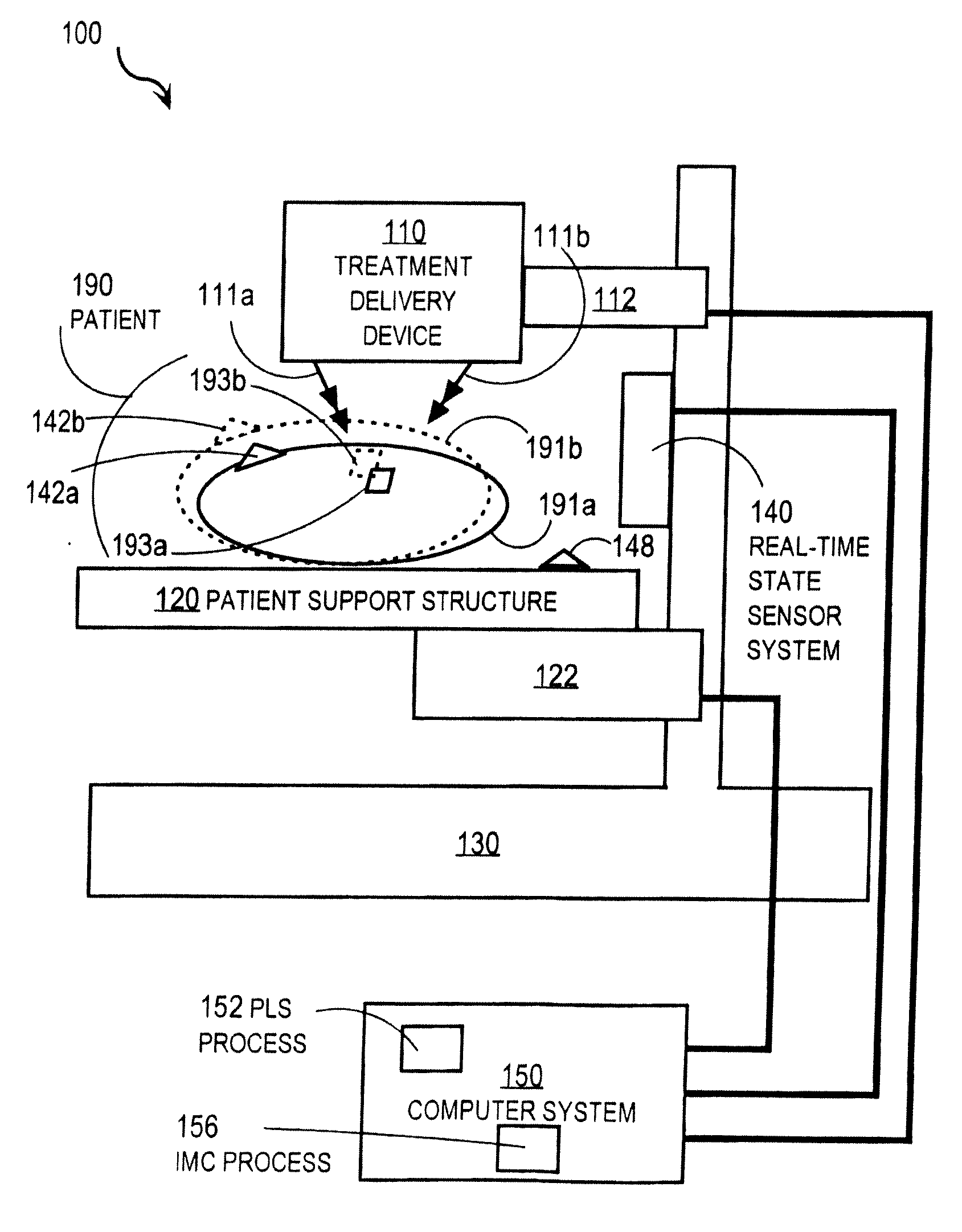

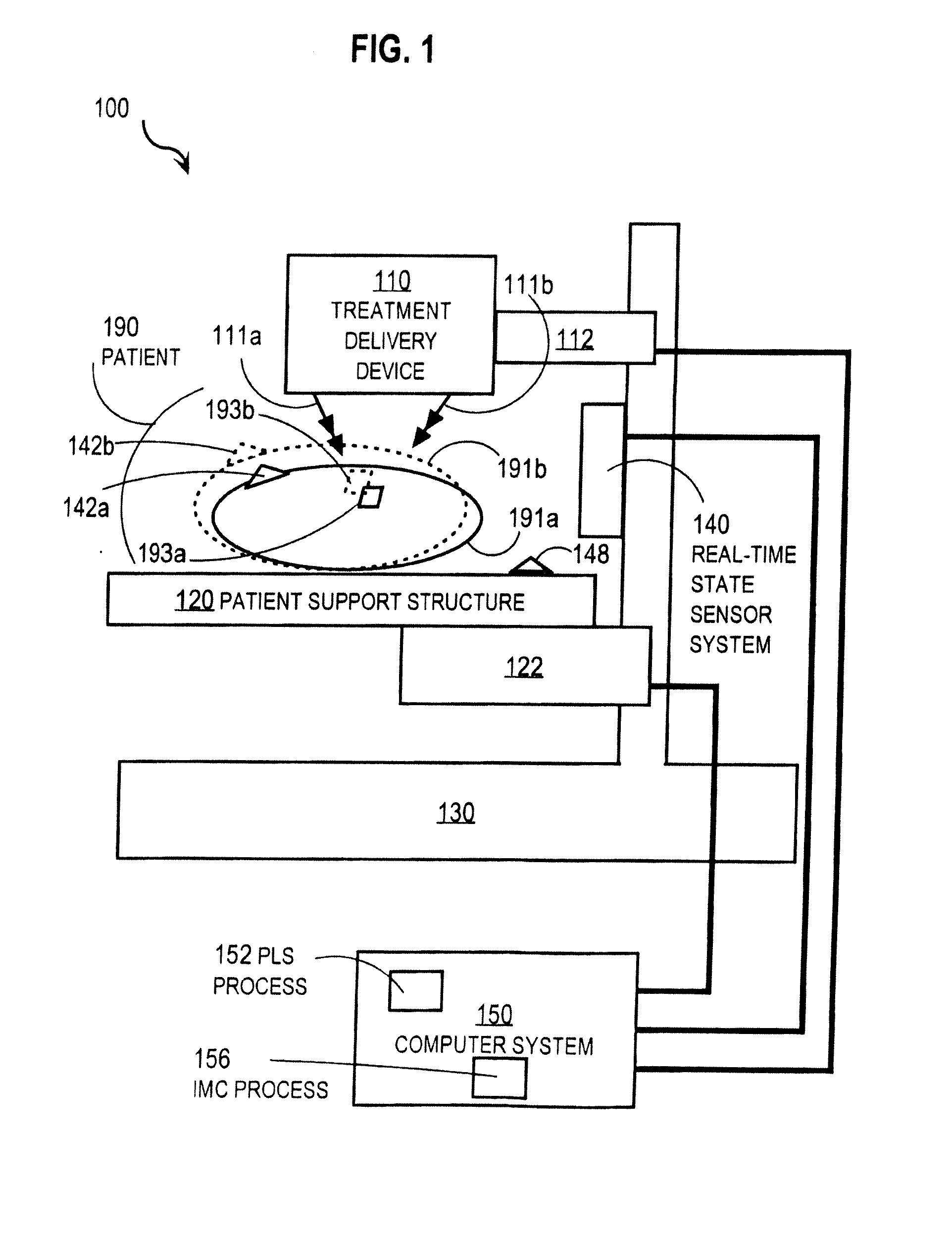

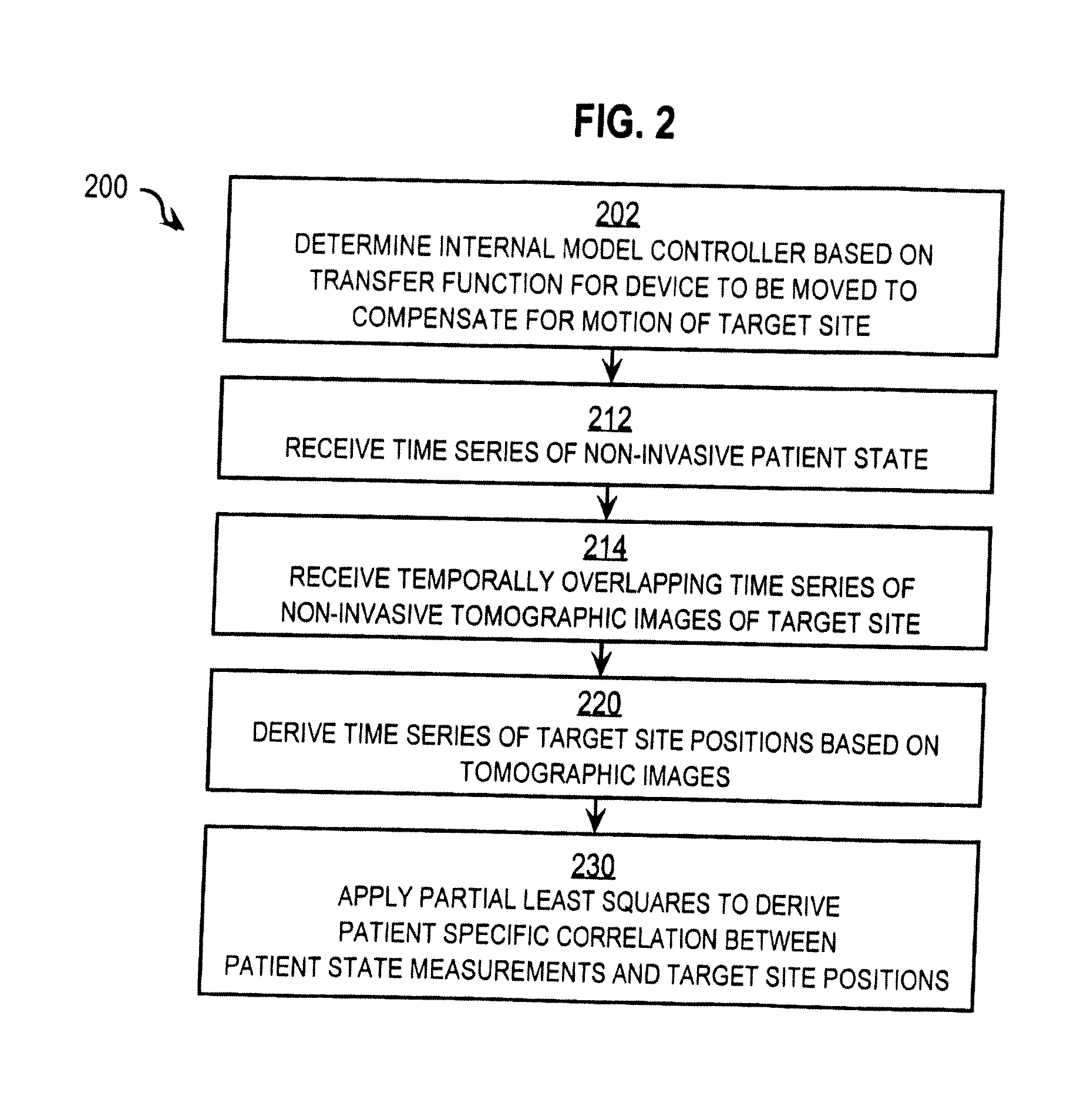

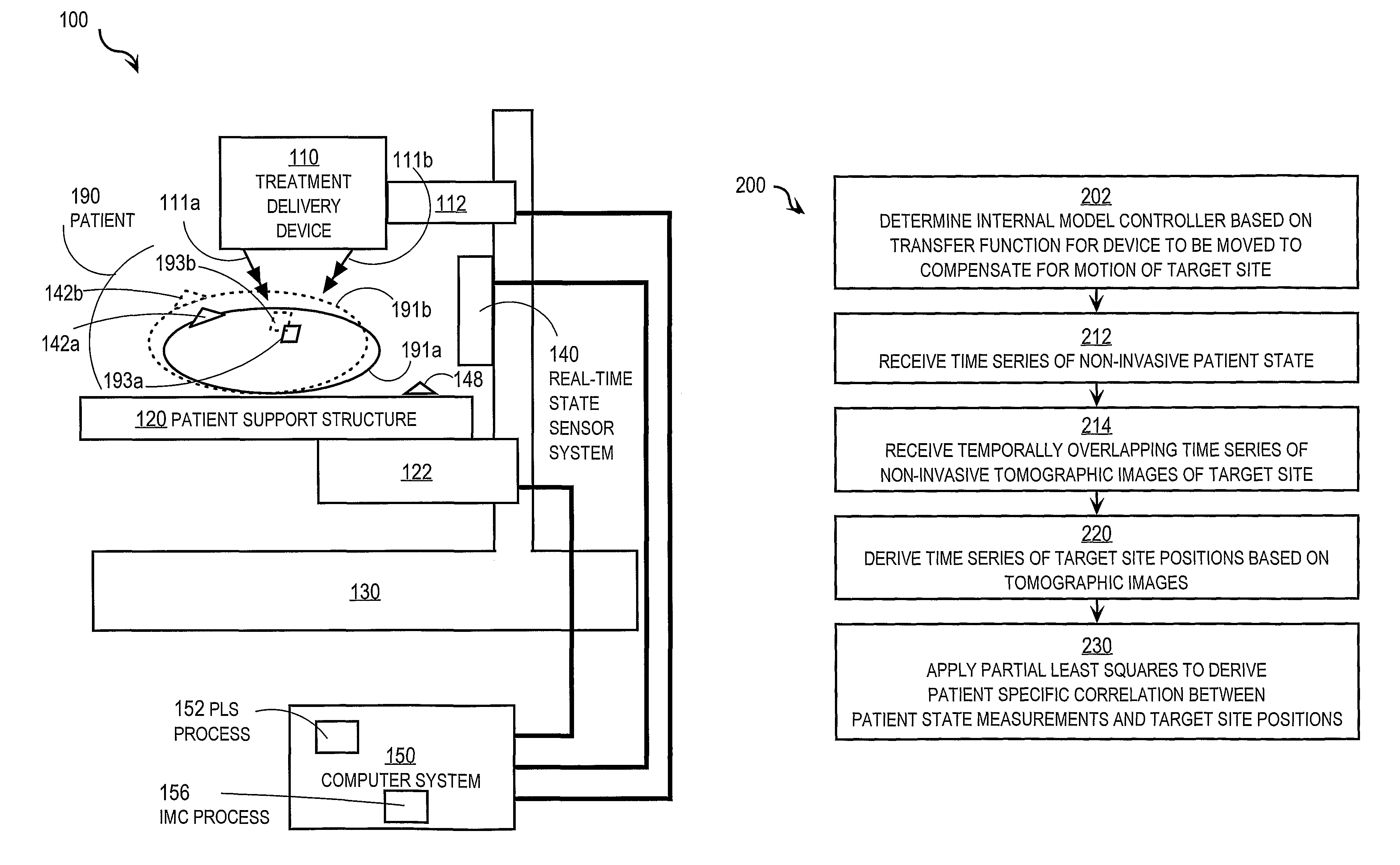

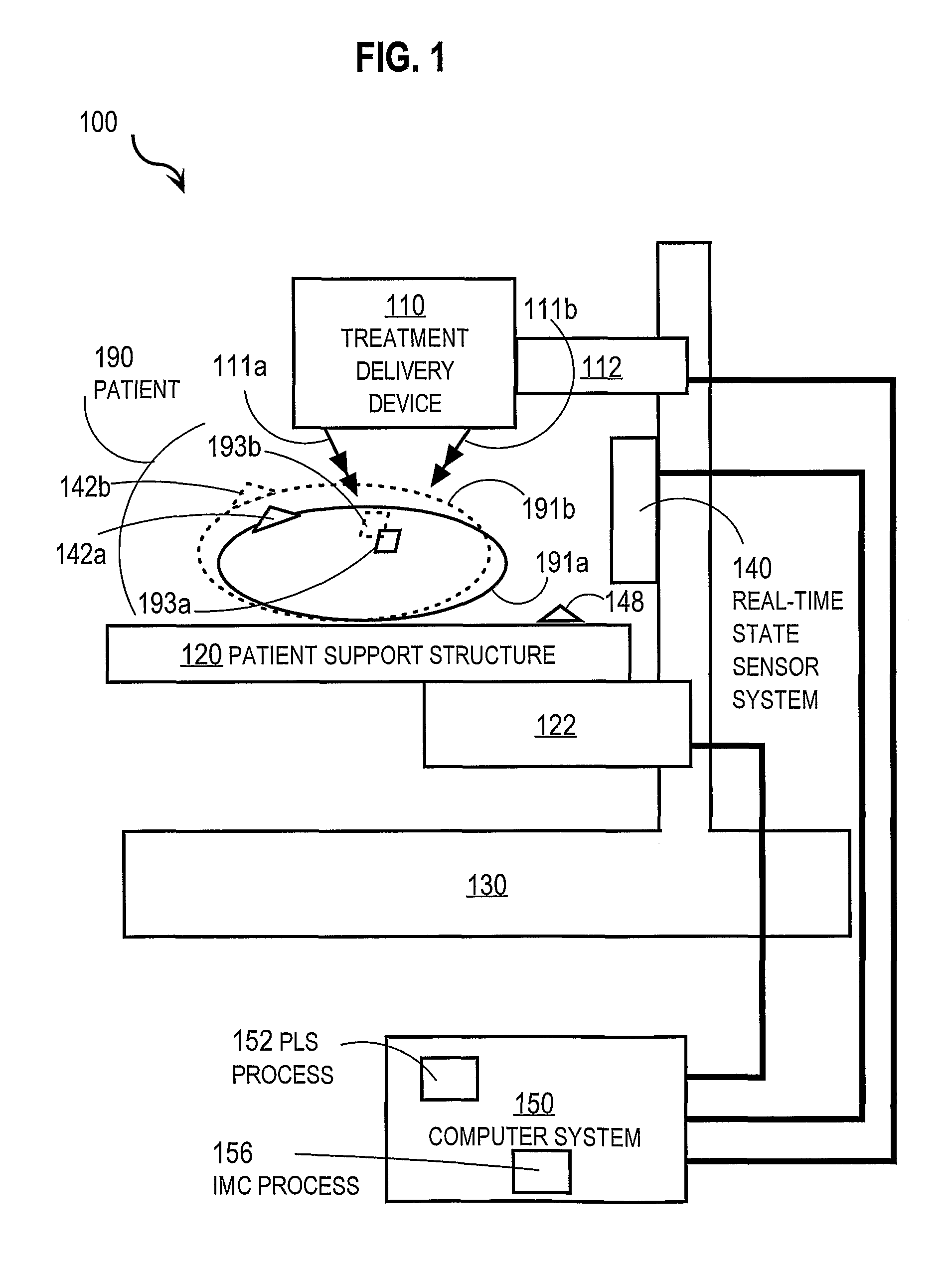

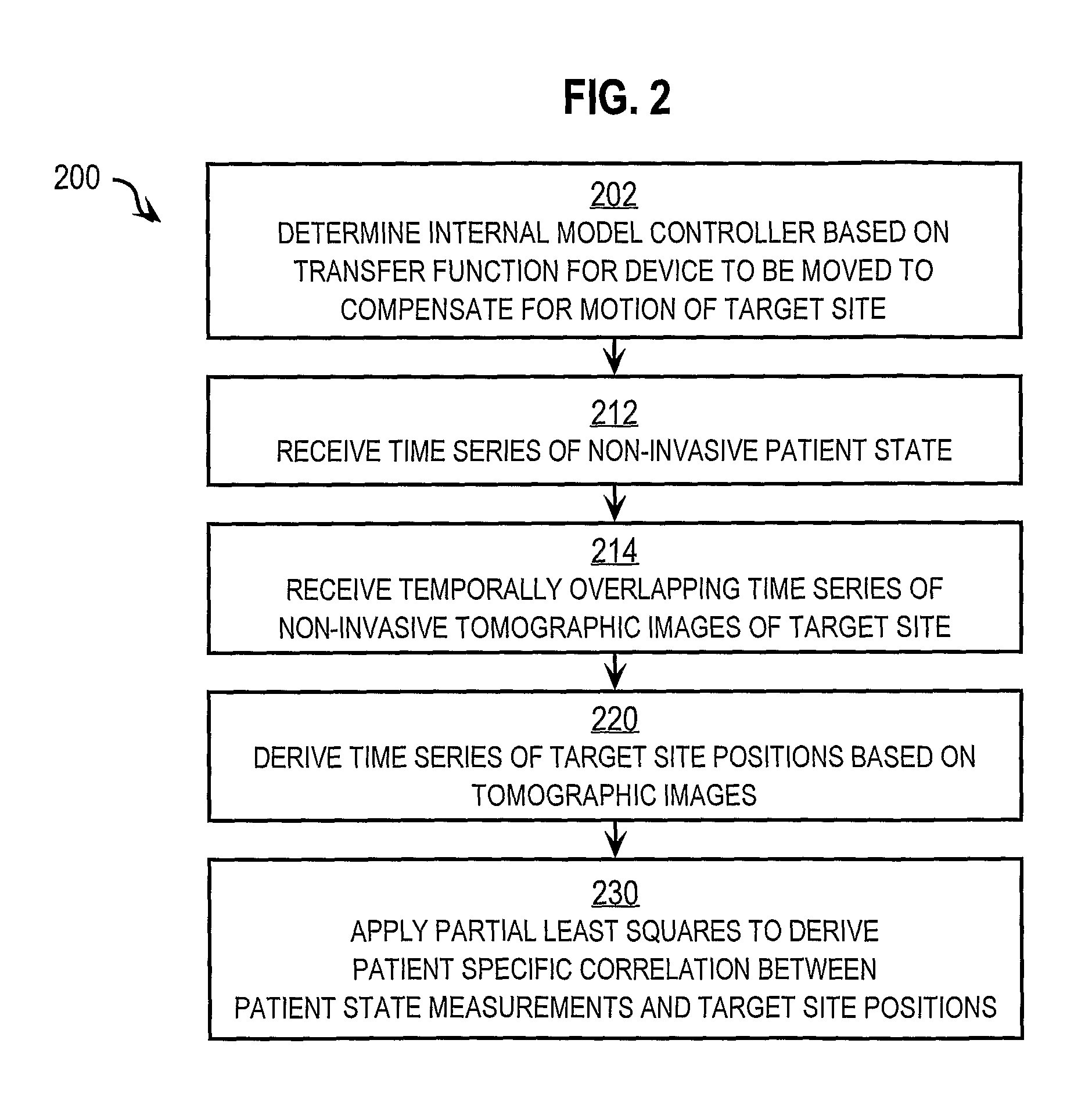

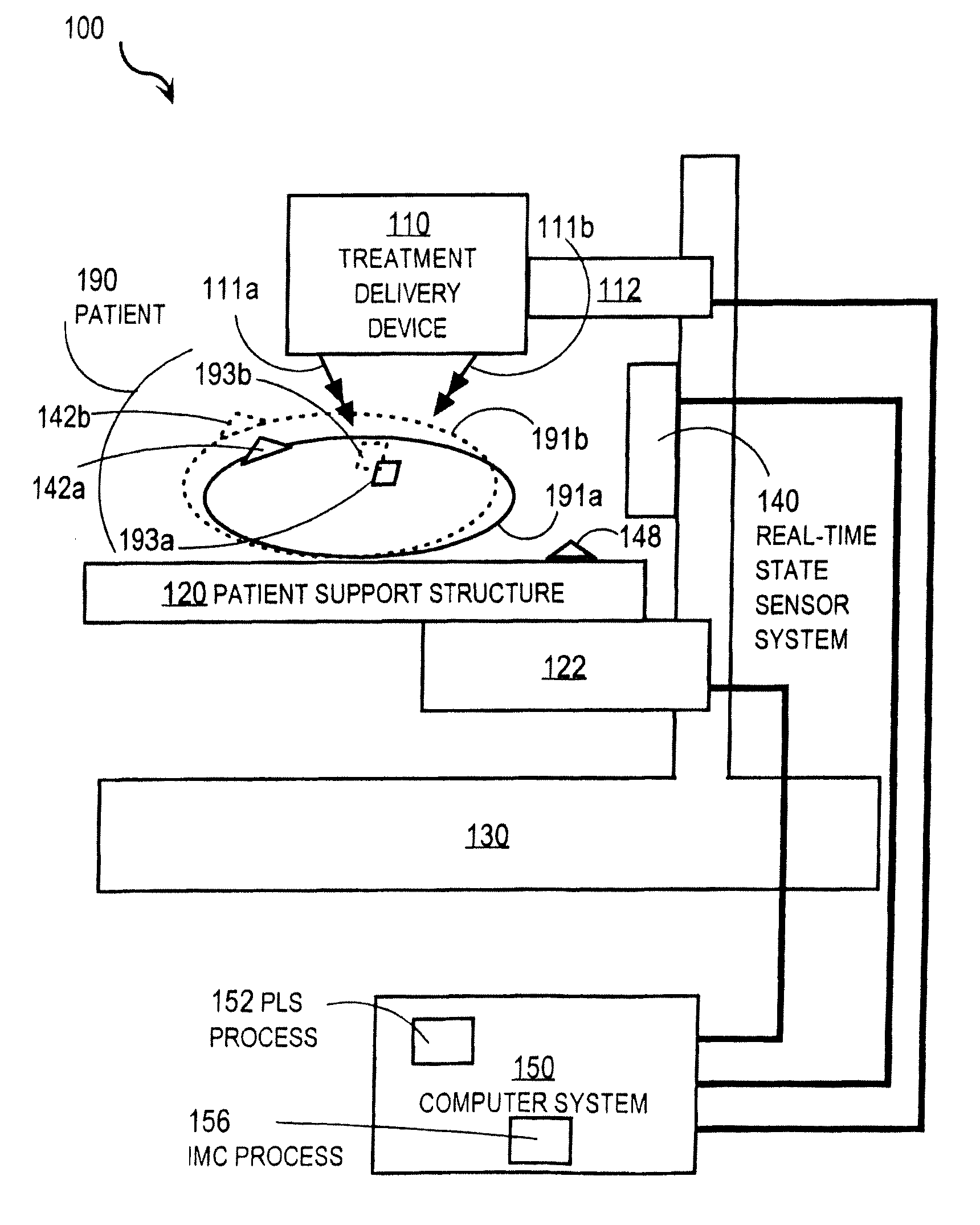

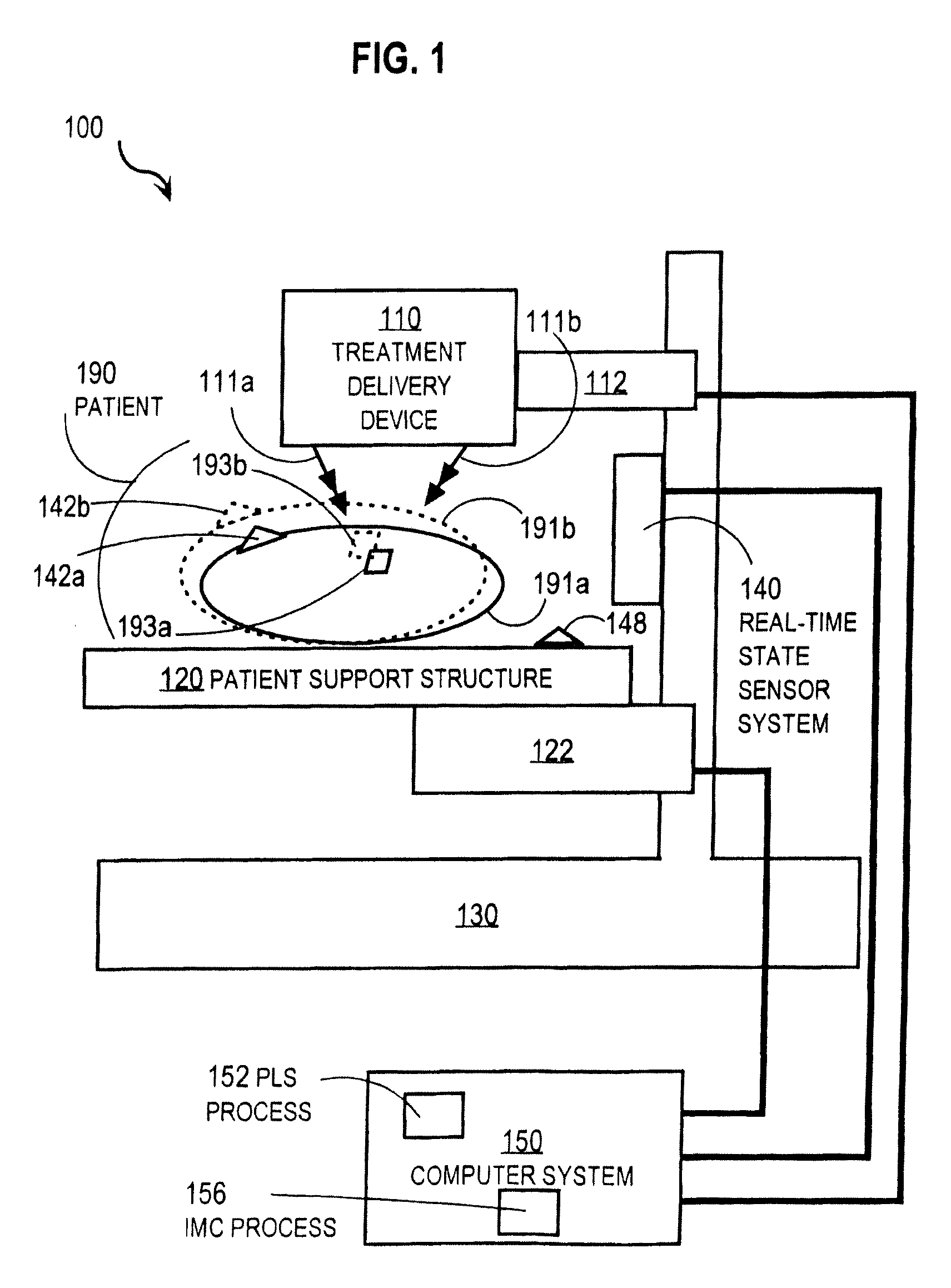

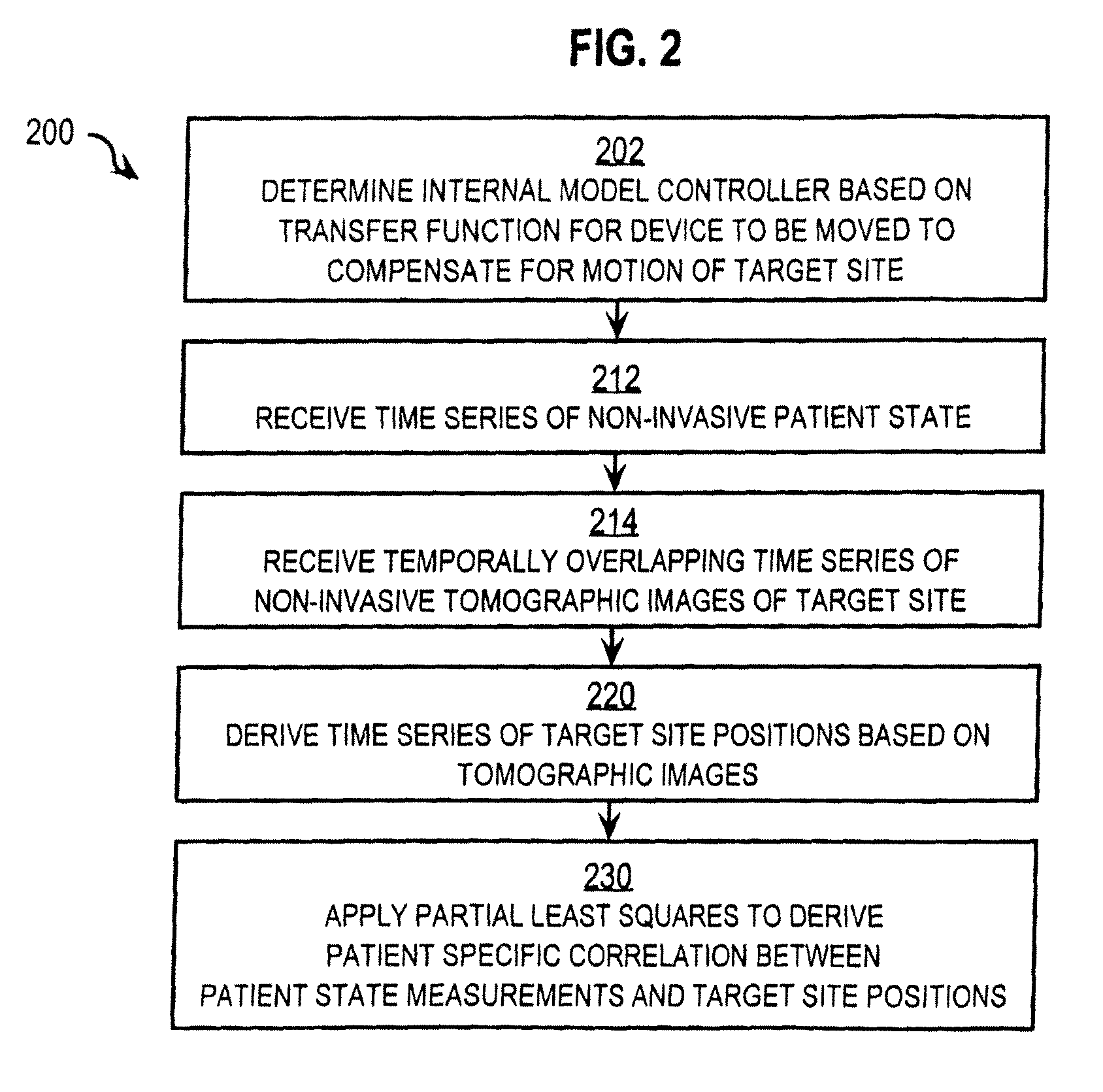

Techniques For Compensating Movement of a Treatment Target in a Patient

ActiveUS20080212737A1Reduce deliveryConvenient treatmentDiagnostic recording/measuringSensorsTreatment deliveryMedicine

Techniques for improving treatment delivered to a target site in a patient include delivering a treatment from a treatment delivery device to a target site in a patient supported by a patient support structure. During the delivery of treatment, a state of the patient is measured to produce real-time measurement data. Measuring the state is non-invasive; and the measured state is a correlated surrogate for position of the target site. Compensating movement data is determined based on the real-time measurement data to cause the target site to maintain a particular spatial relationship with the treatment delivery device. Either the treatment delivery device, or the support structure, or both, are moved based on the compensating movement data. When the delivery device alone is moved, the correlation between measured state and target site is based on partial least squares applied to pre-treatment measurements of both.

Owner:UNIV OF MARYLAND +1

Techniques for compensating movement of a treatment target in a patient

InactiveUS20120004518A1Reduce deliveryConvenient treatmentHealth-index calculationDiagnostic recording/measuringTreatment targetsCompensating movements

One embodiment includes a method of predicting a position of a target site inside a body using surrogates is provided. The method includes transforming surrogate measurements and target positions into different representations by applying an operator, establishing a special relationship between the transformed surrogate measurements and the transformed target positions, and continuously predicting the target position from the transformed surrogate measurements and the established special relationship.

Owner:UNIV OF MARYLAND

Techniques for compensating movement of a treatment target in a patient

ActiveUS8042209B2Convenient treatmentReduce deliveryDiagnostic recording/measuringSensorsTreatment deliveryMedicine

Techniques for improving treatment delivered to a target site in a patient include delivering a treatment from a treatment delivery device to a target site in a patient supported by a patient support structure. During the delivery of treatment, a state of the patient is measured to produce real-time measurement data. Measuring the state is non-invasive; and the measured state is a correlated surrogate for position of the target site. Compensating movement data is determined based on the real-time measurement data to cause the target site to maintain a particular spatial relationship with the treatment delivery device. Either the treatment delivery device, or the support structure, or both, are moved based on the compensating movement data. When the delivery device alone is moved, the correlation between measured state and target site is based on partial least squares applied to pre-treatment measurements of both.

Owner:UNIV OF MARYLAND BALTIMORE +2

Techniques for compensating movement of a treatment target in a patient

InactiveUS8747382B2Convenient treatmentReduce deliveryHealth-index calculationMedical devicesTreatment targetsCompensating movements

One embodiment includes a method of predicting a position of a target site inside a body using surrogates is provided. The method includes transforming surrogate measurements and target positions into different representations by applying an operator, establishing a special relationship between the transformed surrogate measurements and the transformed target positions, and continuously predicting the target position from the transformed surrogate measurements and the established special relationship.

Owner:UNIV OF MARYLAND BALTIMORE +1

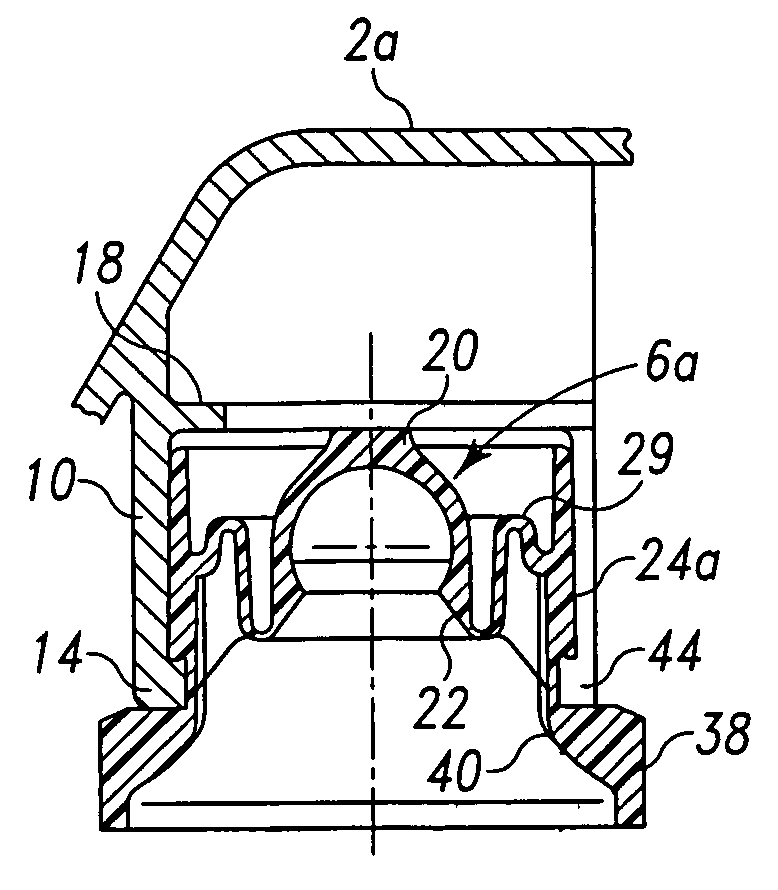

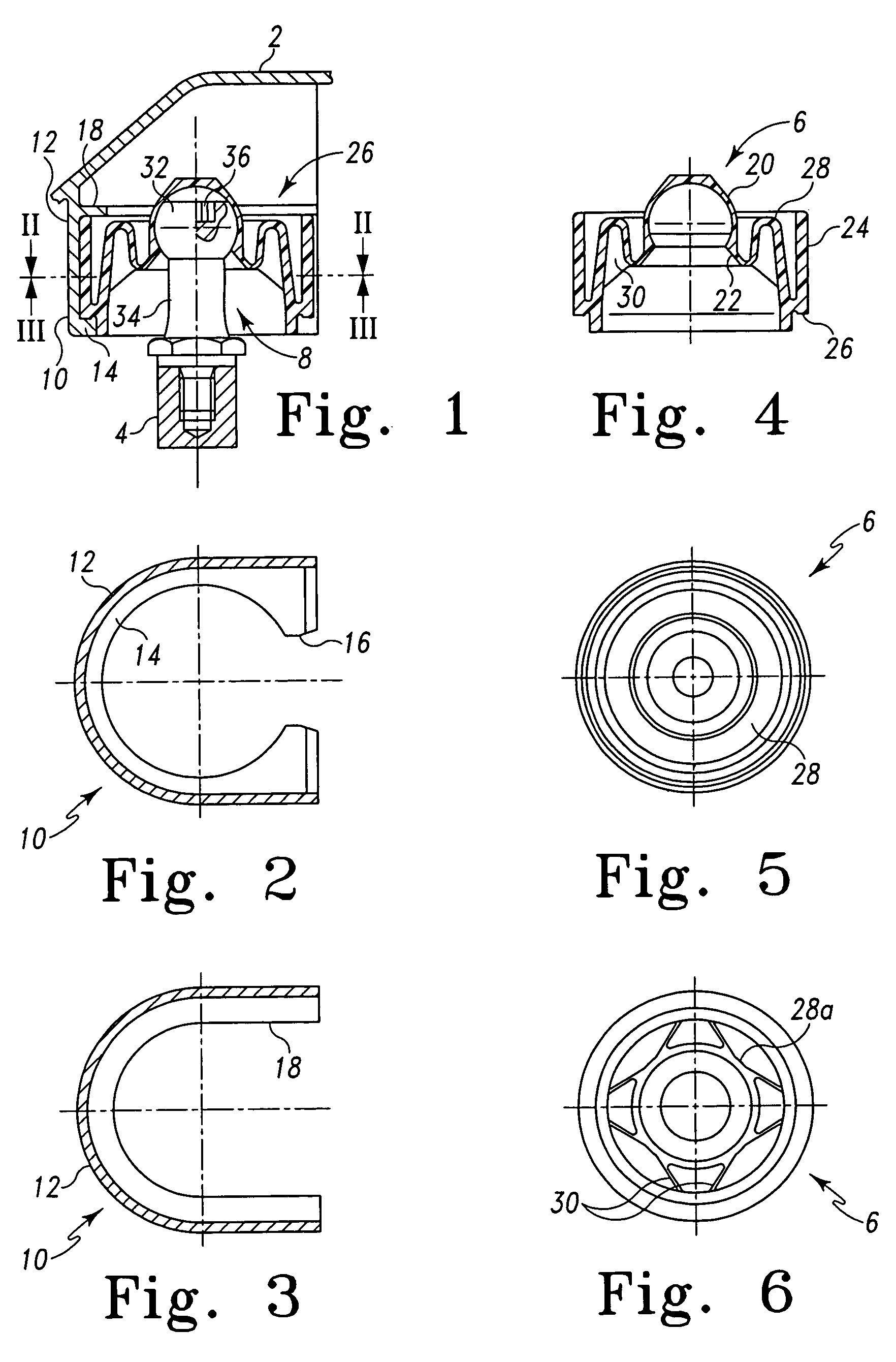

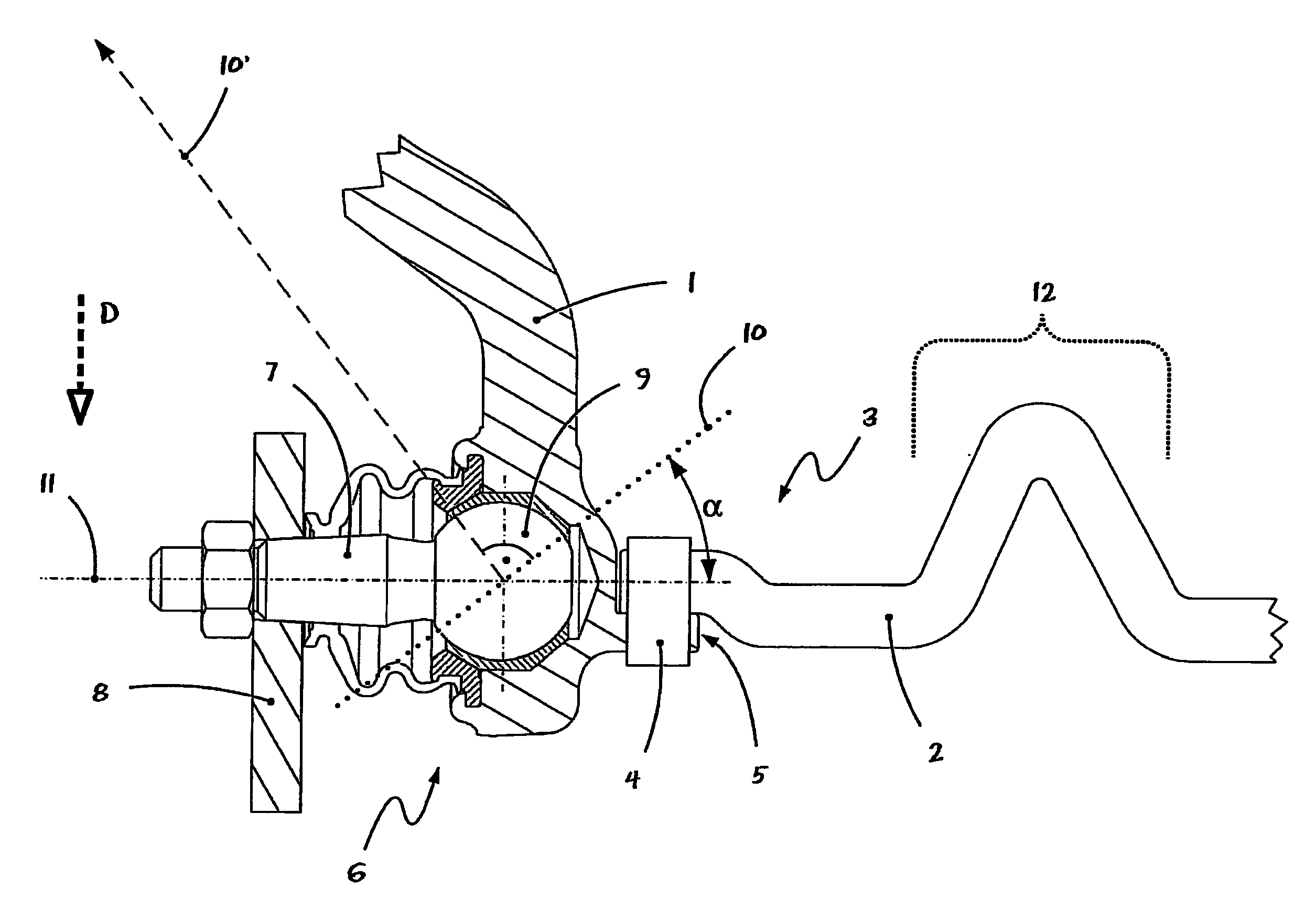

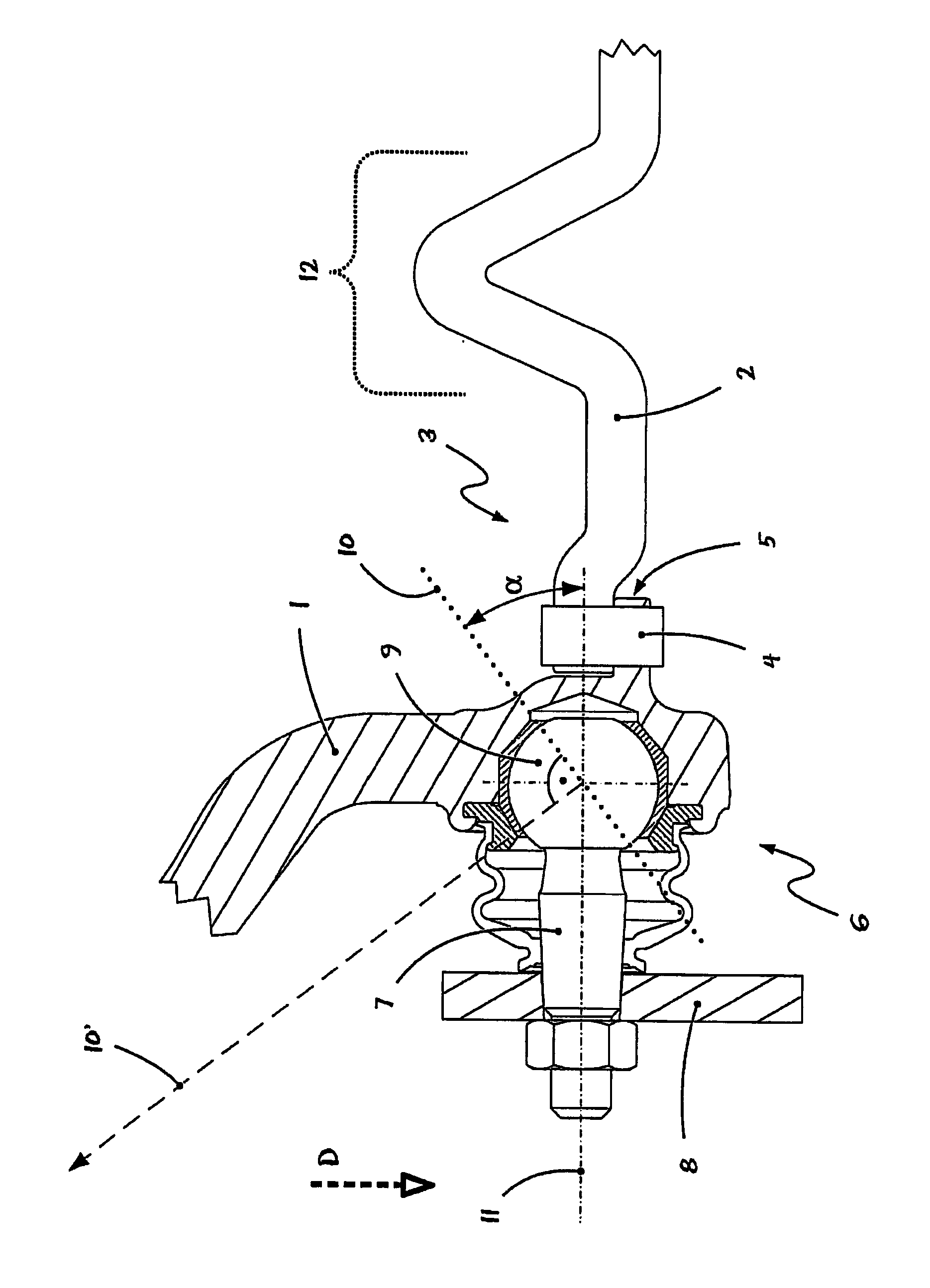

Plug-in coupling allowing for compensating movements

ActiveUS7168879B2Good chemical resistanceIncreased resistance thermal dimensionalSnap-action fastenersEngine sealsCouplingEngineering

A plug-in coupling for removably interconnecting a first structural member and a second structural member comprises a resiliently deformable female coupling part adapted to be inserted into a socket at the first structural member such that it is retained therein. The female coupling part comprises a ball-shaped cup, an intermediate annular wall integral with said ball-shaped cup and serving as a guide portion, and a tubular external wall integral with said annular intermediate wall. The external wall surrounds at least a part of the ball-shaped cup in spaced relation thereto and engages a peripheral wall of the socket when the female coupling part is inserted into the socket. A male coupling part comprises a ball-shaped head and a fixing portion for securing the male coupling part to the second structural member. The intermediate annular wall of the female coupling part is of an undulated shape at least in a certain area thereof.

Owner:BOLLHOFF GMBH

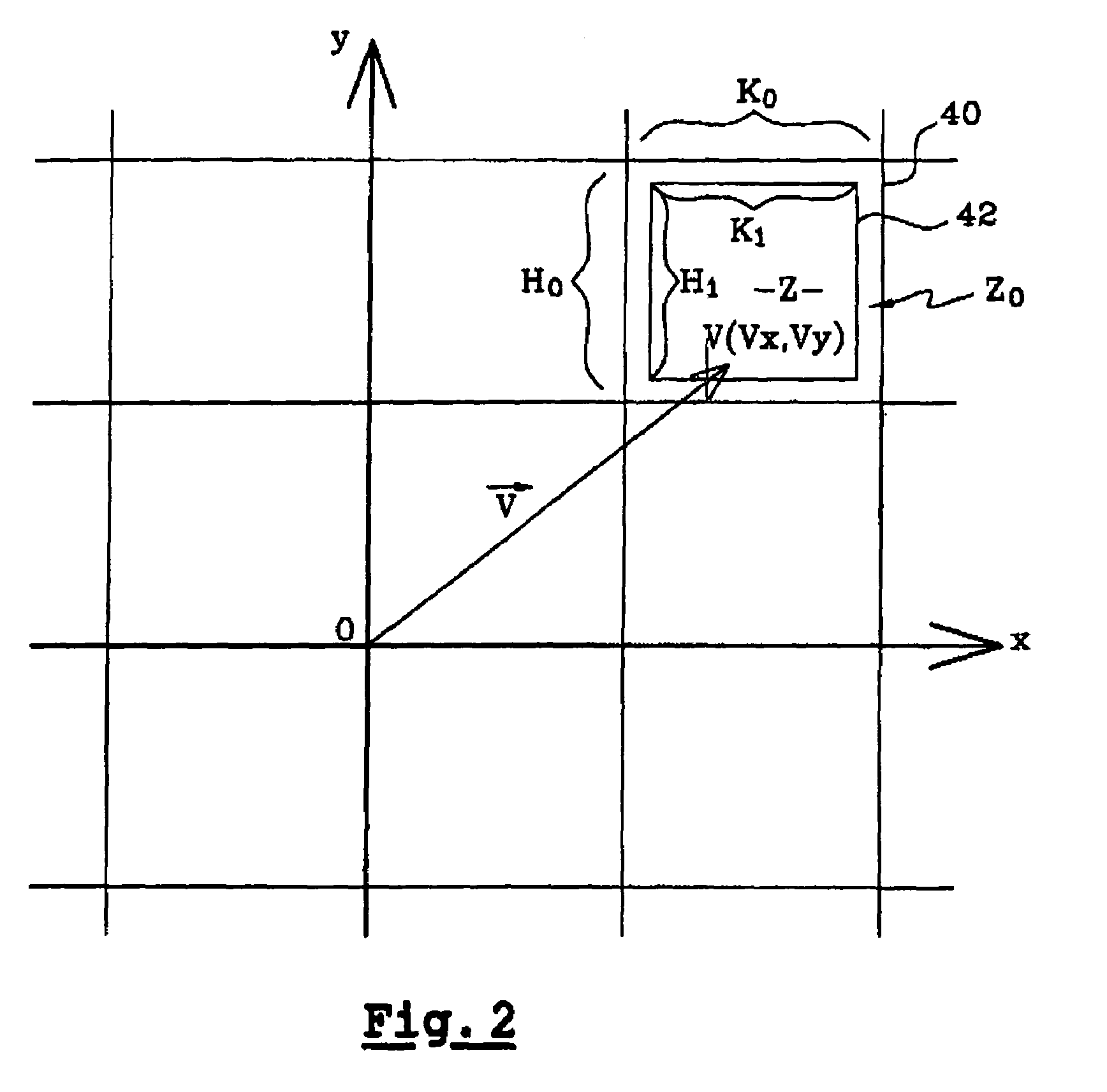

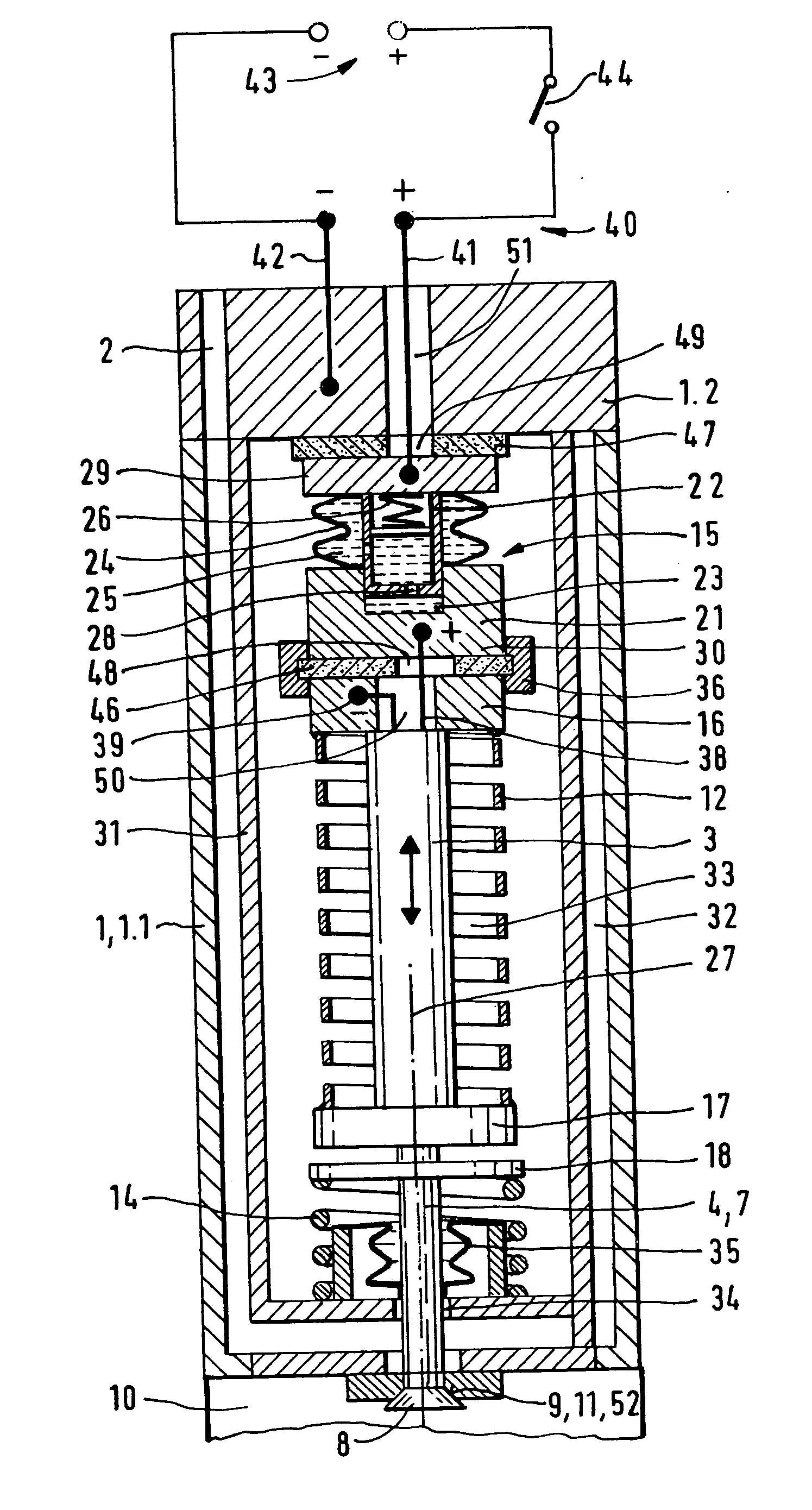

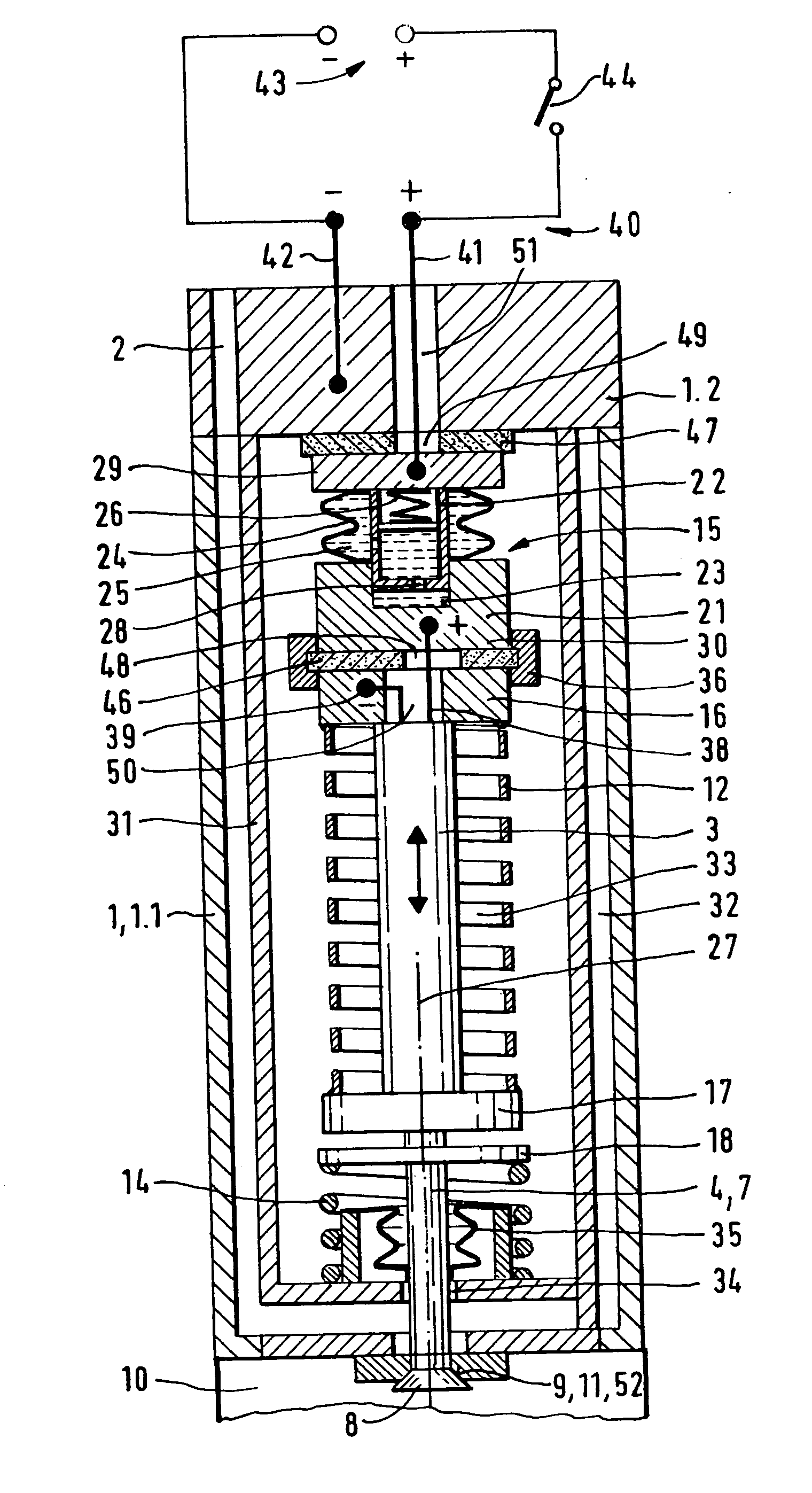

Fuel injector

InactiveUS7267111B2Small designExtended service lifeMovable spraying apparatusSpray nozzlesElectricityActuator

Owner:ROBERT BOSCH GMBH +1

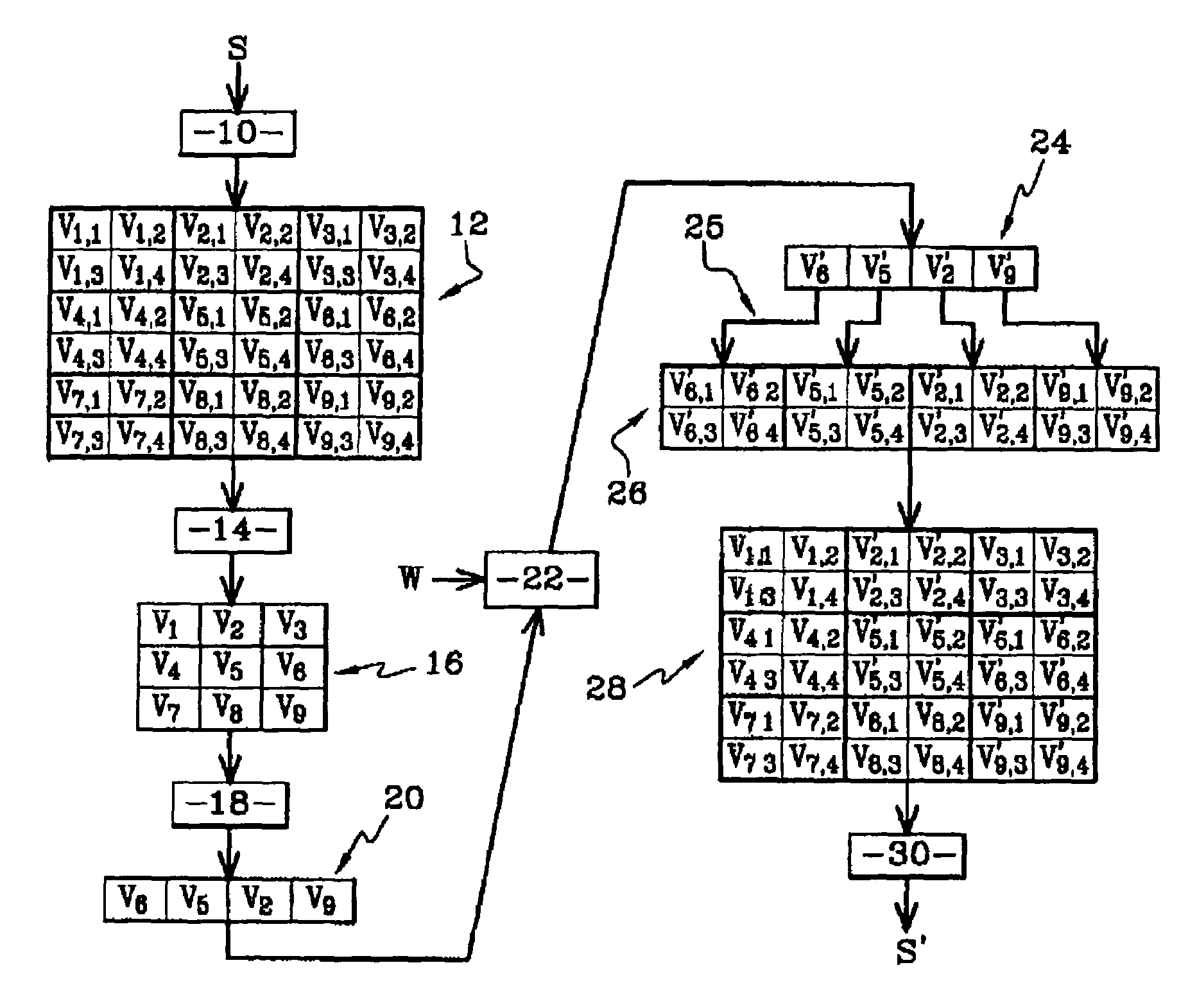

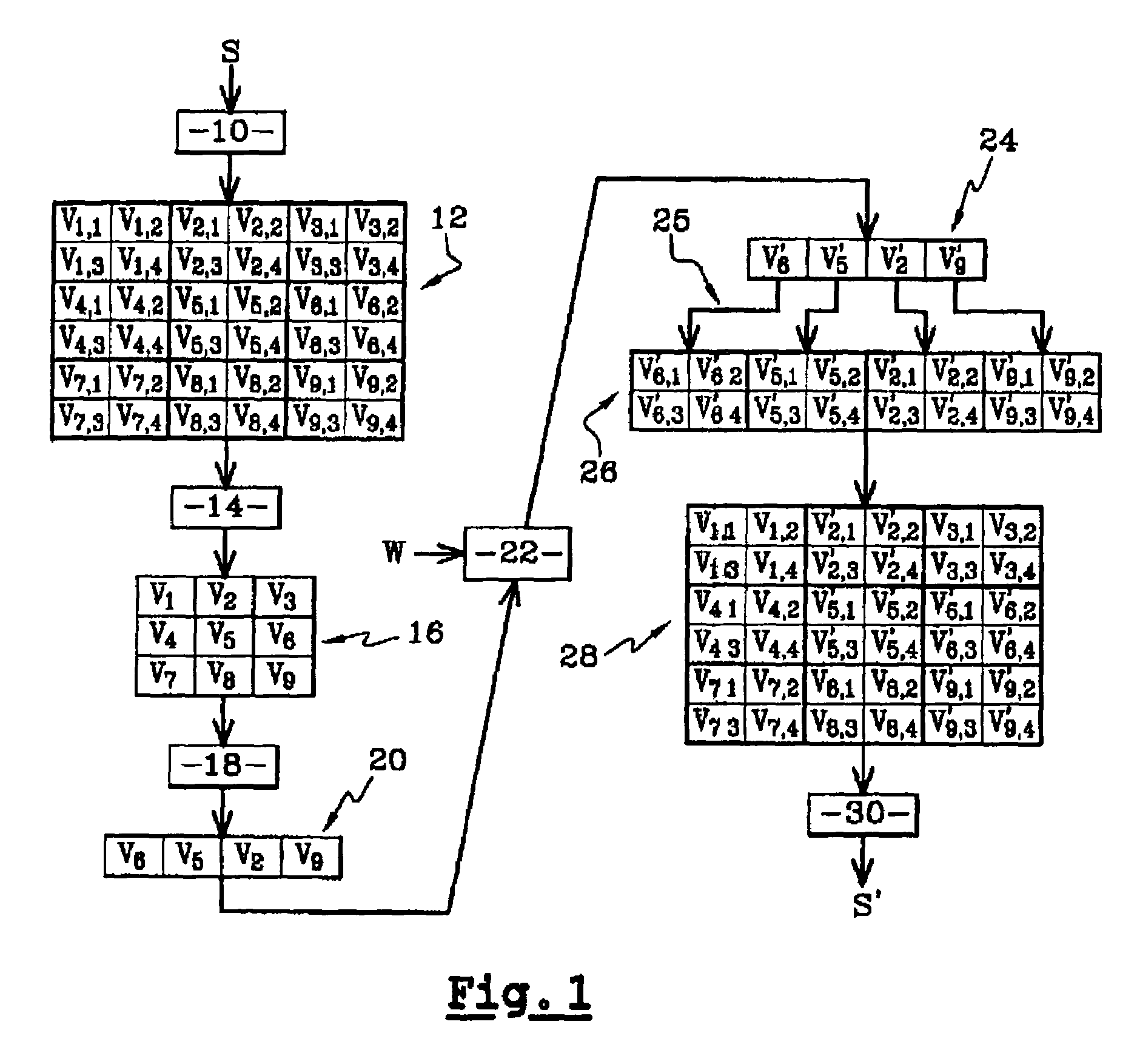

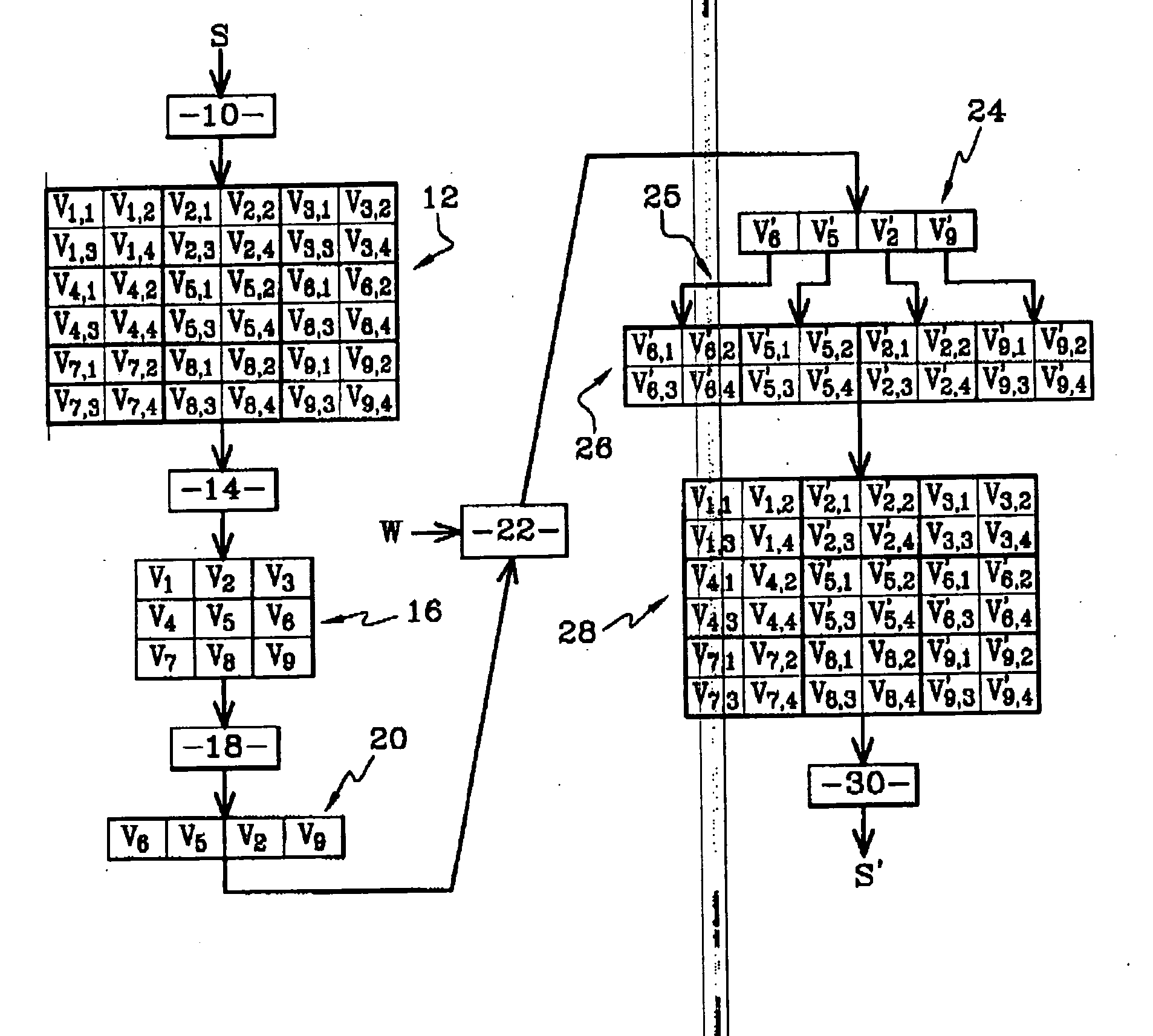

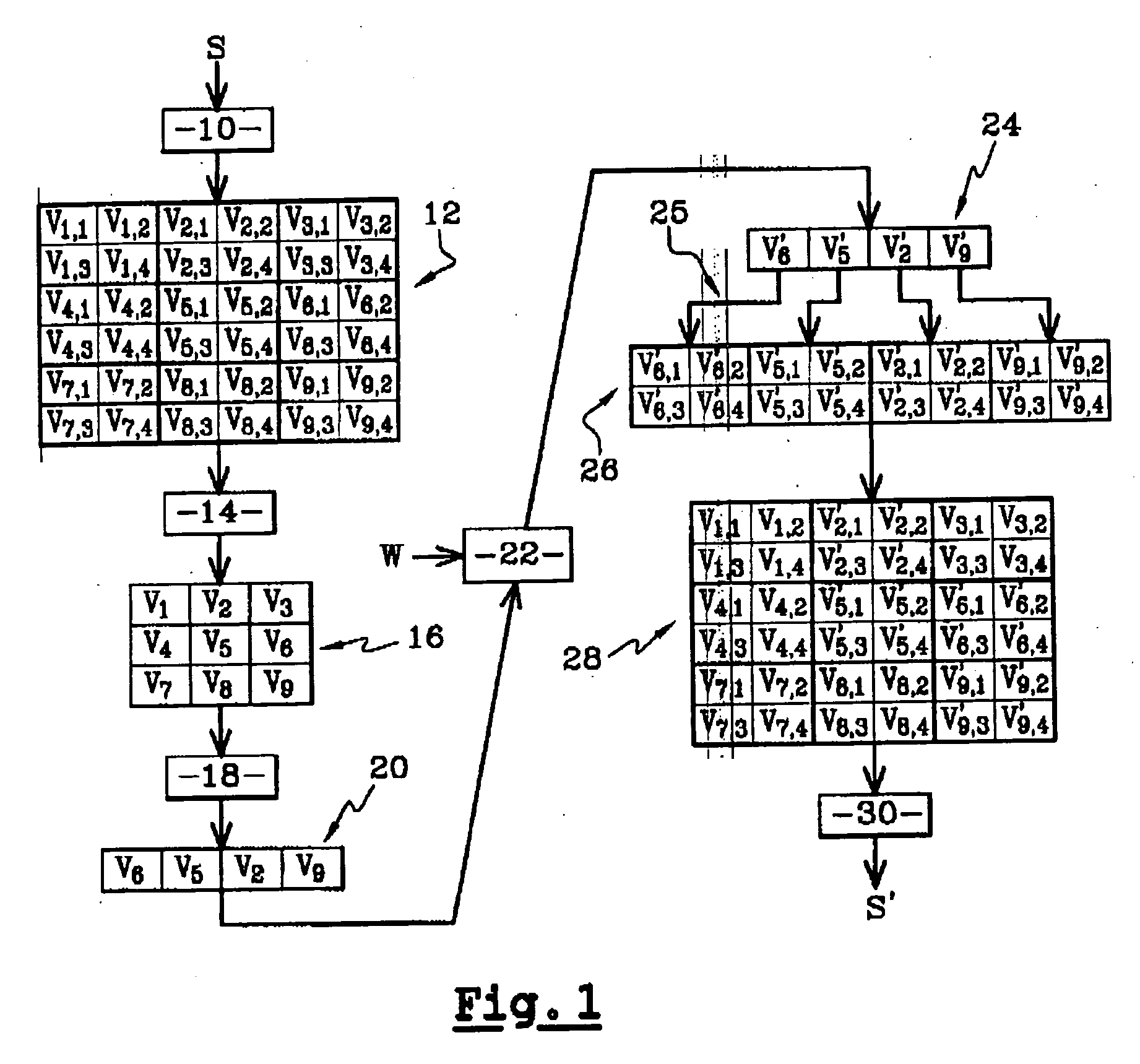

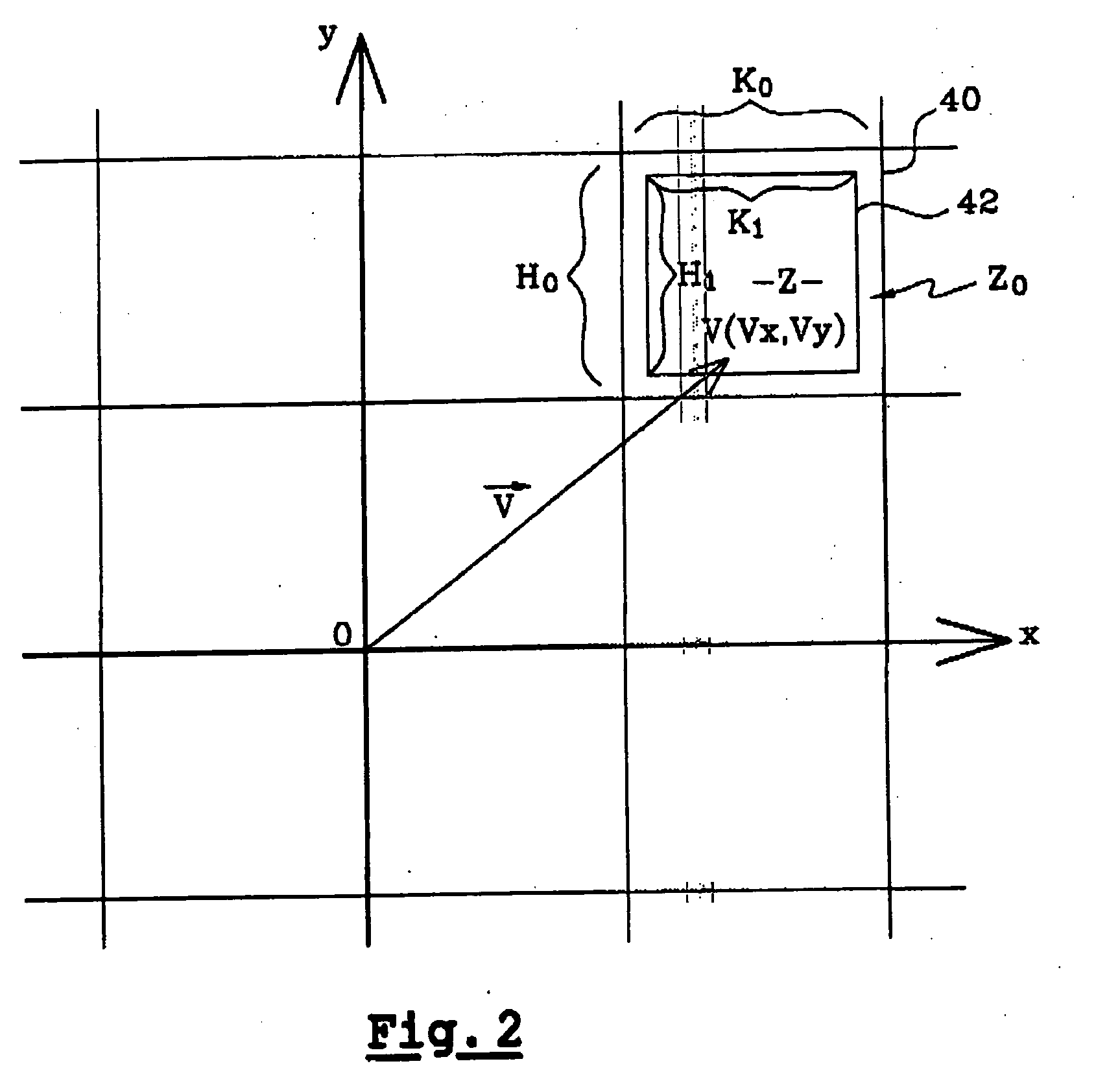

System and method of watermarking a video signal and extracting the watermarking from a video signal

InactiveUS7415127B2Improve performanceQuality improvementCharacter and pattern recognitionTelevision systemsReference spaceMotion vector

This method comprises the following steps of applying a watermarking function to motion vectors calculated by estimation of movement between images of a video signal, followed by a step of generating the watermarked video signal by compensating movement with the aid of the watermarked motion vectors. The watermarking function is applied by marking the coordinates of the selected motion vector in a reference space, certain portions of this space constituting a first zone and the other portions of this space constituting a second zone complementary to the first, assigning a binary value to each of the two zones, and, if necessary, modifying the coordinates of the selected motion vector so that it is in the zone whose binary value corresponds to a bit of a marking key associated with the selected motion vector.

Owner:FRANCE TELECOM SA

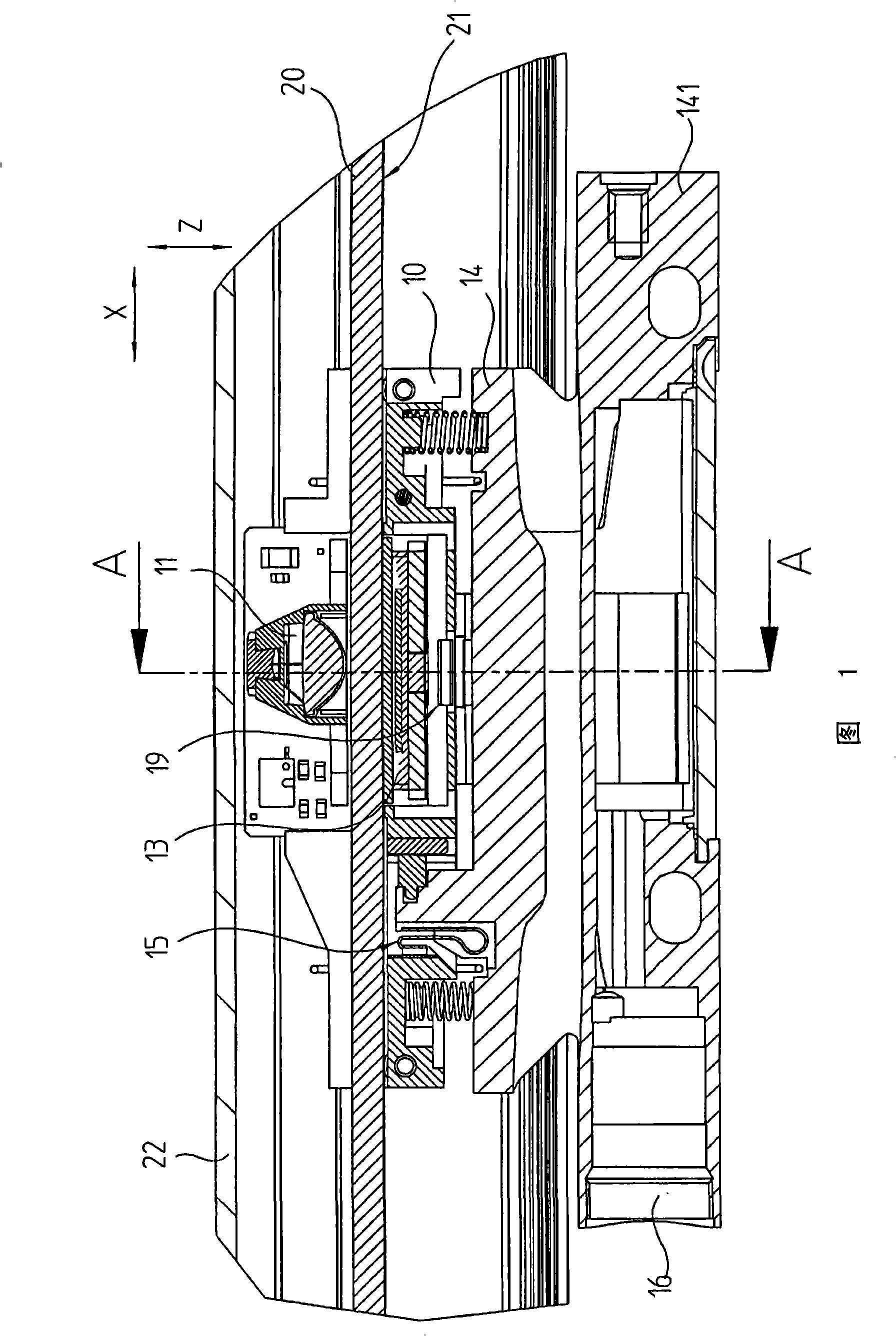

Measurement system, lithographic apparatus and method for measuring a position dependent signal of a movable object

ActiveUS7903866B2Improve accuracySemiconductor/solid-state device testing/measurementPhotomechanical apparatusPosition dependentCompensating movements

An encoder-type measurement system is configured to measure a position dependent signal of a movable object, the measurement system including at least one sensor mountable on the movable object a sensor target object mountable on a substantially stationary frame, and a mounting device configured to mount the sensor target object on the substantially stationary frame. The measurement system further includes a compensation device configured to compensate movements and / or deformations of the sensor target object with respect to the substantially stationary frame. The compensation device may include a passive or an active damping device and / or a feedback position control system. In an alternative embodiment, the compensation device includes a gripping device which fixes the position of the sensor target object during a high accuracy movement of the movable object.

Owner:ASML NETHERLANDS BV

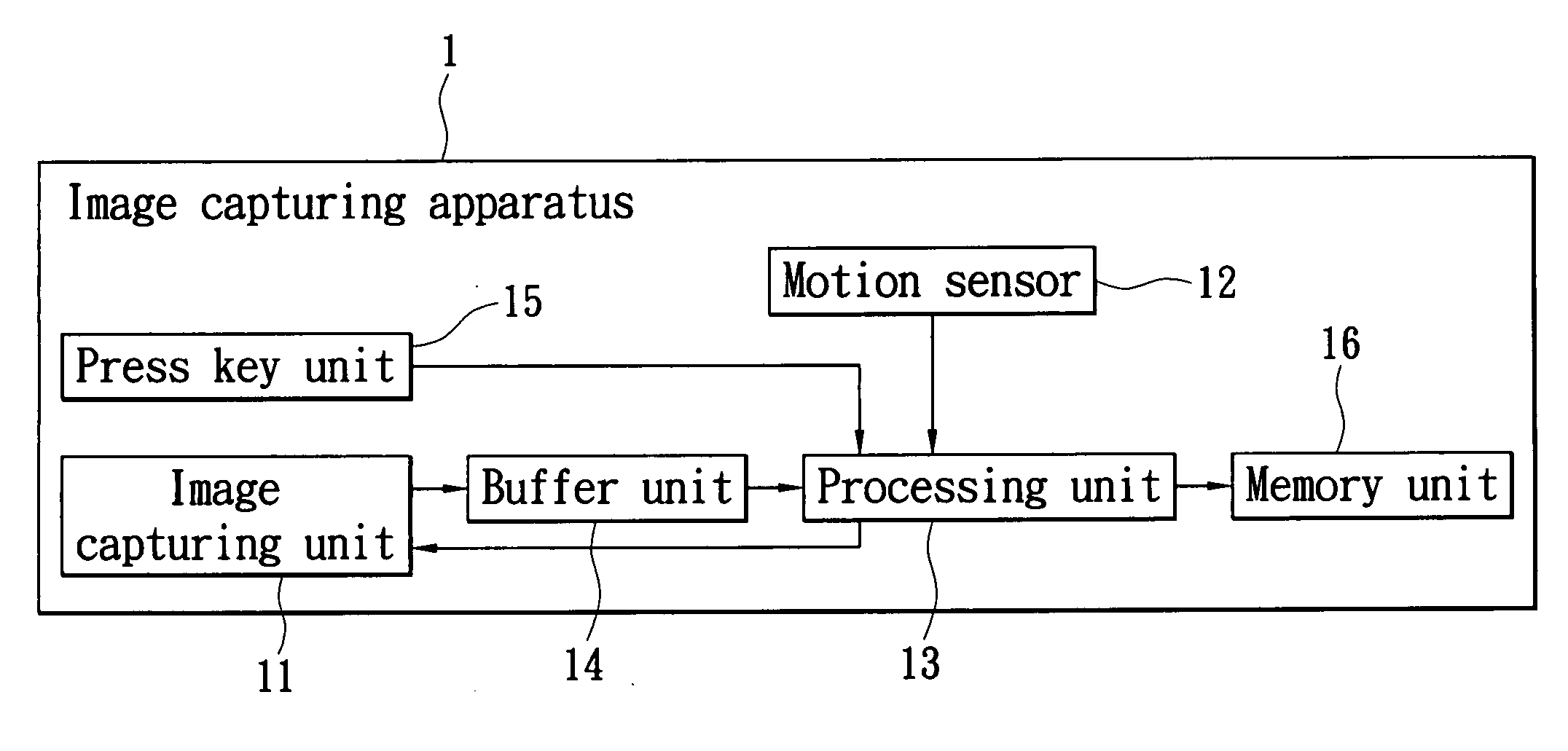

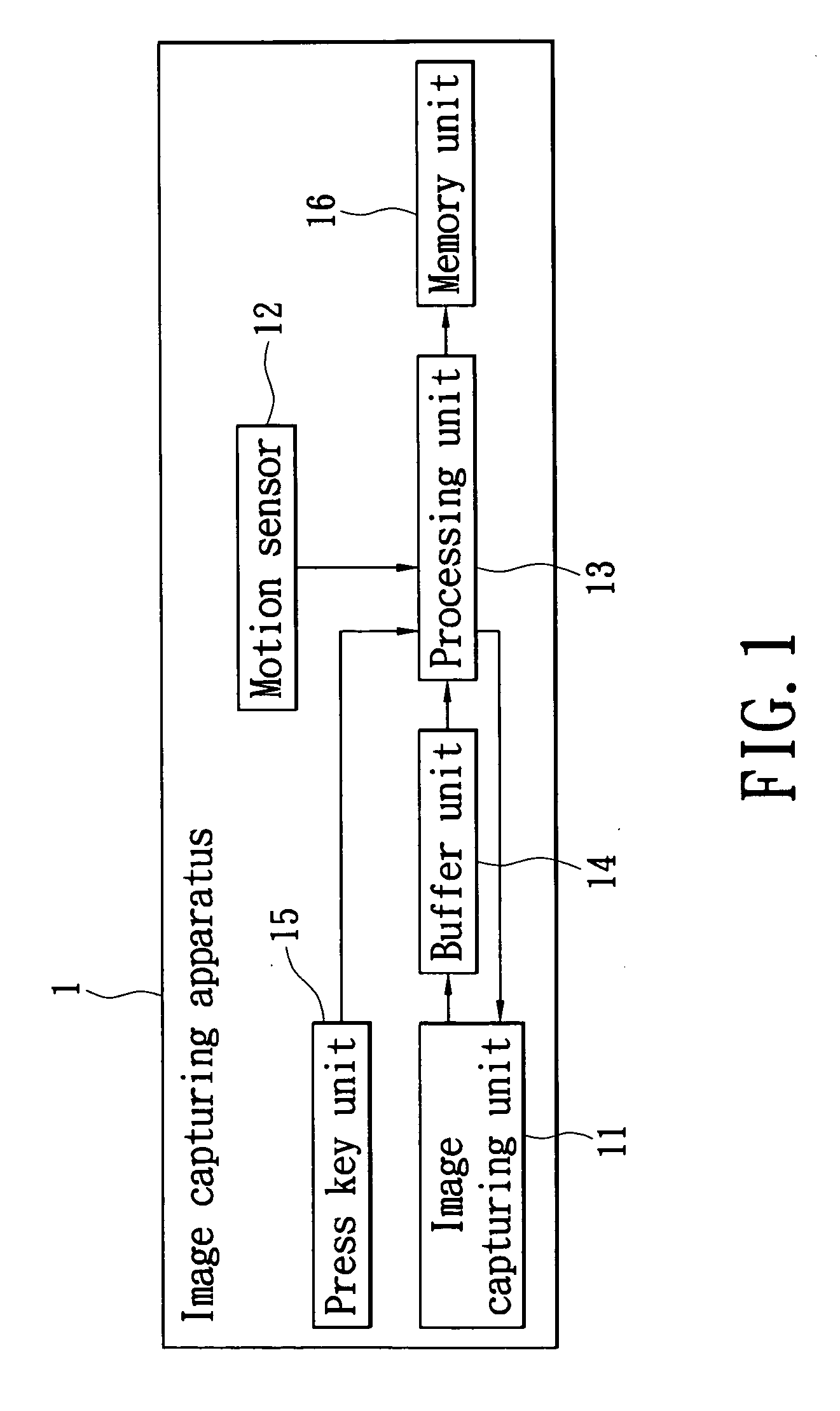

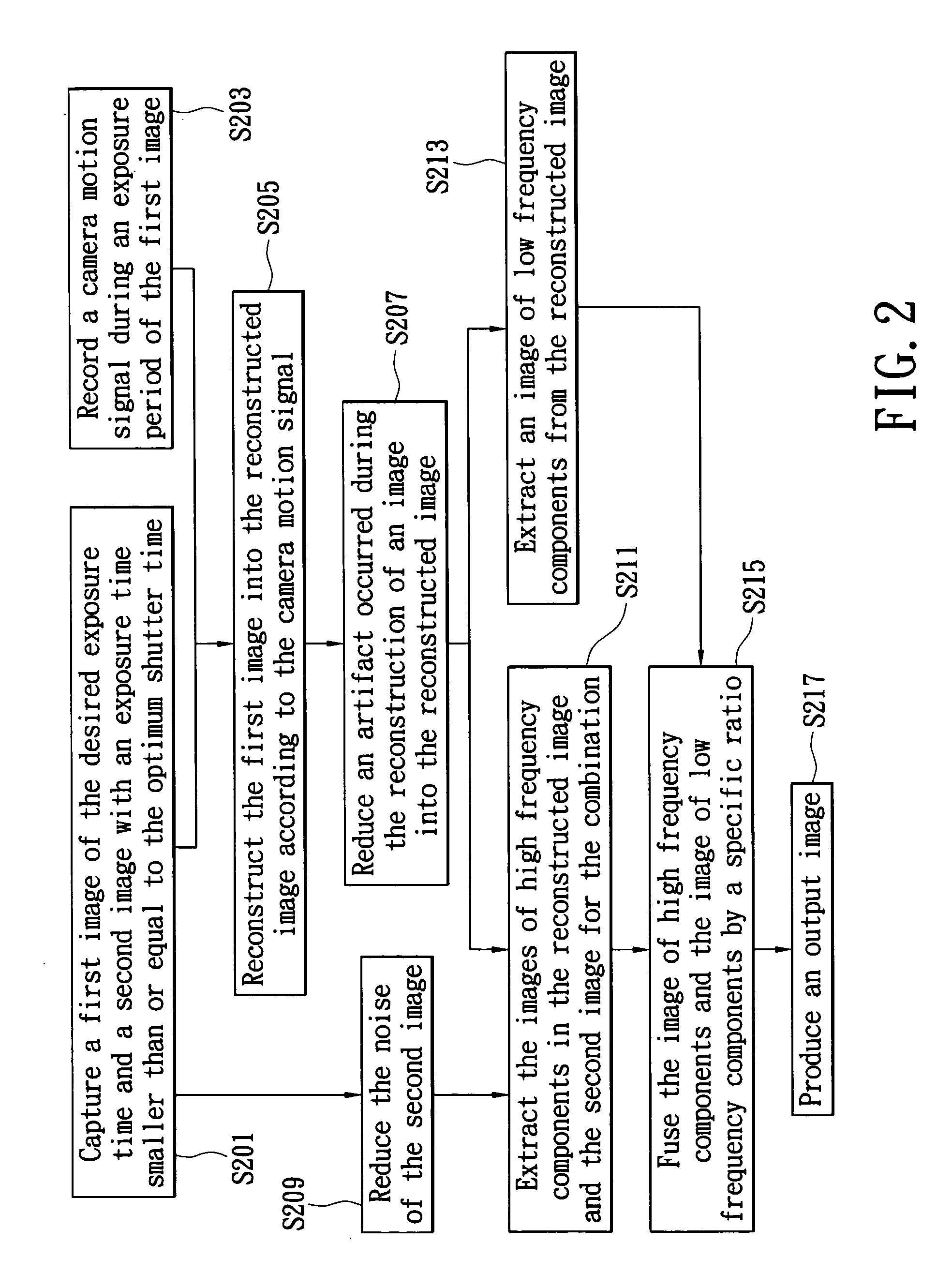

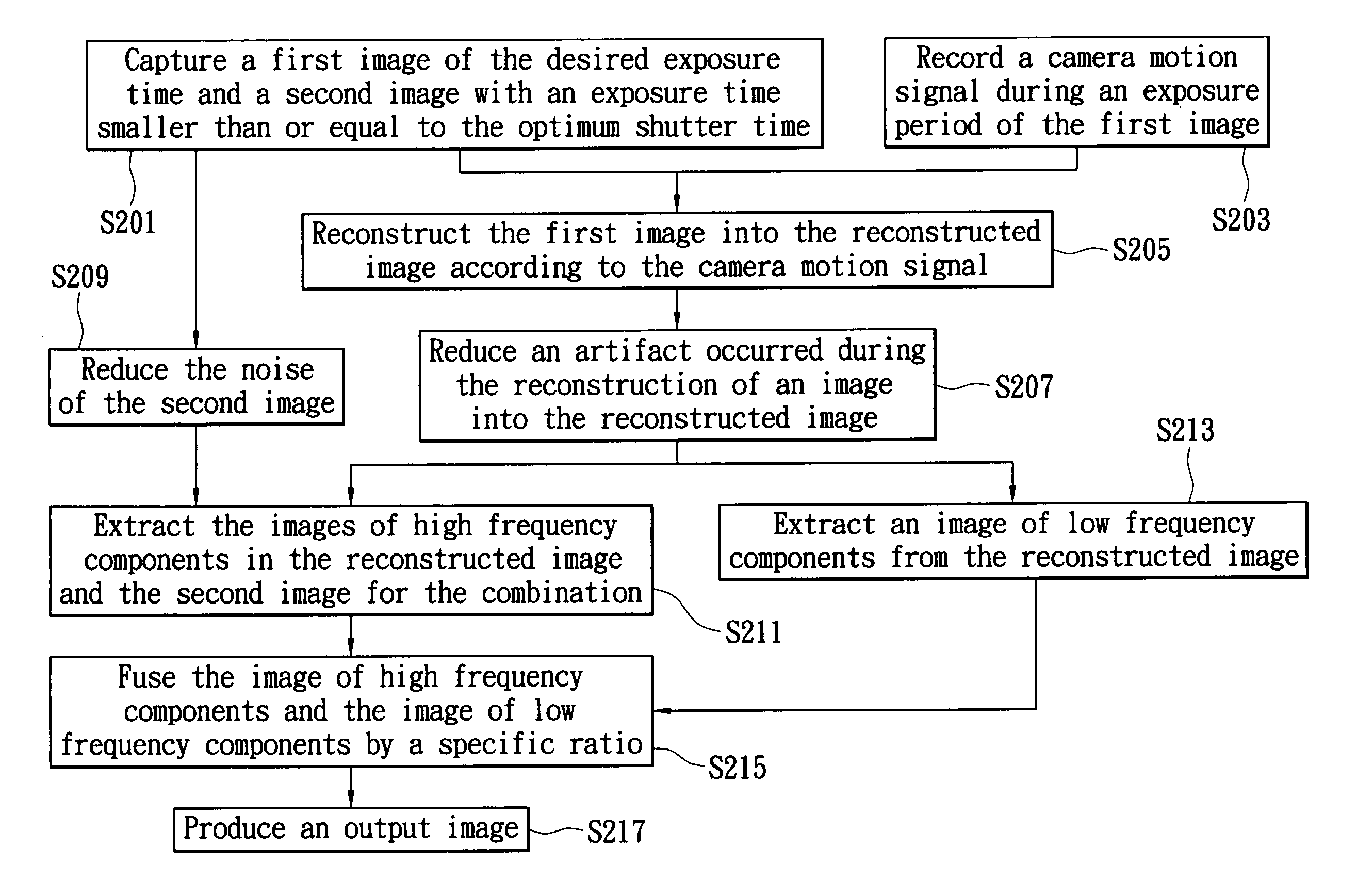

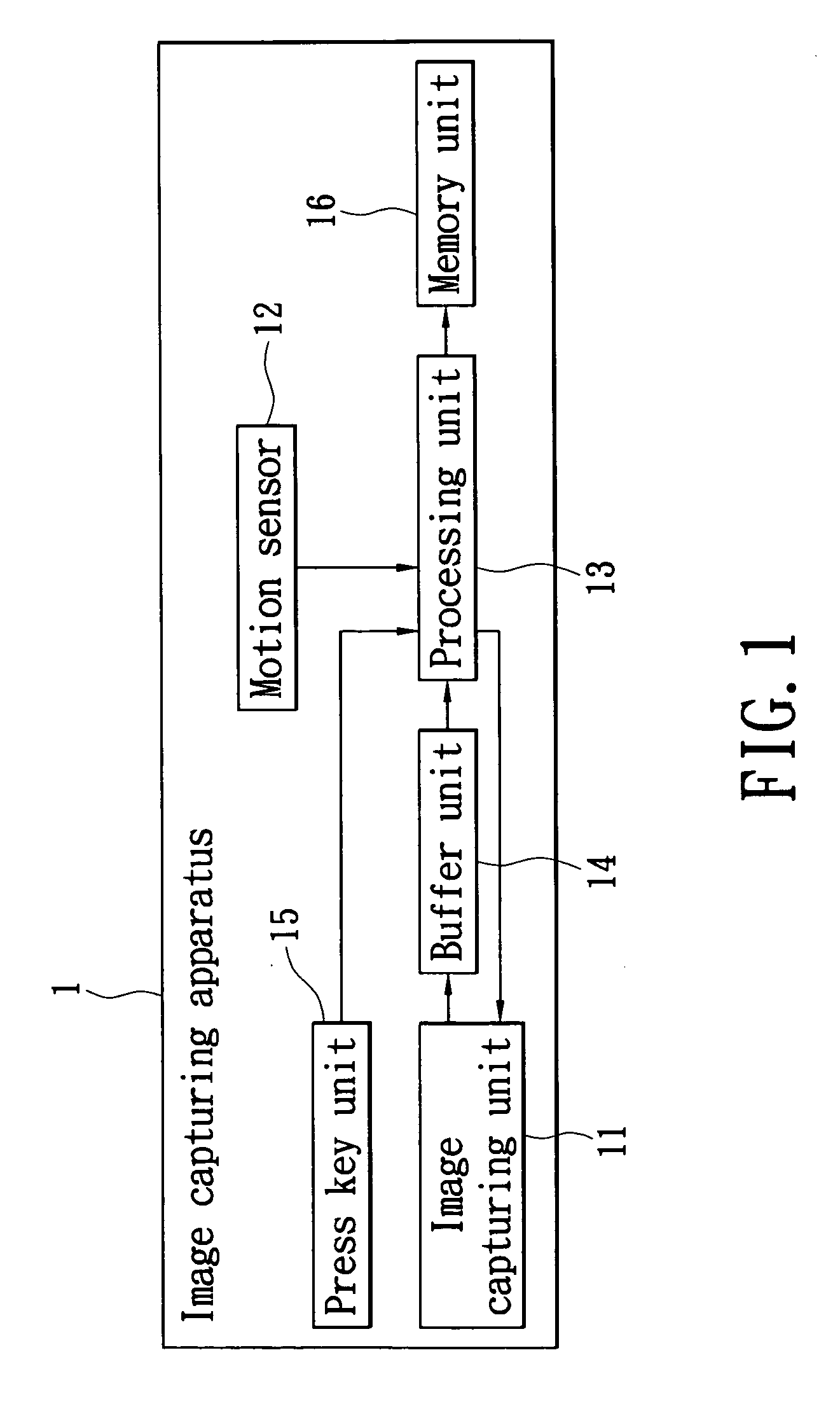

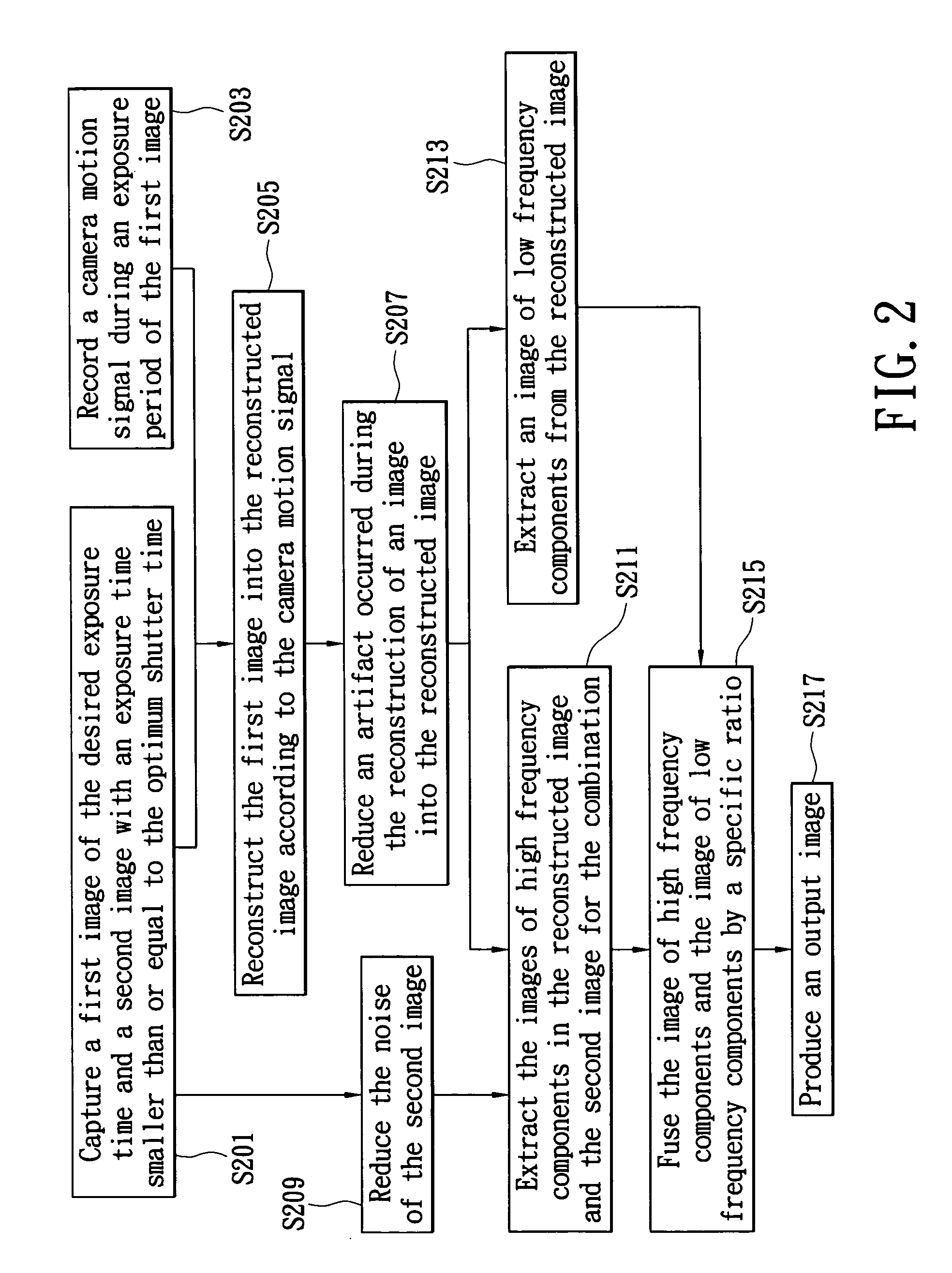

Image capturing apparatus with movement compensation function and method for movement compensation thereof

ActiveUS20090087173A1Clearer and less noisyReduce noiseTelevision system detailsCamera body detailsComputer visionCompensating movements

A method for compensating movement of an image capturing apparatus is applied in a photographing mode whose exposure time is greater than the safe shutter time. The method includes the steps of: capturing a long exposure image under the desired exposure time and a short exposure image with an exposure time smaller than or equal to the safe shutter time, and recording a camera motion signal in the exposure time of the long exposure image. The image-shift signal is used to reconstruct the short exposure image and form a reconstructed image, and an image analyzing algorithm is utilized to extract the reconstructed image and the short exposure image of a different frequency component. Finally, different frequency components of the image are fused according to the specific ratios to produce a clear output image.

Owner:ALTEK CORP

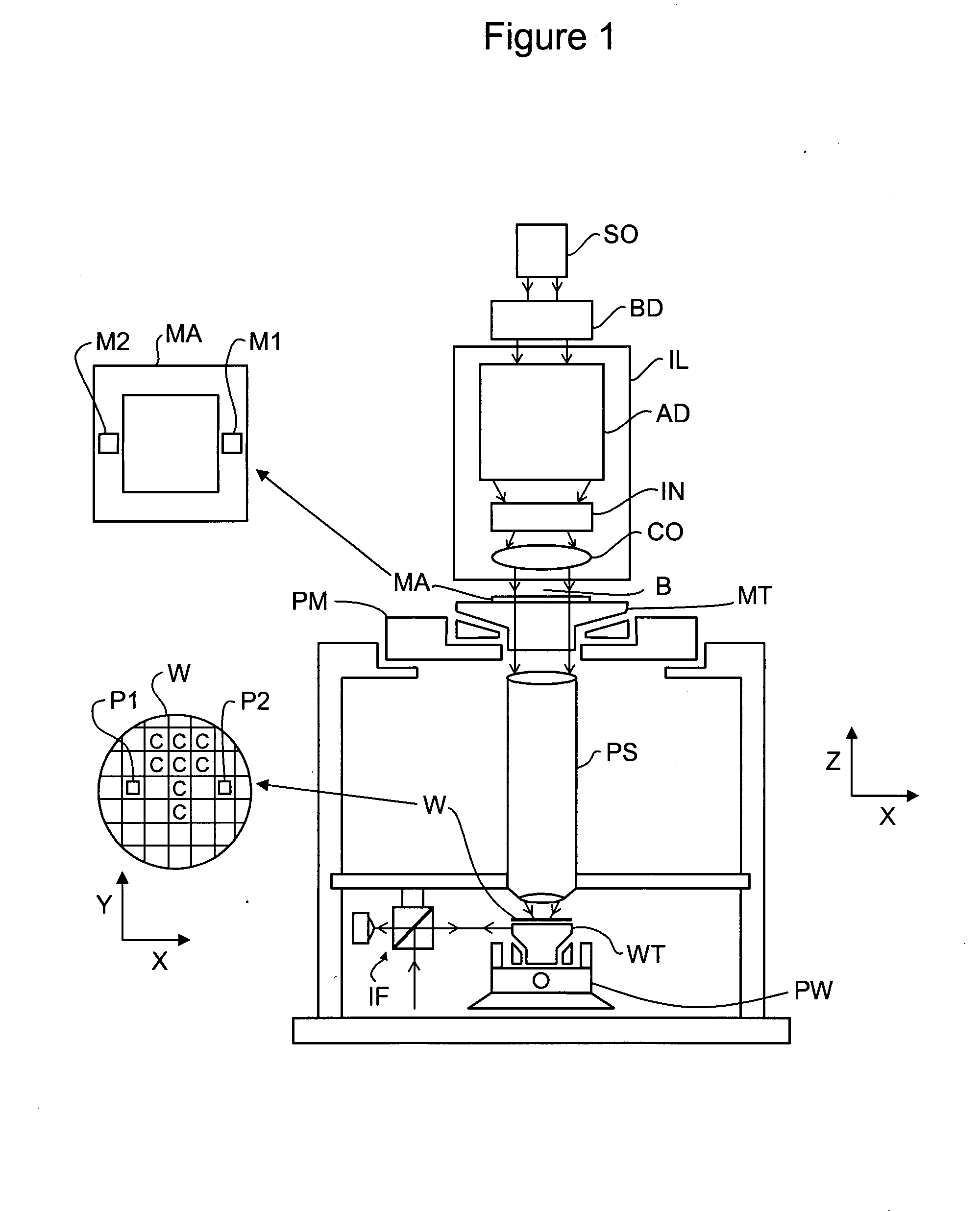

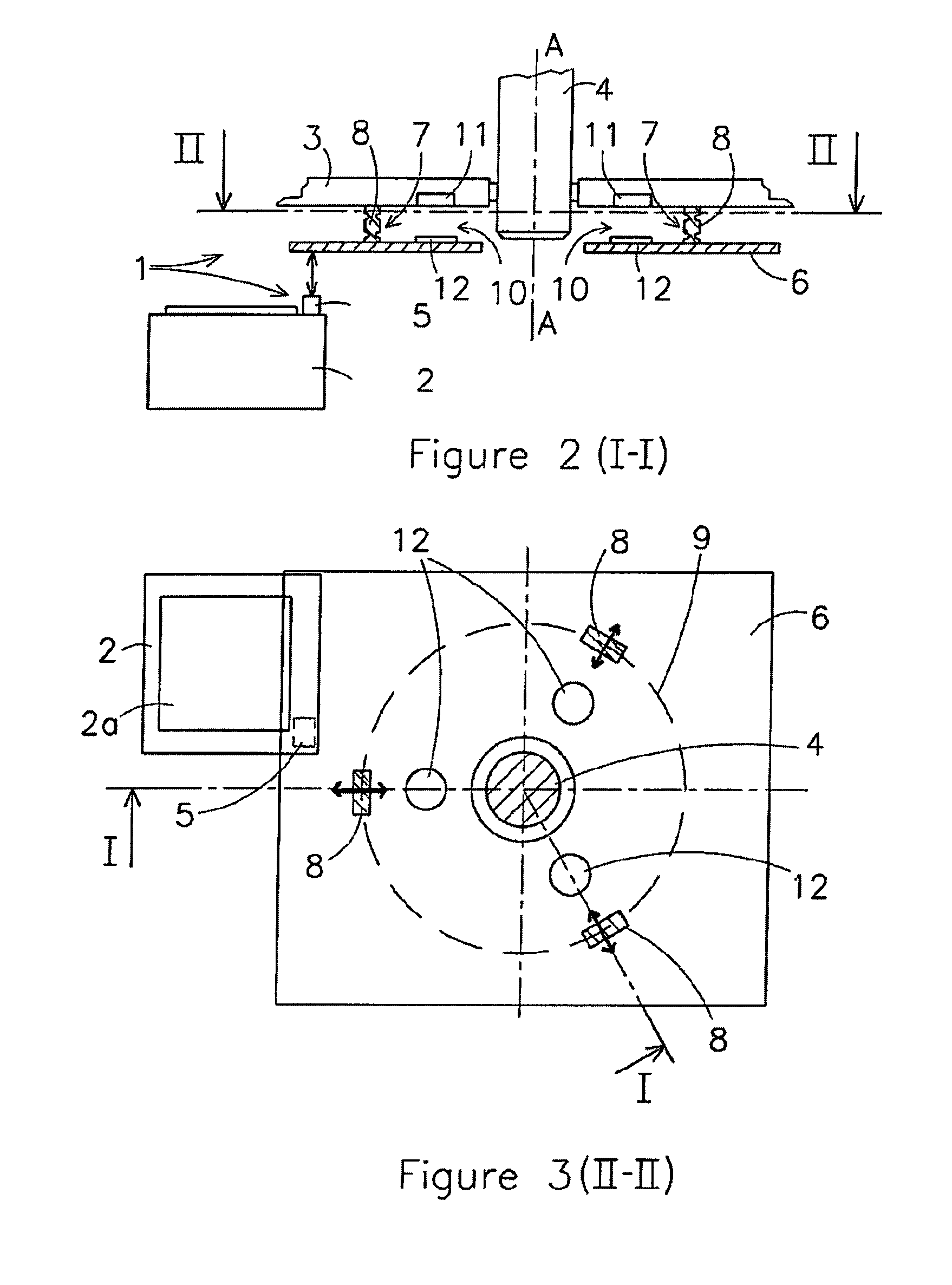

Stage apparatus, lithographic apparatus and method of positioning an object table

ActiveCN102385255ASemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPosition dependentComputer science

The invention discloses a stage apparatus, a lithographic apparatus and a method of positioning an object table. The stage apparatus comprises a measurement system configured to measure a position dependent signal of an object table, the measurement system including at least one sensor mountable on the object table and a sensor target object mountable on a substantially stationary frame, and a mounting device configured to mount the sensor target object on the substantially stationary frame, wherein the measurement system further includes a compensator configured to compensate movements and / or deformations of the sensor target object with respect to the substantially stationary frame. The compensator may include a passive or an active damper and / or a feedback position controller. In an alternative embodiment, the compensator includes a gripping device which fixes the position of the sensor target object during a high accuracy movement of the movable object.

Owner:ASML NETHERLANDS BV

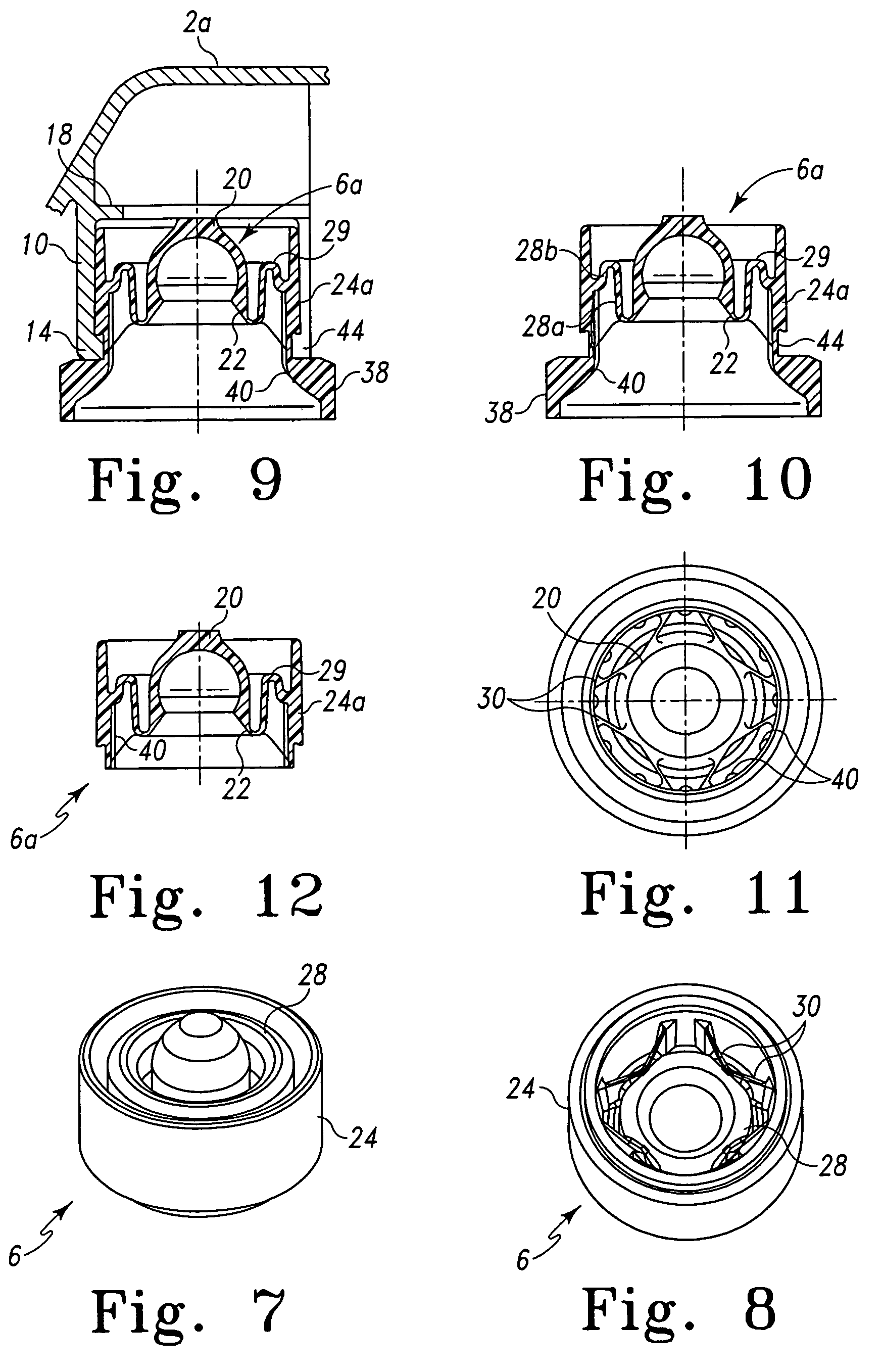

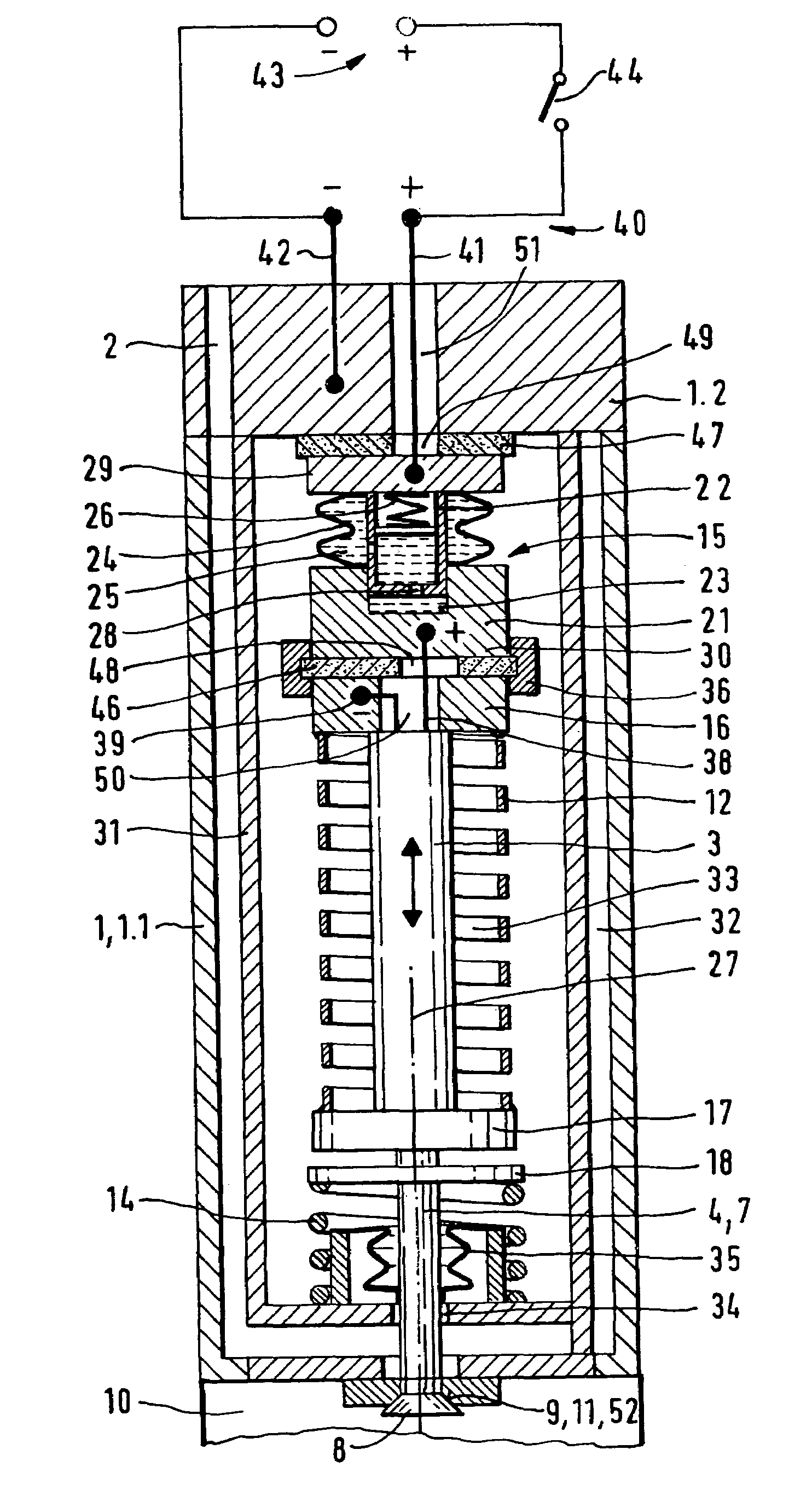

Fuel injector

InactiveUS20050247803A1Small designExtended service lifeMovable spraying apparatusSpray nozzlesElectricityActuator

Known fuel injectors have a valve housing in which an actuator and an hydraulic coupler are arranged, an electrical plug being provided on the valve housing for contact with a voltage source. The cables running from the plug to the actuator must be guided around the coupler to the actuator. It is disadvantageous that the compensating movements put heavy mechanical stress on the cables, so that a cable fracture as a result of material fatigue occurs after a predefined service life of the fuel injector, or that the solder or welding points of the cables tear. This leads to malfunctioning of the fuel injector. In the present fuel injector, the service life is increased by the provision of connections without cables. The earth pole of the actuator is electrically connected to the ground terminal of the plug in a cable-less manner, and the positive pole of the actuator is electrically connected to the positive terminal in a cable-less manner.

Owner:ROBERT BOSCH GMBH +1

Image capturing apparatus with movement compensation function and method for movement compensation thereof

ActiveUS8018495B2Quality improvementLower captureTelevision system detailsColor television detailsComputer visionCompensating movements

A method for compensating movement of an image capturing apparatus is applied in a photographing mode whose exposure time is greater than the safe shutter time. The method includes the steps of: capturing a long exposure image under the desired exposure time and a short exposure image with an exposure time smaller than or equal to the safe shutter time, and recording a camera motion signal in the exposure time of the long exposure image. The image-shift signal is used to reconstruct the short exposure image and form a reconstructed image, and an image analyzing algorithm is utilized to extract the reconstructed image and the short exposure image of a different frequency component. Finally, different frequency components of the image are fused according to the specific ratios to produce a clear output image.

Owner:ALTEK CORP

Method of watermarking a video signal, a system and a data medium for implementing said method, a method of extracting the watermarking from a video signal, and system for implementing said method

InactiveUS20040175017A1Improves watermarking performanceImprove performanceCharacter and pattern recognitionTelevision systemsMotion vectorCompensating movements

The method comprises the following steps: applying a watermarking function to motion vectors calculated by estimation of movement between images of a video signal; and generating the watermarked video signal by compensating movement with the aid of the watermarked motion vectors. The watermarking function is applied by: marking the coordinates of the selected motion vector in a space, certain portions of this space constituting a first zone and the other portions of this space constituting a second zone complementary to the first; assigning a binary value to each of the two zones; and where necessary, modifying the coordinates of the selected motion vector so that it is in the zone whose binary value corresponds to a bit of a marking key associated with the selected motion vector.

Owner:FRANCE TELECOM SA

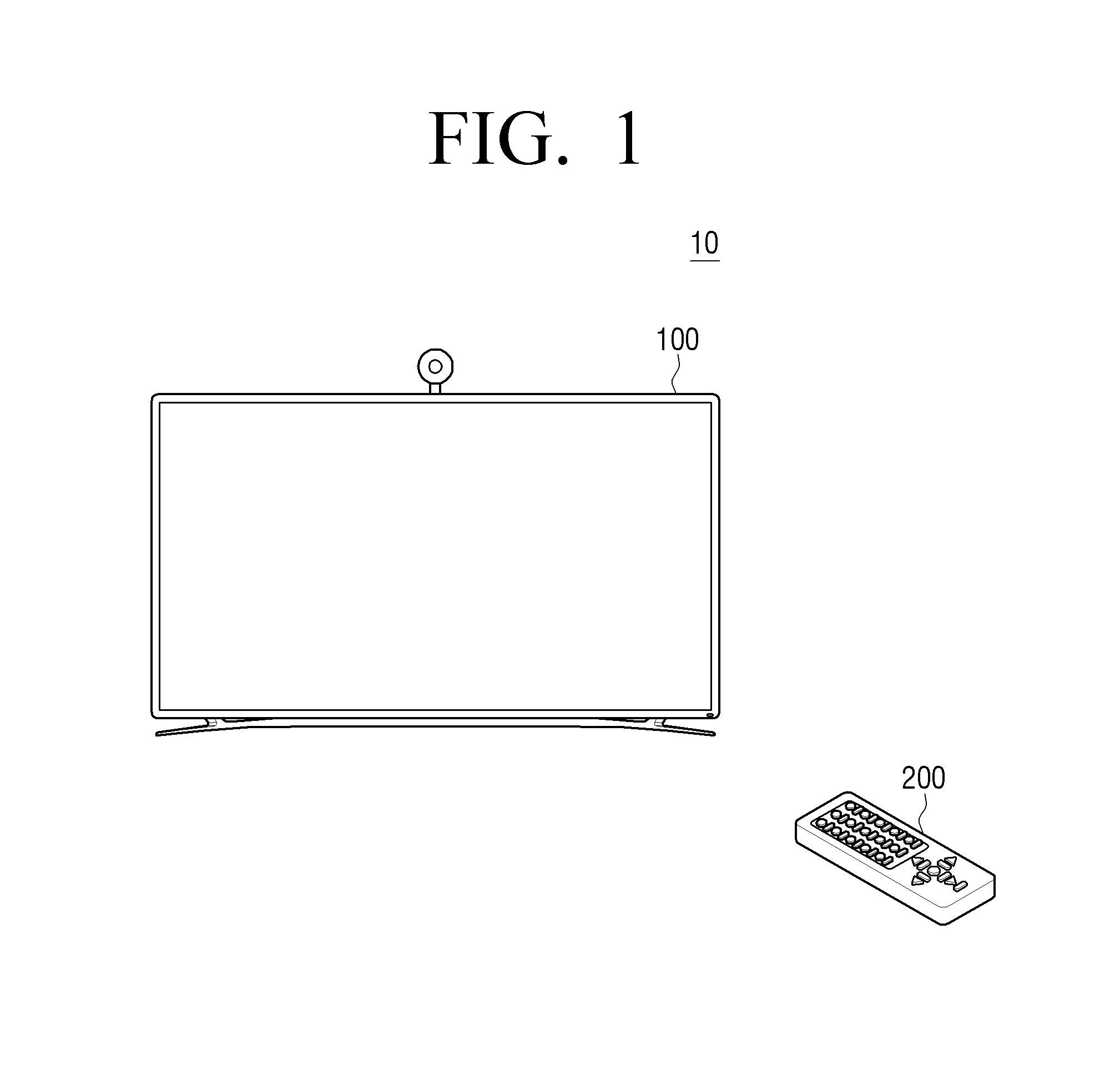

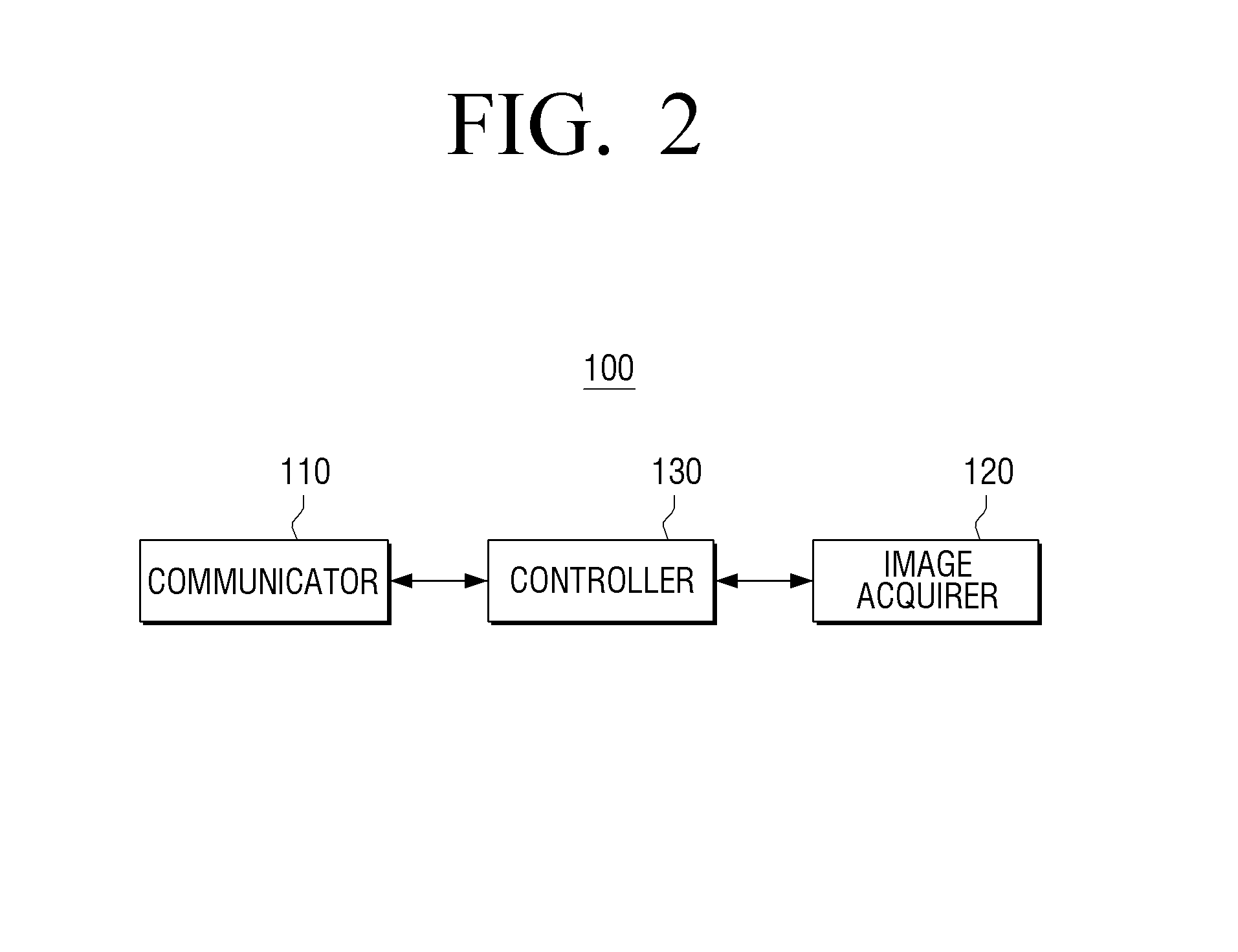

Display apparatus and method for controlling display apparatus thereof

ActiveUS20150002390A1Easy to controlInput/output for user-computer interactionCathode-ray tube indicatorsComputer scienceCompensating movements

A display apparatus and a controlling method are provided, in which the controlling method of the display apparatus receives movement information of a mobile terminal from the mobile terminal, obtains mobile terminal images by photographing the mobile terminal, transforms the received movement information into a screen coordinate system arrayed based on screen of the display apparatus, compensates the movement information transformed into the screen coordinate system based on the mobile terminal images, and controls the display apparatus by using the compensated movement information.

Owner:SAMSUNG ELECTRONICS CO LTD

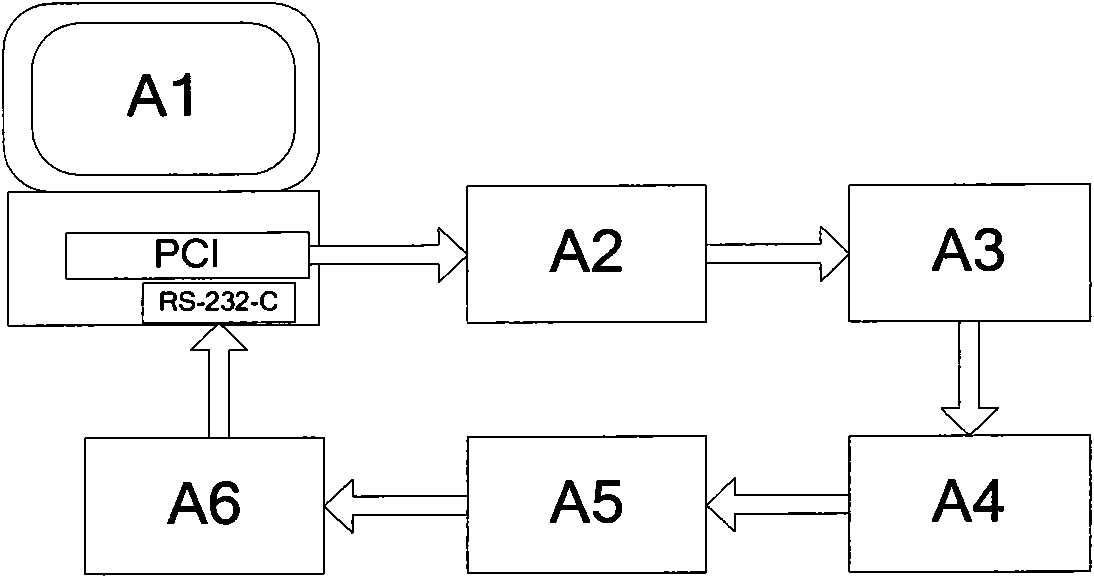

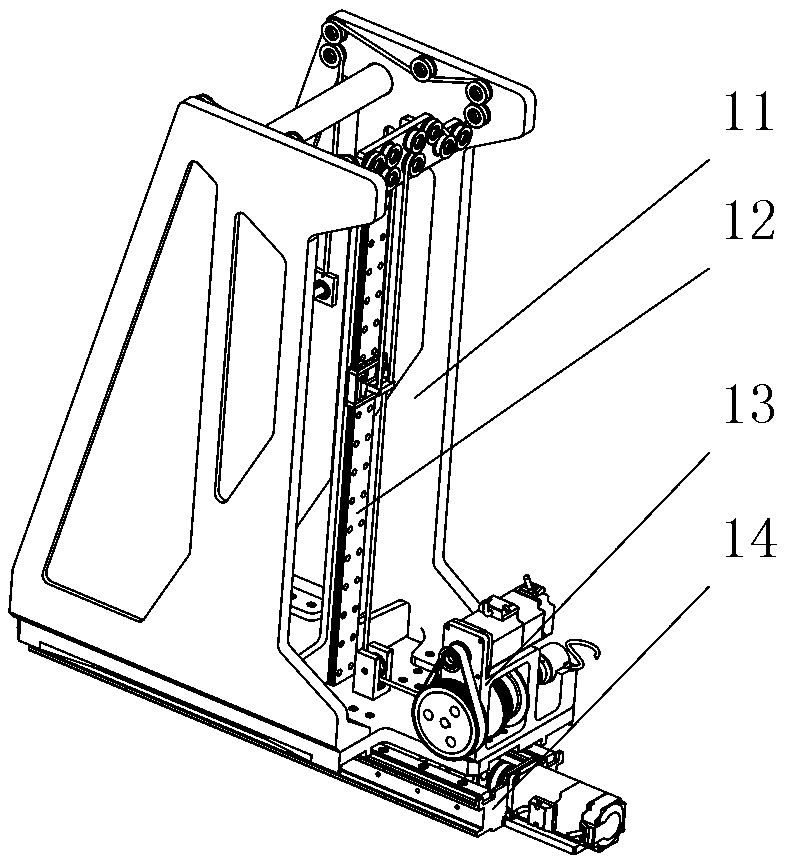

Graduation device for detecting surface shape of aspheric optical element

The invention relates to a graduation device for detecting the surface shape of an aspheric optical element, in particular to a graduation device for accurately controlling the displacement of a rotation angle. The invention provides a graduation device for accurately controlling the displacement of a rotation angle, which can feed back and compensate movement quantity and accurately control angular displacement in real time. The graduation device comprises a control system and a graduation device, wherein the control system is provided with an industrial personnel computer, an interface circuit board, a servo amplifier, a servo motor, an angular coder and a numeral display meter of the coder; and the graduation device is provided with a base, an upper bearing base, a main shaft, a motor base, a deep groove ball bearing, a main shaft synchronous pulley, a motor synchronous pulley, a synchronous belt, a rotary disk and a clamp.

Owner:XIAMEN UNIV

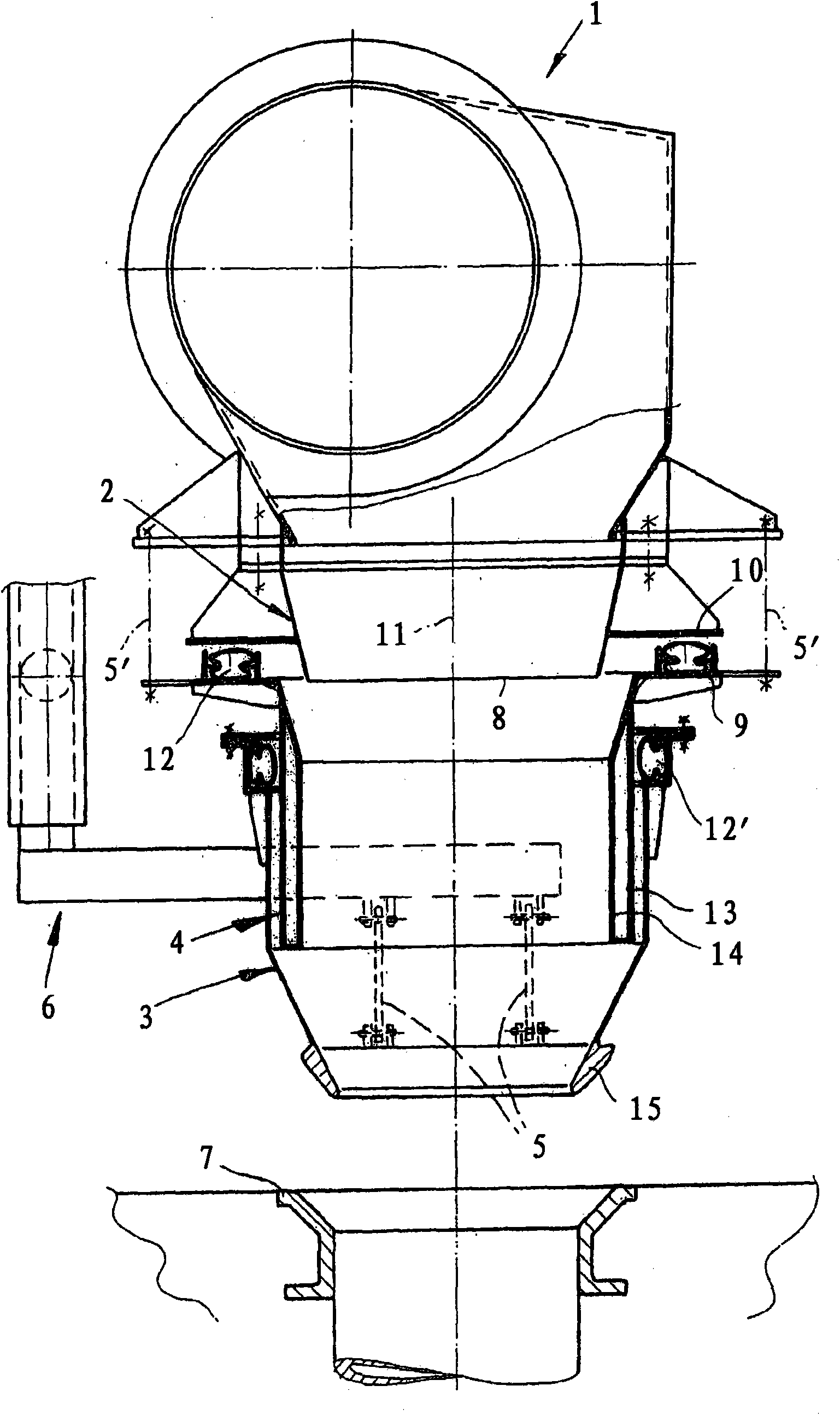

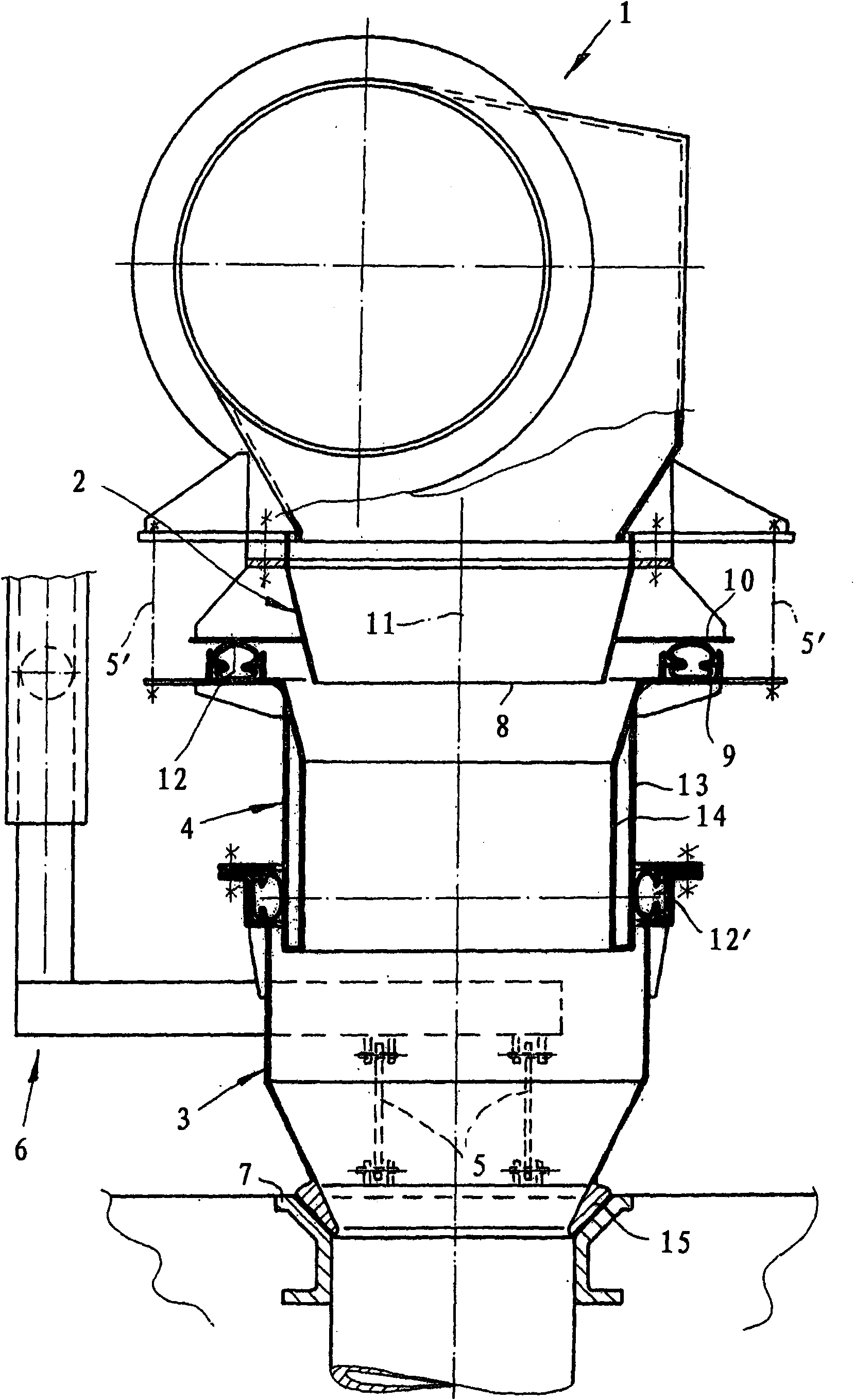

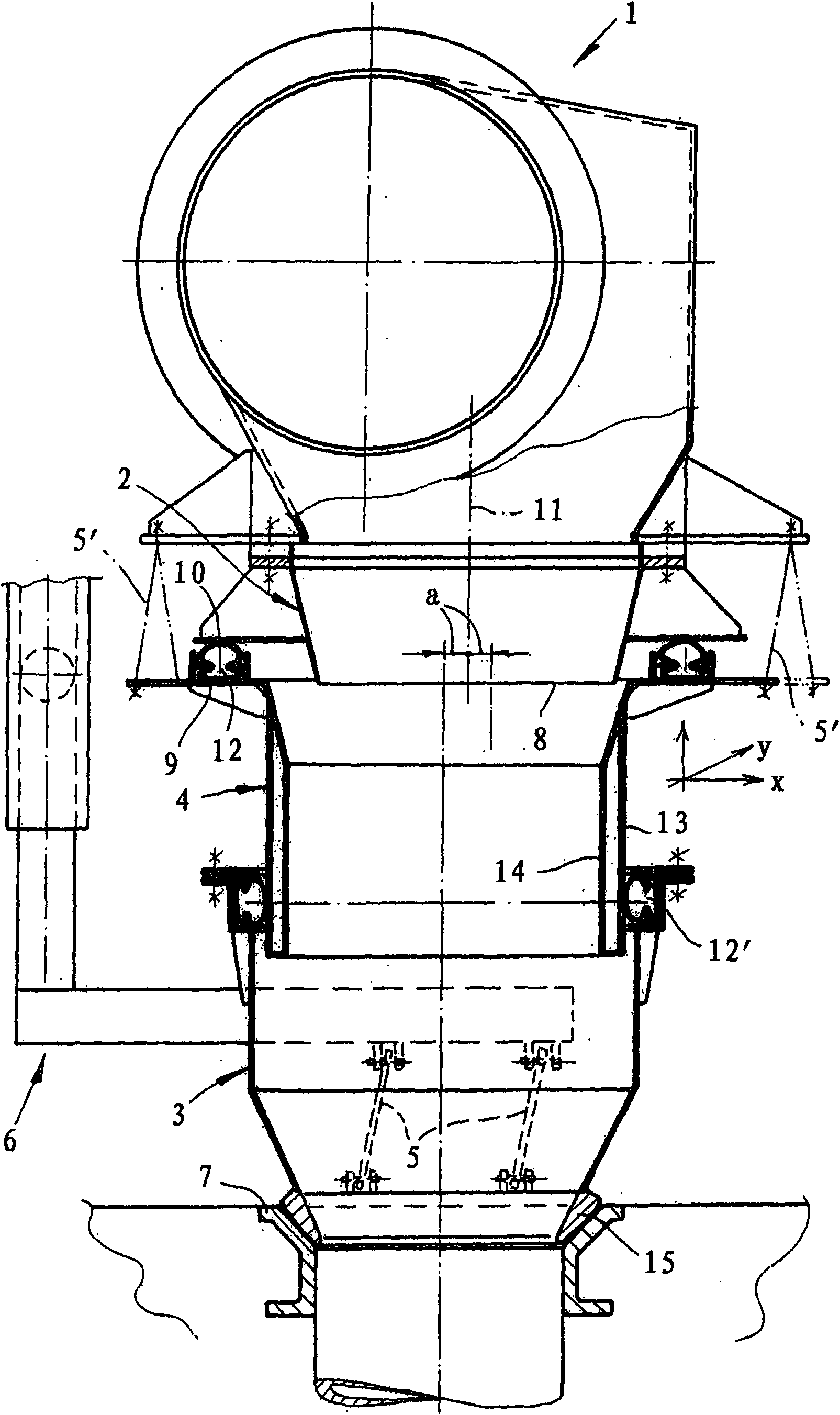

Telescopic chute for charging coke ovens

InactiveCN101802132AAvoid reclined positionsNo squeezing forceBulk conveyorsCharging devicesCoke ovenEngineering

Owner:UHDE GMBH

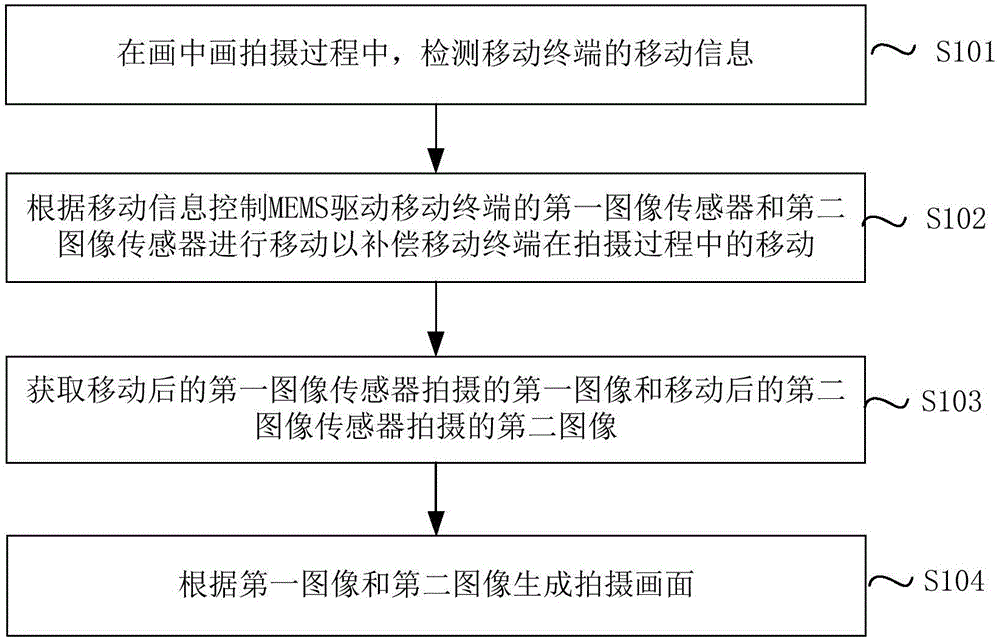

Photographing anti-shaking method, photographing anti-shaking device and mobile terminal

ActiveCN106254771AEnsure stabilityAvoid faultTelevision system detailsColor television detailsCompensating movementsMechanical system

The invention provides a photographing anti-shaking method, a photographing anti-shaking device and a mobile terminal. The photographing anti-shaking method comprises the steps of detecting movement information of the mobile terminal in a picture-in-picture photographing process, wherein the mobile terminal comprises an MEMS (Micro Electro Mechanical System), a first image sensor and a second image sensor; controlling the MEMS to drive the first image sensor and the second image sensor to move according to the movement information so as to compensate movement of the mobile terminal in the photographing process; acquiring a first image photographed by the moved first image sensor and a second image photographed by the moved second image sensor; and generating a photographed picture according to the first image and the second image. According to the photographing anti-shaking method, the photographing anti-shaking device and the mobile terminal provided by the embodiment of the invention, the stability of the photographed picture is ensured in picture-in-picture photographing, occurrence of a fracture in the picture is prevented, and the photographing effect is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

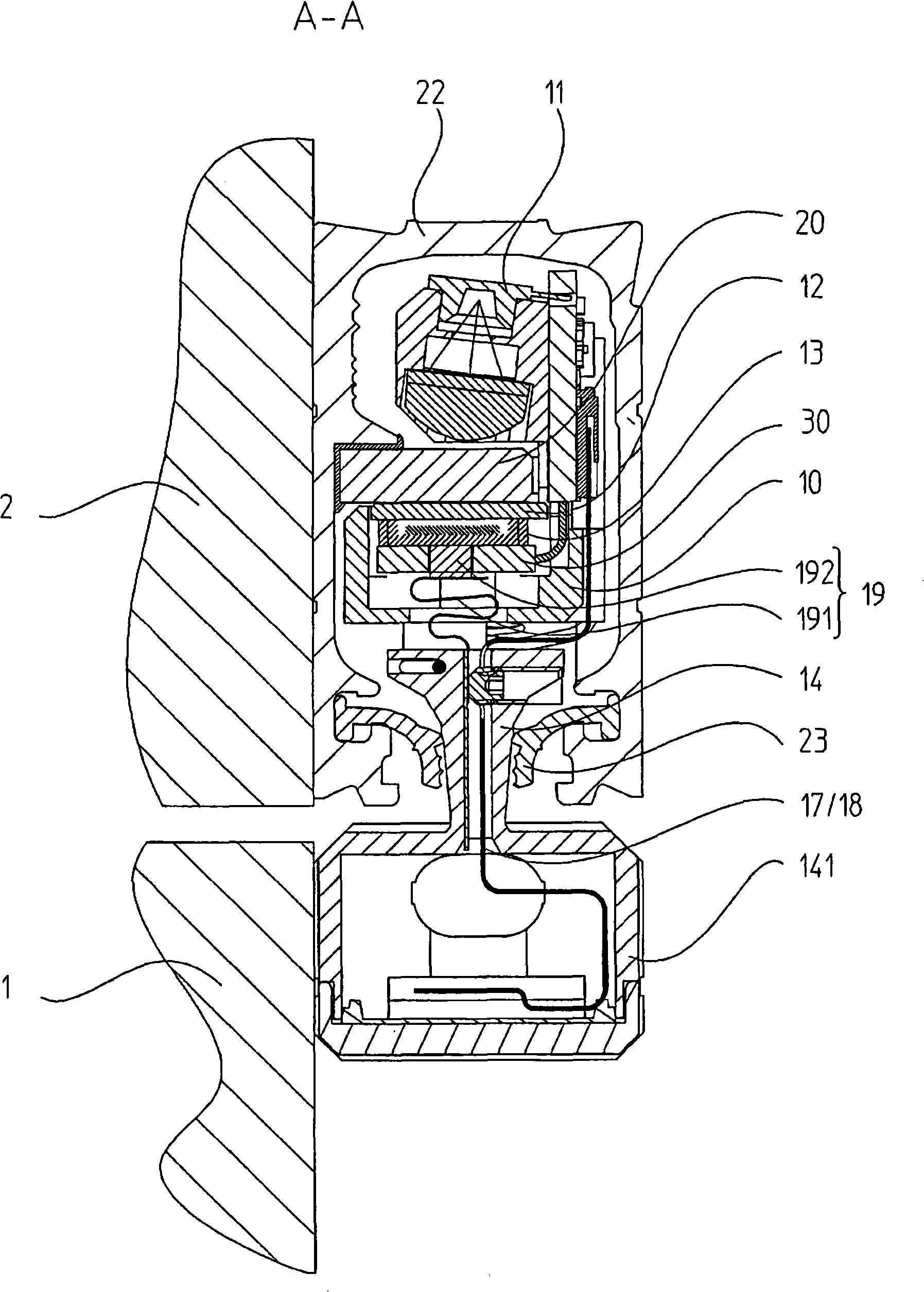

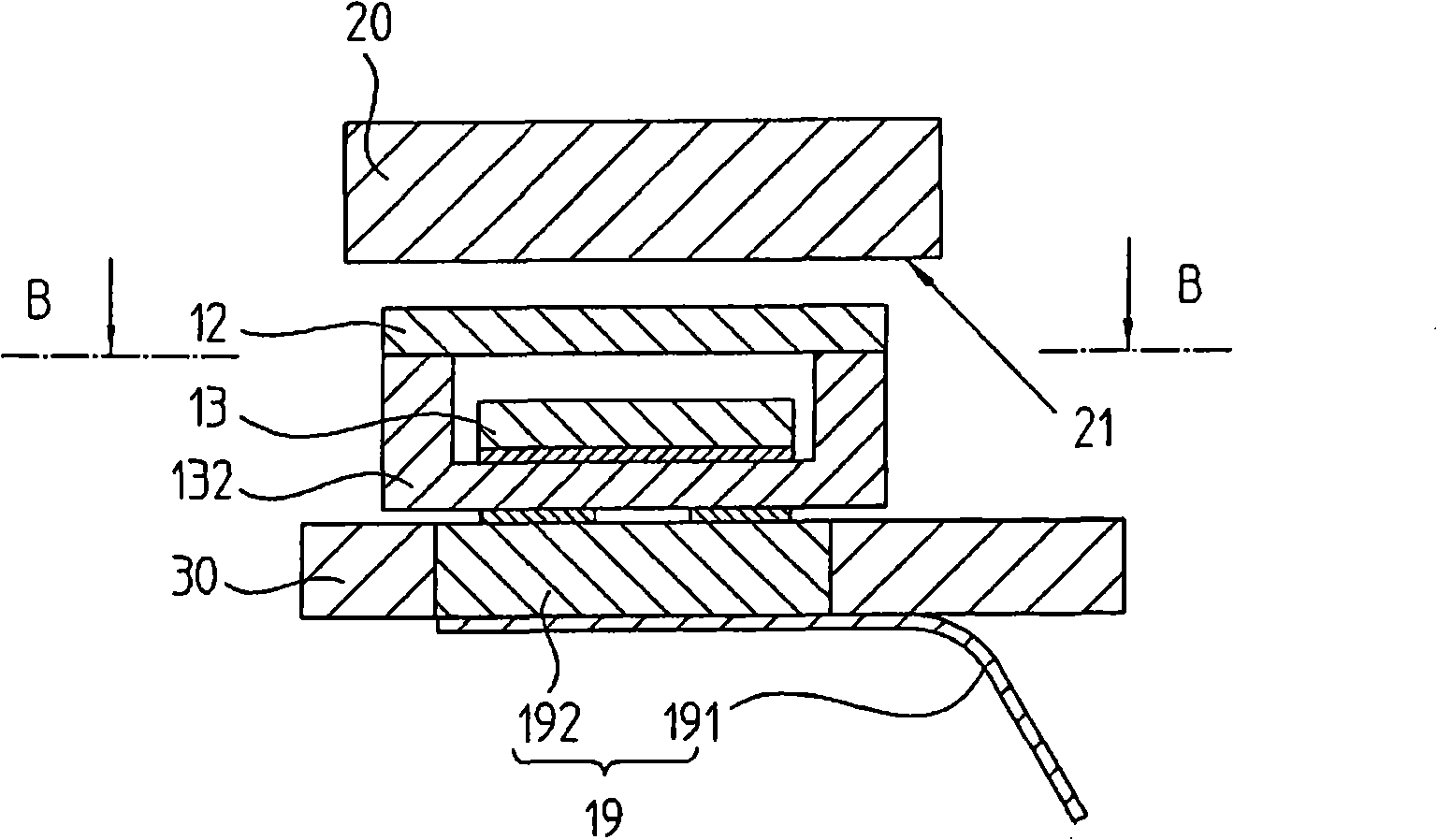

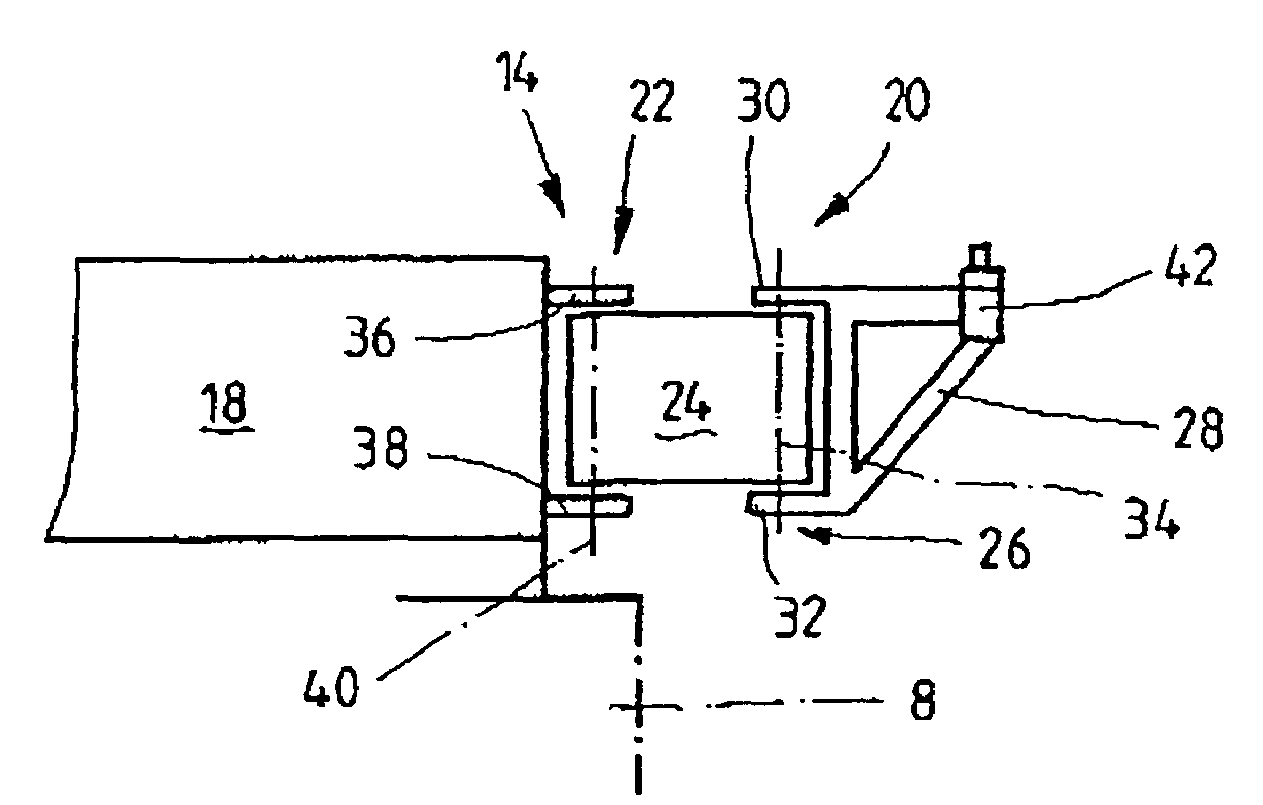

Length measuring device

ActiveCN101344380AReduce heat transfer resistanceInstrumental cooling apparatusUsing optical meansHeat conductingLength measurement

A length-measuring device is composed of a scale (20) having a housing, a sensor chip (13) of a scanning unit (10) for scanning the scale (20). A follower (14) rigidly and transversely coupled on the scanning unit (10) movably along a measurement direction X through a coupling mechanism (15). Heat generated by the sensor chip (13) is transmitted from the scale (20) to the follower (14) with pertinence. Therefore, a heat conducting element (19) is coupled on the sensor chip (13), wherein the heat conducting element is led to the follower (14) and is configured to be flexible, to compensate movement allowed by the coupling mechanism (15).

Owner:DR JOHANNES HEIDENHAIN GMBH

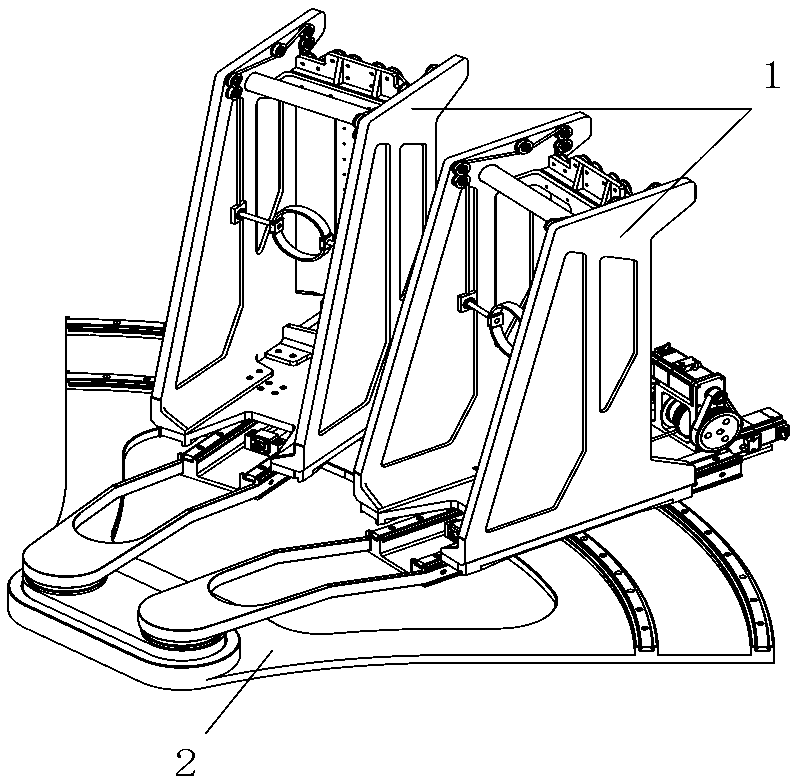

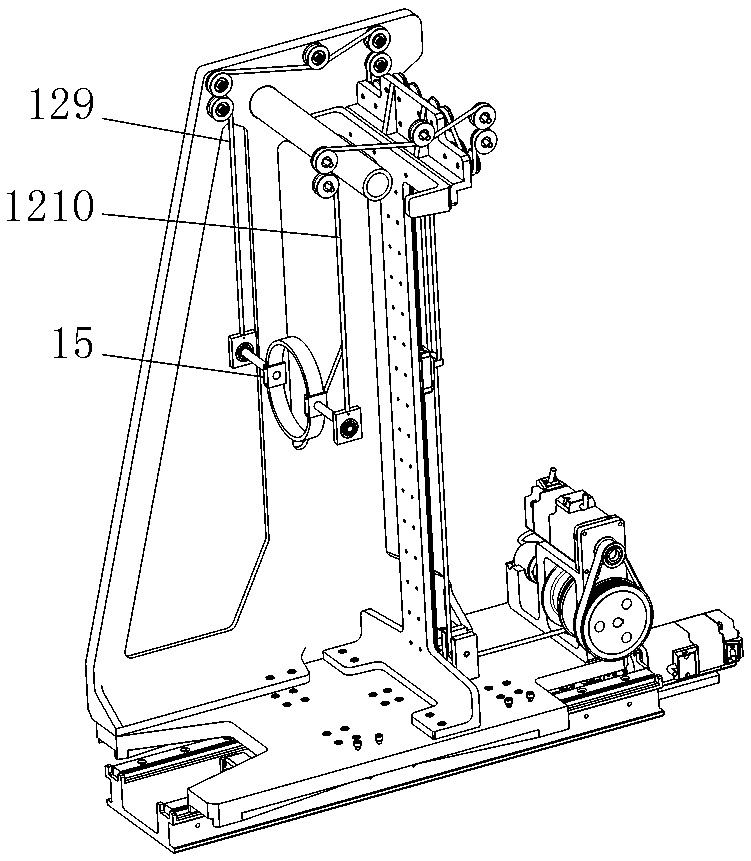

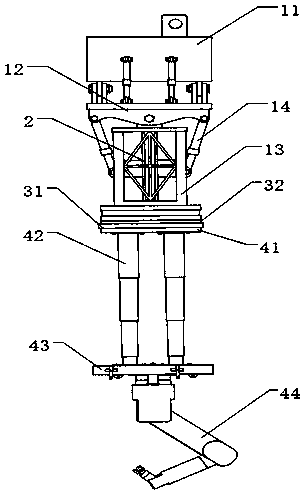

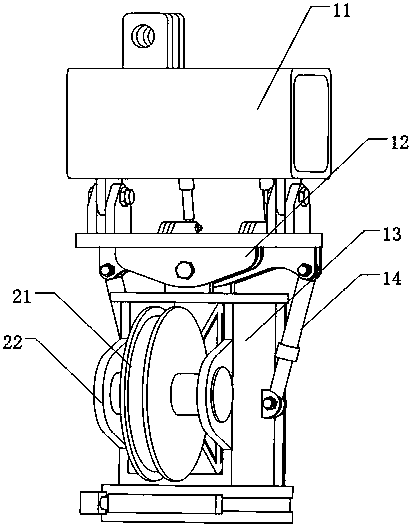

Wire-driven horizontal lower limb rehabilitation robot

ActiveCN111053674AIncreased opening and closing assistance degrees of freedomHigh simulationChiropractic devicesPhysical medicine and rehabilitationEngineering

The invention relates to a wire-driven horizontal lower limb rehabilitation robot, and belongs to medical equipment for assisting lower limb rehabilitation by robots. The wire-driven horizontal lowerlimb rehabilitation robot comprises a pair of foot fixing mechanisms and a support mechanism; each foot fixing mechanism comprises a foot rack, a wire guiding mechanism, a vertical driving mechanism,a horizontal driving mechanism and an ankle-containing mechanism; the horizontal driving mechanisms drive the pair of foot fixing mechanisms to slide back and forth relative to the support mechanism;and the vertical driving mechanisms control vertical movement in leg lifting rehabilitation exercise through the wire guiding mechanisms and the ankle-containing mechanisms. The freedom degree in thefront-back direction is innovatively introduced, wire driving is adopted, and lifting exercise cooperates with front-back compensation exercise in leg lifting rehabilitation training exercise to wellsimulate the leg lifting exercise; and the opening and closing auxiliary freedom degree of the two legs is increased, and the flexible lower limb rehabilitation exercise process can be well completed,so the good rehabilitation treatment effect is achieved. The robot is reasonable in structural design, convenient to disassemble and assemble and low in manufacturing cost.

Owner:HEFEI UNIV OF TECH

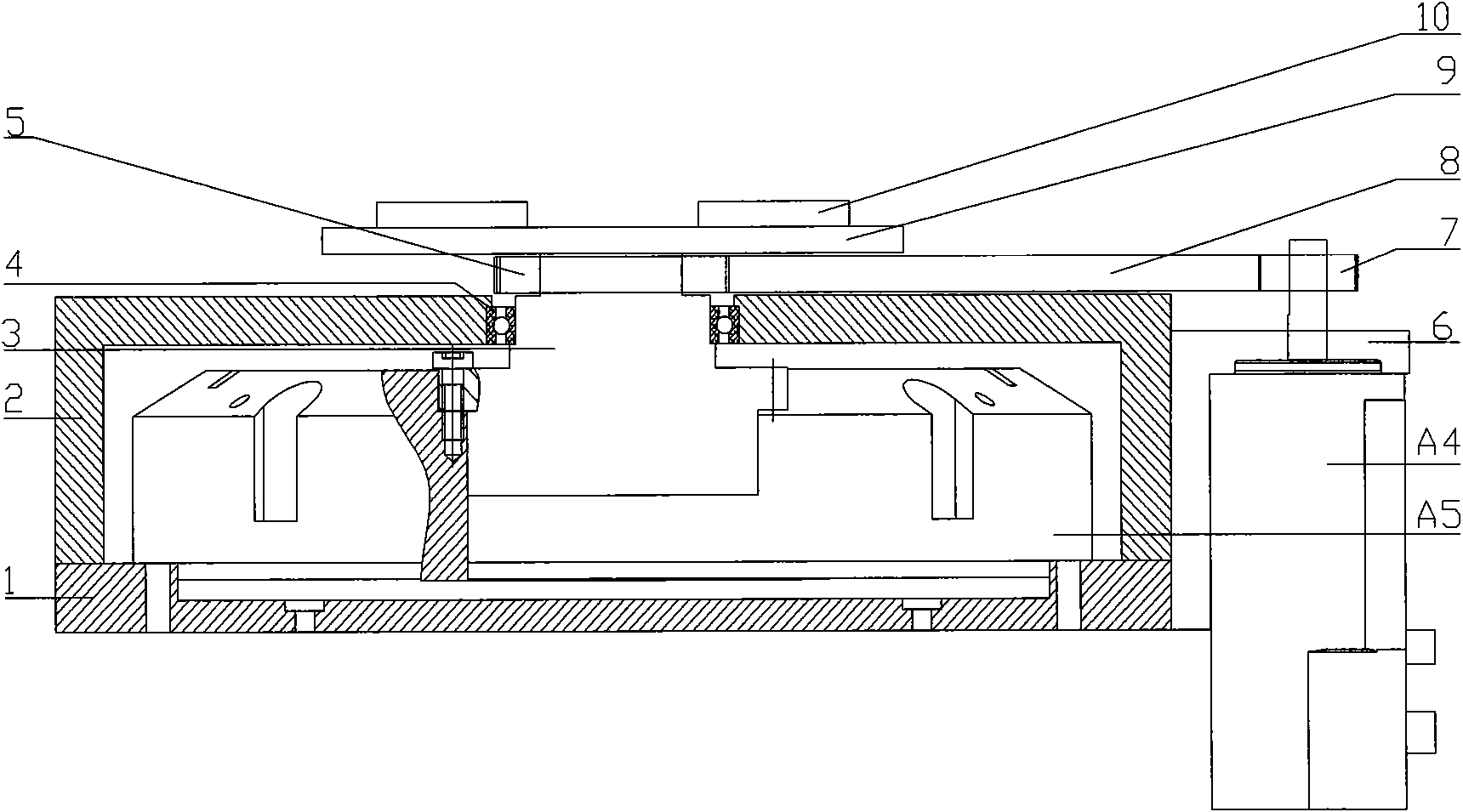

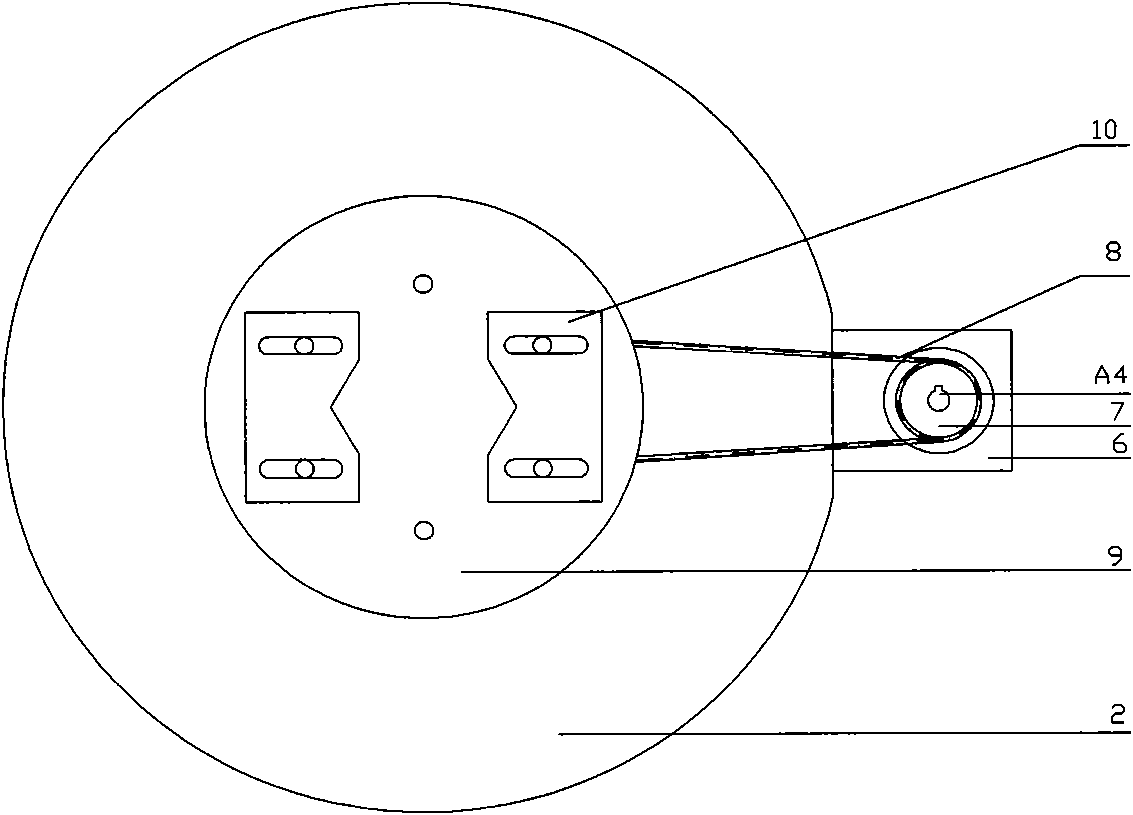

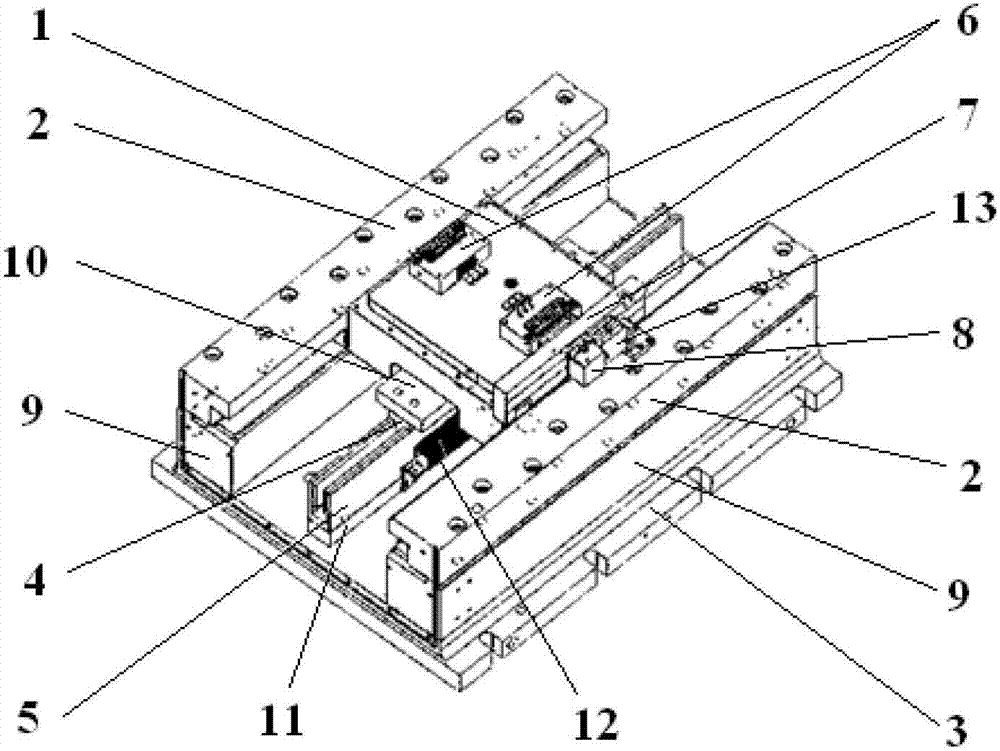

Liquid static pressure movement platform

InactiveCN102950474AEliminate backhaul errorsHigh movement precisionMeasurement/indication equipmentsLarge fixed membersBall bearingGrating

The invention provides a liquid static pressure movement platform which comprises a platform main body, a driving device and a position detection device; the platform main body comprises a sliding table, guide rails and a base; the guide rails are arranged on the base, and the sliding table is inlaid in the grooves of the guide rails; the driving device comprises a rotor, a stator and three oil distribution blocks; the stator is arranged on the base; one end of the rotor is inlaid in the groove of the stator, and the other end of the rotor is fixedly arranged on the lower surface of the sliding table; the three oil distribution blocks are arranged on the upper surface of the sliding table; the position detection device comprises a grating ruler and a reading head; the grating ruler is arranged on the side surface of the sliding table, and the scale surface of the grating ruler is jointed with the reading head; and the reading head is fixedly arranged on the guide rails. According to the liquid static pressure movement platform, because a linear motor is adopted to drive, the problem of hysterisis error in the transmission of a ball bearing lead screw is solved; and due to the position detection device for compensating movement errors, the movement precision of the platform is improved.

Owner:KUNSHAN YUNCO PRECISION IND TECH

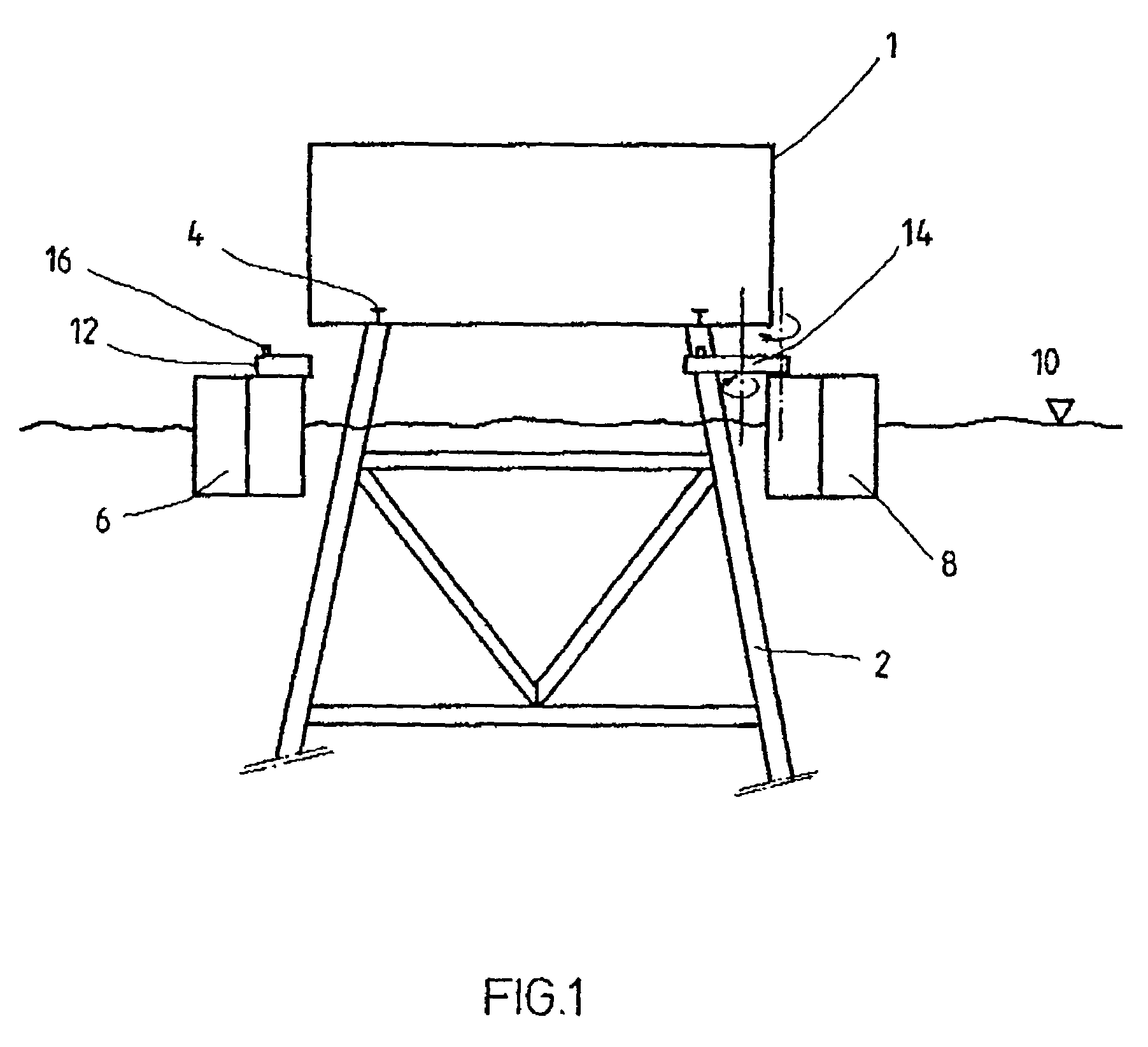

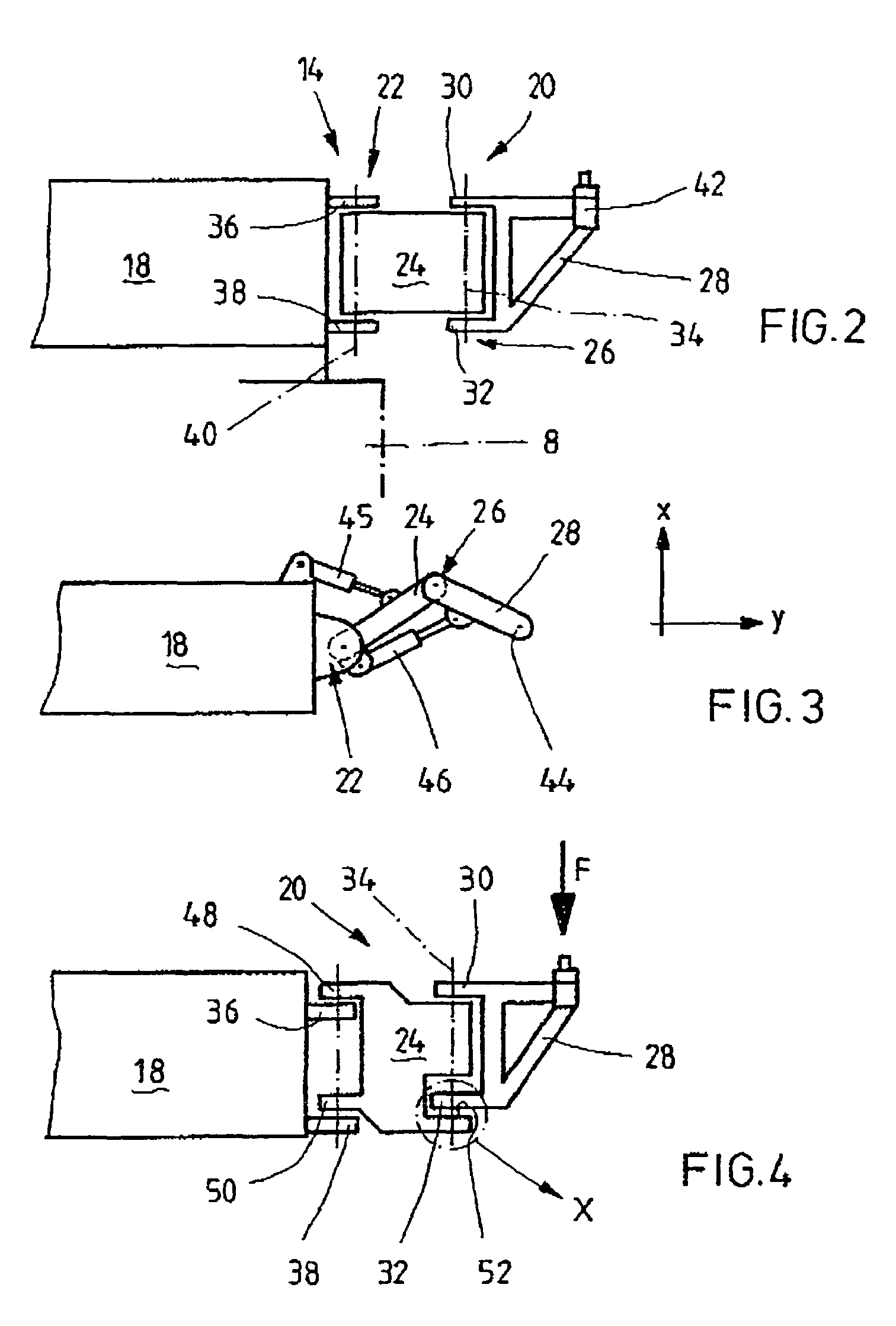

Supporting device comprising jointed arms

InactiveUS7465126B2Simple componentsCompensation is simpleArtificial islandsCargo handling apparatusEngineeringMarine engineering

Owner:BOSCH REXROTH AG

Stabilizer device with wheeled guide arm

InactiveUS20100052282A1Less bendingEasy to useInterconnection systemsResilient suspensionsEngineeringControl theory

An anti-roll bar device of an axle of a motor vehicle. The axle has an anti-roll bar (2) and, for each wheel, at least one steering rod (1). The chassis articulation (6) of the steering rod (1) is connected with an end (3) of the anti-roll bar (2), while the compensation movement of the steering rod (1) causes a twisting actuation of the (1) anti-roll bar (2). The anti-roll bar device is distinguished by the fact that the anti-roll bar (2) is rigidly connected with the chassis side end of the steering rod (1). The anti-roll bar arrangement facilitates constructively simple and sturdy articulation of the steering rod directly on the anti-roll bar as well as on the vehicle chassis or the axle mount. Furthermore, the assembly and installation of the anti-roll bar is simplified and the required structural space, weight and cost of the anti-roll bar are improved.

Owner:ZF FRIEDRICHSHAFEN AG

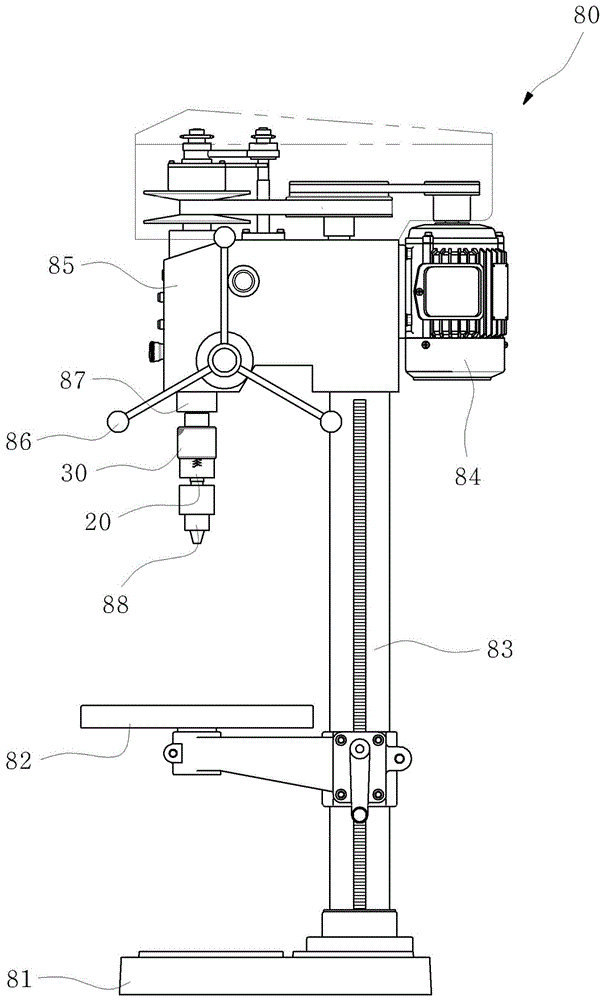

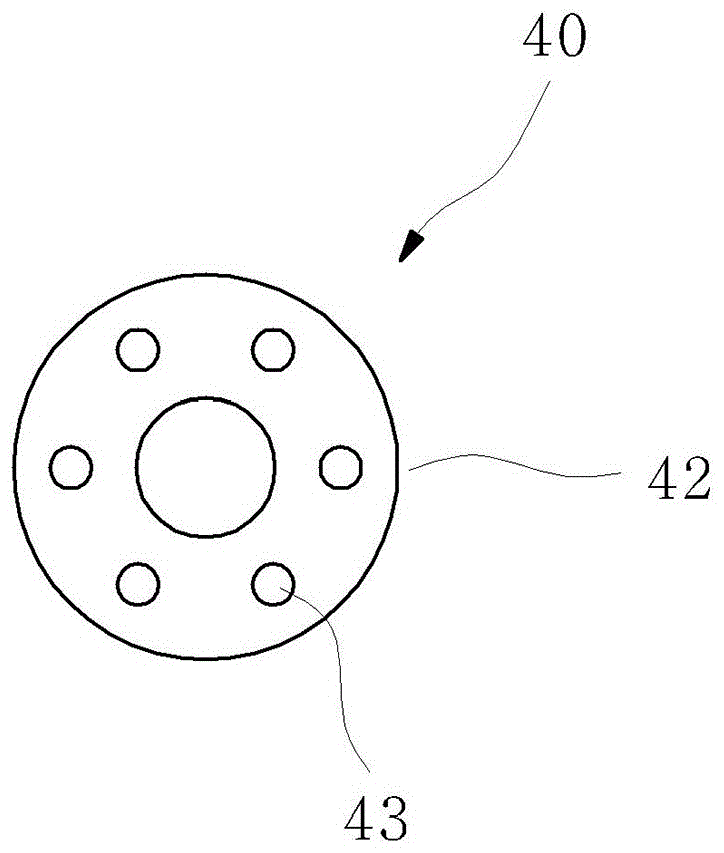

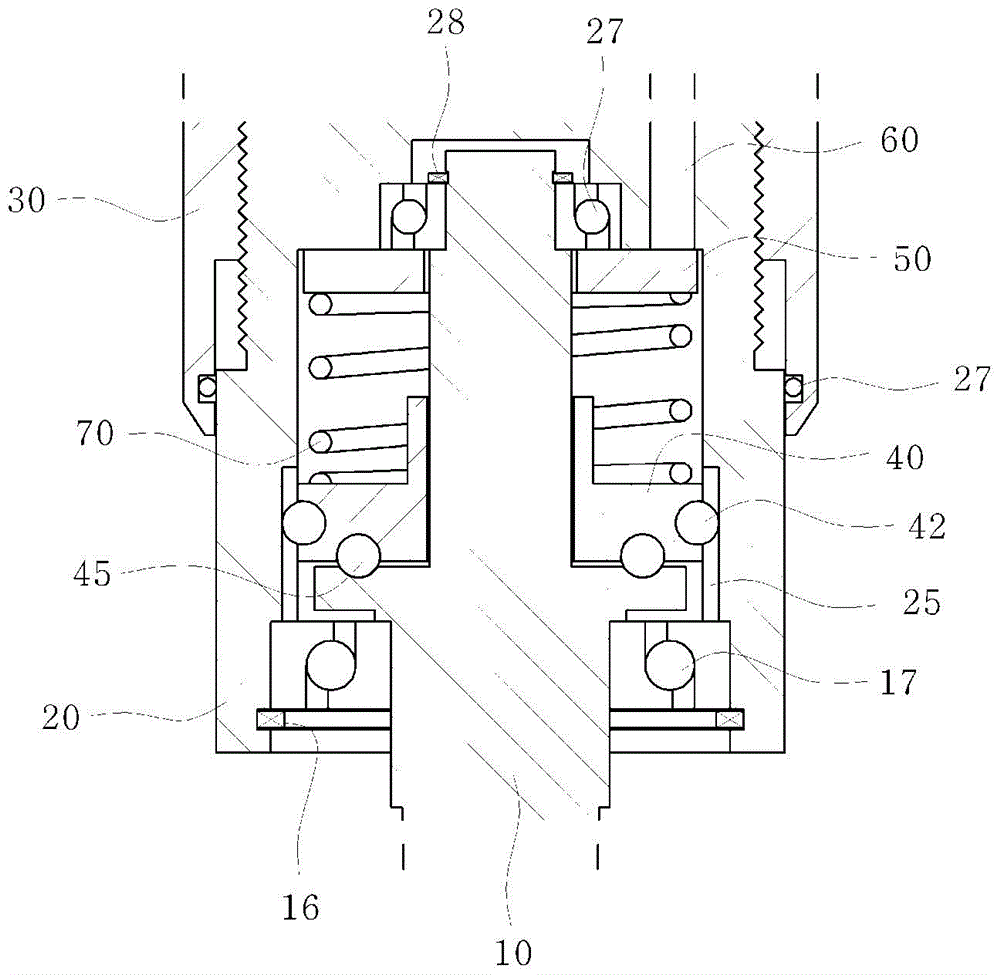

Screw tap safety special torque tool and metal plate preventing impact during occured torsion

InactiveCN106166635AAvoid breakingExtend your lifeThread cutting machinesBoring/drilling componentsDigital controlDrill

The invention discloses a screw tap safety special torque tool and metal plate preventing impact during occurred torque. The torque tool comprises a main shaft connection rod, an elastic regulation pin, a clamping connection shaft, an elastic regulation part, an idle gasket and a spring; when a bench drill is connected to a boring machine connected to a digital control miller formation hole and a screw tap forming the turnbuckle, the torsion tool is installed on the lower side of the main shaft; if an overloaded torsion acts on the boring machine or on the screw tap, power transmitted from the main shaft is not directly transmitted to the boring machine or the screw tap, but performing idling in the torsion tool to prevent damage of the boring machine or the screw tap and safely protect the boring machine or the screw tap. The screw tap safety special torque tool and metal plate preventing impact during occurred torsion can prevent noise generated in the idling torsion tool and breaking of the boring machine or the screw tap because of torsion clutch collision and impact; a torsion clamping plate grip compensates movement distance of the torsion tool and prevents the screw tap breaking or damage.

Owner:SAMSEONGMIRAETECH +1

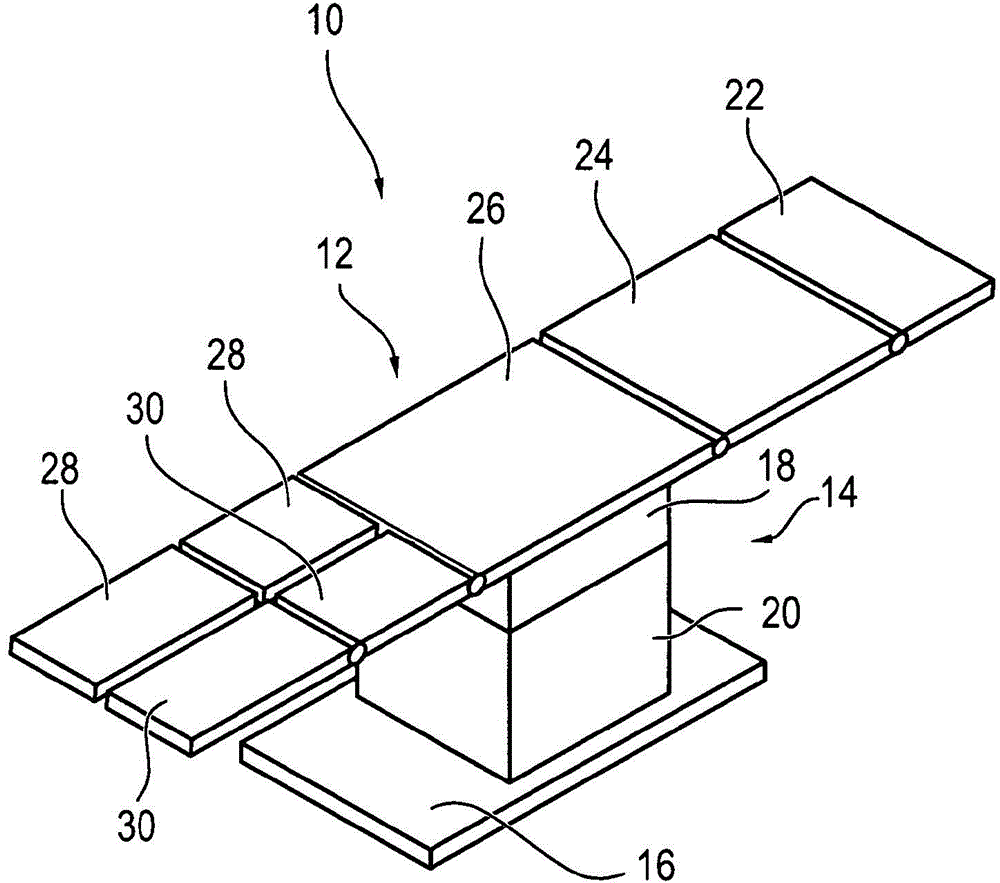

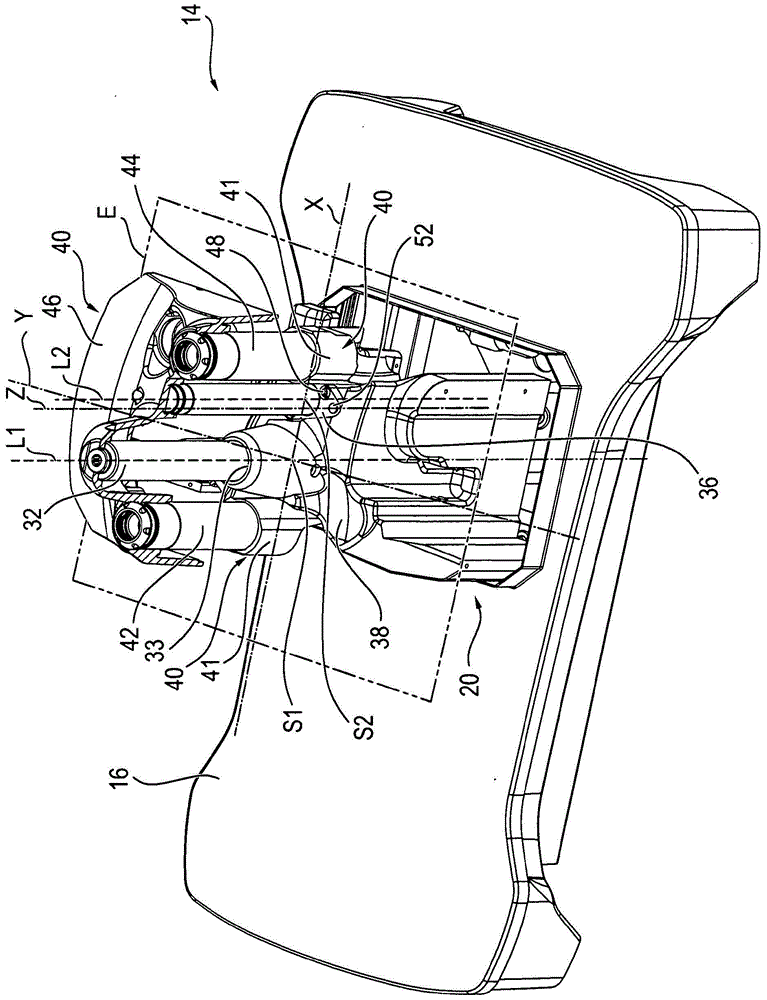

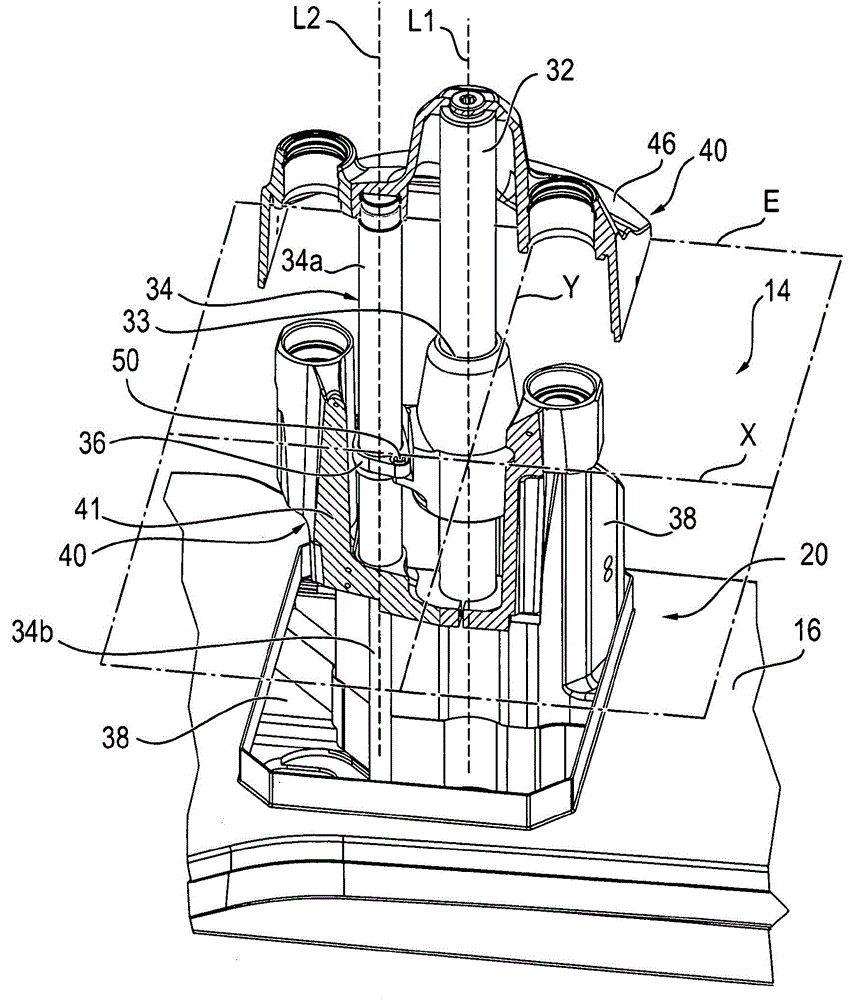

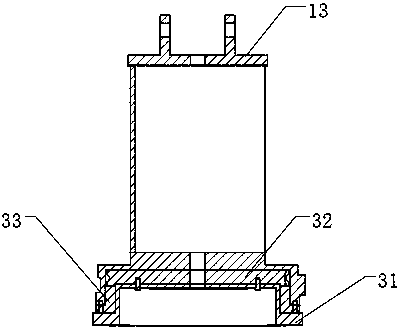

Device for adjusting the height of an operation table

ActiveCN105310852AAvoid supportImprove rigidityOperating tablesNursing bedsEngineeringOperating table

A device for height adjustment of an operating table (10), including a lifting carriage (40) which is movable relative to a chassis (38) of the operating table (10), including a primary guide (32, 33) having a first longitudinal axis (L1) about which the lifting carriage (40) is rotatable, including a secondary guide (34a) having a second longitudinal axis (L2), and including a guide means (36) which is connected to the chassis (38) of the operating table (10) and which has a contact area in which the guide means (36) contacts the secondary guide (34a) in a contact area of the secondary guide (34a). The primary guide (32, 33) and the secondary guide (34a) serve for guiding a lifting motion of the lifting carriage (40) within an adjustment range of the lifting carriage (40) parallel to the first longitudinal axis (L1), wherein a plane (E) extending perpendicular to the first longitudinal axis (L1) and through the guide means (36) has a first point of intersection (S1) with the first longitudinal axis (L1) and a second point of intersection (S2) with the second longitudinal axis (L2), and wherein the position (P1, P2) of the second point of intersection (S2) changes by a displacement distance (53) during the lifting motion of the lifting carriage (40) within the adjustment range thereof. The connection between the guide means (36) and the chassis (38) permits a complementing motion of the guide means (36) such that the contact area of the guide means (36) is shiftable by said displacement distance (53).

Owner:MAQUET GMBH

Hanging joint special for wave compensation of A-type portal frame

The invention relates to a hanging joint special for wave compensation of an A-type portal frame. The hanging joint is characterized by comprising a compensation mechanism, a winch, a rotary mechanismand an auxiliary mechanism. According to the hanging joint special for wave compensation of the A-type portal frame, an attitude sensor on a base of the A-type portal frame monitors precise values ofswing and displacement of a mother ship in real time and transmits the values to a controller, after calculating the compensation dosage, the controller controls all compensating hydraulic cylindersto cooperate to compensate movement of the mother ship, and thus equipment can be safely and stably lifted, lowered and recycled under the terrible ocean environment. According to the hanging joint special for wave compensation of the A-type portal frame, a manipulator can be lowered to the sea surface through telescopic rods, the manipulator can quickly hang hooks hung on a load-bearing table toa to-be-recycled unmanned submersible, then a mother ship towing system and the A-type portal frame are matched to conduct recycle, the consumed time is short, precision is high, and the recycling efficiency is greatly improved.

Owner:JIANGSU UNIV OF SCI & TECH +1

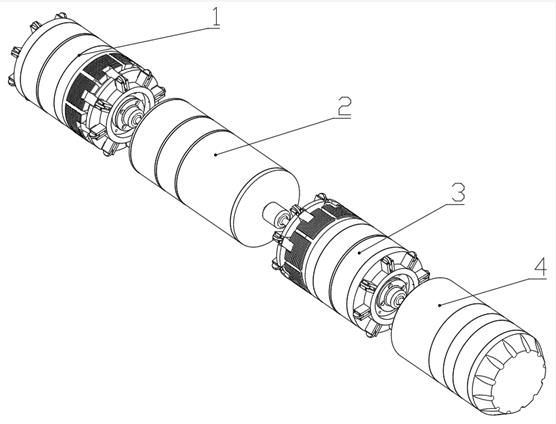

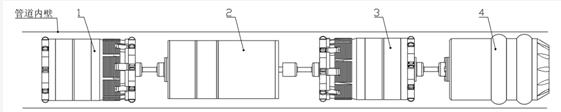

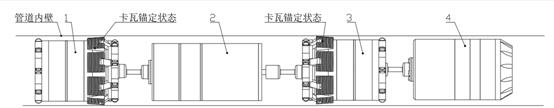

Active speed-adjustable intelligent pipeline plugging robot

The invention discloses an active speed-adjustable intelligent pipeline plugging robot. The robot comprises a first parking sealing mechanism, a crawling mechanism, a second parking sealing mechanism, a pigging speed regulating mechanism and the like, the pigging speed regulating mechanism is located at the lowest end, and the second parking sealing mechanism is connected to the upper portion of the pigging speed regulating mechanism through a connecting rod. The crawling mechanism is connected between the first parking sealing mechanism and the second parking sealing mechanism through a connecting rod, a plugging mechanism conducts plugging and anchoring through slip opening and closing and rubber deformation, and the crawling mechanism is matched with a front plugging mechanism body and a rear plugging mechanism body through hydraulic pistons to conduct crawling movement. The pigging speed regulating mechanism controls the overall movement speed through rubber deformation and compensates movement abrasion of rubber. According to the robot, intelligent plugging of an oil and gas transportation pipeline can be achieved, the robot can smoothly pass through complex pipeline conditions through rebound of rolling wheels, pigging rubber can continuously and efficiently conduct pigging speed regulation, the robot can accurately move to a designated working point through the crawling mechanism, and rapid, safe and accurate plugging in the oil and gas transportation pipeline first-aid repair and maintenance operation is achieved.

Owner:SOUTHWEST PETROLEUM UNIV +1

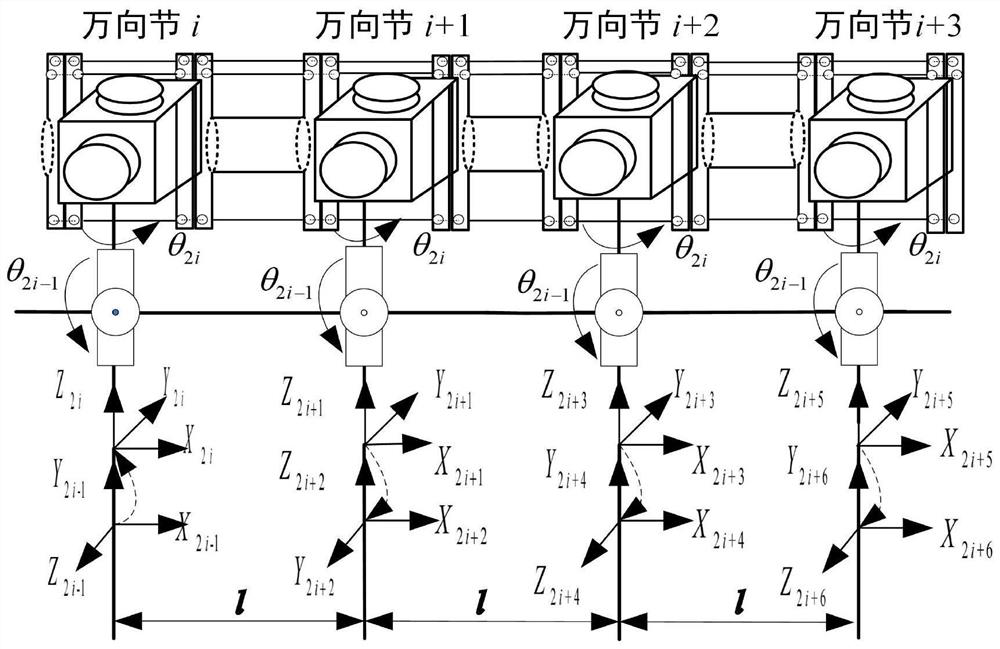

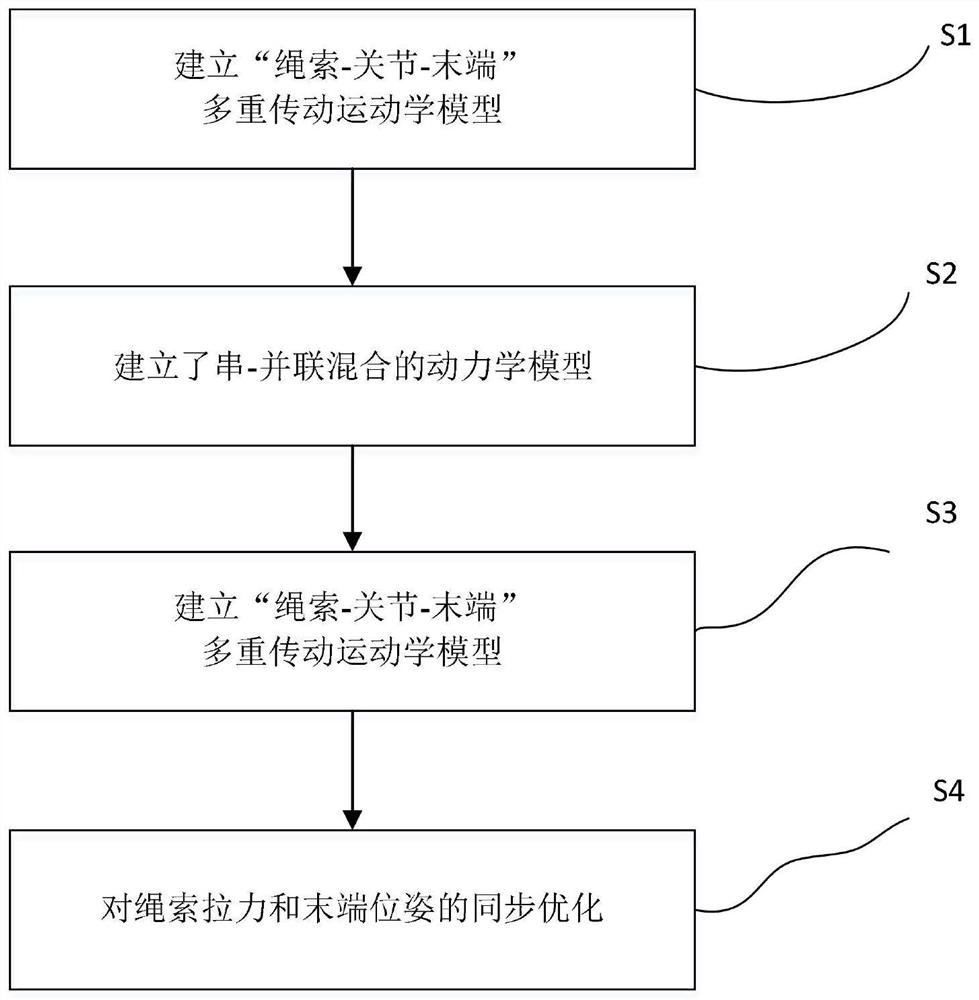

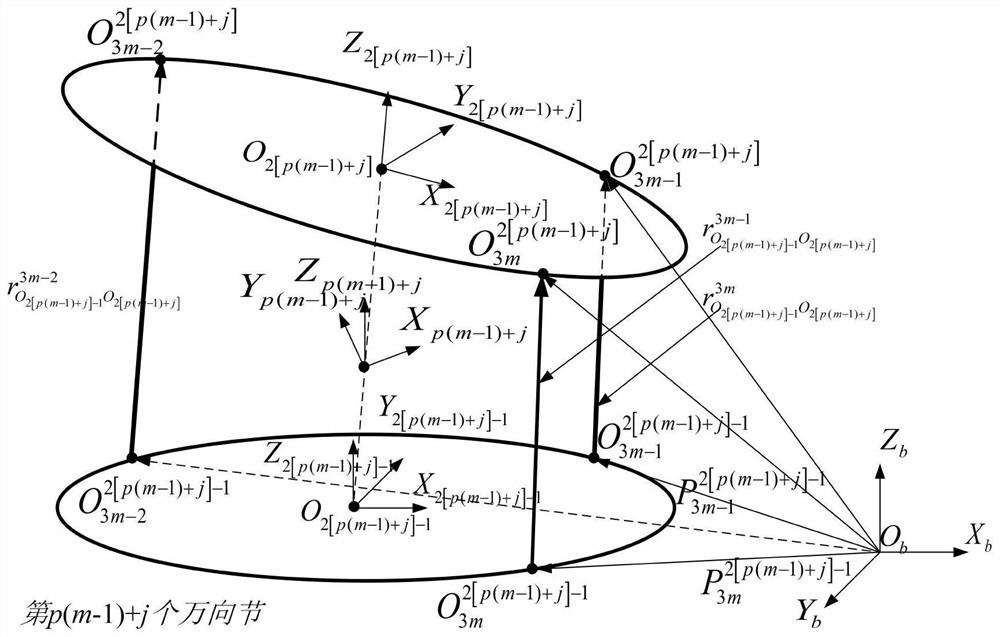

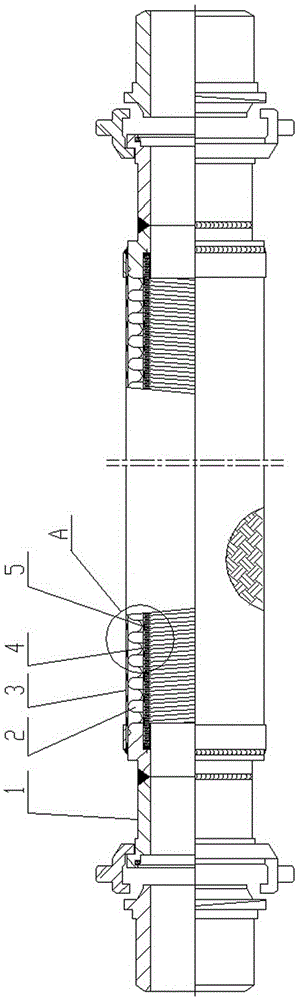

Dynamic modeling and track following control method and device for flexible robot

PendingCN113146617ASolve the mechanical propertiesSolving Trajectory Optimization ChallengesProgramme-controlled manipulatorDynamic modelsSimulation

The invention discloses a dynamic modeling and track following control method and device for a flexible robot. The method comprises the steps of establishing, according to mechanism geometric parameters of a discrete rigid connecting rod and linkage mechanism configuration type rope-driven series robot, a joint-tail end kinematic model by means of a D-H parameter method; and establishing, according to the rope transmission relation between joints, a rope-joint-tail end multiple dynamic coupling model. Furthermore, a segmented linkage type series-parallel hybrid dynamic solving method is provided, and a series-parallel hybrid dynamic model of the rope-driven series robot is deduced and established by solving the acting force of a driving rope and a linkage rope according to the driving-driven passive transmission characteristic; and the obtained dynamic model is used as feedforward control input of a controller to compensate motion errors, and meanwhile, a nonlinear quadratic programming module is designed to perform weighted optimization on rope tension and operation space precision indexes, so that high-precision following motion of a tail end operation space pose is realized, and the rope tension and the tail end pose are synchronously optimized.

Owner:SUN YAT SEN UNIV

Wear-resistant metal hose

PendingCN106523811ASimple structureEasy to manufactureFlexible pipesPipe protection against damage/wearWear resistantEngineering

The invention discloses a wear-resistant metal hose. The wear-resistant metal hose consists of joints, a corrugated tube, an outer net sleeve, a spring and an inner net sleeve. The outer net sleeve sleeves the corrugated tube, and after the outer net sleeve sleeves the corrugated tube, two ports of the combination of the corrugated tube and the outer net sleeve are respectively connected with the matched joints in a sealed manner. A liner of a cavity of the corrugated tube is combined with the spring in a sleeving manner, the inner net sleeve sleeves the outer wall of the spring, and two ports of the combination of the spring and the inner net sleeve positioned on the inner layer are also respectively connected with the matched joints in a sealed manner, so that a protecting structure of the spring to the cavity of the corrugated tube is formed. The matched spring is a flexible body, on the basis of improvement of wear resistance, the flexible structural feature of the corrugated tube is not changed, and therefore, the wear-resistant metal hose has enough flexibility to absorb or compensate movement of the hose. The metal hose has reasonable wear resistance and flexibility, the repairing and changing frequency is greatly reduced, and therefore, conditions are created for improvement of work efficiency and saving of costs.

Owner:JIANGSU ZHONGYUAN CONDUIT EQUIP

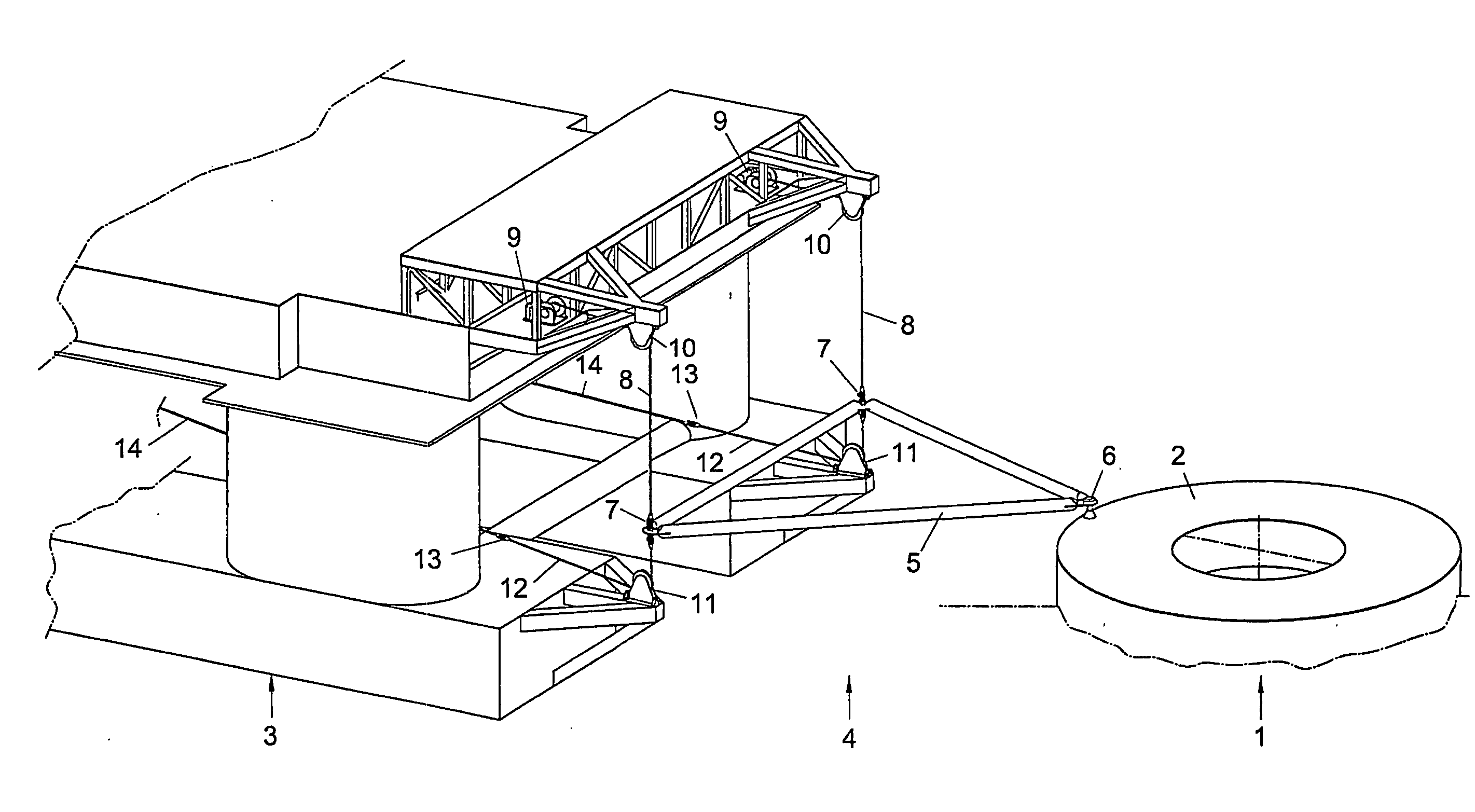

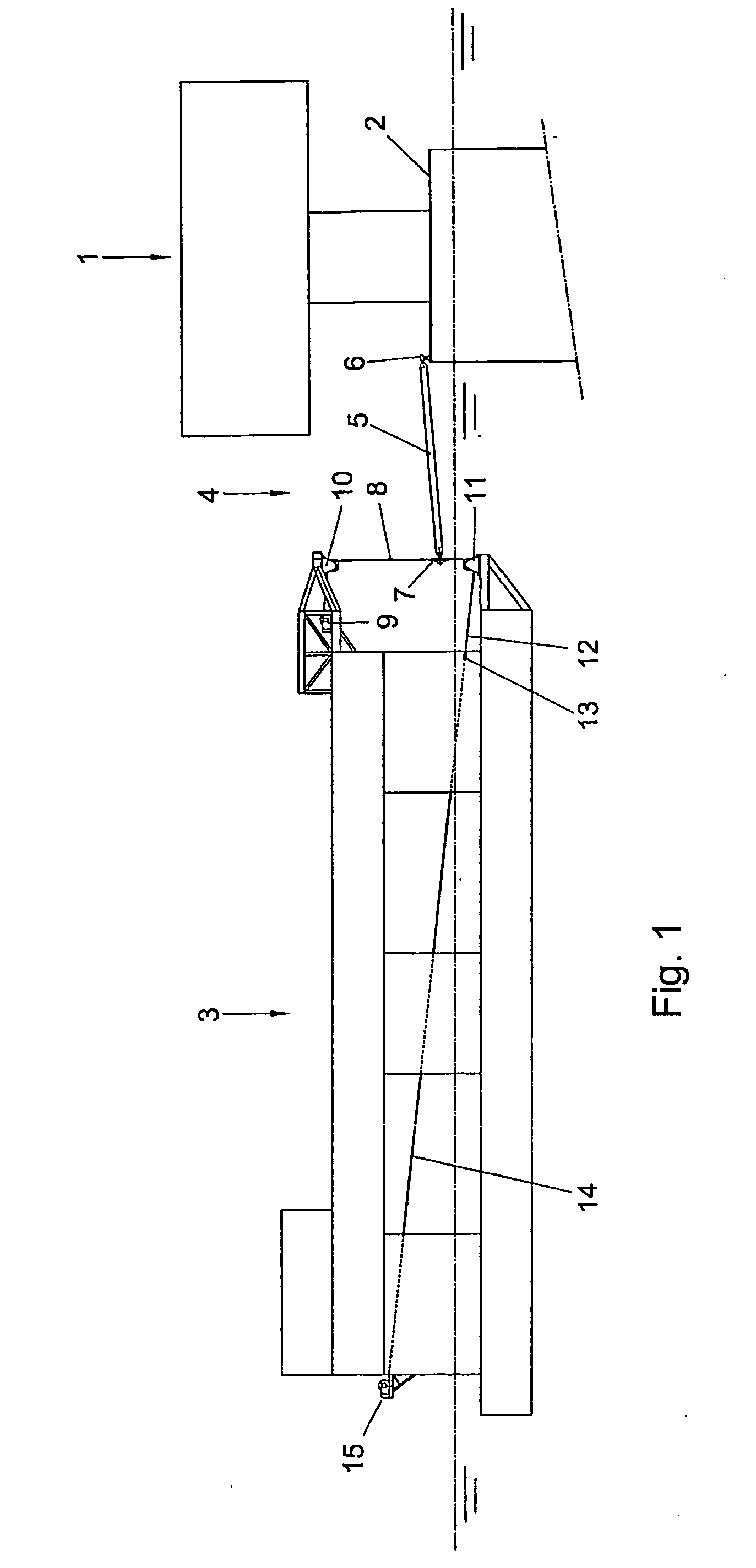

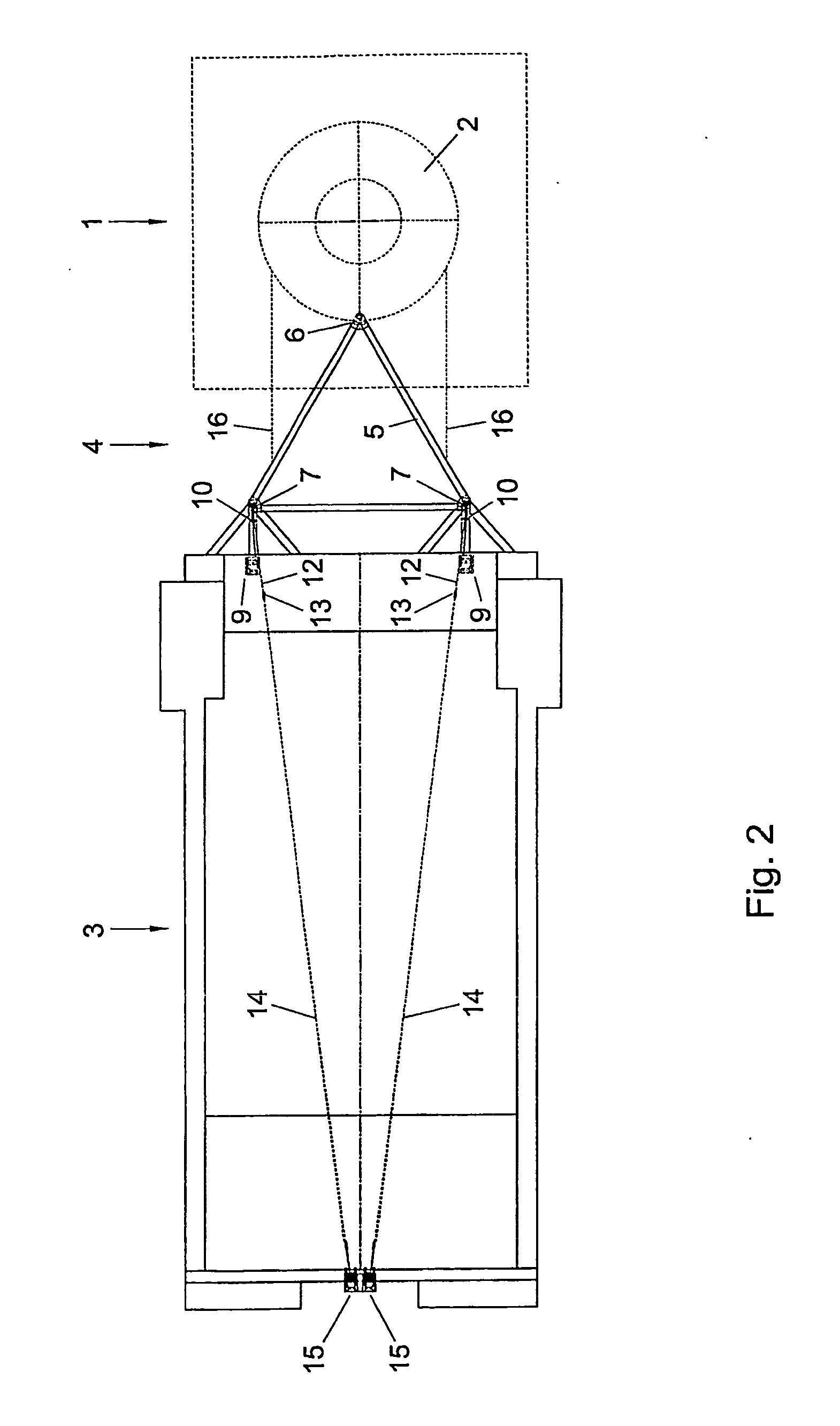

Apparatus for Connecting Two Offshore Units

A connecting apparatus for two offshore units includes a coupling element with two sets of couplings and resetting facilities that compensate movements between the two offshore units. The coupling element includes a frame connected with the offshore units by two sets of couplings in a manner allowing pivotal movement and rotation. At least one set of couplings includes a first and a second elongated element that are each connected with both the frame and an offshore unit via constructions allowing pivotal movement and rotation. The resetting facilities include a first and a second resilient element that are each stationary connected with the offshore unit and force either the first or the second elongated element to a position extending substantially vertically downwards.

Owner:MARINE STRUCTURE CONSULTANTS MSC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com