Wear-resistant metal hose

A metal hose and corrugated pipe technology, which is applied in the field of pipeline safety devices, can solve the problems of short service life and low wear resistance of metal hoses, and achieve the effects of easy manufacture, simple structure, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the following, the present invention will be further explained based on the drawings and the embodiments.

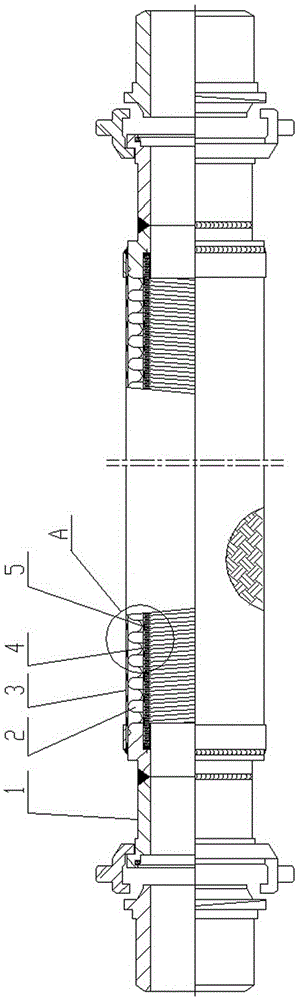

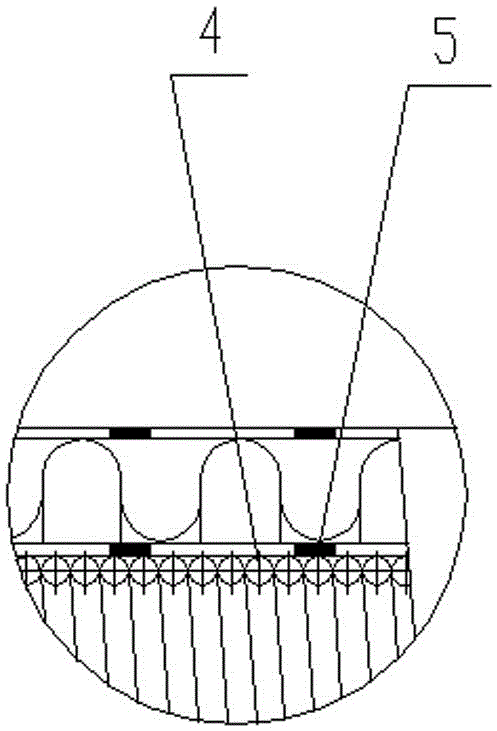

[0015] figure 1 The wear-resistant metal hose shown is applied to a pulverized coal boiler of a metallurgical enterprise. It consists of a pipe joint 1, a bellows 2, an outer mesh sleeve 3, a spring 4, and an inner mesh sleeve 5. The corrugated tube 2 is the main component of the metal hose. The outer wall of the corrugated tube 2 is made of a thin plate and the outer mesh sleeve 3 is sheathed. After the corrugated tube 2 and the outer mesh sleeve 3 are sleeved, the two ports are respectively connected with the matched tube Joint 2 is hermetically connected. When the pulverized coal flow passes, in order to isolate the pulverized coal flow from directly contacting the inner wall of the corrugated pipe 2, the present invention lines the inner cavity of the corrugated pipe 2 with a spring 4 sleeved, a sleeved spring 4, an outer wall sleeve, an inner mesh sleeve 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com