Active speed-adjustable intelligent pipeline plugging robot

A technology of robot and speed regulating mechanism, which is applied in the direction of pipe components, special pipes, mechanical equipment, etc., can solve the problems that the intelligent plugging robot cannot accurately block the designated working point, and the intelligent plugging robot cannot continuously and efficiently pig the pipes, etc. Achieve continuous and efficient pigging efficiency, avoid too fast out of control, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in combination with specific implementation modes and with reference to the accompanying drawings. It is worth mentioning that these are examples and are not intended to limit the scope of application of the present invention.

[0037] An example of an active and speed-adjustable pipeline intelligent plugging robot is as follows:

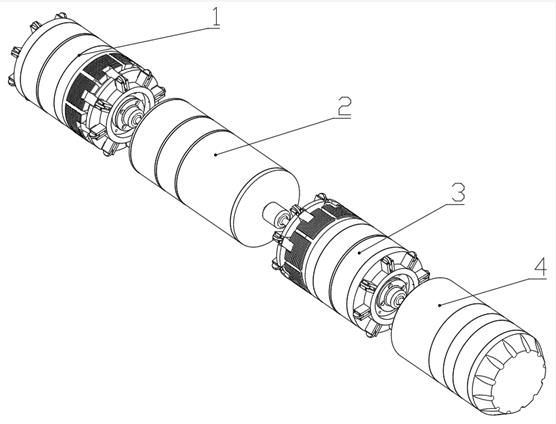

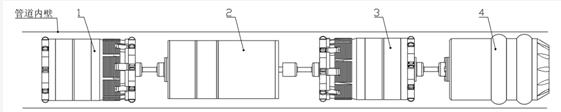

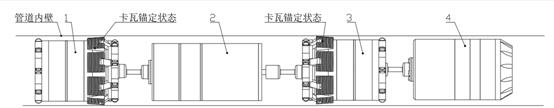

[0038] as attached Figure 1-6 An active speed-adjustable pipeline intelligent plugging robot is shown, which is characterized in that it includes a plugging mechanism 1 (1), a crawling mechanism (2), a second parking sealing mechanism (3), and a pigging speed regulating mechanism ( 4). Among them, the pigging speed regulating mechanism (4) is located at the bottom of the device, the second parking sealing mechanism (3) is connected above the pigging speed regulating mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com