Apparatus for Connecting Two Offshore Units

a technology a propeller is applied in the field of propellers for connecting two offshore units, which can solve the problems of requiring extra investment and installation time, ballast weight, and relatively mild environmental conditions, and achieve the effect of accurate control and guidance, rapid and efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

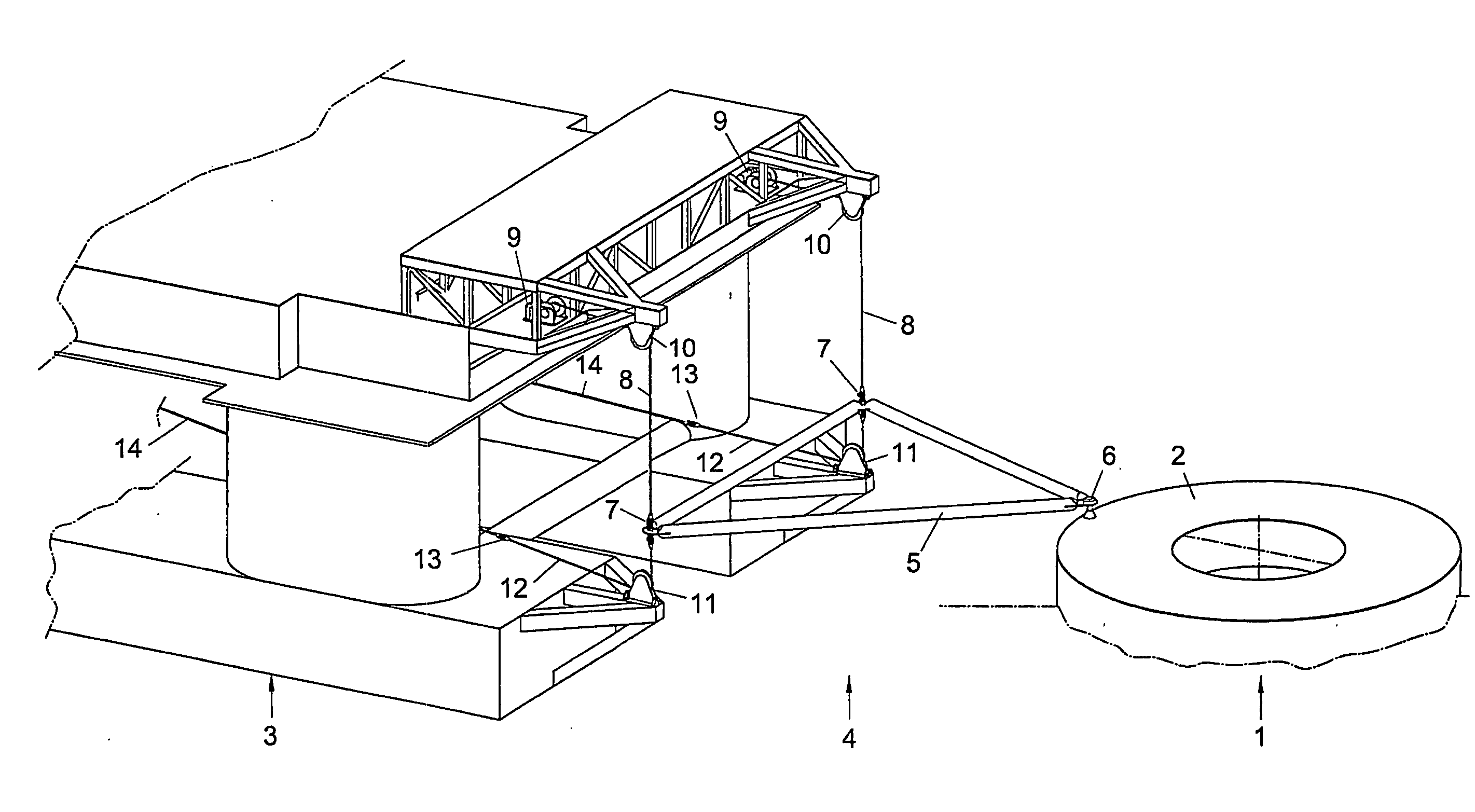

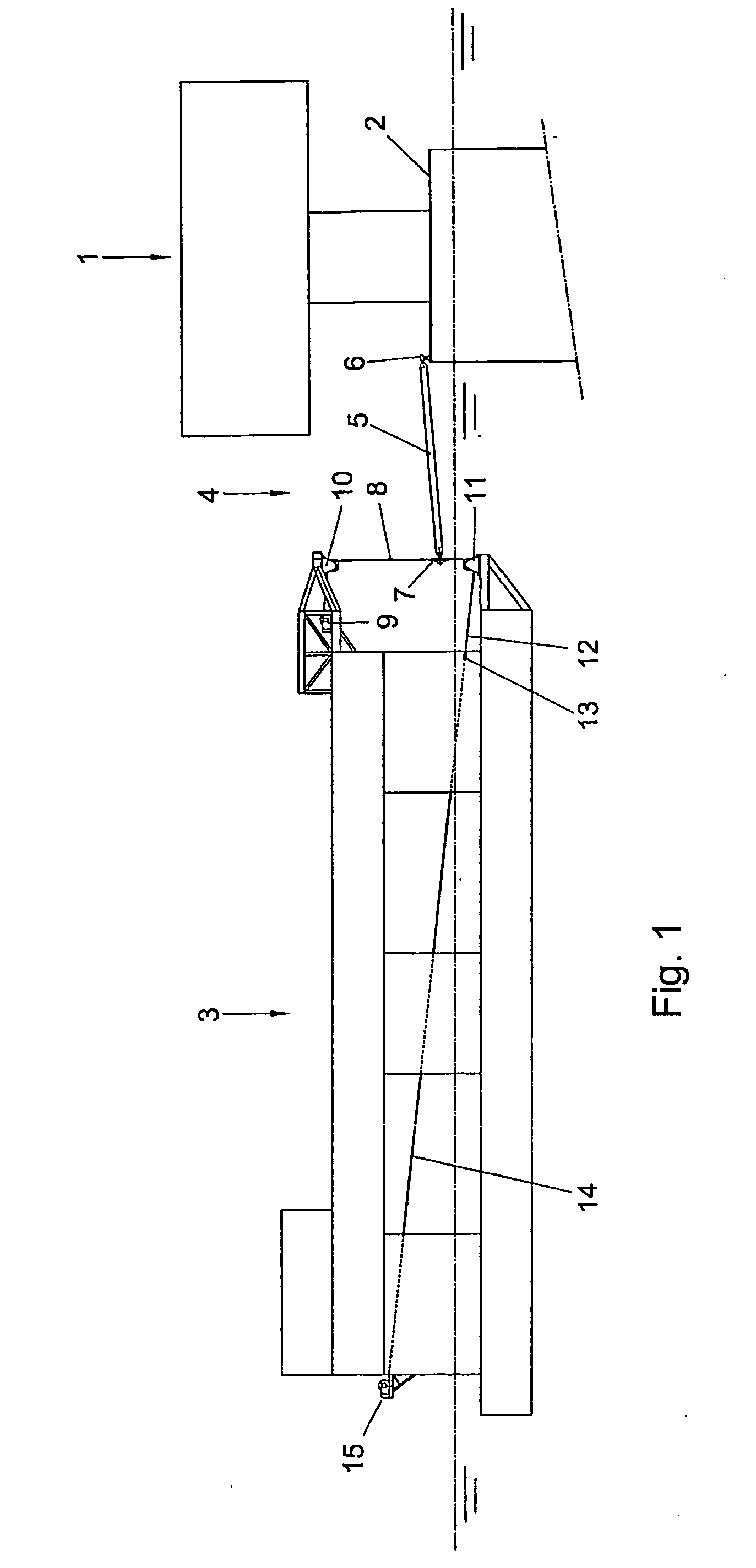

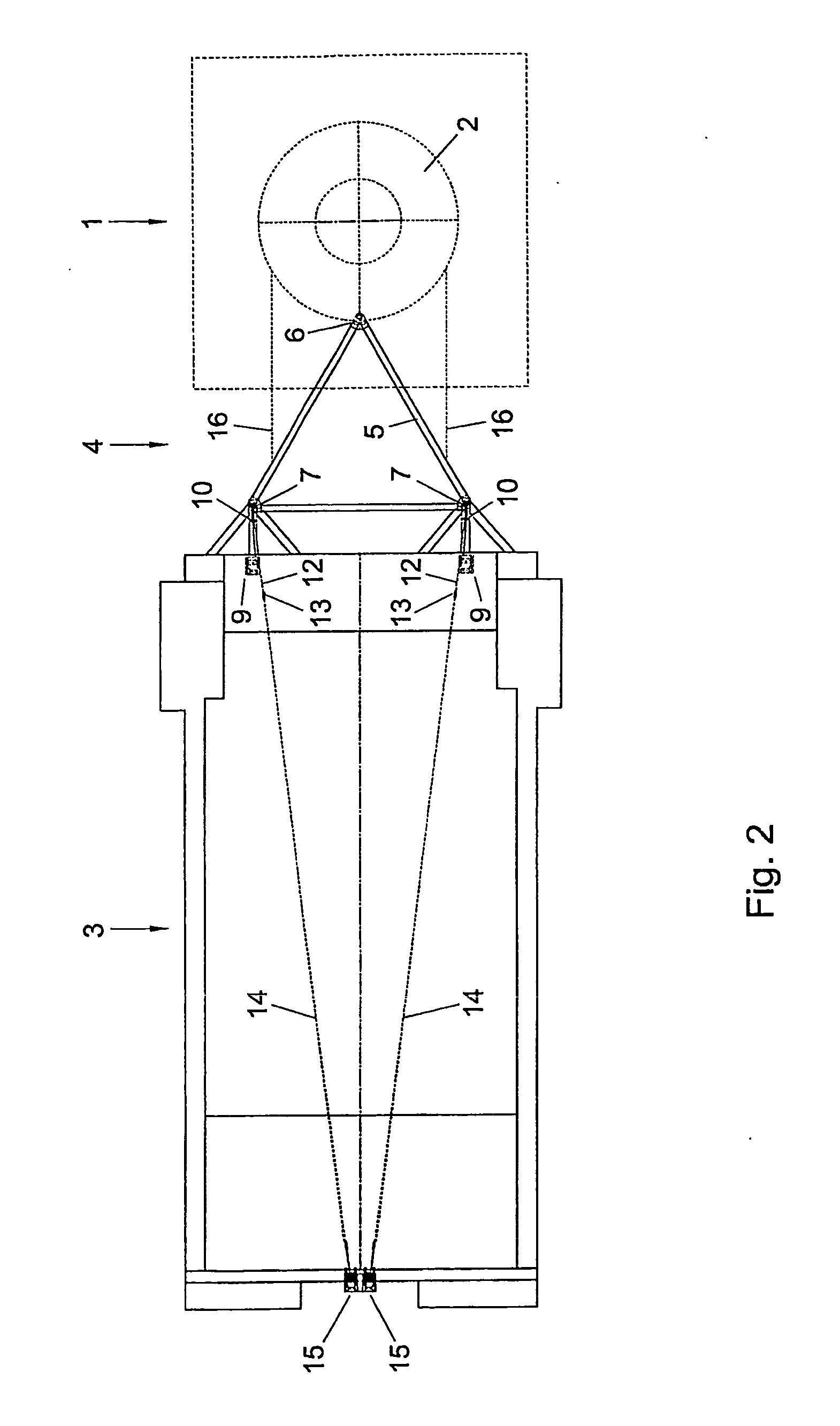

[0035] In FIGS. 1-3, a floating, anchored offshore unit in the form of a wellhead platform 1 is shown, which is provided with a deck 2 and is anchored to a bottom under water in a manner not shown. Further, FIGS. 1-3 show a floating offshore unit 1 in the form of a tender unit 3 moored in a manner not shown near the wellhead platform 1.

[0036] The wellhead platform 1 and the tender unit 3 are mutually coupled by a connecting apparatus 4, which is provided with a relatively rigid triangular frame 5, for instance formed by a rod construction, of which a first angular point bears a ball hinge 6, which is also fixed on the deck 2 of the wellhead platform 1, with which the coupling between the connecting apparatus 4 and the wellhead platform 1 has been brought about. The two other angular points of the triangular frame 5 are each connected, via connecting means 7 allowing pivotal movement and rotation, with a steel cable 8, which initially runs substantially horizontal from a winch 9 fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com