Billet ejection system and method of billet continuous casting machine

A technology of billet continuous casting and billet casting, which is applied in the field of billet discharge system of billet continuous casting machine, which can solve problems such as high casting speed, low billet discharge efficiency, and roller scratches, so as to avoid roller scratches and casting billet, improve the efficiency of blanking, and avoid the effect of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

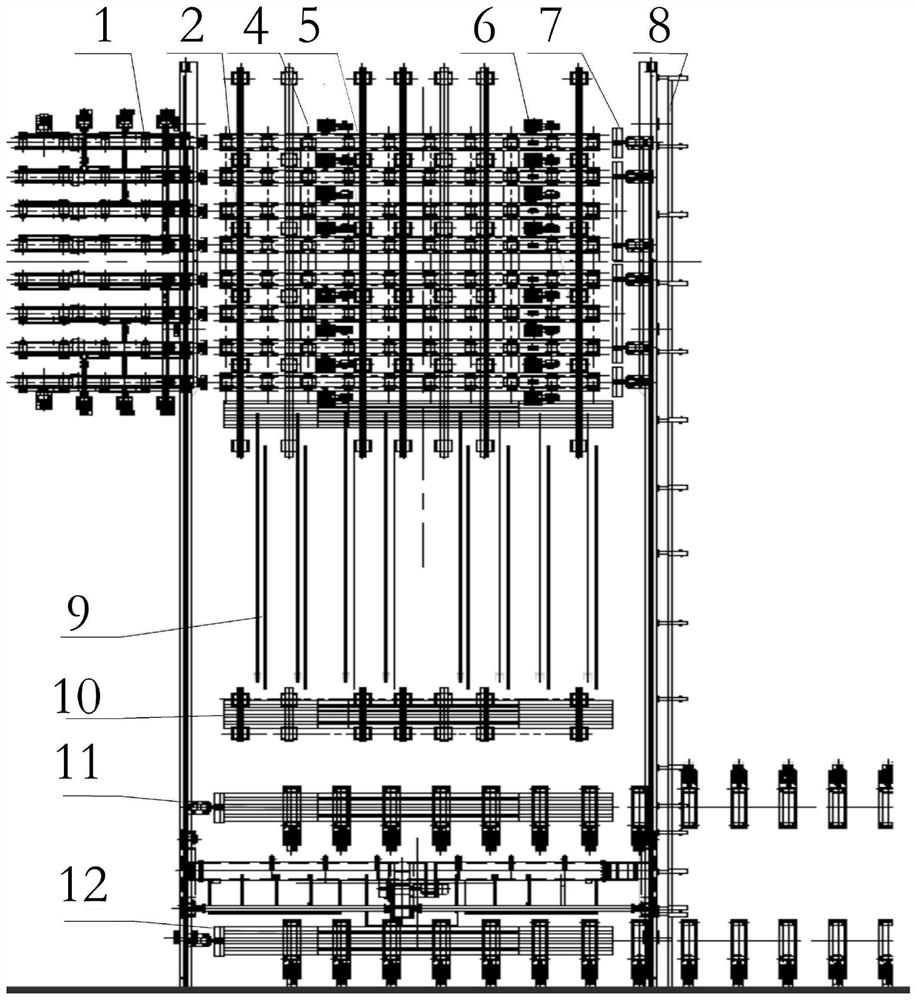

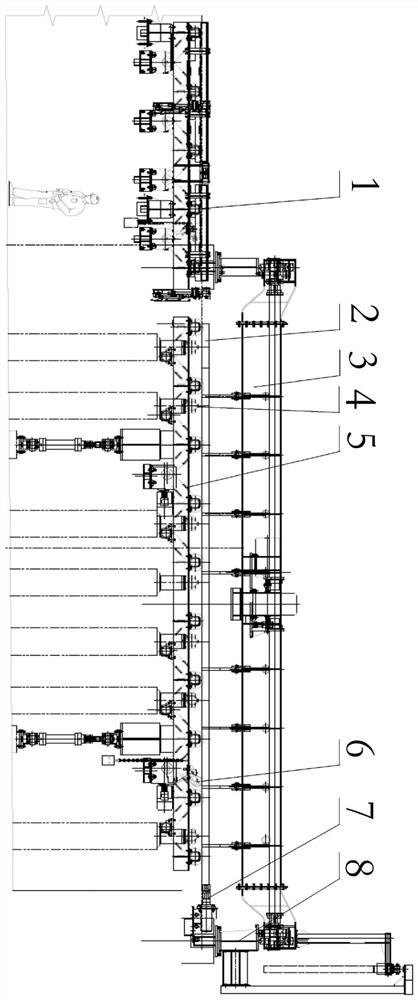

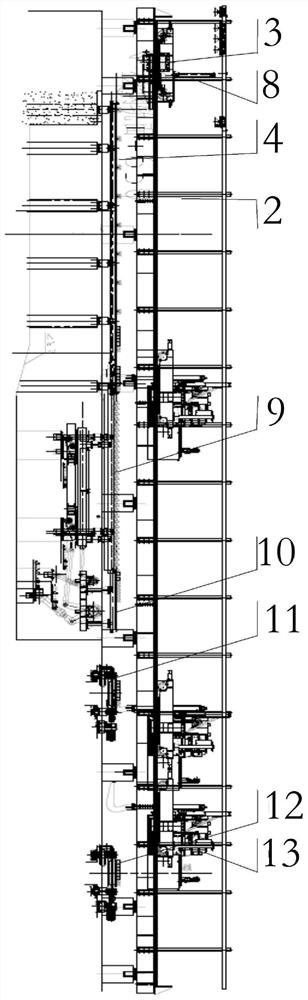

[0032] Such as Figure 1-3 As shown, a billet discharge system of a billet continuous casting machine includes a conveying roller table 1, a steel transfer machine 3, a steel transfer rail 4, a billet discharge roller table 5, a detection device 6, a trolley rail 8, and a steel scooping machine 13 , the cold delivery roller table 11, the hot delivery roller table 12 and the temporary storage device, the conveying roller table 1 and the billet roller table 5 are arranged horizontally from left to right in sequence, and the billet roller table 5 is vertically connected with the steel transfer track 4, The right end of the billet roller table 5 is longitudinally connected to the trolley track 8, the detection device 6 is connected to the billet roller table 5, the steel moving machine 3 and the steel scooping machine 13 are sequentially connected to the trolley rail 8 from back to front, and the steel moving track 4 The front of the machine is provided with a temporary storage de...

Embodiment 2

[0045] A billet discharging method of a billet continuous casting machine, comprising the steps of:

[0046] When the billet 2 needs to be cold-delivered, it includes the following steps: when the detection device 6 detects that there is a billet 2 above the billet roller table 5, the billet roller table 5 is lowered to a low position, and the billet 2 falls on the top of the steel moving track 4, and the billet 2 is moved The steel machine 3 moves the casting slab 2 to the top of the step-and-turn cooling bed 9, and the step-and-turn cooling bed 9 transports the casting slab 2 above to the temporary storage stand 10, and the steel scooping machine 13 stores the cast slab on the stand 10. The billet 2 is moved to the top of the cold delivery roller table 11, and the casting billet 2 is transported to the destination area by the cold delivery roller table 11;

[0047] When the billet 2 needs hot delivery, the steps include the following steps: when the detection device 6 detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com