Telescopic chute for charging coke ovens

A telescopic cylinder and coke oven technology, applied in coke ovens, charging devices, conveying bulk materials, etc., can solve problems such as unsatisfactory service life of charging telescopic cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

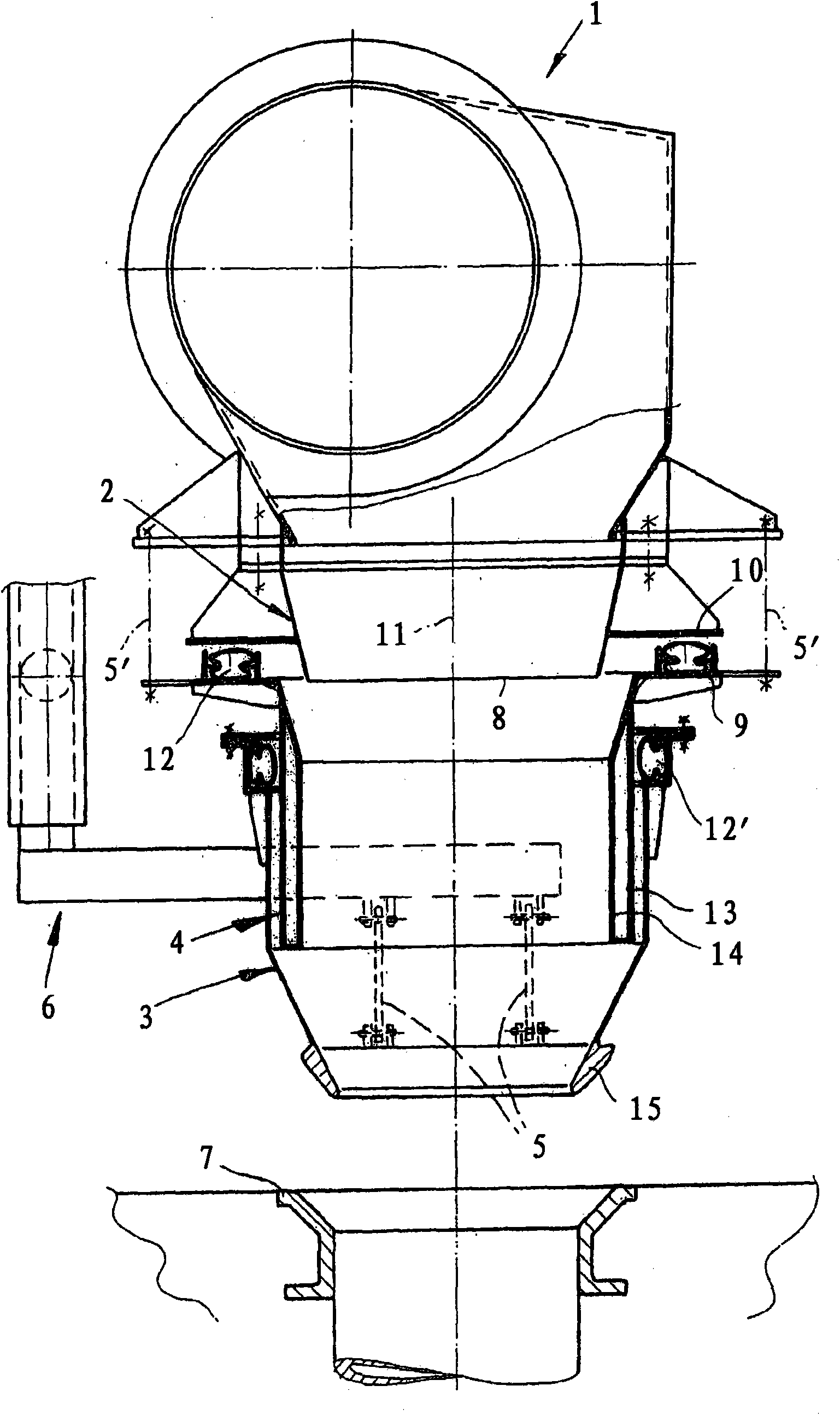

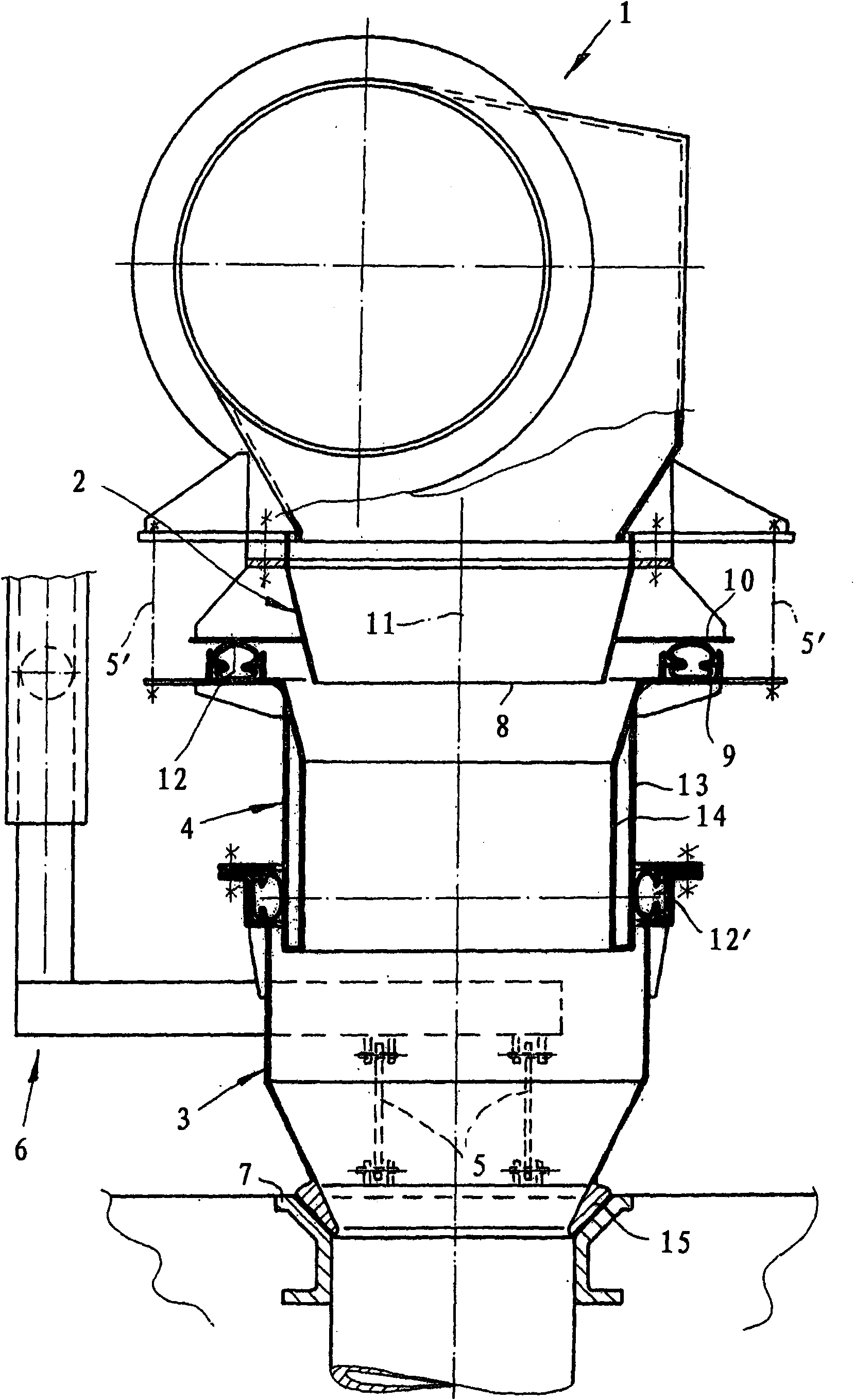

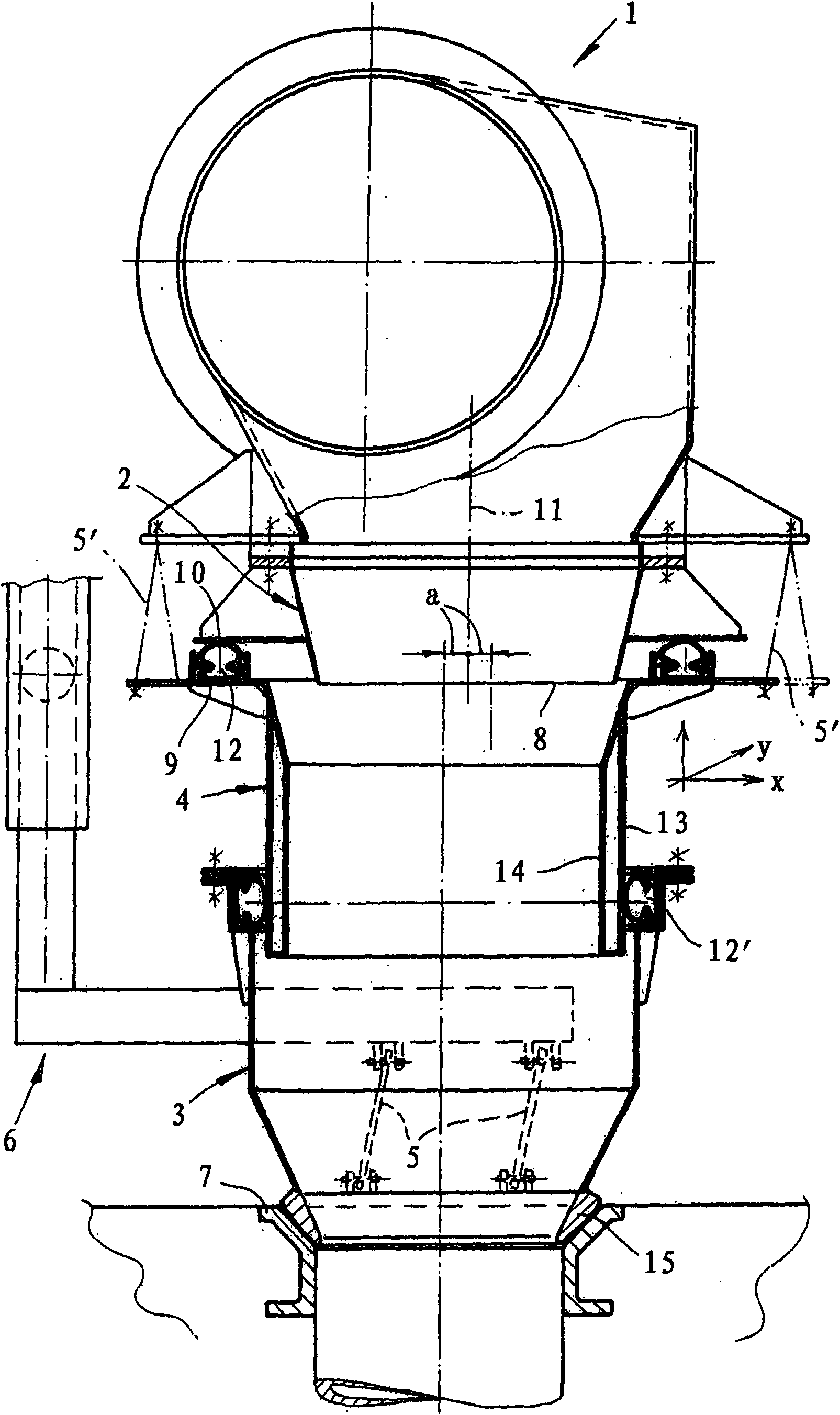

[0014] The charging telescopic cylinder shown in each figure is fixed to the unloading device 1 on the lower side of a coal charging truck, not shown, and is used to transfer the used coal from the unloading device 1 to the coke oven without any emissions. In the furnace cavity. In terms of its basic structure, the charging telescopic cylinder includes a feeding funnel 2 connected to the unloading device 1, a lower part 3 of the telescopic cylinder, and a tubular insert set between the feeding funnel 2 and the lower part 3 of the telescopic cylinder. 4. The lower part 3 of the telescopic cylinder is suspended on a vertically adjustable lifting device 6 using multiple swing elements 5, preferably multiple swing rods, and can be lowered to the charge in the furnace cover of the coke oven by the adjusting movement of the lifting device 6 Hole frame 7 on. The charging hole frame 7 forms an opening in the furnace cover.

[0015] The tubular insert 4 of the charging telescope is lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com