Off-square detection automation feeding method based on machine vision

A technology of machine vision and automatic detection, which is applied to furnace control devices, furnaces, lighting and heating equipment, etc., can solve the problems of unpredictable impact caused by billet removal, inability to judge whether the billet has fallen out of the square, deformation, etc., to improve production The effect of improving the line operation rate, reducing the risk of stacking steel, and stabilizing the heating rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

[0024] The invention utilizes the method of machine vision to intelligently identify the stripped billets of the loading platform, and automatically removes the identified stripped billets, thereby stabilizing the heating rhythm of the heating furnace, reducing the risk of stacking steel in the production line, and improving the production line operation rate.

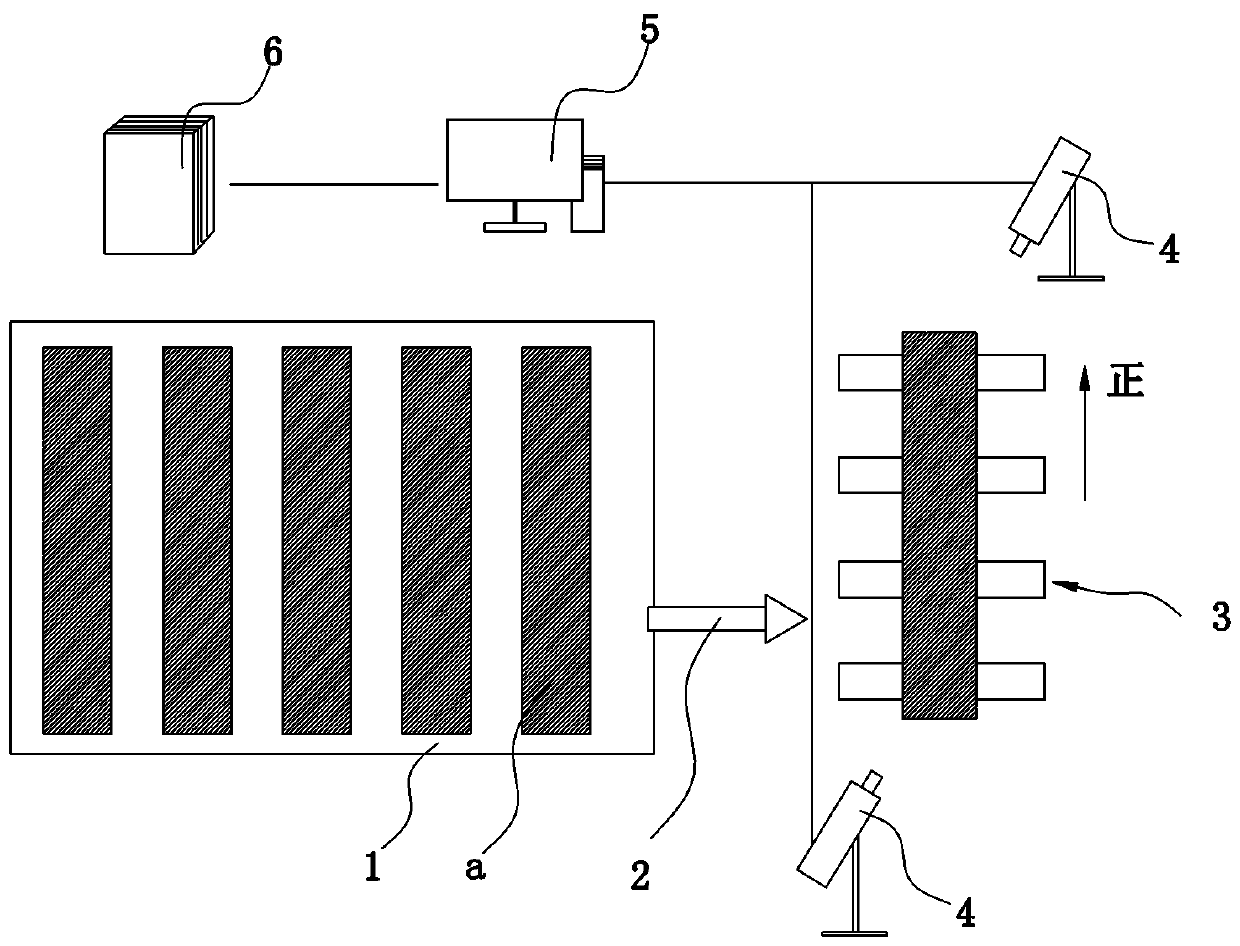

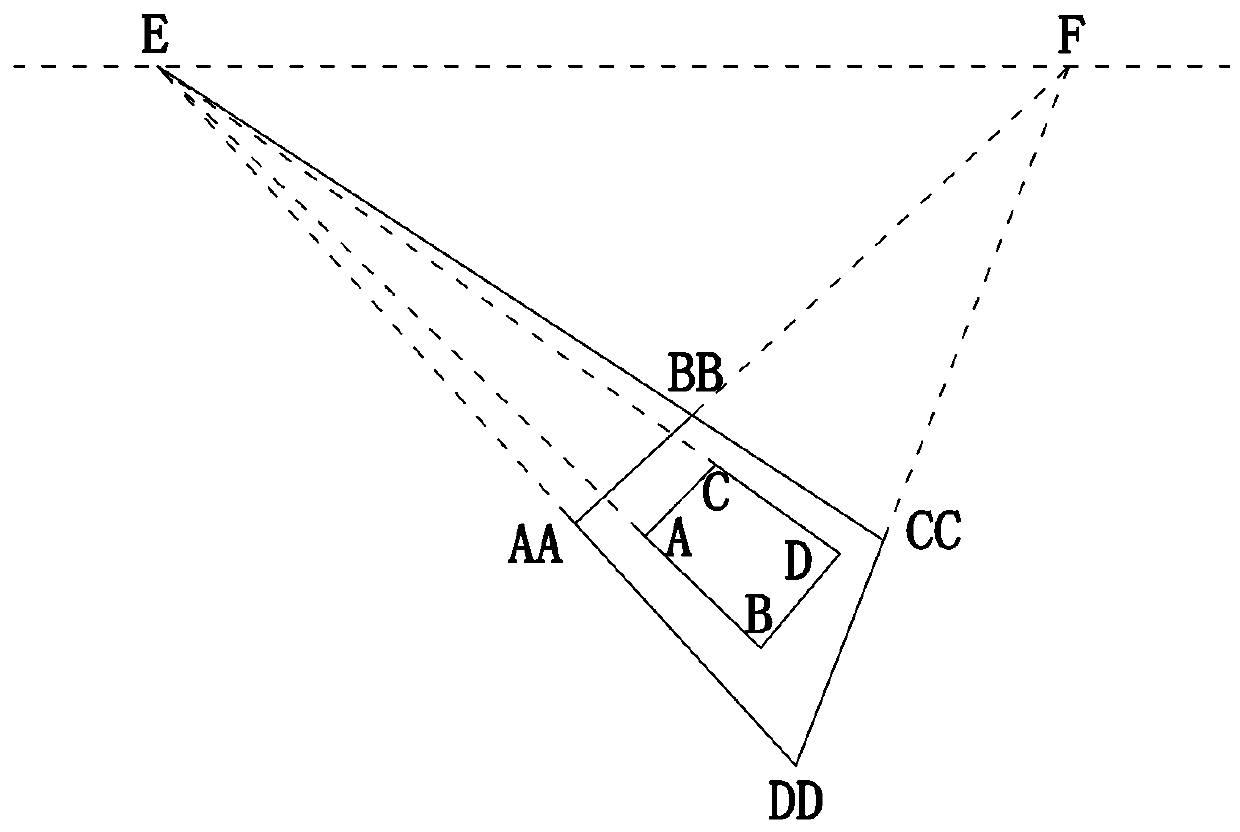

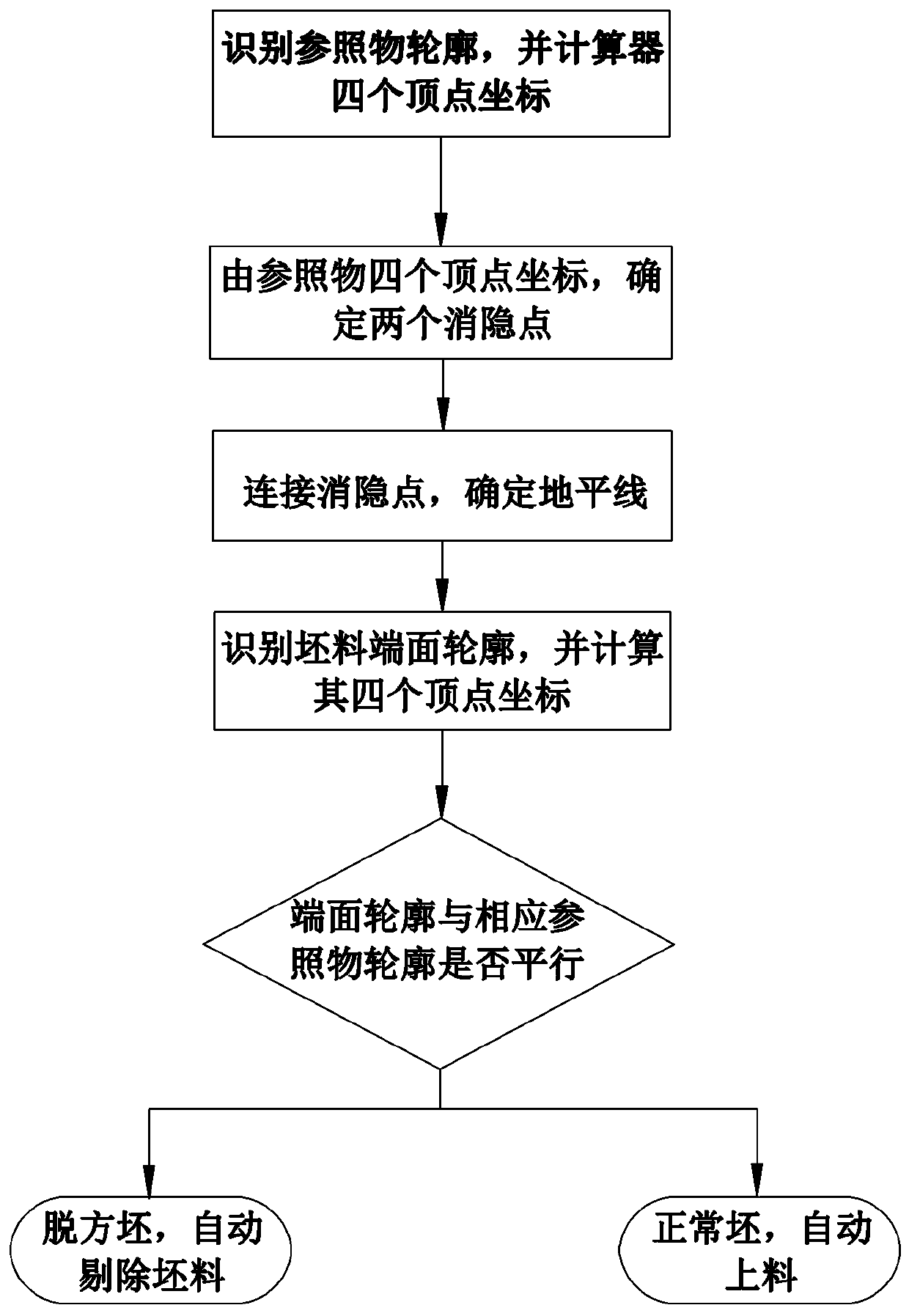

[0025] The invention mainly includes a machine vision recognition system and an automatic control system. The machine vision recognition system is responsible for identifying whether the billets at the front of the loading platform are out of square. If th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com