Graduation device for detecting surface shape of aspheric optical element

A technology for indexing devices and optical components, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of control accuracy, positioning accuracy, lack of information feedback, etc., and achieve small structure, wide application, and high hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below by means of embodiments in conjunction with the accompanying drawings.

[0021] The embodiments of the present invention basically include two parts: a control system and an indexing device.

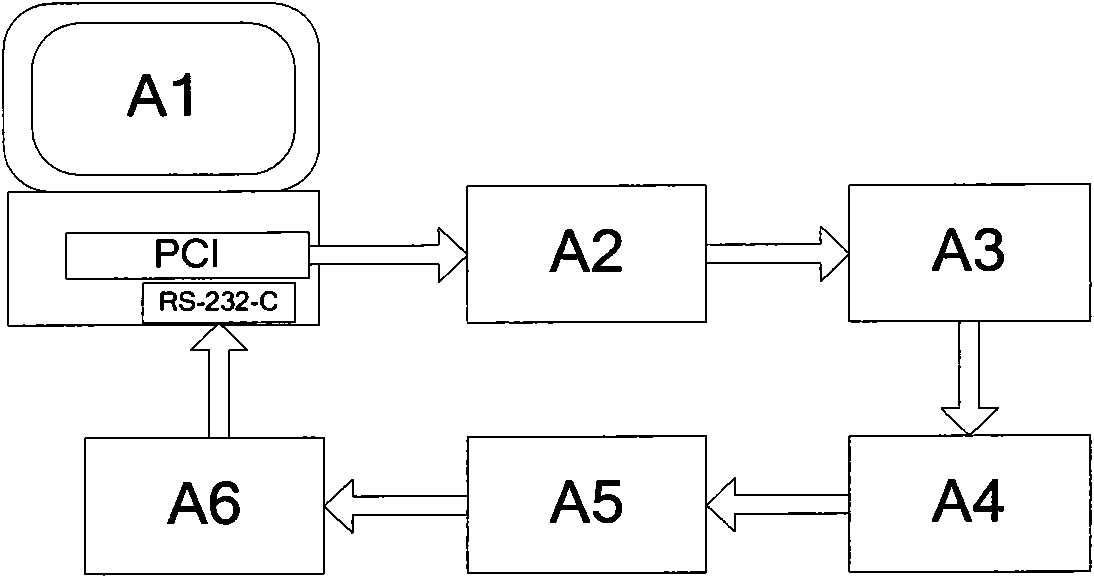

[0022] see figure 1 , The control system is equipped with industrial computer A1, interface circuit board A2, servo amplifier A3, servo motor A4, angle encoder A5 and encoder digital display meter A6. The motion controller of the industrial computer A1 is installed in the PCI slot of the IPC, connected to the input terminal of the servo amplifier A3 through the interface circuit board A2, the output terminal of the servo amplifier A3 is connected to the servo motor A4, and the angle encoder A5 is driven by the servo motor A4 , the data output end of the angle encoder A5 is connected to the input end of the encoder digital display meter A6, and the output end of the encoder digital display meter A6 is connected to the RS-232-C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com