Screw tap safety special torque tool and metal plate preventing impact during occured torsion

A technology for torsion tools and metal plates, applied in the direction of manufacturing tools, metal processing equipment, components of boring machines/drilling machines, etc., can solve the problems of tap breakage, safety accidents, size inconsistencies, etc., to prevent tool breakage, prevent safety accidents, and facilitate the The effect of the torque value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings.

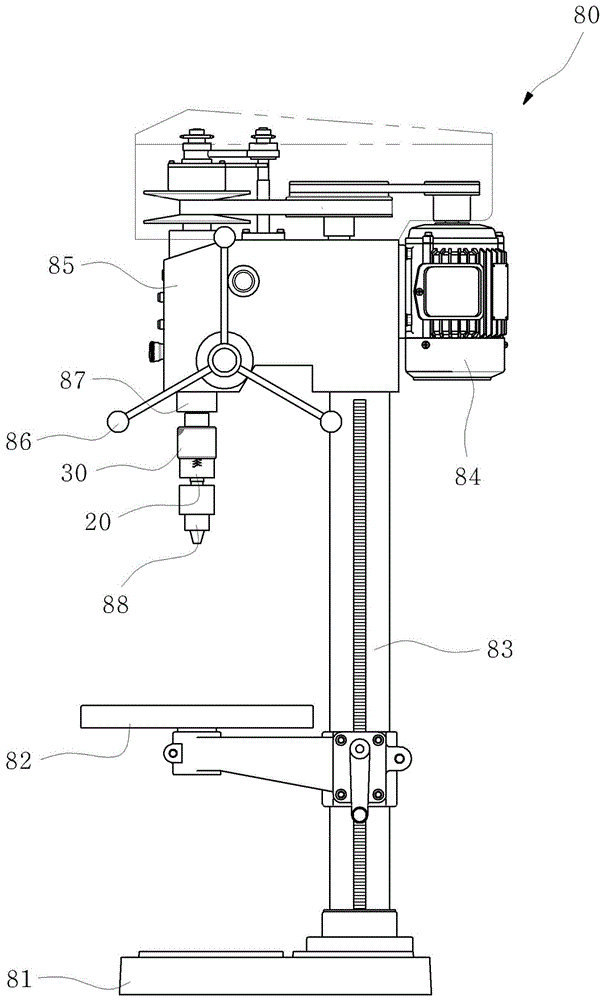

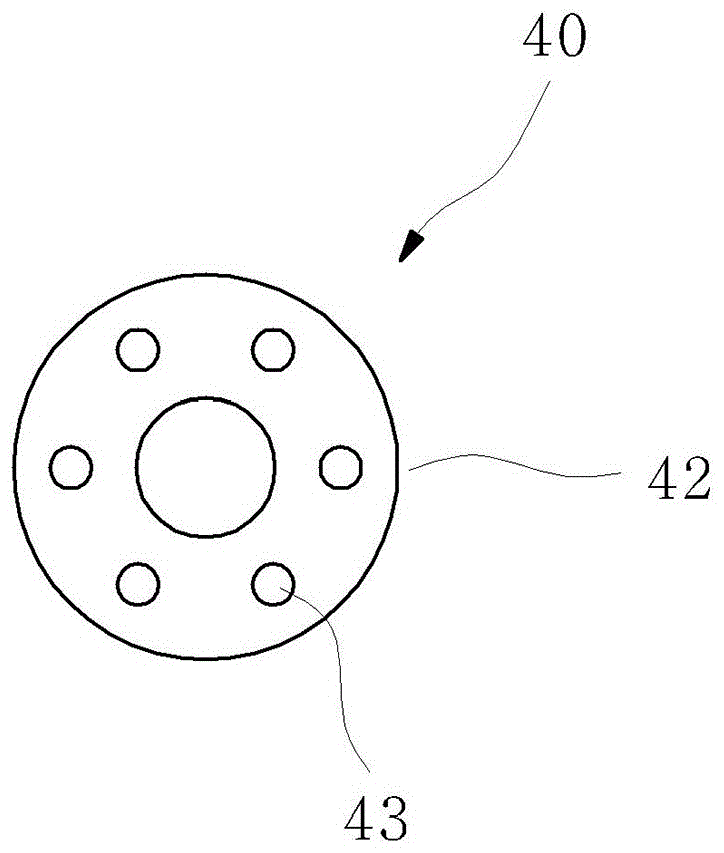

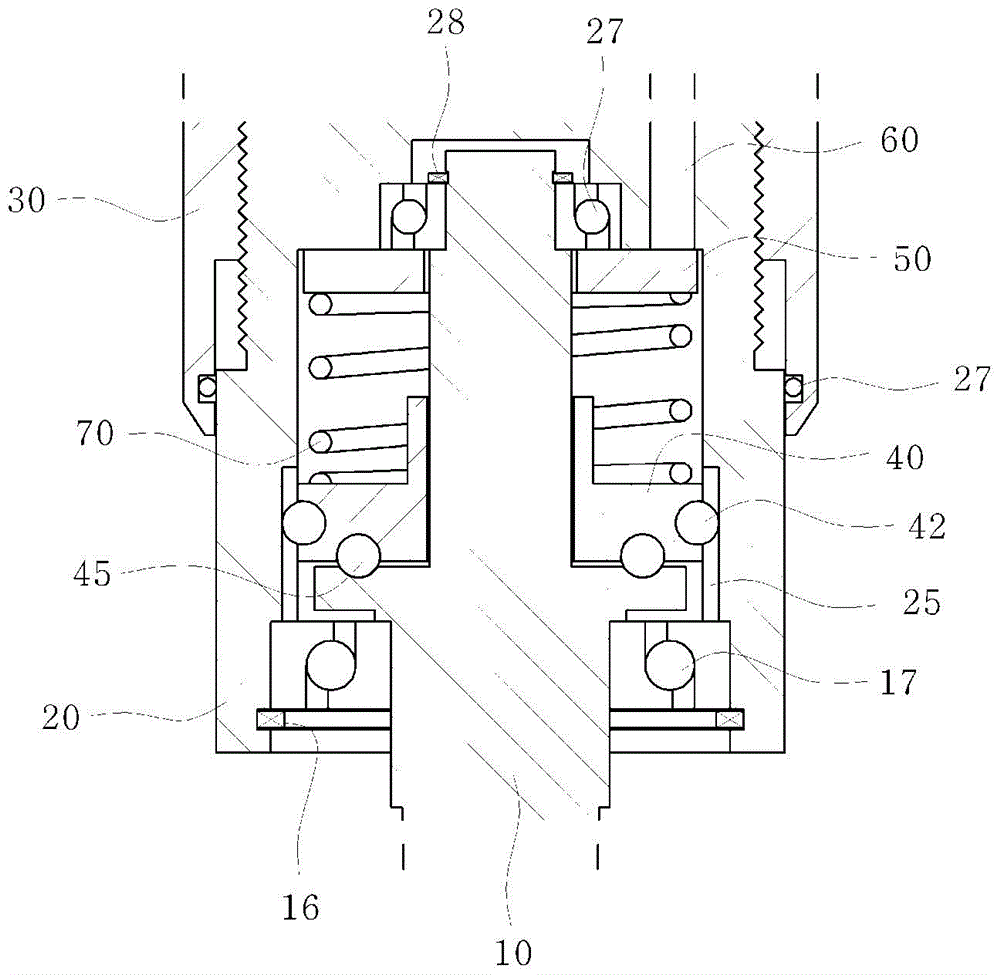

[0116] figure 1 It is a front view showing the installation state of the preferred embodiment of the present invention; figure 2 is a front view showing an embodiment of the torque tool of the present invention; image 3 is a sectional view showing an embodiment of the torque tool of the present invention.

[0117] A workbench 82 is installed on a part of the frame 83 erected on the upper side of the base 81, and it can be adjusted in height; an upper trunk 85 is installed on the upper side of the frame 83 to transmit the power of the motor assembly 84, and the main shaft 87 is rotated ; rotate the joystick 86 protruding from the side of the upper body 85 to vertically move the drill or tap (hereinafter referred to as the "tool") attached to the chuck 88 while the finished product mounted on the table 82 Form a through hole 2 or hole 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com