Double-sided material falling device

A blanking device and double-sided technology, applied in the direction of packaging, transportation and packaging, conveyors, etc., can solve the problem that the two-way blanking of steel pipes cannot be applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

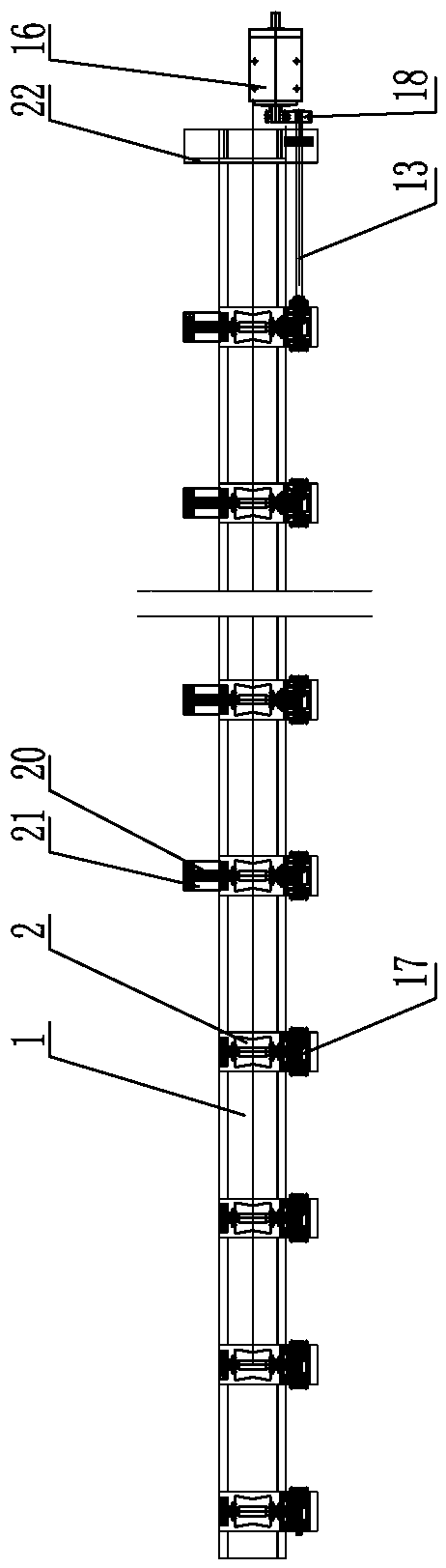

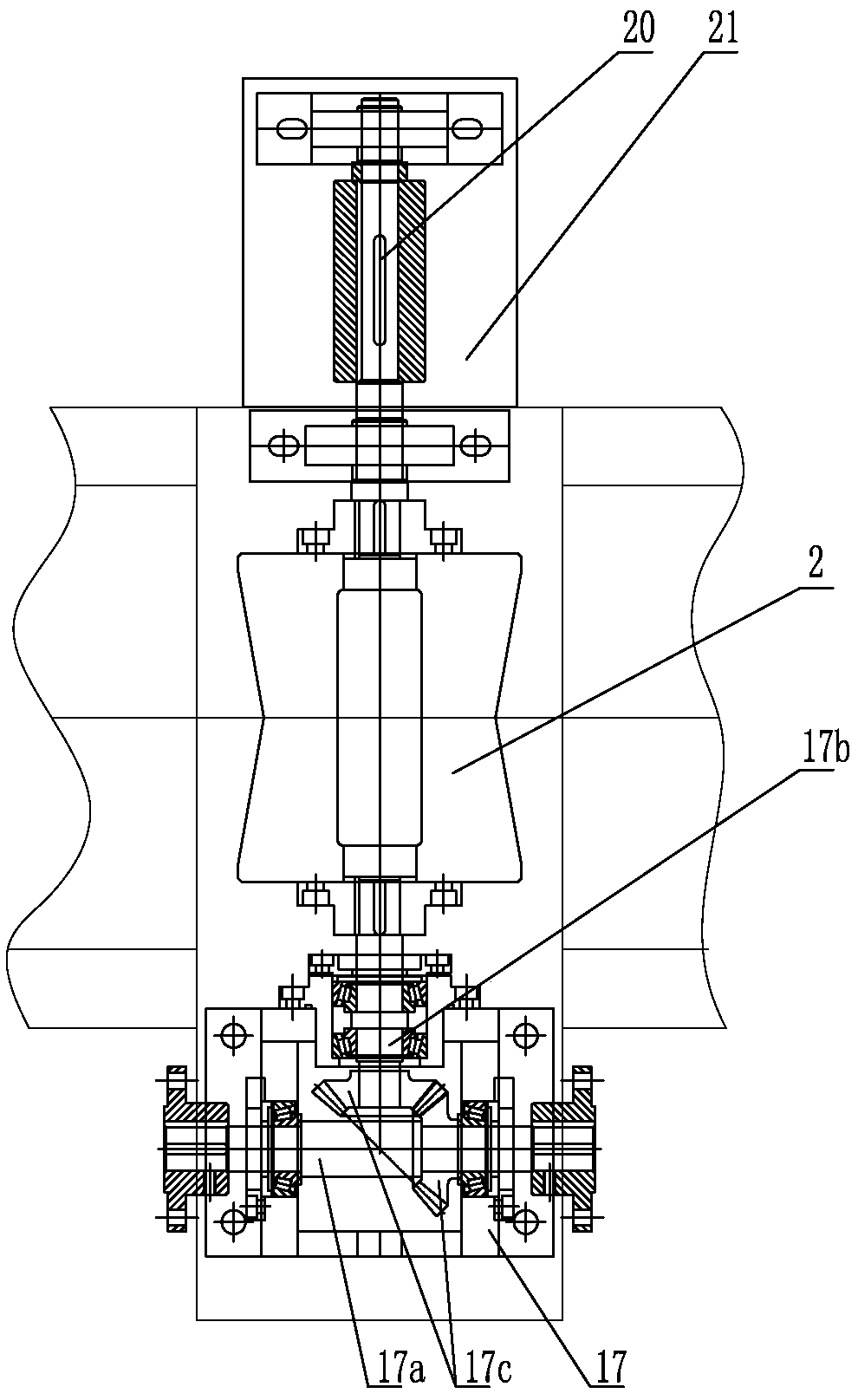

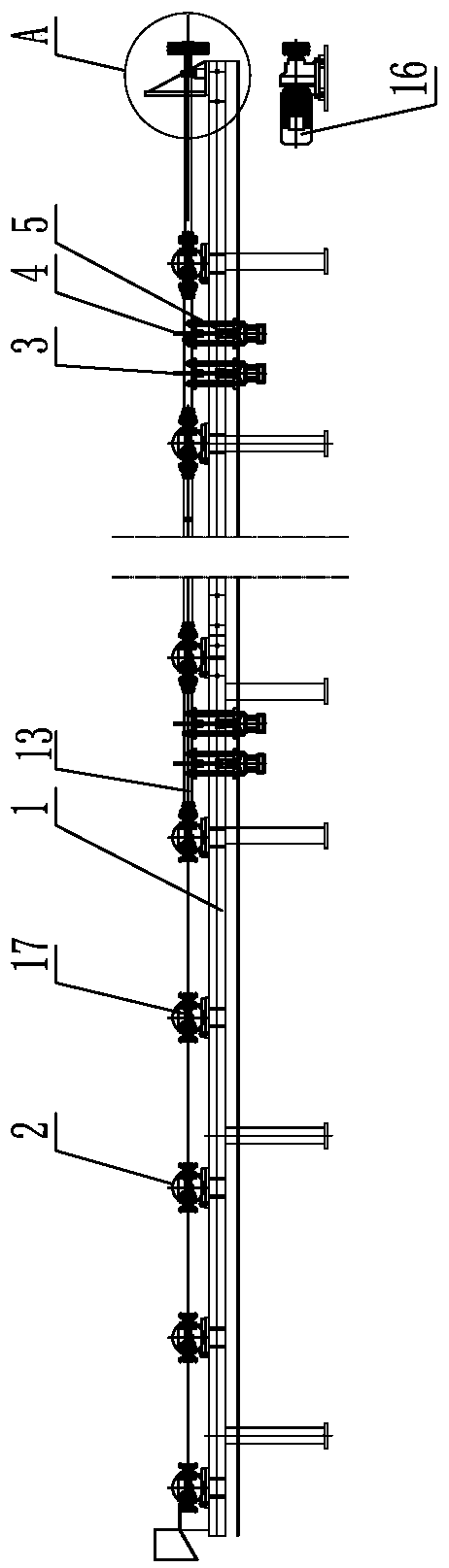

[0031] like Figure 1-7As shown, it is a double-sided blanking device, including a machine base 1, on which a number of rotatable transmission rollers 2 are arranged sequentially from left to right, and the transmission rollers 2 are arranged horizontally, and each transmission roller 2 is connected to the rotating drive Mechanism-transmission connection, the pipe fitting 24 is horizontally supported on the transmission roller 2, and the machine base 1 is provided with a pushing mechanism that can push the pipe fitting 24 to the front side blanking area and the rear side blanking area respectively. The rollers 2 are staggered from each other. Described pushing mechanism comprises at least one group of bidirectional pushing assembly, and bidirectional pushing assembly comprises front blanking plate 3 and rear blanking plate 4, and bidirectional pushing assembly is positioned at pipe fitting 24 below, and the upper side of front blanking plate 3 is inclined and Corresponding to...

Embodiment 2

[0034] like Figure 8-13 As shown, the difference from Example 1 is that the pusher mechanism includes a number of supports 6 arranged at intervals from left to right on the base 1, the top of the support 6 is provided with a rotating shaft 7, and the rotating shaft 1 7 is parallel to the axis of the pipe fitting 24, and one end of the rotating shaft 7 is provided with a blanking wheel 8, and the outer circumference of the blanking wheel 8 is uniformly provided with a number of pusher arms 8a, and the pusher arm 8a is correspondingly arranged with the pipe fitting 24, and the pusher arm 8a and the transmission roller 2 are mutually staggered, and the first rotating shaft 7 is connected with the second rotating drive mechanism. The second rotating drive mechanism includes a sprocket 9 sleeved on the other end of the rotating shaft 7, the bottom of the support 6 is provided with a rotating shaft 10, the rotating shaft 10 is located below the machine base 1, and the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com