Multi-wire slitting and rolling controlled cooling device for bar

A technology of split rolling and controlled cooling, which is applied in the direction of workpiece cooling devices, metal rolling, metal rolling, etc., and can solve the problem of poor alignment before and after passing through the water cooling device, uneven cooling of the bar surface, and increased risk of stacking steel and other problems to achieve rapid production process and production errors, avoid uneven cooling, and reduce the risk of stacking steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

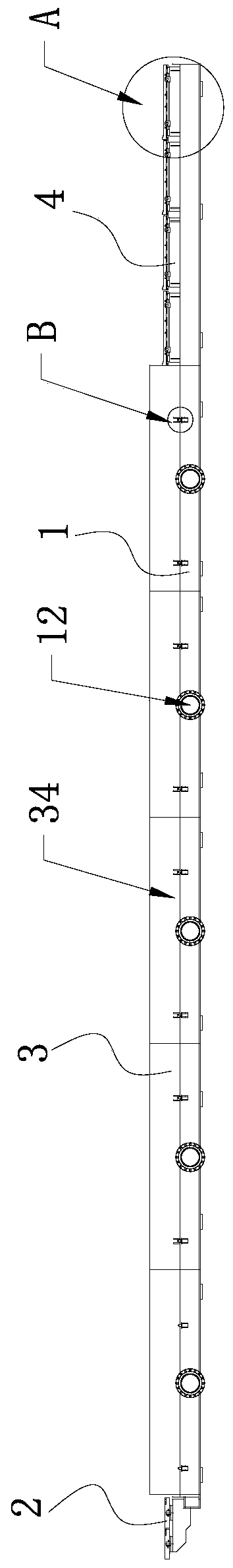

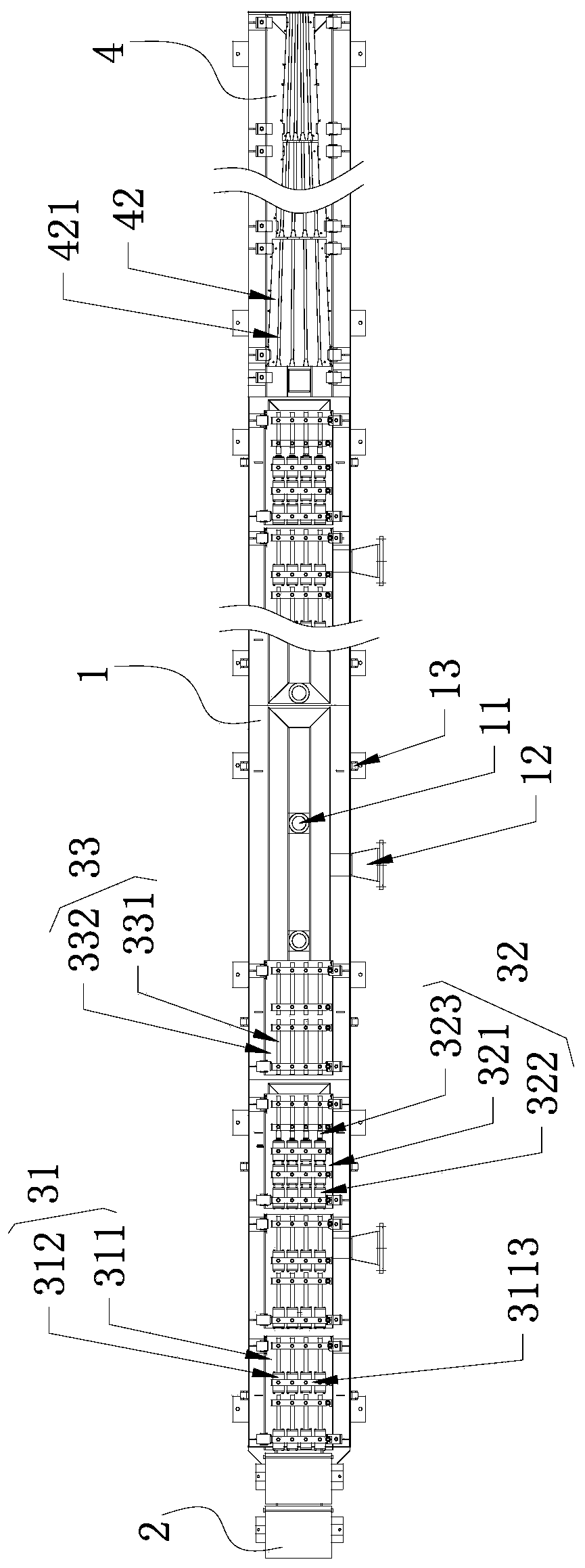

[0064] Such as Figure 1-10 As shown, in this embodiment, the multi-line slitting and rolling control cooling device of the bar includes a plurality of single-line cooling devices arranged in parallel, and the multiple single-line cooling devices are arranged on the same fixed water beam 1, so that the single-line cooling device can be improved. To be neutral and reduce the risk of bar stocking, each single-line cooling device includes a transition guide groove 2, a cooling structure 3, and a collection guide groove 4 arranged in sequence along the bar production direction. The cooling structure 3 includes a water cooling unit 31 and a counterattack Water unit 32 and empty unit 33;

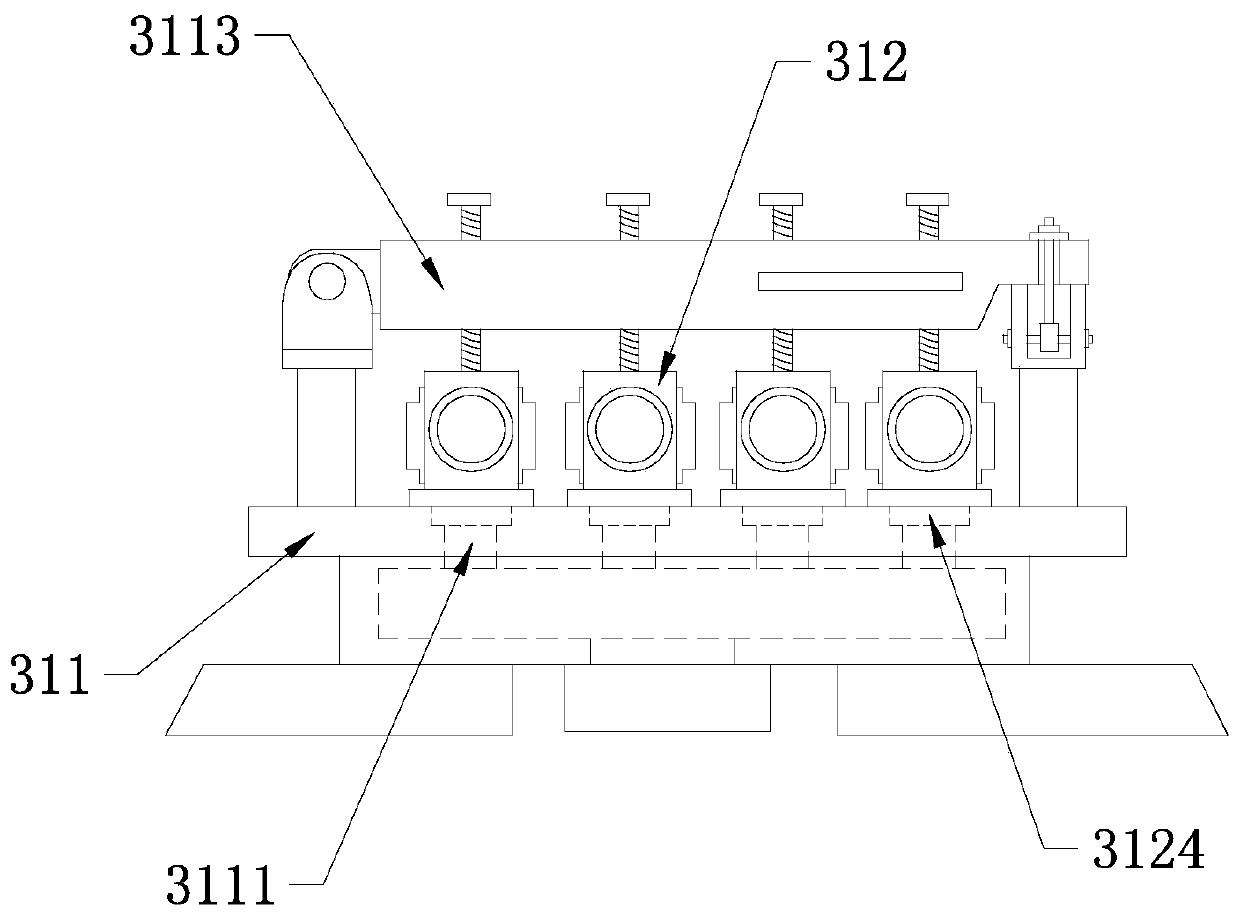

[0065] The water cooling unit 31 includes a first assembly seat 311 installed on the fixed water beam 1, and a cooling nozzle 312 is installed on the first assembly seat 311. The cooling nozzle 312 is provided with a water inlet 3121 and a second assembly along the bar production direction. A chuckin...

Embodiment 2

[0080] Such as Picture 11 As shown, on the basis of Embodiment 1, the arrangement of the cooling structure is different from that of Embodiment 1. Specifically, the cooling structure consists of at least one water cooling unit—at least one counter-flushing water unit—at least one empty The minimum unit structure formed by the unit, and the cooling structure of adjacent single lines is the same. This arrangement can realize continuous cooling production of the bar. The water cooling unit 31 is used for cooling the bar through water, and the counter-water unit 32 is used to prevent the bar from backwards. Running with water, the empty passing unit 33 is used to guide the bar to the collecting guide groove.

Embodiment 3

[0082] Such as Picture 12 As shown, on the basis of Embodiment 1 or Embodiment 2, at least one empty passing unit 33 is provided at the beginning of the cooling structure, and the cooling structures 3 of adjacent single wires are the same. At this time, the empty passing unit 33 is used for guiding the bar from the transition channel to the water cooling unit 31, and can prevent the water of the water cooling unit 31 from being sprayed back to the temperature measuring device at the end of the transition channel to a certain extent, affecting its use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com